Professional Documents

Culture Documents

Master 36 Module 3 Main Impeller Types

Uploaded by

naseer lateeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Master 36 Module 3 Main Impeller Types

Uploaded by

naseer lateeCopyright:

Available Formats

BASIC PRINCIPLES AND PUMP TYPES

MAIN IMPELLER TYPES

What is an impeller?

The impeller is the main component of

a centrifugal pump.

When the impeller rotates, it generates

the force required to move – or “pump” –

the fluid.

Impellers are also used in compressors,

turbines and many other machines that

move gas.

Main impeller types

The vast majority of the pumps Grundfos sells are centrifugal pumps, although positive displacement

pumps are also a part of the range. Pumps are often categorised by the type of impeller they use, with the

main types in Grundfos pumps being:

Positive

Centrifugal

Radial flow Mixed flow displacement

pumps

pumps

Reciprocating

Channel

Rotational Rotating

and tube

Liquid ring Membrane

Axial flow Vortex Helical rotor

Radial flow impellers

Radial flow impellers work

by moving the fluid out of the

pump “radially” or perpendicular

to the pump shaft. 1

This pump design creates a 2

relatively high level of pressure

compared to flow. 3

Radial flow impellers are typically 4

used in circulating pumps, machine

tool pumps, boiler feed pumps and 5

industrial pumps with flows up to

20–30 m3/h. They are also used in

most single-stage pumps.

Mixed flow impellers

Mixed flow impellers are similar

to radial flow impellers but subject

1

the fluid to a degree of radial flow

in order to improve efficiency. 2

Mixed flow impellers can handle

3

greater flows than radial impellers,

and pumps with mixed flow

4

impellers are typically used for

larger water intake or distribution 5

purposes in water supply, irrigation

and cooling applications.

Channel and tube impellers

Channel impellers, also known

as solids handling impellers, are

designed to allow large free

passage of solids measuring

80 mm or more in diameter. 1

Because they are able to cope 2

with solids and fibres, pumps with

channel impellers are used in 3

wastewater applications.

4

In 2012, Grundfos launched the

S-tube impeller, a new type of 5

channel impeller where the

channel is shaped like a tube.

This design improves efficiency

and clog-free reliability.

Vortex impellers

A vortex impeller creates vortices

in the pump housing that moves

fibers, solids and sand through the

pump. This makes these impellers

ideal for handling liquids with long 1

fibers, particles and abrasive sand.

2

Although vortex impeller pumps

deliver high clog-free reliability, 3

they are typically only about half

as efficient as channel impellers. 4

Because of this, pumps with vortex

impellers are normally used in 5

smaller wastewater applications

with large amounts of fibers and

sand, but where reliability is more

important than efficiency.

Axial flow impellers

An axial flow impeller is essentially a

propeller and motor shaft unit,

housed in a tube. The propeller

simply moves the liquid along

through the tube. 1

Axial flow impellers do not

2

generate much pressure, but they

are very good at providing high

3

flow (more than 40,000 m3/hour).

Pumps with axial flow impellers 4

are mainly used for recirculating

5

liquids between tanks in wastewater

treatment plants, and for flood

control applications where large

volumes of water need to be

pumped at a low head.

You might also like

- Chapter 3 - Francis and Kaplan Turbine - Fluid MachineryDocument26 pagesChapter 3 - Francis and Kaplan Turbine - Fluid Machineryamanpreet2190100% (6)

- Suggested Vendors ListDocument137 pagesSuggested Vendors Listrajiv kumar100% (1)

- Daftar Harga Pompa Grunfos Terbaru Juni 2021Document158 pagesDaftar Harga Pompa Grunfos Terbaru Juni 2021lukmanNo ratings yet

- GE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Centrifugal Compressor 2Bcl 608Document1 pageGE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Centrifugal Compressor 2Bcl 608Mohammed ElarbedNo ratings yet

- Module 3 Basic Principles and Pump Types Main Impeller Types Master PDFDocument9 pagesModule 3 Basic Principles and Pump Types Main Impeller Types Master PDFadel allamNo ratings yet

