Professional Documents

Culture Documents

Inspection & Test Plan (For Reference)

Uploaded by

Hadi MoosaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection & Test Plan (For Reference)

Uploaded by

Hadi MoosaviCopyright:

Available Formats

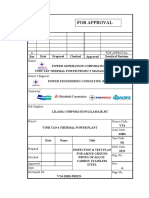

Rev.

: 0

Page : 1 of 2

JOB No. CLIENT HAVAYAR INDUSTRIAL GROUP

NARGESI ASSOCIATED GAS

PROJECT NAME LOCATION IRAN

GATHERING

INSPECTION & TEST PLAN

(DOC.NO. : VP-11017-08)

ITEM NO. : C-2601A/B

ITEM NAME : AIR COMPRESSOR

MODEL : KSDYNL-2, 2Cy. 200HP AIR COMPRESSOR

0 2011.06.22 FOR APPROVAL S.B.BAEK J.Y.KIM H.CH.JANG

REV. DATE DESCRIPTION PRP'D REV'D APP'D

KWANGSHIN MACHINE IND CO.,LTD.

ITP-SR11017-001

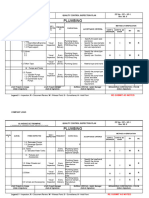

INSPECTION AND TEST PLAN

PAGE : 1 OF 3

M/O NO. : SR11017

PROJECT NAME : Nargesi Associated Gathering

CUSTOMER : HAVAYAR Industrial Group

TYPE : KSDYNL-2, 200HP 8.7K AIR COMPRESSOR

ITEM NO. : C-101

QUANTITY : 2 SETS

LEGEND

R : DOC. REVIEW

W : WITNESS POINT

H : HOLD POINT

0 June. 17. 2011 S. H. JOO D. H. Youn

Q.C SECTION Q.C MANAGER CUSTOMER

REV

DATE REMARKS

NO.

PREPARED BY REVIEW & APPROVED BY

KWANGSHIN MACHINE IND. CO., LTD.

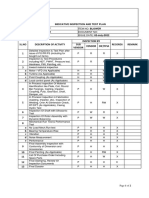

INSPECTION AND TEST PLAN

PAGE NO. 2 / 3

REV. NO. 0

INSPECTION BY

INSPECTION ACTIVITY

NOTE

DESCRIPTION

KSK HIG

1. CRANK CASE

- Material Test H R

- Dimensional Inspection H R

2. CRANK SHAFT

- Material Test R R

- NDE (U.T, M.T) W R

- Dimensional Inspection H R

3. CONNECTING ROD

- Material Test R R

- NDE (U.T, M.T) W R

- Dimensional Inspection H R

4. CYLINDER

- Material Test H R

- NDE (M.T) W R

- Dimensional Inspection H R

- Hydrostatic Test

Water Jacket Side H R

Gas Side H R

5. PISTON ROD

- Material Test R R

- NDE (U.T, M.T) W R

- Dimensional Inspection H R

6. PISTON BODY

- Material Test R R

- Dimensional Inspection H R

NOTE : 1. ABBREVIATION

KSK : KWANGSHIN MACHINE IND. CO., LTD. HIG : HAVAYAR Industrial Group

R : REVIEW OF DOCUMENTS W : WITNESS

SW : WITNESS, BUT SPOT CHECK H : HOLD POINT

M : MANUFACTURER INSPECTION W+ : PREVIOUS RECORD MAY BE REVIEWED

KWANGSHIN MACHINE IND. CO., LTD.

