Professional Documents

Culture Documents

JSA Lifting Works

Uploaded by

Santhoesh srinivasanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Lifting Works

Uploaded by

Santhoesh srinivasanCopyright:

Available Formats

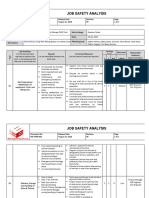

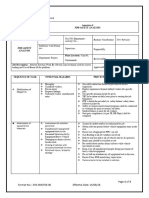

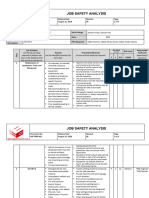

Job Safety Analysis on Lifting Works

Residual

Initial Risk

Risk

Rating Control Measures Responsible

Task / Activities Initial Risk Rating

H M L H M L

• Safe Work Permit and other pertinent documents shall Supervisor

be secured before any works commence.

• Pre-start meeting shall be discussed during daily Permit Issuer

· Check safety condition of whole area toolbox meeting before work commence.

1. Work permit Permit Receiver

for electrical exposure • Equipment and tool inspection must be carried out.

Prior to commencing all • Concerned supervisor / foreman to prepare required

L HSE Officer

-Slip, trip, fall during site inspection. safe work plan / permit one day in advance. L

works, a work permit is

• Joint Visit of Permit Issuer, Permit Receiver, Supervisor

required. and HSE Officer should be conducted before issuing

-Moving machineries.

the Work Permit.

• Supervisor / foreman and safety officer to supervise

and monitor the activity respectively

-Lack of hazard recognition and • Hire competent workers. Work Supervisor

awareness of the new workers. • Safety induction and training.

• Toolbox meeting before work HSE Officer

2. Manpower • All workers shall be issued with basic PPE and must

- Incompetent and inexperience L

mobilization wear them on site at all time L

workers

• Proper supervision and safety coverage

-Lack of training • Initial gas testing should be conducted

• Inspect before use for qualification. Work Supervisor

• Defective equip or tool shall not be used.

• Regularly check and maintenance. HSE Officer

3. Equipment

-Injury of workers (cutting, pinch points, • Implementation of color coding system,

mobilization &

caught in between, struck by flying • Ensure competent workers with necessary training

Usage of tools & L

objects, etc.) L

equipment. • Proper usage of PPE.

- Ergonomics and manual handling.

- Moving machineries. • Following proper procedure on tools & equipment

usage.

• Proper supervision and safety coverage.

Doc. No. REV. A Page 2 of 4

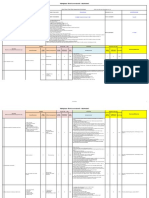

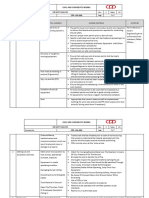

Job Safety Analysis on Lifting Works

Residual

Initial Risk

Risk

Rating Control Measures Responsible

Task / Activities Initial Risk Rating

H M L H M L

• The driver or operator shall be trained or certified for

competence. Third Party Certificate or TUV license if

necessary.

• The flagmen shall be stationed when vehicles reversing

Fatality or serious injury • Follow site traffic rule, not overload, shortcut or driving

4. Transportation of over speed limit of 20km/h. Work Supervisor

materials -Collision with other vehicles & other H • Ensure to follow Defensive Driving Safety to all drivers and M

properties operators. HSE Officer

• The equipment, tools or materials on vehicle shall be

properly fixed.

• Regularly inspect and maintenance.

• Ensure to follow Defensive Driving Safety to all drivers

and operators.

• Properly wear correct PPE, including safety gloves and Work Supervisor

5. Unpacking -Hand or foot injury (slip, trip & fall steel-toed shoes.

-unloading and hazard) • Handle with care and good position. Proper body HSE Officer

L positioning while work execution.

arrangement of L

materials. -Ergonomics and manual handling. • Proper coordination with fellow workers.

• Proper supervision and safety coverage.

-Personal Injury or Equipment Failure • Check all the equipment or rigging devices to ensure Work Supervisor

good performance.

-Tumbling of the crane. • Set the barriers around operating area and assign the HSE Officer

watchman to keep non-related persons away.

-Collision of crane to powerlines & other • The equipment operator and riggers shall be qualified Rigger

properties. and certified for competence. (Should have 3rd Party

Certification). Operator

6. Lifting, incl. loading • Riggers should have designated reflective vest &

-Falling of the crane load to workers & H

and unloading whistle. M

other properties.

• Operate as per the lift instruction and load chart.

• Load shall be controlled with taglines during hoisting.

-Strong winds & abnormal weather

• Only rigging devices (sling, chain block, etc.) of correct

conditions. capacity shall be used for hoisting.

