Professional Documents

Culture Documents

CAPA Gasket 850-1213

CAPA Gasket 850-1213

Uploaded by

NAGRAJOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAPA Gasket 850-1213

CAPA Gasket 850-1213

Uploaded by

NAGRAJCopyright:

Available Formats

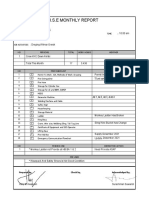

DOC. NO.

: QA-F-17-00

CORRECTIVE & PREVENTIVE

REV. NO : 0

ACTION REPORT REV DATE : 01.01.2020

For the Month : OCT. Occurrence Date :11.10.2022 Invoice Date : 970

Problem Statement:- Customer Name :-J Pan Tubular Components Pvt. Ltd. Banglore

Occurance Stage Total Qty. : 1000 Nos.

850-1213 Gasket diameter variation Total NG Qty. :757 Nos.

INHOUSE CUSTOMER

Immediate Action (s) / Correction.

Sl # Action (s) Responsibility Target Target Completed Remarks

1 Similar parts were kept separate and updated in WI. Rammilan 13.10.2022 13.10.2022 OK

ROOT CAUSE ANALYSIS - WHY ~ WHY .. ANALYSIS (Ishikawa diagram-Cause & Effect)

MAN Machine

Unskilled operator Polythene roll piston was not jammed

unskilled Shop floor Helper Cover blade was not working properly

850-1213 gasket mixed with 875-01622

Material did not have flexibility

Cover belt was not working properly

Packing Condition of Raw Material not ok

The material was mixed

Materials Methods

S.No. Potential Causes Identified Verification Date Significant Non Significant

Unskilled operator

1 Found ok 13.10.2022

2 Unskilled Shop Floor Helper Found ok 13.10.2022

Polythene roll piston was not jammed

3 Found ok 13.10.2022

Cover blade was not working properly

4 Found ok 13.10.2022

Material did not have flexibility

5 Found ok 13.10.2022

6 Packing Condition of Raw Material not ok Found ok 13.10.2022

Cover belt was not working properly

7 Found ok 13.10.2022

The material was mixed

8 Found NG 13.10.2022

Why 1: 850-1213 Gasket diameter variation.

Why 2:.The two parts were the same which was kept in the finish good area.(850-1213 &875-01622 Mixed).

Why 3: While dispatching, the incharge part got mixed up and the wrong part got detected.

Why 4: Similar parts were kept separate and updated in WI.

IDENTIFIED ROOT CAUSE

While dispatching, the incharge part got mixed up and the wrong part got detected.

Permanent Corrective & Preventive Action(s)

Sl # Actions Responsibility Target Implemented on Remarks

1 Similar parts were kept separate and updated in WI. Rammilan 13.10.2022 13.10.2022 ok

ANALYSIS REPORT WITH PHOTO

NG

OK

Check List for Document updation

S l# Document Description Yes No Not Applicable Responsibility Target Date Implemented

1 STANDARD OPERATING PROCEDURE. Pradeep/Adarsh

2 WORK INSTRUCTIONS. Mukesh 13.10.2022 13.10.2022

3 QUALITY ALERT NOTE. Mukesh

4 MACHINE PARAMETERS. Pradeep/Adarsh

5 DAILY MACHINE CHECKSHEET. Pradeep/Adarsh

6 MACHINE PREVENTIVE MAINTAINENCE. Guddo

HORIZONTAL DEPLOYMENT :

Sl # Actions Responsibility Target Implemented on Remarks

1 Similar parts were kept separate and updated in WI. Rammilan 13.10.2022 13.10.2022 ok

Mr.Mukesh Mr.Chandraprakash Mr. Alok Gupta

(Prepared By) (Checked By) (Approved By)

Page 1 of 1

You might also like

- VERIFICATION / CHECK POINTS (Implementation of Countermeasures in Process & Documentation With Date)Document1 pageVERIFICATION / CHECK POINTS (Implementation of Countermeasures in Process & Documentation With Date)amritanshuNo ratings yet

- 8D Report Blank Problem SolvingDocument16 pages8D Report Blank Problem SolvingTan LeNo ratings yet