- Main Impeller Types for PumpsDocument9 pagesMain Impeller Types for PumpsThinagaran N ManiamNo ratings yet

- Positive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitDocument9 pagesPositive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitMerie Ann Aumentado CallejaNo ratings yet

- Pumps N MechDocument17 pagesPumps N MechmeerhatNo ratings yet

- Fluid machinery-2024S-CH342-2Document19 pagesFluid machinery-2024S-CH342-2ahmedhammad7838No ratings yet

- PumpsDocument6 pagesPumpsSunil JasrotiaNo ratings yet

- Assignment - 1Document10 pagesAssignment - 1TolphasNo ratings yet

- Pump Types Used in Aquaculture OperationsDocument5 pagesPump Types Used in Aquaculture OperationsJensiNo ratings yet

- Positive Displacement PumpsDocument5 pagesPositive Displacement PumpsGabriel Andrés Barcha Angulo100% (1)

- Type of PumpsDocument16 pagesType of PumpsABHIJEET DHOBALENo ratings yet

- Term Paper: Fluid MechanicsDocument13 pagesTerm Paper: Fluid Mechanicsdharmendrarj_3No ratings yet

- Active Learning Process: Branch: Computer EngineeringDocument29 pagesActive Learning Process: Branch: Computer EngineeringAjit KumarNo ratings yet

- Fluid Machinery: Pumps and PumpingDocument26 pagesFluid Machinery: Pumps and Pumpingmathews munyumbeNo ratings yet

- Axial and mixed flow pump componentsDocument39 pagesAxial and mixed flow pump componentsYhuloopz AlvarezNo ratings yet

- For Other Uses of "Pump" or "Pumps", SeeDocument26 pagesFor Other Uses of "Pump" or "Pumps", Seekhalil zahaniNo ratings yet

- Lecture 6-7 Pumps and Pump DesignDocument68 pagesLecture 6-7 Pumps and Pump Designbaruhiye0020No ratings yet

- Pump-Pipe Systems Design OptimizedDocument64 pagesPump-Pipe Systems Design OptimizedNeetor TendekayiNo ratings yet

- Pota ble: Types of Pumps and Pumping StationsDocument18 pagesPota ble: Types of Pumps and Pumping StationsJelou SibiNo ratings yet

- Types of PumpsDocument6 pagesTypes of PumpsDevashish VaidyaNo ratings yet

- Presentation - Pumps and ValvesDocument31 pagesPresentation - Pumps and ValvesisharaNo ratings yet

- PUMPSDocument7 pagesPUMPSmohammed yusufNo ratings yet

- A Small, Electrically Powered Pump: Positive Displacement PumpsDocument6 pagesA Small, Electrically Powered Pump: Positive Displacement PumpsabduNo ratings yet

- PumpDocument38 pagesPumpCjNo ratings yet

- Centrifugal - Pump - Hand Book PDFDocument150 pagesCentrifugal - Pump - Hand Book PDFbarun1977100% (1)

- Assignment of HMCDocument6 pagesAssignment of HMCmuhammad aliNo ratings yet

- Process EquipmentsDocument277 pagesProcess EquipmentsnatarajaNo ratings yet

- Classification of PumpsDocument15 pagesClassification of PumpsCelester FernandezNo ratings yet

- Me-Lab (Pumps and Turbines)Document28 pagesMe-Lab (Pumps and Turbines)ALL THE GOOD STUFFNo ratings yet

- Types: Positive Displacement PumpsDocument9 pagesTypes: Positive Displacement PumpsShailesh BansiwalNo ratings yet

- Rotary & Centrifugal Pumps ExplainedDocument10 pagesRotary & Centrifugal Pumps ExplainedAnnamalai PalaniappanNo ratings yet

- Reciprocating Pump: Group 3Document13 pagesReciprocating Pump: Group 3Ariel GamboaNo ratings yet