INSPECTION AND TEST PLAN

PAGE NO. 3 / 3

REV. NO. 0

INSPECTION BY

INSPECTION ACTIVITY

NOTE

DESCRIPTION

KSK HIG

7. PRESSURE VESSEL PARTS

◈ 1ST DISCHARGE SNUBBER

◈ INTER COOLER

◈ 2ND SUCTION SNUBBER

◈ 2ND DISCHARGE SNUBBER

◈ AFTER COOLER

◈ SEPARATOR

- Material Test R R

- NDE (M.T) W R

- Hydrostatic Test H R

- Visual & Dimensional Inspection H R

8. MEASURING INSTRUMENTS

- Tag & Model No. Check H R

- Spec. & Data Check H R

9. LOCAL CONTROL PANEL

- Visual & Dimensional Inspection H R

- Name Plant & Tag & Model No. Check H R

- Function Test (Sequence Test) H R

10. COMPRESSOR PACKAGE ASSEMBLY

- Visual & Dimensional Inspection H SW

- Performance Running Test H SW

- Painting & Packing Inspection H R

11. MOTOR

- Receiving Inspection W R

NOTE : 1. ABBREVIATION

KSK : KWANGSHIN MACHINE IND. CO., LTD. HIG : HAVAYAR Industrial Group

R : REVIEW OF DOCUMENTS W : WITNESS

SW : WITNESS, BUT SPOT CHECK H : HOLD POINT

M : MANUFACTURER INSPECTION W+ : PREVIOUS RECORD MAY BE REVIEWED

KWANGSHIN MACHINE IND. CO., LTD.

VP-SR11017-001

K.S.K INSPECTION AND TEST PROCEDURE

PAGE 1 OF 7

TITLE : Nargesi Associated Gathering

TABLE OF CONTENTS

◈ SCOPE (150KW AIR COMPRESSOR)

1. INSPECTION AND TEST

2. INSPECTION AND TEST ITEM

3. ACCEPTANCE CRITERIA

4. LOCAL CONTROL PANEL

0 June. 13. 2011 S. H. JOO D. H. Youn

REV Q.C SECTION Q.C MANAGER CUSTOMER

DATE REMARKS

No. PREPARED BY REVIEW & APPROVED BY

KWANGSHIN MACHINE IND. CO., LTD.

VP-SR11017-001

K.S.K INSPECTION AND TEST PROCEDURE

PAGE 2 OF 7

TITLE : Nargesi Associated Gathering

◈. SCOPE

THIS PROCEDURE COVERS THE PARTS INSPECTION AND TRIAL OF THE 150KW AIR COMPRESSOR

BEFORE DELIVERED TO YOUR COMPANY.

* PROJECT NAME : Nargesi Associated Gathering

* TYPE : KSDYNL-2, 8.7K 200HP AIR COMPRESSOR

* MFG. SERIAL NO. : SR11017-1~2

* SUCTION PRESSURE : 0.0 Kg/cm 2G

* DISCHARGE PRESSURE : 8.667 Kg/cm 2G

* ROTATIONAL SPEED : 450 RPM

* PISTON DISPLACEMENT : 1534.35 m 3/hr

* CAPACITY : 840.0 Nm 3/hr

* REQUIRED POWER : 150 KW

1. INSPECTION & TEST

1-1. MATERIAL TEST

THE QUALITY OF THE MATERIAL OF THE MAJOR PARTS SHALL BE INSPECTED TO COMPLY WITH

WHAT ARE SPECIFIED ON THE FABRICATION DRAWING OR SPECIFICATION.

THE EXTENT OF MAJOR PARTS ARE :

1) CRANK CASE

2) CRANK SHAFT

3) CONNECTING ROD

4) CYLINDER

5) PISTON ROD

6) PISTON BODY

7) 1ST/2ND DISCHARGE SNUBBER

8) 2ND SUCTION SNUBBER

9) SEPARATOR

10) INTER COOLER

11) AFTER COOLER

KWANGSHIN MACHINE IND. CO., LTD.

VP-SR11017-001

K.S.K INSPECTION AND TEST PROCEDURE

PAGE 3 OF 7

TITLE : Nargesi Associated Gathering

1-2. VISUAL AND DIMENSIONAL INSPECTION

PARTS SHALL BE INSPECTED OF SIZE AND DIMENSION TO COMPLY WITH WHAT ARE SPECIFIED

ON THE WORKING DRAWING AND SHALL BE CHECKED FOR SUCCESSFUL USE IN COMBINATION WITH

OTHER PARTS OF THE COMPRESSOR.