- Risk RegisterDocument7 pagesRisk RegisterAlhad Panwalkar67% (3)

- Customer Name: Schneider Electric: SPL ClassDocument2 pagesCustomer Name: Schneider Electric: SPL ClassSachin Sam100% (1)

- 8D Report For VDC Wrong - NNLDocument10 pages8D Report For VDC Wrong - NNLAbhinav SinghNo ratings yet

- 12 MGD MRM Report Jan-2020Document156 pages12 MGD MRM Report Jan-2020Manish KaushikNo ratings yet

- Sand Replacement MethodDocument19 pagesSand Replacement MethodMazliah Zainal Abidin100% (1)

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- D3 For Bkt. 428Document4 pagesD3 For Bkt. 428RD PlcsNo ratings yet

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Document13 pagesJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNo ratings yet

- 8D Front Map Pocket Short MoldDocument10 pages8D Front Map Pocket Short MoldNirmal polyplastic100% (1)

- IMUS CITY New Zonal ValuesDocument53 pagesIMUS CITY New Zonal ValuesAlfred Tungpal57% (7)

- Oracle Kanban PlanningDocument18 pagesOracle Kanban PlanningPritesh MoganeNo ratings yet

- 8D Report Blank Problem SolvingDocument16 pages8D Report Blank Problem SolvingIsmael VaraNo ratings yet

- 8D: Problem Solving Sheet: We Use Cause and Effect Diagram For Find Out Possible CausesDocument7 pages8D: Problem Solving Sheet: We Use Cause and Effect Diagram For Find Out Possible CausesPuneet SharmaNo ratings yet

- Inspection Report 008PE2018 HowdenDocument2 pagesInspection Report 008PE2018 HowdenrcpretoriusNo ratings yet

- Time Sheet T218Document3 pagesTime Sheet T218RanjithNo ratings yet

- Colonel (US Army Ret.) Chris Paparone-The Sociology of Military Science - Prospects For Postinstitutional Military Design-Bloomsbury Academic (2012)Document257 pagesColonel (US Army Ret.) Chris Paparone-The Sociology of Military Science - Prospects For Postinstitutional Military Design-Bloomsbury Academic (2012)Marcos Cereceda Otarola100% (1)

- (Advances in Econometrics, 39) David T. Jacho-Chavez, Gautam Tripathi - The Econometrics of Complex Survey Data - Theory and Applications-Emerald Publishing (2019)Document338 pages(Advances in Econometrics, 39) David T. Jacho-Chavez, Gautam Tripathi - The Econometrics of Complex Survey Data - Theory and Applications-Emerald Publishing (2019)Rachid BarryNo ratings yet

- Supplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksDocument3 pagesSupplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksdysonNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorDocument6 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorVasanth KumarNo ratings yet

- Sample Report For Amazon FBA Jeans - RedactedDocument37 pagesSample Report For Amazon FBA Jeans - RedactedChulaka PitigalaNo ratings yet

- Complaint AnalysisDocument8 pagesComplaint AnalysisJKP OperationNo ratings yet

- Hyva 149 End Cover Fitment Direction WrongDocument1 pageHyva 149 End Cover Fitment Direction WrongRenju ChandranNo ratings yet

- RD-BBN01-COW-MDA-3004 - Rev.B MAR Lightwall (Approved)Document3 pagesRD-BBN01-COW-MDA-3004 - Rev.B MAR Lightwall (Approved)M Risaldhi KusumoNo ratings yet

- Copie de 8D-Report-Blank-Problem-SolvingDocument12 pagesCopie de 8D-Report-Blank-Problem-SolvinglabidiNo ratings yet

- RN 005 Airman Generator Id. 1723A62663Document4 pagesRN 005 Airman Generator Id. 1723A62663Wahyu RahmadNo ratings yet

- Form Inspection HSE April 2022 PDFDocument2 pagesForm Inspection HSE April 2022 PDFHery AwaludinNo ratings yet

- Invoice 1242 From Mendbnb LLCDocument1 pageInvoice 1242 From Mendbnb LLCMILBERT DE GRACIANo ratings yet