- Types of Pumps and Their UsesDocument10 pagesTypes of Pumps and Their UsesArjohn De Los Santos100% (1)

- Chapter Four: Hydraulic Machines 4. Hydraulic Machines: Hydraulics-II Lecture Notes June 1, 2014Document15 pagesChapter Four: Hydraulic Machines 4. Hydraulic Machines: Hydraulics-II Lecture Notes June 1, 2014Ermiyas AlhegnNo ratings yet

- Chapter Four: Hydraulic Machines 4. Hydraulic Machines: Hydraulics-II Lecture Notes June 1, 2014Document15 pagesChapter Four: Hydraulic Machines 4. Hydraulic Machines: Hydraulics-II Lecture Notes June 1, 2014Ermiyas AlhegnNo ratings yet

- Unit 4 HHM Part 2Document75 pagesUnit 4 HHM Part 2Swati ChaudharyNo ratings yet

- Pump Working PrinciplesDocument7 pagesPump Working PrinciplesamirulbznNo ratings yet

- Course: Unit Operations IIDocument17 pagesCourse: Unit Operations IIGarfield SmithNo ratings yet

- Pump TypesDocument13 pagesPump Typesvikas patelNo ratings yet

- Rotodynamic Pumps ExplainedDocument6 pagesRotodynamic Pumps ExplainedKornelius Chandra WNo ratings yet

- Master 36 Module 5 Centrifugal Pump TypesDocument5 pagesMaster 36 Module 5 Centrifugal Pump TypesSandeep YadavNo ratings yet

- Domestic Pump Guide for Bungalow HomesDocument10 pagesDomestic Pump Guide for Bungalow HomesCollins Obari AdiyeNo ratings yet

- PumpsDocument11 pagesPumpsamk3745No ratings yet

- Positive Displacement Pump: Positive Displacement Pumps Impulse Pumps Velocity Pumps Gravity Pumps Valveless PumpsDocument11 pagesPositive Displacement Pump: Positive Displacement Pumps Impulse Pumps Velocity Pumps Gravity Pumps Valveless PumpsRao Qaisar ShahzadNo ratings yet

- REINC Rotary PumpDocument15 pagesREINC Rotary PumpMuhammadAuliaRahmanNo ratings yet

- D-Pumps-3rd ClassDocument40 pagesD-Pumps-3rd ClassFaruq. MechanicNo ratings yet

- Project 2Document7 pagesProject 2Lalaine RamosNo ratings yet

- PumpDocument81 pagesPumpabdulmuqutadir1No ratings yet

- Pump TypesDocument5 pagesPump TypesJayanth VarmaNo ratings yet

- 2 Pumps Part IDocument5 pages2 Pumps Part IJoel CariazNo ratings yet

- Pump Part 1Document82 pagesPump Part 1Amit KhadkaNo ratings yet

- PumpDocument13 pagesPumpDomagoj ButumovićNo ratings yet

- Presentation Pump 1Document27 pagesPresentation Pump 1Mohammed.abudi1996No ratings yet

- PumpsDocument54 pagesPumpsMark SantosNo ratings yet

- Radial Impellers Best for Mixing Due to High Shear RatesDocument1 pageRadial Impellers Best for Mixing Due to High Shear RatesLim Xiu XianNo ratings yet

- Pumps Are Devices Used To Move Fluids 78Document2 pagesPumps Are Devices Used To Move Fluids 78aroosadilbar27No ratings yet

- Positive Displacement Pump Types and Uses ExplainedDocument14 pagesPositive Displacement Pump Types and Uses Explainedatkilt mechNo ratings yet

- Centrifugal Pumps: PARAN, John Lloyd MACASAET, Alwin MALABUYOC, Lean ErnestDocument74 pagesCentrifugal Pumps: PARAN, John Lloyd MACASAET, Alwin MALABUYOC, Lean ErnestMeryL Ang100% (1)

- Classification of Pumps: Dynamic vs DisplacementDocument23 pagesClassification of Pumps: Dynamic vs DisplacementRaph ToelNo ratings yet