1) CRANK CASE

2) CRANK SHAFT

3) CONNECTING ROD

4) CYLINDER

5) PISTON ROD

6) PISTON BODY

7) 1ST/2ND DISCHARGE SNUBBER

8) 2ND SUCTION SNUBBER

9) SEPARATOR

10) INTER COOLER

11) AFTER COOLER

1-3. NONDESTRUCTIVE EXAMINATION

NONDESTRUCTIVE INSPECTION SHALL BE CARRIED OUT FOR THE FOLLOWING ITEMS:

(SHALL BE PERFORMED IN ACCORDANCE WITH ASME CODE & ASTM CODE)

1) CRANK SHAFT ------------------------ (U.T, M.T : ALL MACHINED AREA)

2) CONNECTING ROD --------------------- (U.T, M.T : ALL MACHINED AREA)

3) CYLINDER --------------------------- (M.T : ALL MACHINED AREA)

4) PISTON ROD ------------------------- (U.T, M.T : ALL MACHINED AREA)

5) 1ST/2ND DISCHARGE SNUBBER ---------- (M.T : WELDING AREA)

6) 2ND SUCTION SNUBBER ---------------- (M.T : WELDING AREA)

7) SEPARATOR -------------------------- (M.T : WELDING AREA)

8) INTER COOLER ----------------------- (M.T : WELDING AREA)

9) AFTER COOLER ----------------------- (M.T : WELDING AREA)

1-4. PRESSURE TEST

THE FOLLOWING PARTS AND EQUIPMENT SHALL BE HYDROSTATICALLY TESTED AT PRESSURE OF

1.5 TIMES THE MAWP(Maximum Allowable Working Pressure) WITH CALIBRATED TWO DIAL

GAUGE WHICH HAVE TO THE RANGE OF 1.5 - 3.0 TIMES OF TEST PRESSURE.

THE PRESSURE SHALL BE MAINTAINED FOR AT LEAST 60 MINUTES.

( PS-QA-003 Rev.0 ) - Hydrostatic Test Procedure of kwangshin Standard

1) CYLINDER (WATER JACKET SIDE, GAS SIDE)

2) 1ST/2ND DISCHARGE SNUBBER, 2ND SUCTION SNUBBER, SEPARATOR, INTER COOLER, AFTER COOLER

KWANGSHIN MACHINE IND. CO., LTD.

VP-SR11017-001

K.S.K INSPECTION AND TEST PROCEDURE

PAGE 4 OF 7

TITLE : Nargesi Associated Gathering

1-5. PERFORMANCE RUNNING TEST

1-5-1. PERFORMANCE RUNNING TEST

PROCEDURES FOR PERFORMANCE TEST SHALL CONFORM TO KS B 6351- 2001 AS A FUNDAMENTAL RULE.

THE CONTENT OF PERFORMANCE TEST IS INDICATED FROM THE 1-5-1-1 TERM.

1-5-1-1. MEASURING OF GAS QUANTITIES TEST

THE TESTS SHALL BE PERFORMED AT SUPPLIED ATMOSPHERIC PRESSURE AIR TO COMPRESSOR

SUCTION SIDE, AND LOADING TO DISCHARGE PRESSURE IS 8.667 Kg/㎠.G.

METHOD OF MEASUREMENT SHALL BE CARRIED OUT MEANS OF ORIFICE AND ITEM TO

BE MEASURED ARE GIVEN AS FOLLOWS.

Pa : Atmospheric Pressure (Kg/㎠.G)

ta : Atmospheric Temperature (℃)

Ps : Suction Pressure (Kg/㎠.G)

ts : Suction Temperature (℃)

tn : Temperature Just At Upstream Side Of Orifice Plate (℃)

P1 : Pressure Just At Upstream Side Of Orifice Plate (Kg/㎠.G)

△P : Difference Between Pressures Directly

Before And Directly Behind Orifice Plate (Kg/㎠.G)

Measuring Pipe Line

D : Inner Diameter Of Pipe (mm)

L : Length (mm)

△

USE THE FOLLOWING EQUATION FOR THE CALCULATION OF AIR QUANTITIES.

(KS B 6351- 2001 8.5.4 (3) EQUATION)

KWANGSHIN MACHINE IND. CO., LTD.

