Professional Documents

Culture Documents

(W PD SL Cem011) Yoke Page1

(W PD SL Cem011) Yoke Page1

Uploaded by

SumaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(W PD SL Cem011) Yoke Page1

(W PD SL Cem011) Yoke Page1

Uploaded by

SumaCopyright:

Available Formats

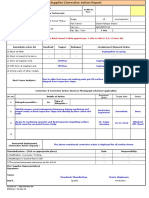

CHECKING AND SELECTION WORK INSTRUCTION

Customer Name CANON ELECTRONICS (M) Reference Number W-PD-SL-CEM011

Part Name ALL YOKE PART Part Number ALL YOKE PART

A. APPEARANCE CHECK

1. Operator perlu memakai hand-glove dan finger coat

sebelum menjalankan proses 'Checking and Selection'.

2. Operator must wear hand glove and finger coat during

Checking and selection process

2. Periksa part appearance di bawah 3X Magnifying

glass cahaya. Pastikan tiada reject part yang

dinyatakan dibawah:

2. Check part under 3X Magnifying glass. Make sure no

defect part as stated below :

a. Rusty

b. Dented

c. Sticking

d. Scratches

3. Untuk memeriksa permukaan belakang part, plat

bermagnet perlu digunakan dengan cara meletakkannya

ke atas part.

Angkat plat tersebut dan periksa permukaan

belakang setiap part . Pastikan tiada reject seperti

yang telah dinyatakan di atas.

4. Jika terjumpa NG Part, pengasingan perlu dilakukan.

Asingkan part yang reject ke dalam NG PARTS

Plastic Container yang disediakan mengikut jenis reject .

RUSTY DENTED STICKING SCRATCHES

NG PARTS

PLASTIC CONTAINER

5. Kesemua part yang telah diperiksa dan didapati tidak

mengalami sebarang reject akan dimasukkan ke dalam

bekas yang berlabel 'OK'.

Date Rev. Revise Reason Prepared by : Checked by : Approved by:

20/09/2011 /1\ Update work instruction MPD MPD

MPD

20/10/2018 /2\ Update work instruction PROD PACKING PROD

19/02/2019 /3\ Update work instruction 06 FEB 2021 06 FEB 2021 06 FEB 2021

06/02/2021 /4\ Revise check point no. 16a KHALIL YATHIRAJ NATHAN

/5\

Matomek Precision Die Sdn.Bhd. (214140-K) Page 1 of 3

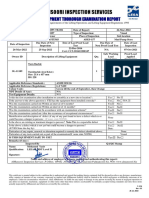

CHECKING AND SELECTION WORK INSTRUCTION

Customer Name CANON ELECTRONICS (M) Reference Number W-PD-SL-CEM011

Part Name ALL YOKE GRINDING Part Number ALL YOKE GRINDING

B. APPEARANCE CHECK

Body-Black Mark

6. Operator perlu memakai hand-glove dan finger coat sebelum

menjalankan proses 'Checking and Selection'.

6. Operator must wear handglove and finger coat before checking

and selection process

7. Letakkan tray di bawah cahaya Magnifying glass untuk melihat bahagian

badan part.

7. Put tray contain with part under magnifiying glass light to check

part body

8. Periksa setiap baris part dengan teliti. Pastikan tidak ada black mark

pada setiap bahagian badan part.

8. Check part every row properly, make sure no black mark every part body

Example: BLACK MARK

J16-2005 CB3-6755 CB3-7103

9. Jika terdapat part yang reject, asingkan part tersebut ke dalam tray

yang telah disediakan.

9. If found defect part, segregate the part into NG part tray

NG PART TRAY

C. APPEARANCE CHECK

Leg Surface

10. Terbalikan tray dengan berhati-hati untuk melihat bahagian bawah.

Kemudian buka tray bahagian atas.

10. Please be carefull during flip over the tray, open the bottom side

tray to check leg surface.

Date Rev. Revise Reason Prepared by : Checked by : Approved by:

21/10/2011 /1\ Add in body checking procedures MPD MPD

MPD

20/10/2018 /2\ Review work instruction PROD PACKING PROD

19/02/2019 /3\ Revise WI add in NG part tray with label 06 FEB 2021 06 FEB 2021 06 FEB 2021

06/02/2021 /4\ Revise check point no. 16a KHALIL YATHIRAJ NATHAN

/5\

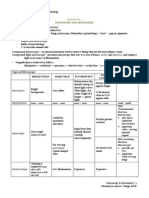

CHECKING AND SELECTION WORK INSTRUCTION

Customer Name CANON ELECTRONICS (M) Reference Number W-PD-SL-CEM011

Part Name ALL YOKE Part Number ALL YOKE

11. Gunakan microscope 'Min 20X' zoom Di bawah Mikroskop 20X, sapu

bahagian permukaan kaki part dengan menggunakan putik kapas.