• Ground must be even and compacted where the crane is

-Working or passing of workers to to be positioned.

suspended load. • Ensure that the outriggers are fully extended prior to lift.

• Ensure to use proper outrigger pads and proper size.

Doc. No. REV. A Page 3 of 4

Job Safety Analysis on Lifting Works

Residual

Initial Risk

Risk

Rating Control Measures Responsible

Task / Activities Initial Risk Rating

H M L H M L

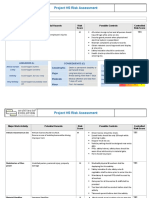

• Proper lifting signage must be in place.

• Ensure to have lifting plans in all critical lifts activities.

• No operation of crane if the wind speed exceeds 32kph

or refers to manufacturer’s specification.

• No working or passing to the suspended load.

• Ensure proper illumination when working at night works.

• Beacon lights should be turned on at all times during

operation.

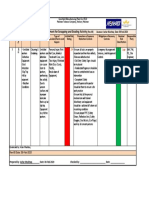

Please Refer Below for Risk Assessment Rating:

Risk Assessment Table

Likelihood Severity

Risk Assessment Matrix

1. Highly improbable 1. Minor injury, no time off

2. Remotely possible but 5 5 10 15 20 25

known to occur 2. Injury resulting in up to 3 days off

4 4 8 12 16 20

3. Infrequent 3. Injury resulting in 3 or more days off

4. Occasional 4. Major disability injury 3 3 6 9 12 15

Severity

5. Frequent and Regular 5. Fatality 2 2 4 6 8 10

Likelihood X Severity = Risk Rating 1 1 2 3 4 5

Likelihood X

Equivalent Risk Rating

Severity Result Rating 1 2 3 4 5

15 to 25 High Risk H Likelihood

8 to 14 Medium Risk M

1 to 7 Low Risk L

Doc. No. REV. A Page 4 of 4

You might also like

- JSA Tie in ActivitiesDocument15 pagesJSA Tie in ActivitiesQADEER SHANNo ratings yet

- Waterproofing JhaDocument5 pagesWaterproofing Jhaprince olanNo ratings yet

- Paint Work Using Mobile Crane PSO FSD.Document5 pagesPaint Work Using Mobile Crane PSO FSD.fiazhussaindbxNo ratings yet

- Porta Cabins Shifting Risk AssessmentDocument8 pagesPorta Cabins Shifting Risk AssessmentAsad Raza100% (3)

- RA Pump TemoraryDocument12 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- Risk Assessment For Hand RenderingDocument5 pagesRisk Assessment For Hand RenderingSyed AmjadNo ratings yet

- Risk Assessment - Pipe Fit Up - Hot WorkDocument7 pagesRisk Assessment - Pipe Fit Up - Hot WorkHanu JemberNo ratings yet

- RA-SurveyingDocument7 pagesRA-SurveyingAbdul LatheefNo ratings yet

- Nut Bolt Tighten by Hammering Spanner and Torque Machine JsaDocument4 pagesNut Bolt Tighten by Hammering Spanner and Torque Machine JsaAKBAR ALINo ratings yet

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- Job Safety Analysis & Risk Assessment For Scrapping and Grading ActivityDocument1 pageJob Safety Analysis & Risk Assessment For Scrapping and Grading ActivityAzhar Mushtaq100% (1)

- Risk Assessment - BackfillingDocument6 pagesRisk Assessment - Backfillingmahmoud nada100% (1)

- RAMS MAnual LiftingDocument12 pagesRAMS MAnual LiftingCarlos Immanuel100% (1)

- Jsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBDocument6 pagesJsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBMohammed MinhajNo ratings yet

- Rare GusterDocument16 pagesRare Gusterreemy sarkNo ratings yet

- AST JSA Excavations.Document3 pagesAST JSA Excavations.md_rehan_2No ratings yet

- JHA ISO Container Lifting Point MPI InspectionDocument7 pagesJHA ISO Container Lifting Point MPI InspectionMohamedNo ratings yet

- JSA-control Panel Final Reviwed AVCDocument5 pagesJSA-control Panel Final Reviwed AVCSubhash Chekka SEC 115KV ProjectNo ratings yet

- RA Pump TemoraryDocument11 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- Jsa For Hvac Equipment InstallDocument4 pagesJsa For Hvac Equipment Installpowergroup engineersNo ratings yet

- Jsa For Installation of Pipe Railing On SkidDocument6 pagesJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- TASK HAZARD CONTROL MainDocument6 pagesTASK HAZARD CONTROL MaintimothyNo ratings yet

- 5.19 JSP Self Levelling Epoxy Painting ActivityDocument8 pages5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisNo ratings yet