- Pumps TypesDocument14 pagesPumps TypesAbdallah Mansour100% (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Hdpe NICDocument57 pagesHdpe NICsaravananNo ratings yet

- Adwea Approved Vendors ListDocument315 pagesAdwea Approved Vendors Listjohndavsg8022No ratings yet

- Product Group ListDocument17 pagesProduct Group Listnaseer lateeNo ratings yet

- 12-II.2. Tower SpottingDocument16 pages12-II.2. Tower Spottingashok10577No ratings yet

- Opgw System General BrochureDocument20 pagesOpgw System General BrochureapichartjNo ratings yet

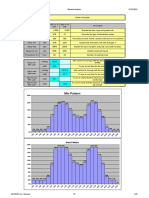

- Tank Design: Population Average Cons. Consommation Flow Heure Consumption Sources DifDocument4 pagesTank Design: Population Average Cons. Consommation Flow Heure Consumption Sources Difnaseer lateeNo ratings yet

- Tech - spec - vol - II مهم بو OHTLDocument138 pagesTech - spec - vol - II مهم بو OHTLnaseer lateeNo ratings yet

- GRP Pipe Specification GuideDocument8 pagesGRP Pipe Specification GuidekarunaNo ratings yet

- Tuyaux Trop Grands: Elevation H Stat Ref. Enrgy Sup. Enrgy Inf. SelectionDocument3 pagesTuyaux Trop Grands: Elevation H Stat Ref. Enrgy Sup. Enrgy Inf. Selectionnaseer lateeNo ratings yet

- Transmission Line DesignDocument84 pagesTransmission Line DesignCamille Licuanan NaboNo ratings yet

- 1 DemandDocument3 pages1 Demandnaseer lateeNo ratings yet

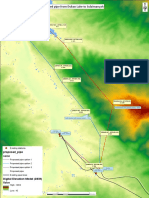

- Suleimaniyah City 3Document1 pageSuleimaniyah City 3naseer lateeNo ratings yet

- PAM Guide For Designing GBDocument80 pagesPAM Guide For Designing GBAly AnisNo ratings yet

- 4 CR64-4Document6 pages4 CR64-4naseer lateeNo ratings yet

- Village Domestic WaterDocument26 pagesVillage Domestic Waternaseer lateeNo ratings yet

- Headloss Table RawanduzDocument12 pagesHeadloss Table Rawanduznaseer lateeNo ratings yet

- Irregation CalculationDocument18 pagesIrregation Calculationnaseer lateeNo ratings yet

- Vol2 Suleimaniyah en PrintDocument110 pagesVol2 Suleimaniyah en Printnaseer lateeNo ratings yet

- 2022 Caleffi Plumbing and Hydronics Catalog 0222Document128 pages2022 Caleffi Plumbing and Hydronics Catalog 0222naseer lateeNo ratings yet

- Awp PL 01 - 1643737099Document1 pageAwp PL 01 - 1643737099naseer lateeNo ratings yet

- Pumping StationsDocument45 pagesPumping Stationsnaseer lateeNo ratings yet

- Sherkuzh Water Infrastructure MapDocument1 pageSherkuzh Water Infrastructure Mapnaseer lateeNo ratings yet

- Dokan Dam Proposed Pipe ProjectDocument1 pageDokan Dam Proposed Pipe Projectnaseer lateeNo ratings yet

- Awp PL 09 - 1643737099Document1 pageAwp PL 09 - 1643737099naseer lateeNo ratings yet

- Suleimaniyah City 1Document1 pageSuleimaniyah City 1naseer lateeNo ratings yet

- 02 BoQDocument589 pages02 BoQnaseer lateeNo ratings yet

- BS EN - 1968 Gas Cylinder-EnglishDocument49 pagesBS EN - 1968 Gas Cylinder-Englishnaseer lateeNo ratings yet

- Fire Fighting SummaryDocument23 pagesFire Fighting SummarySaleh El-hawaryNo ratings yet