11. Please use microscope 'Min 20x' zooming, lapping

leg surface with cotton buts (refer photo)

12. Periksa setiap baris part dengan teliti. Condongkan kedudukan tray/ part

untuk periksa part. Pastikan tidak ada reject seperti berikut :

12. Check every rows tilted position to checking please ensure

no reject as stated below :

a) Scratch d) Whitish g) Foreign Material

b) Dented e) Stain

c) Burr f) No plating

13. Jika terdapat part yang reject, asingkan part tersebut ke dalam tray

yang telah disediakan.

13. If found defect part, segregate part into prepared tray

NG tray, Indicates

with proper label

NG PART TRAY

14. Selepas proses siap dijalankan, letak semula tray di bahagian

atas part.

14. After selection process ok, put back the bottom side tray

15. Kemudian, terbalikkan semula tray tersebut ke keadaan asal dengan

berhati-hati.

15. Please be carefull during flip over the tray

16a. Selepas proses pemilihan 100%, keseluruhan dulang harus diisi

sebelum dihantar ke bahagian pembungkusan.

Kuantiti kekurangan tidak dibenarkan

16a. After100% selection process, entire tray should be filled before

pass to OQC section for final checking.

No shortage quantity allowed.

Shortage qty 16b. Setelah pemeriksaan akhir OQC, semua bahagian OK dihantar

ke bahagian pembungkusan untuk melakukan

pembungkusan & Pelabelan Kod Bar

16b. After OQC final checking , all OK part pass to packing section

to perform packing & Barcode Labelling

Date Rev. Revise Reason Prepared by : Checked by : Approved by:

20/10/2018 /1\ Revise numbering MPD

MPD MPD

19/02/2019 /2\ Revise WI add in NG part tray with label PROD PACKING PROD

19/02/2019 /3\ Revise WI add in NG part tray with label 06 FEB 2021 06 FEB 2021 06 FEB 2021

06/02/2021 /4\ Revise check point no. 16a KHALIL YATHIRAJ NATHAN

/5\

Matomek Precision Die Sdn.Bhd. (214140-K)

You might also like

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- JCB 3CX - 4CX - 214 - 214e - 215 - 217 PDF Service Manual - Part30Document5 pagesJCB 3CX - 4CX - 214 - 214e - 215 - 217 PDF Service Manual - Part30mojbarNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Attachment A - Scope of WorkDocument7 pagesAttachment A - Scope of WorkMazhar MahadzirNo ratings yet

- Check List For Pre Commissioning of MV SwitchgearDocument2 pagesCheck List For Pre Commissioning of MV Switchgeararuna100% (9)

- Section C - Preparation and Coating Audit TemplateDocument7 pagesSection C - Preparation and Coating Audit TemplateAnnNo ratings yet

- HT MotorDocument25 pagesHT MotorgaladrialNo ratings yet

- Passenger HoistDocument10 pagesPassenger HoistParshant SainiNo ratings yet

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- Standard Operating Procedure / Work Instructions / Visual AidsDocument3 pagesStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavNo ratings yet

- Science7 Q2 Mod2of9 LifethroughtheLens v2Document31 pagesScience7 Q2 Mod2of9 LifethroughtheLens v2Sugar CortezNo ratings yet

- Microscope Parts and FunctionsDocument3 pagesMicroscope Parts and FunctionsAntonov VodkaNo ratings yet

- Science: Quarter 2 - Module 1Document20 pagesScience: Quarter 2 - Module 1kaysia kerra deiparine100% (1)

- 1 - COMPOUND MICROSCOPE - Parts & FunctionsDocument7 pages1 - COMPOUND MICROSCOPE - Parts & FunctionsMichael Ritz Estillore100% (1)

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- Science 7: Learning Activity Sheet Quarter 2 Week 1Document11 pagesScience 7: Learning Activity Sheet Quarter 2 Week 1GINA OTARANo ratings yet

- AHU FAHU - AnnuallyDocument3 pagesAHU FAHU - AnnuallyDreamliner100% (1)

- Pre-Shipment Inspection: Product PhotoDocument35 pagesPre-Shipment Inspection: Product Photo123456No ratings yet