VP-SR11017-001

K.S.K INSPECTION AND TEST PROCEDURE

PAGE 5 OF 7

TITLE : Nargesi Associated Gathering

WHERE

Qs : Suction Gas Quantity (㎥/min)

α : Flow Coefficient (-)

ε : Correction Factor By Expansion Fo Gas (-)

π 2

A : Area Of Circular Hole = d (㎡)

4

d : Hole Diameter Of Restrictor ( m)

Ps : Density Of Suction Gas (㎏/㎥)

P : Gas Density Driectly Before Orifice Plate (㎏/㎥)

[JUDGMENT]

MEASURED CAPACITY SHALL BE MORE THAN SPECIFIED CAPACITY ( 840.0 N㎥/hr)

A TEST IS DONE WITH THE FOLLOWING EQUIPMENT.

THE CONTENT OF PERFORMANCE TEST IS INDICATED FROM THE VIBRATION,

LUBRICANT CONDITION & LEAK, BEARING TEMPERATURE, NOISE AND COOLING WATER FLOW

CONDITION SHALL BE CHECKED.

1-5-2. TEST CONDITION

COMPRESSOR SHALL BE TESTED AT THE SPECIFIED NUMBER OF REVOLUTIONS.

HOWEVER, WHERE IT IS DIFFICULT, THE TESTING MAY BE PERFORMED AT A NUMBER OF

REVOLUTIONS WITHIN +10% AND -5% OF THE SPECIFIED NUMBER OF REVOLUTIONS.

THE TEST SHALL BE PERFORMED AT ONE POINT OF THE SPECIFIED PRESSURE.

2. INSPECTION AND TEST ITEM

THE COMPRESSOR WILL BE OPERATED AT RATED OPERATING SPEED AND TEST PRESSURE FOR 2 HOURS.

WHILE THE COMPRESSOR IS OPERATING AT RATED OPERATING SPEED AND TEST PRESSURE,

FOLLOWING MEASUREMENT WILL BE MADE.

1) NOISE CHECK

2) VIBRATION CHECK

3) TEMPERATURE CHECK

4) OTHER LUBRICATING OIL SUPPLY AND COOLING WATER CIRCULATION CONDITION CHECK

5) CAPACITY

KWANGSHIN MACHINE IND. CO., LTD.

VP-SR11017-001

K.S.K INSPECTION AND TEST PROCEDURE

PAGE 6 OF 7

TITLE : Nargesi Associated Gathering

3. ACCEPTANCE CRITERIA

3-1. NOISE TEST

NOISE TEST SHALL BE CARRIED OUT WHEN THE COMPRESSOR IS OPERATED AT THE

SPECIFIED CONDITION.

MEASUREMENT OF NOISE LEVEL (dB(A)) OF THE COMPRESSOR SHALL BE PLACED AT THE

LOCATION APART FROM THE COMPRESSOR FROM 1.0 m DISTANCE, AND AT THE HEIGHT OF

ABOUT 1.0m ABOVE THE FLOOR. 90dB(A) FOR REFERENCE

BECAUSE THE SHOP TEST CONDITION IS DIFFERENT TO SITE TEST THE REASON OF PIPING, etc.

3-2. VIBRATION

AS A RULE, VIBRATION SHALL BE MEASURED AT THE BEARINGS OR IN THE VICINITY

THEREOF WITH RESPECT TO THREE DIRECTIONS.(AXIAL/VERTICAL/HORIZONTAL)

80㎛ MAX.

3-3. TEMPERATURE

DURING MECHANICAL RUNNING TEST, BEARING TEMPERATURE SHALL BE BELOW MAX.(AMBIENT +55℃).

1) MAIN BEARING TEMPERATURE(DRIVER SIDE AND OTHER SIDE)

2) LUBRICATING OIL TEMPERATURE(MAX. 70℃ FOR PRESSURIZED OIL SYSTEM)

3) MOTOR BEARING TEMPERATURE

3-4. NUMBER OF REVOLUTIONS

THE MEASUREMENT SHALL BE CARRIED OUT BY USING A PRELIMINARILY CALIBRATED

HAND TACHOMETER. THE MEASUREMENT OF THE NUMBER OF REVOLUTIONS SHALL BE CARRIED

OUT 2 OR 3 TIMES UNDER THE SAME CONDITION, AND THE AVERAGE VALUE SHALL BE TAKEN.

4. LOCAL CONTROL PANEL

4-1. VISUAL AND DIMENSIONAL INSPECTION

PARTS SHALL BE INSPECTED OF SIZE AND DIMENSION TO COMPLY WITH WHAT ARE SPECIFIED

ON THE FABRICATION DRAWING.