- Swivel 11 TDocument8 pagesSwivel 11 TGuruh SuprayitnoNo ratings yet

- 8D Report For Eye Bolt Thickness ProblemDocument1 page8D Report For Eye Bolt Thickness ProblemKapil HarchekarNo ratings yet

- Form Inspection HSE PDFDocument2 pagesForm Inspection HSE PDFHery AwaludinNo ratings yet

- Rca 2Document4 pagesRca 2KrunalVakilNo ratings yet

- Corrective Action For KPI - Supplier PPM in Nov-21Document1 pageCorrective Action For KPI - Supplier PPM in Nov-21jayNo ratings yet

- Ahmed Eid - SurveyerDocument1 pageAhmed Eid - Surveyerمسابح الكهرمانNo ratings yet

- AUDIT REPORT CompressedDocument8 pagesAUDIT REPORT CompressedSigantengPisanNo ratings yet

- ETB - Insulation Test Quote - Spire TowerDocument1 pageETB - Insulation Test Quote - Spire TowerJulian P. EE-JvNo ratings yet

- QCR NPP200 BergelombangDocument2 pagesQCR NPP200 BergelombangmulyadisaputraNo ratings yet

- (W PD SL Cem011) Yoke Page1Document3 pages(W PD SL Cem011) Yoke Page1SumaNo ratings yet

- Signature of The Firm's RepresentativeDocument1 pageSignature of The Firm's Representativepuri16No ratings yet

- Almansoori Inspection Services: Pre & Post Job Check ListDocument1 pageAlmansoori Inspection Services: Pre & Post Job Check ListMohamed YasirNo ratings yet

- SMETADocument5 pagesSMETArizky rahmanNo ratings yet

- Ny2.Nl BW Fib ZZ ZZ ZZ Mi Ar 00101Document24 pagesNy2.Nl BW Fib ZZ ZZ ZZ Mi Ar 00101Azam KhanNo ratings yet

- FMEA For PROFILE Unit-II 2Document3 pagesFMEA For PROFILE Unit-II 2Hitarth_dhamsaniaNo ratings yet

- JN-Q-BKCC-220426 Musnorman Anti Rodent Mesh For B1-25ADocument1 pageJN-Q-BKCC-220426 Musnorman Anti Rodent Mesh For B1-25AVincent LowNo ratings yet

- SFQP-MECH With NDT-SILO-2Document8 pagesSFQP-MECH With NDT-SILO-2Dhananjay BalkiNo ratings yet

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueDocument4 pages43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarNo ratings yet

- Process Pipes Handling and Storage Material Procedure-3 Additional SpheresDocument16 pagesProcess Pipes Handling and Storage Material Procedure-3 Additional Spheresqaqc.nimerlawzi1No ratings yet

- Sample Report-2Document35 pagesSample Report-2raulNo ratings yet

- Indra: Cabinet NameDocument1 pageIndra: Cabinet NameBoualem AisNo ratings yet

- 100 V1B EKL0 01041 Building Dimension Control ProcedureDocument7 pages100 V1B EKL0 01041 Building Dimension Control ProcedureAnonymous FHkX0ANo ratings yet

- GTGC-RID-OP-FRM-10 Personal Custody Statement PDFDocument1 pageGTGC-RID-OP-FRM-10 Personal Custody Statement PDFDanny SolvanNo ratings yet

- Yap MooeDocument13 pagesYap MooeDaisy Medrano VillartaNo ratings yet

- Kind Attn. Gstin NoDocument1 pageKind Attn. Gstin NoSandeep MoreNo ratings yet

- Method Statement For Blanking Rev 0Document15 pagesMethod Statement For Blanking Rev 0Joel Jeffery SarkarNo ratings yet

- Promot Electric Purchase Order: Bill ToDocument2 pagesPromot Electric Purchase Order: Bill ToParth TarsariaNo ratings yet

- 19 Venkatesh (Sangareddy)Document5 pages19 Venkatesh (Sangareddy)Gabriel DavidNo ratings yet

- Process Flow Chart Assy ECU Waterproof & Non-WaterproofDocument9 pagesProcess Flow Chart Assy ECU Waterproof & Non-WaterproofAndi KamriNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument2 pagesQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas Gadnatam100% (1)