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- Rework Process FlowDocument6 pagesRework Process FlowIsaac Samuel100% (1)

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDocument36 pagesDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823No ratings yet

- Casing Stabbing BoardDocument1 pageCasing Stabbing BoardRanjithNo ratings yet

- Comparison MicoscopeDocument10 pagesComparison MicoscopeSwati V NairNo ratings yet

- Bracket Panel Insert Missing 8dDocument14 pagesBracket Panel Insert Missing 8dabinayaNo ratings yet

- DWG Ti 2198 A - 008 - 01Document52 pagesDWG Ti 2198 A - 008 - 01fadilNo ratings yet

- Fat - MSB Pmu JinjangDocument6 pagesFat - MSB Pmu JinjangFirdaus Muhammad100% (1)

- Zf2515 Zoi 4bzw Nach0umt3muccnDocument26 pagesZf2515 Zoi 4bzw Nach0umt3muccnraulNo ratings yet

- Dumper Truck FrontDocument2 pagesDumper Truck Frontengr.haseebbalochNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Customer Complaint FormDocument1 pageCustomer Complaint FormMinal HadiNo ratings yet

- Mark Andy 2200 PM Evaluation Checklist General InformationDocument14 pagesMark Andy 2200 PM Evaluation Checklist General InformationEdwin PerezNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- BOP Lifting Plate VisualDocument1 pageBOP Lifting Plate Visualyasir kunnathNo ratings yet

- Air Winch VisualDocument10 pagesAir Winch VisualRanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Document31 pagesCosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)57641No ratings yet

- Testcoo Sample Report-Air FryerDocument41 pagesTestcoo Sample Report-Air FryerraulNo ratings yet

- SB 10091506 2280Document28 pagesSB 10091506 2280sesentorodriguezNo ratings yet

- Turn Buckle VisualDocument8 pagesTurn Buckle VisualRanjithNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- MC 10186819 0001Document2 pagesMC 10186819 0001scarab scarabNo ratings yet

- BOP Plate VisualDocument1 pageBOP Plate VisualRanjithNo ratings yet

- Travelling Block AdaptorDocument1 pageTravelling Block AdaptormhmdtrainingNo ratings yet

- List of InspectionDocument17 pagesList of InspectionNQTNo ratings yet

- 03 Iris1Document12 pages03 Iris1AndiosoNo ratings yet

- Liquid Penetrant Test Procedure F1Document12 pagesLiquid Penetrant Test Procedure F1abrayalamNo ratings yet

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalDocument8 pagesKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument5 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 2013-2016 ALTIMA AND 2014-2016 ROGUE Mil On With DTC P0776: AT15-015c NTB15-086c April 6, 2016Document19 pages2013-2016 ALTIMA AND 2014-2016 ROGUE Mil On With DTC P0776: AT15-015c NTB15-086c April 6, 2016Alberto Flores AraujoNo ratings yet

- Separator Installation Report (Repaired)Document9 pagesSeparator Installation Report (Repaired)Novan RosyandyNo ratings yet

- Breathing Apparatus-List-SCBA-06072020-GR PDFDocument1 pageBreathing Apparatus-List-SCBA-06072020-GR PDFwarikhNo ratings yet

- Vendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitleDocument6 pagesVendor Document Review Sheet (DECAL) : J3 Program-Offsites & Utilities, Jamnagar, India Project TitlenisargkedarNo ratings yet

- 02-Singl Joint 1Document8 pages02-Singl Joint 1Abdou BoucheritNo ratings yet

- V 2155 508 A 600 - 0 - ITP - CodeBDocument13 pagesV 2155 508 A 600 - 0 - ITP - CodeBHanh BuiminhNo ratings yet

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- Extract Fan/Exhaust Fan - 3M Task SheetDocument3 pagesExtract Fan/Exhaust Fan - 3M Task Sheetobaidur_rehman_3No ratings yet

- Bench Cutting MachineDocument2 pagesBench Cutting MachineProjects DepartmentNo ratings yet

- FORM-HSE-001-028 Checklist Forklift - Id.enDocument6 pagesFORM-HSE-001-028 Checklist Forklift - Id.enroni jasonNo ratings yet

- 52-9000 Tape Sticking To Liner CADocument9 pages52-9000 Tape Sticking To Liner CAQuality MuirTapesNo ratings yet

- Preservation Inspection Checklist-732508Document1 pagePreservation Inspection Checklist-732508Bayu SaputraNo ratings yet