4-2. POINT TO POINT CONTINUITY TEST

AFTER ALL WIRING IS FINISHED, 100% POINT TO POINT CONTINUITY OF WIRING

SHOULD BE VERIFIED.

THIS TEST SHOULD BE VERIFIED IN ACCORDANCE WITH APPROVED WIRING DIAGRAM.

KWANGSHIN MACHINE IND. CO., LTD.

VP-SR11017-001

K.S.K INSPECTION AND TEST PROCEDURE

PAGE 7 OF 7

TITLE : Nargesi Associated Gathering

4-3. SEQUENCE TEST(FUNCTION TEST)

4-3-1. SEQUENCE TEST WILL BE PERFORMED BY APPROVED SEQUENCE LOGIC.

4-3-2. INDICATORS WILL BE TESTED REGARDING TO THEIR OPERATION PERFORMANCE.

4-4. INSULATION RESISTANCE TEST

4-4-1. THE INSULATION RESISTANCE WILL BE MEASURED BETWEEN MAIN POWER PHASE AND GROUND.

4-4-2. THE INSULATION RESISTANCE MEASURED SHALL BE NOT LESS THAN 5㏁ 1000Vdc.

KWANGSHIN MACHINE IND. CO., LTD.

You might also like

- Advances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967From EverandAdvances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967S. A. TobiasRating: 4 out of 5 stars4/5 (1)

- Inspection and Test Plan: S. H. Joo D. H. YounDocument2 pagesInspection and Test Plan: S. H. Joo D. H. YounfitriatitisariNo ratings yet

- Ongc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Document7 pagesOngc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Ankit Kumar100% (1)

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- MD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelDocument8 pagesMD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelTran KhuynhNo ratings yet

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- IRT - CWC Coating Anode InstallationDocument3 pagesIRT - CWC Coating Anode InstallationPrafulla PatilNo ratings yet

- ITP - PV Kontrol Indo RayaDocument5 pagesITP - PV Kontrol Indo RayaZulkarnain ZulkarnainNo ratings yet

- WTG ITP Steel Fabrication InspectionDocument6 pagesWTG ITP Steel Fabrication Inspectionrahid iqubalNo ratings yet

- ITP PLUMBING WORKS SampleDocument1 pageITP PLUMBING WORKS SampleJay Chris L. Beron100% (1)

- Sheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdDocument4 pagesSheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdHafidz FirmansyahNo ratings yet

- Heat Exchanger Inspection & Test PlanDocument6 pagesHeat Exchanger Inspection & Test PlanakisdassasNo ratings yet

- Asorc-Qcp 1652 ModifiedDocument22 pagesAsorc-Qcp 1652 ModifiedalkhiatNo ratings yet

- Inspection & Test Plan for Ni-Al Bronze ValvesDocument4 pagesInspection & Test Plan for Ni-Al Bronze ValvesMuthazhagan SaravananNo ratings yet

- ITP FOR Air Compressor PackageDocument1 pageITP FOR Air Compressor PackageAgus SuriptoNo ratings yet

- Itp For ValvesDocument2 pagesItp For ValvesSuraj ShettyNo ratings yet

- RLC AH QP 91 3001 Inspection Test Plan For Plumbing Works 1 PDFDocument6 pagesRLC AH QP 91 3001 Inspection Test Plan For Plumbing Works 1 PDFQii BagerNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Document2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Suraj ShettyNo ratings yet

- Mar HM 18.06.22Document302 pagesMar HM 18.06.22özgen bölükNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- MD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFDocument8 pagesMD1-0-T-030-05-00073 - ITP For Under Ground Piping PDFTran KhuynhNo ratings yet

- Equipment/Material Name: Vietnam Nisshin Technomic Phase 2 Project (JOB No.: 0-8850-20)Document2 pagesEquipment/Material Name: Vietnam Nisshin Technomic Phase 2 Project (JOB No.: 0-8850-20)Hanh BuiminhNo ratings yet

- MD1-0-T-030-05-00120 - ITP For UG Piping of HDPEDocument7 pagesMD1-0-T-030-05-00120 - ITP For UG Piping of HDPETran KhuynhNo ratings yet