- BV Specimen Certificate - Embarkation or Pilot LaddersDocument2 pagesBV Specimen Certificate - Embarkation or Pilot LaddersMeghna S I Shipping100% (1)

- Bucket ElevatorDocument2 pagesBucket ElevatorMAHENDRANo ratings yet

- DYC Timesheet 05-01-2023Document1 pageDYC Timesheet 05-01-2023DEBASHISHCHATTERJE78No ratings yet

- D1 - Establish The Team: PSA Incident N°815 2008 502 (Poissy) : Clear Coat Run SubjectDocument6 pagesD1 - Establish The Team: PSA Incident N°815 2008 502 (Poissy) : Clear Coat Run Subject57641No ratings yet

- Algec For Energy: Page 3 of 11Document1 pageAlgec For Energy: Page 3 of 11Mohamed JalilNo ratings yet

- Data Leakage Detection - Final 26 AprilDocument62 pagesData Leakage Detection - Final 26 Aprilprashvirus100% (2)

- Technology and Livelihood Education Entre Module 7Document23 pagesTechnology and Livelihood Education Entre Module 7Boy SawagaNo ratings yet

- 4 Daft Mngt13e PPT Ch04Document30 pages4 Daft Mngt13e PPT Ch04Stanley CkNo ratings yet

- Guia Rápido ETAMATIC PDFDocument26 pagesGuia Rápido ETAMATIC PDFWily WayerNo ratings yet

- Body Structures and Chassis OptimizationDocument17 pagesBody Structures and Chassis OptimizationJennyvi NapodNo ratings yet

- Zam P BLOCK NW 4Document212 pagesZam P BLOCK NW 4mrrsiddiquiNo ratings yet

- Ks1150 TC 100 Ipn Fire Resistance Classification ProtocolDocument8 pagesKs1150 TC 100 Ipn Fire Resistance Classification ProtocolBinh HuynhNo ratings yet

- Session 7 Time StudyDocument44 pagesSession 7 Time StudySWAPNIL KRISHNANo ratings yet

- Lesson Plan 2Document4 pagesLesson Plan 2api-253371909No ratings yet

- Publications Catalog - October 2016Document113 pagesPublications Catalog - October 2016amir_fortunateNo ratings yet

- Introduction To: Information RetrievalDocument46 pagesIntroduction To: Information RetrievalRAMESH KESAVANNo ratings yet

- SpanacDocument127 pagesSpanacTimothy BensonNo ratings yet

- Development of Positive Personal AttitudeDocument13 pagesDevelopment of Positive Personal AttitudeRiyas Y75% (4)

- C Coding Style GuidelinesDocument13 pagesC Coding Style GuidelinescanrullNo ratings yet

- SBP - Rule Based System Forward ChainingDocument14 pagesSBP - Rule Based System Forward ChainingTU ElektroNo ratings yet

- Constitutional Reform and Political Participation in The Gulf - Khalaf & LucianiDocument304 pagesConstitutional Reform and Political Participation in The Gulf - Khalaf & Lucianiba7raini100% (41)

- LPC1 EappDocument6 pagesLPC1 EappAriel AlonsagayNo ratings yet

- Microcontroller Level 6 Cat 2Document2 pagesMicrocontroller Level 6 Cat 2itrendwillyNo ratings yet

- Espectrómetro FT-IR Nicolet Is 10Document1 pageEspectrómetro FT-IR Nicolet Is 10Adriano BludegardNo ratings yet

- Introduction To Data WarehousingDocument58 pagesIntroduction To Data WarehousingVarun LalwaniNo ratings yet

- Walk CompassDocument14 pagesWalk CompasstaccountidNo ratings yet

- Professional.C.sharp - Design.patterns - Applied WroxDocument0 pagesProfessional.C.sharp - Design.patterns - Applied Wroxphamhoang12341No ratings yet

- VHDL Coding BasicsDocument242 pagesVHDL Coding BasicsHernan GarciaNo ratings yet

- 1 - Exercise English1210Document1 page1 - Exercise English1210Fernando RodriguezNo ratings yet