- Big Bag Ring VisualDocument1 pageBig Bag Ring VisualRanjithNo ratings yet

- Regular Safety & Mechanical Inspection Light VehicleDocument6 pagesRegular Safety & Mechanical Inspection Light VehicleRie ReiNo ratings yet

- 802870-D Optistar LE PM ChecklistDocument4 pages802870-D Optistar LE PM ChecklistDanilo MirandaNo ratings yet

- DQR Sheet 01Document12 pagesDQR Sheet 01nandi_engineerNo ratings yet

- ITR-CNI (Instrument)Document21 pagesITR-CNI (Instrument)mahmoudNo ratings yet

- Micromaniarvwkey PDFDocument1 pageMicromaniarvwkey PDFAngelica RemosNo ratings yet

- Microscopy & MicrometryDocument4 pagesMicroscopy & MicrometryChristine Jo Ann ZuñigaNo ratings yet

- Puzzle Quiz For Science 7 Quarter 2Document2 pagesPuzzle Quiz For Science 7 Quarter 2Jenelyn Paraiso - PacayraNo ratings yet

- Module in ScienceDocument6 pagesModule in Sciencenasser pazaulan12No ratings yet

- CO-The Parts and Functions of A MicroscopeDocument26 pagesCO-The Parts and Functions of A MicroscopePrincy MoralesNo ratings yet

- 1st Summative test.7-Nov.29-Dec. 6,2021Document2 pages1st Summative test.7-Nov.29-Dec. 6,2021karizajean desalisaNo ratings yet

- Labreport Exp2.1a2.2 g10Document9 pagesLabreport Exp2.1a2.2 g10NUR NAJWA BINTI MOHD RAFIE MoeNo ratings yet

- A. Bonifacio Integrated School Supplemental Activities in Science 7 Second Quarter Week 1Document3 pagesA. Bonifacio Integrated School Supplemental Activities in Science 7 Second Quarter Week 1Rose Ann ChavezNo ratings yet

- Direction: Read and Analyze Each Item Carefully, Then Encircle The Letter of The Correct AnswerDocument1 pageDirection: Read and Analyze Each Item Carefully, Then Encircle The Letter of The Correct AnswerJenhrel MolateNo ratings yet

- Light MicroscopeDocument10 pagesLight MicroscopeAnkit MishraNo ratings yet

- Microscopy TechniquesDocument3 pagesMicroscopy Techniqueskai dollNo ratings yet

- David James Ignacio - Label The MicroscopeDocument3 pagesDavid James Ignacio - Label The MicroscopeDavid James IgnacioNo ratings yet

- T700 Series PDF Versión en EspañolDocument27 pagesT700 Series PDF Versión en EspañolPepe GayoNo ratings yet

- Biology Notebook: 02.02 Microscopes: Key Questions and Terms Notes (Quoted From Lesson)Document3 pagesBiology Notebook: 02.02 Microscopes: Key Questions and Terms Notes (Quoted From Lesson)MatthewNo ratings yet

- DB17-008 Various DiscontinuedDocument3 pagesDB17-008 Various DiscontinuedMichael LopezNo ratings yet

- Experiment 1 - MicrosDocument9 pagesExperiment 1 - MicrosCOLLEEN GULLENNo ratings yet

- Parts of Microscope and Their FunctionsDocument3 pagesParts of Microscope and Their FunctionsAlfina SafiraNo ratings yet

- Second Quarter Summative Test-MDL Science VII S.Y. 2021-2022Document4 pagesSecond Quarter Summative Test-MDL Science VII S.Y. 2021-2022ShengNo ratings yet

- Kenneth RomeroDocument4 pagesKenneth RomeroKenneth RomeroNo ratings yet

- Week11 - The MicroscopeDocument31 pagesWeek11 - The MicroscopeJr BalagtasNo ratings yet

- Ci Po Ucs01-0000003030 Nikon Instruments Inc Sol. 431Document2 pagesCi Po Ucs01-0000003030 Nikon Instruments Inc Sol. 431Deans C DezaNo ratings yet

- Deped Physical Fitness Test V.Mapa High School Ii-Ss2 Mrs. MantoDocument4 pagesDeped Physical Fitness Test V.Mapa High School Ii-Ss2 Mrs. Mantoalfonse_sarmiento3194No ratings yet

- Parts of MicroscopeDocument4 pagesParts of MicroscopeJohn Rey F. CastroNo ratings yet

- Biology Microscope ExperimentDocument2 pagesBiology Microscope ExperimentSakkunthala Elil100% (2)