- Inspection and Test Plan For Steel StructureDocument1 pageInspection and Test Plan For Steel Structureeva maniceNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Air Comp 4 Inspection Report Mall of EgyptDocument4 pagesAir Comp 4 Inspection Report Mall of EgyptKadry Nabil HegazyNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Types of Boilers ExplainedDocument112 pagesTypes of Boilers ExplainedAldy Bagus PratamaNo ratings yet

- Itp PRDSDocument3 pagesItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- Inspection & Test Plan PT. Barata Indonesia: Fabrication DocumentDocument22 pagesInspection & Test Plan PT. Barata Indonesia: Fabrication DocumentmoddysNo ratings yet

- Temperature ControlsDocument2 pagesTemperature ControlsRhomadona DasopangNo ratings yet

- Mechanical ITP Inspection of Oil TankDocument2 pagesMechanical ITP Inspection of Oil TankikramNo ratings yet

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- ITP For Installation of Automatic Sliding DoorDocument1 pageITP For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- Inspection of Test Plan: Pressure Vessel EquipmentDocument6 pagesInspection of Test Plan: Pressure Vessel Equipmentzvlcar nainNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- INSPECTION PLAN TITLEDocument1 pageINSPECTION PLAN TITLEMohit SharmaNo ratings yet

- Valves - Kirloskar BrothersDocument4 pagesValves - Kirloskar BrothersJaydev ChakrabortyNo ratings yet

- Metallic Bellow QAPDocument2 pagesMetallic Bellow QAPPavul RajNo ratings yet

- 1029 Itp Asme R.ADocument23 pages1029 Itp Asme R.AAnonymous dj2xK2XONo ratings yet

- Sheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdDocument4 pagesSheet 1 of 4: Rev - No Date Description Prepd CHKD AppvdHafidz FirmansyahNo ratings yet

- Reliance Industries heat exchanger inspection procedureDocument3 pagesReliance Industries heat exchanger inspection procedureRajnikant PatelNo ratings yet

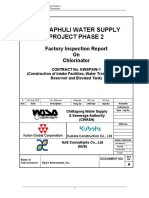

- Karnaphuli Water Supply Project Phase 2: Factory Inspection Report On ChlorinatorDocument7 pagesKarnaphuli Water Supply Project Phase 2: Factory Inspection Report On ChlorinatorJahangir AlamNo ratings yet

- Blank Quality Plan PAGE-2 TG 60663Document15 pagesBlank Quality Plan PAGE-2 TG 60663NEERAJ JINDALNo ratings yet

- Natural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at ShopDocument3 pagesNatural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at Shopanang_priNo ratings yet

- Itp Piping QicpDocument6 pagesItp Piping QicpLuis Enrico PamintuanNo ratings yet

- P1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkDocument9 pagesP1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkEILA545 QAQCNo ratings yet

- 34222-4010 Itp Rev 0Document2 pages34222-4010 Itp Rev 0anwar sadatNo ratings yet

- Inspection and Test Plan (Itp) Rades-C 450 MW CCPP Project: Gama Supplier/Subcontractor 3Rd Party StegDocument3 pagesInspection and Test Plan (Itp) Rades-C 450 MW CCPP Project: Gama Supplier/Subcontractor 3Rd Party StegRamzi ZoghlamiNo ratings yet

- Gate Valves For Wellhead: Inspection Data Sheet (I D S)Document5 pagesGate Valves For Wellhead: Inspection Data Sheet (I D S)kais rguiguiNo ratings yet

- Field ITP For Piping Work Rev.1 RDF 1404Document45 pagesField ITP For Piping Work Rev.1 RDF 1404Ichsan BahrilNo ratings yet

- Inspection and Test Planrev01Document16 pagesInspection and Test Planrev01Nguyễn MinhNo ratings yet

- Inspection and Test Plan - Pressure Vessel Fabrication (ITP)Document9 pagesInspection and Test Plan - Pressure Vessel Fabrication (ITP)Senthil Kumaran100% (2)

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDocument3 pagesInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNo ratings yet

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- Amiitp G 310500 - 2Document4 pagesAmiitp G 310500 - 2wangkai01.sneiNo ratings yet