- Jsa Steel ErectionDocument9 pagesJsa Steel Erection01095902062ahmedNo ratings yet

- Jsa Welding and Sleeve InstallationDocument5 pagesJsa Welding and Sleeve Installationshinto Lawrence100% (2)

- 10 - Risk Assessment - PlumpingDocument7 pages10 - Risk Assessment - Plumpingmahmoud nada0% (1)

- Material Lifting Shifting by Farana/craneDocument1 pageMaterial Lifting Shifting by Farana/craneAKBAR ALINo ratings yet

- Jha 006Document8 pagesJha 006Fatin ZawawiNo ratings yet

- RA For TTP FILTER BED OUTLET BACKWASH PENSTOCKS PASSING RECTIFICATIONDocument10 pagesRA For TTP FILTER BED OUTLET BACKWASH PENSTOCKS PASSING RECTIFICATIONAnsari TanveerNo ratings yet

- Equipment/reactor Erection Work JsaDocument3 pagesEquipment/reactor Erection Work JsaAKBAR ALINo ratings yet

- Risk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesDocument8 pagesRisk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesGopinath SekarNo ratings yet

- Shear Wall Jumping Platform R A - 50Document6 pagesShear Wall Jumping Platform R A - 50Saranlal M0% (1)

- Project HS Risk AssessmentDocument6 pagesProject HS Risk AssessmentParas100% (1)

- JSA Master 2021 HIRE MANPOWER REQUIRMENTS FOR SPLP-IIDocument25 pagesJSA Master 2021 HIRE MANPOWER REQUIRMENTS FOR SPLP-IIrishibarathiNo ratings yet

- HIRAC-52-CDP-MEP Tunnel WorkDocument14 pagesHIRAC-52-CDP-MEP Tunnel WorkWidyardi SaputraNo ratings yet

- Mob DemobDocument6 pagesMob DemobMohammad Irfan Kiki IsmailNo ratings yet

- JSA For Scaffolding.Document16 pagesJSA For Scaffolding.jeswinimanualNo ratings yet

- Risk AssessmetDocument24 pagesRisk AssessmetyasNo ratings yet

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- Night Work Risk Assessment1Document1 pageNight Work Risk Assessment1Muhammad ShafiqNo ratings yet

- JSP 42 Use of Power ToolsDocument6 pagesJSP 42 Use of Power ToolsMuhammad AtifNo ratings yet

- JSA For Formwork (Shuttering)Document1 pageJSA For Formwork (Shuttering)HSE fahadNo ratings yet

- Fire Risk Assessment-2Document8 pagesFire Risk Assessment-2Asad RazaNo ratings yet

- Project HS Risk AssessmentDocument8 pagesProject HS Risk AssessmentParasNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- JSA For Suspended CielingDocument4 pagesJSA For Suspended Cielingumar KhitabNo ratings yet

- Project HS Risk AssessmentDocument5 pagesProject HS Risk AssessmentParasNo ratings yet

- Risk Assesment - Utg - CtsiDocument6 pagesRisk Assesment - Utg - CtsiJohn Eric OliverNo ratings yet

- Project HS Risk AssessmentDocument8 pagesProject HS Risk AssessmentParasNo ratings yet

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetDocument4 pagesHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟No ratings yet

- Jsa Welding GrindingDocument5 pagesJsa Welding GrindingWiedz PrastNo ratings yet

- JSA # 3 Column ErectionDocument6 pagesJSA # 3 Column ErectionRaghava Richhu100% (2)

- Hot Work JSA FSDDocument3 pagesHot Work JSA FSDfiazhussaindbxNo ratings yet

- Risk Assessment Erection Steel StructureDocument10 pagesRisk Assessment Erection Steel StructureTubagus DikaNo ratings yet

- JSA Installation of GearboxDocument2 pagesJSA Installation of Gearboxprasong100% (2)

- JSA Installation of GearboxDocument2 pagesJSA Installation of GearboxDaniel TOMBENo ratings yet

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- Optimum Tu2506v ManualDocument132 pagesOptimum Tu2506v Manualga6ba5No ratings yet

- Dr. Ronald B. MaderaDocument3 pagesDr. Ronald B. MaderaSiena KaleiNo ratings yet

- ESTADIOS de CIRROSIS Clinical States of Cirrhosis and Competing RisksDocument14 pagesESTADIOS de CIRROSIS Clinical States of Cirrhosis and Competing RisksAndreé MonjardinNo ratings yet

- Financi Al Instrum Ents: Financial Market: Trends and IssuesDocument41 pagesFinanci Al Instrum Ents: Financial Market: Trends and IssuesEunice Dimple CaliwagNo ratings yet