- Wall Mounted and Channel Mounted Penstocks ManualDocument24 pagesWall Mounted and Channel Mounted Penstocks Manualnaseer lateeNo ratings yet

- Protivpožarni Sistemi EbaraDocument28 pagesProtivpožarni Sistemi EbaraMarkoNo ratings yet

- Introduction to TurbomachinesDocument38 pagesIntroduction to TurbomachinesmohamedovicNo ratings yet

- GE Low Pressure Stator Breakdown GuideDocument12 pagesGE Low Pressure Stator Breakdown GuideAlejandro Romero BallestasNo ratings yet

- CIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 2 (Impulse Turbine)Document1 pageCIRT, Bhopal Turbo Machinery (ME 502) Tutorial/Assignment Sheet 2 (Impulse Turbine)AnkurTripathiNo ratings yet

- Types of Pumps PDFDocument40 pagesTypes of Pumps PDFasdج asdNo ratings yet

- 02 - Wet Riser SystemDocument2 pages02 - Wet Riser SystemJeghiNo ratings yet

- 04 CompressorsDocument12 pages04 CompressorsApostolos AvraamidesNo ratings yet

- Study of Steam TurbineDocument3 pagesStudy of Steam TurbineJohn FredyNo ratings yet

- Axial Flow Compressor 2Document11 pagesAxial Flow Compressor 2ram kishor singhNo ratings yet

- Energy transfer in turbomachinesDocument60 pagesEnergy transfer in turbomachinesAtheer Sat0% (1)

- Assignment #3Document2 pagesAssignment #3Choa Pei ShuangNo ratings yet

- Catálogo de Turbinas WEIRDocument5 pagesCatálogo de Turbinas WEIRruben colqueNo ratings yet

- Assignment Turbomachinery Made by Akita Sukhdave 2K19/THE/01Document9 pagesAssignment Turbomachinery Made by Akita Sukhdave 2K19/THE/01Raunak KumarNo ratings yet

- Unsteady Flows in A Single-Stage Transonic Axial-Flow Fan Stator PDFDocument220 pagesUnsteady Flows in A Single-Stage Transonic Axial-Flow Fan Stator PDFZhifengNo ratings yet

- FM 2e SI Chap14 LectureDocument123 pagesFM 2e SI Chap14 LectureJavinKhongNo ratings yet

- Lab Name: Performance and Analysis of Kaplan Turbine On Multi Turbine TestDocument11 pagesLab Name: Performance and Analysis of Kaplan Turbine On Multi Turbine TestFarhan EdwinNo ratings yet

- Practice Midterm ProblemsDocument4 pagesPractice Midterm ProblemsAnonymous Ms8nYcbxY2No ratings yet

- 18ME54 Turbo Machines Module 02 Question No 4a & 4bDocument15 pages18ME54 Turbo Machines Module 02 Question No 4a & 4bThanmay JSNo ratings yet

- Modern Research Topics in Aerospace PropulsionDocument389 pagesModern Research Topics in Aerospace PropulsionawarialocksNo ratings yet

- TM Numerical 1Document1 pageTM Numerical 1Keerthi GowdaNo ratings yet

- AEC3101 Compressors & Turbines: Dr.P.N.Kadiresh Professor/Aerospace EngineeringDocument75 pagesAEC3101 Compressors & Turbines: Dr.P.N.Kadiresh Professor/Aerospace EngineeringPraveen SundararajanNo ratings yet

- Hydraulics MicroprojectDocument17 pagesHydraulics MicroprojectAkash ChourasiaNo ratings yet

- M 33Document1 pageM 33navneetkpatil8409No ratings yet

- Table of Contents (Centrifugal Pumps)Document4 pagesTable of Contents (Centrifugal Pumps)Ton BlokNo ratings yet

- MT186e - V1.2 enDocument142 pagesMT186e - V1.2 enIlhamzNo ratings yet

- Pump Efficiency CalculatorDocument3 pagesPump Efficiency Calculatorjkhan_7243840% (1)