- # Inspection Test Plan #: Dokumen EngineeringDocument2 pages# Inspection Test Plan #: Dokumen EngineeringDIANTORONo ratings yet

- Inspection and Test Plan Sheet: Pt. Pertamina Geothermal Energy Pt. Bina Rasano EngineeringDocument2 pagesInspection and Test Plan Sheet: Pt. Pertamina Geothermal Energy Pt. Bina Rasano EngineeringHerruSetiawan100% (1)

- Oxford Reading Tree: The Pet ShopDocument12 pagesOxford Reading Tree: The Pet ShopKanjaNo ratings yet

- 09 Exp 11 Buffer SolutionsDocument8 pages09 Exp 11 Buffer SolutionsShainmaugne AdvientoNo ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- Adding True Bypass To A Vintage Big MuffDocument8 pagesAdding True Bypass To A Vintage Big MuffOliver SuttonNo ratings yet

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- MetdsgffggDocument263 pagesMetdsgffggVishal Singh GaharwarNo ratings yet

- Mañanita Songs Mañanita SongsDocument2 pagesMañanita Songs Mañanita SongsSanchez Bayan100% (1)

- 2a CTRL DecDocument75 pages2a CTRL Decramanathan balamoorthyNo ratings yet

- Cadence Monte Carlo Simulation TutorialDocument51 pagesCadence Monte Carlo Simulation Tutorialkuomatt100% (1)

- 2008 Infosys Model QuestionsDocument23 pages2008 Infosys Model Questionsapi-3824713No ratings yet

- Science 8-02.02 - Sensitivity in Living OrganismsDocument9 pagesScience 8-02.02 - Sensitivity in Living OrganismsAnoushia AhmerNo ratings yet

- Queer Ecology Critique - Georgetown 2014Document104 pagesQueer Ecology Critique - Georgetown 2014Evan JackNo ratings yet

- Tabcalcs.com general equations sheetDocument2 pagesTabcalcs.com general equations sheetRamadan RashadNo ratings yet

- Osha Top 25 Physical HazardsDocument100 pagesOsha Top 25 Physical HazardsHasan Shakeel100% (2)

- 0610 m16 QP 62Document12 pages0610 m16 QP 62faryal khanNo ratings yet

- Construction Site PremisesDocument78 pagesConstruction Site PremisesDrew B Mrtnz67% (6)

- Mass DisasterDocument70 pagesMass DisasterJoseph RadovanNo ratings yet

- CaseStudy AmtrakDocument14 pagesCaseStudy Amtraksnob_kNo ratings yet

- The Respiratory System - Freebie GuideDocument4 pagesThe Respiratory System - Freebie GuideIndustria Quimica0% (1)

- Astm D2467-2013Document8 pagesAstm D2467-2013Renato CorrêaNo ratings yet

- Spesifikasi Siemens MRI AERA 1,5 TDocument2 pagesSpesifikasi Siemens MRI AERA 1,5 TDr.gendjutNo ratings yet

- Effect of Pregnancy Induced Hypertension on Mothers and Babies Hematological ProfilesDocument3 pagesEffect of Pregnancy Induced Hypertension on Mothers and Babies Hematological ProfilesAbdifatah AhmedNo ratings yet

- 14-Friedel Crafts Acylation FerroceneDocument10 pages14-Friedel Crafts Acylation FerroceneNguyen Minh Duc100% (1)

- Understanding of AVO and Its Use in InterpretationDocument35 pagesUnderstanding of AVO and Its Use in Interpretationbrian_schulte_esp803100% (1)

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- Bio Sem2 EssayDocument2 pagesBio Sem2 EssayEileen WongNo ratings yet

- Tables and Bar ChartsDocument7 pagesTables and Bar ChartsVictoria FedoseevaNo ratings yet

- Lecture No.3 Part 1 (Fan)Document6 pagesLecture No.3 Part 1 (Fan)Mohsen HassanNo ratings yet

- Hydromechanical Piercing Perforation: Oil Service Innovation TechnologiesDocument8 pagesHydromechanical Piercing Perforation: Oil Service Innovation TechnologiesЕлена ПаниотNo ratings yet

- When Ceramic Sociology Meets Material SCDocument10 pagesWhen Ceramic Sociology Meets Material SCJosé Renato TeixeiraNo ratings yet