- Problem Solving Process & TechniquesDocument29 pagesProblem Solving Process & TechniquesAbiram VSNo ratings yet

- Valsova, Denisa - 509466 - Senior Project ThesisDocument69 pagesValsova, Denisa - 509466 - Senior Project ThesisMuhammad Nauman Hafeez KhanNo ratings yet

- Birla Institute of Technology and Science, Pilani K.K. BIRLA Goa CampusDocument6 pagesBirla Institute of Technology and Science, Pilani K.K. BIRLA Goa CampusHritik Vinayak LalNo ratings yet

- Falls Wah Residential Roofing Root Cause Analysis Phase 1Document19 pagesFalls Wah Residential Roofing Root Cause Analysis Phase 1nirashaNo ratings yet

- Biosafety, Biosecurity and Biorisk Management: John Laurence A. Bautista, RMTDocument28 pagesBiosafety, Biosecurity and Biorisk Management: John Laurence A. Bautista, RMTLawrenceNo ratings yet

- EfDocument15 pagesEfshawn mattNo ratings yet

- NDRP Terrorism 2018Document149 pagesNDRP Terrorism 2018Yusuf Al Rasheed SamijonNo ratings yet

- Strategic ManagmentDocument23 pagesStrategic ManagmentKayla SheltonNo ratings yet

- Audit Preparatory ChecklistDocument4 pagesAudit Preparatory Checklist3MIBIZNo ratings yet

- Fin201 Termpaper Group-6 s3Document18 pagesFin201 Termpaper Group-6 s3wasi chaudhuryNo ratings yet

- Coal, Nuclear, Oil, Natural Gas Power Plant Case Study - SolutionDocument7 pagesCoal, Nuclear, Oil, Natural Gas Power Plant Case Study - SolutionKshitishNo ratings yet

- BSBOPS504 Topic 4 V1 1220Document29 pagesBSBOPS504 Topic 4 V1 1220Natti NonglekNo ratings yet

- Goals of Financial ManagementDocument22 pagesGoals of Financial ManagementBhuvanNo ratings yet

- 10 Benefits of Using A RAID Log On Your Next ProjectDocument6 pages10 Benefits of Using A RAID Log On Your Next Project3menhimmNo ratings yet

- Informatica DGIQW2023 Q32023 WPDocument21 pagesInformatica DGIQW2023 Q32023 WPMarco BrittesNo ratings yet

- PMP Test: Download Full PDF Package Translate PDFDocument51 pagesPMP Test: Download Full PDF Package Translate PDFJoaoNo ratings yet

- Bauxite Residue Utilization and The Lack Thereof Craig Klauber, Markus Gräfe, Greg Power ISSOBA 2011Document8 pagesBauxite Residue Utilization and The Lack Thereof Craig Klauber, Markus Gräfe, Greg Power ISSOBA 2011laurentiu_filipescuNo ratings yet

- 2023 Week 1 Risk Mapping Regional Tourism PPT 2023 IntroductionDocument88 pages2023 Week 1 Risk Mapping Regional Tourism PPT 2023 IntroductionAditya ChoudharyNo ratings yet

- Gelatin - Black Particle - Tuppguide2015-1539615522Document11 pagesGelatin - Black Particle - Tuppguide2015-1539615522GaneshNo ratings yet

- Final Name Muhammad Abdul QadirDocument5 pagesFinal Name Muhammad Abdul Qadirkhadija aroojNo ratings yet

- Question Paper & Key of First Class Unrestricted Under MMR - Mine Management Legislation and General SafetyDocument23 pagesQuestion Paper & Key of First Class Unrestricted Under MMR - Mine Management Legislation and General SafetyRammesh100% (1)

- Evaluating The Condition & Remaining Life of Older Power PlantsDocument7 pagesEvaluating The Condition & Remaining Life of Older Power PlantsAlif Nur FirdausNo ratings yet

- Emergency Capacity Building Project: Safety, Security & Civil / Military RelationsDocument36 pagesEmergency Capacity Building Project: Safety, Security & Civil / Military Relationseliasox123No ratings yet

- Liabilities Liability: Measurement Initial SubsequentDocument4 pagesLiabilities Liability: Measurement Initial SubsequentAmie SosmeñaNo ratings yet

- Public Private Partnership in Public Administration Discipline A Literature ReviewDocument25 pagesPublic Private Partnership in Public Administration Discipline A Literature ReviewJuan GalarzaNo ratings yet

- Probability Based Load Criteria For Structural Design PDFDocument6 pagesProbability Based Load Criteria For Structural Design PDFJessica CastriciniNo ratings yet