Professional Documents

Culture Documents

6gr Smaw WQTR - F. Edilo (Sn-189)

Uploaded by

hanz bermejoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6gr Smaw WQTR - F. Edilo (Sn-189)

Uploaded by

hanz bermejoCopyright:

Available Formats

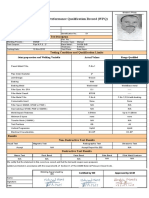

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

AWS QC7-93 ----

Welder’s Name FILOMENO C. EDILO ATF No. 120101 Test No. Supplement G

Welder’s SS No. SN-189 Date July 28, 2023 Reference WPS No: OSFI - SMAW - 008

VARIABLE QUALIFICATION TEST DETAIL QUALIFICATION RANGE*

Code or Specification Used: AWS D1.1 (2020)

Welding Process and Type:

Manual Semiautomatic Manual Semiautomatic

SMAW ( MANUAL ) Mechanized Automatic Mechanized Automatic

Backing: None Used Not Used Required if usedBacking

With or Without

Base Metal

Base Metal Spec/P or Mor -M -Number

Spec/P Number A106 Gr. B (AWS Group 1 Steel of Table 5.3) Any AWS Group 1 & 2 Steels

Plate / Plate

Pipe / Thickness – –Groove

Pipe Thickness Groove Plate Pipe Thick. 11 / 14.27 mm. 5 mm. to Unlimited

Plate Plate

/ Pipe/ Pipe

Thickness – –Fillet

Thickness Fillet Plate Pipe Thick. NA Unlimited

Pipe/Tubular

Pipe/Tubular OutsideOutside

Diameter – –Groove

Diameter Groove 6" OD Schedules 80 and 120 100 mm. (4") OD to Unlimited

Pipe/Tubular

Pipe/Tubular Outside Diameter

Outside – –Fillet

Diameter Fillet NA NA

FillerMetal

Filler Metal Specification

SpecificationNo.

No. A 5.1 A 5.1

Classification

Classification No.

No. E7018 E7018

FF No.

No. F4 F4

Diameter

Diameter 2.5, 3.2 mm. As to WPS

Consumable

Consumable Insert

Insert Yes No Only Without Insert

Penetration

PenetrationEnhancing Flux

Enhancing Flux Yes No NA

Deposited

Stringer Weld Metal

or Weave Bead Thickness Stringer or Weave Both

Current/Polarity

Current & Current Range

Type/Polarity Type/Polarity: DCEP [Reverse] for E7018. Only DCEP [Reverse] for E7018.

Range: Amperes

MetalTransfer

Metal Transfer Mode

Mode (GMAW

(GMAW or FCAW)

or FCAW) NA NA

TorchShielding

Torch ShieldingGas

Gas Type: NA Flow: NA

RootShielding

Root ShieldingGas

Gas NA Type: Flow: NA

Position(s) Test Position(s) (1G, 2G, etc.): Qualified Position(s) (F, H, V, O, or All)

Position(s)

6GR ALL, except CJP of T-Y-K connections (box tube).

VerticalProgression

Vertical Progression Uphill Downhill Uphill Downhill

*NOTE: Insert NA for Variables that are identified as Non-essential in the Code or Specification used for the Performance Qualification Test

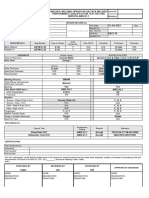

MECHANICAL TEST RESULTS

Type And Figure No. Results Type And Figure No. Results

Side Bend Specimen, SB-185 No open defect was observed. Side Bend Specimen, SB-187 No open defect was observed.

Side Bend Specimen, SB-186 No open defect was observed. Side Bend Specimen, SB-188 No open defect was observed.

REPORT NO.: BT-23-07/SB-06

GuidedMechanical

Guided mechanicalTesting Conducted

Testing Conducted By:

By: G. SHERRY Figure's. 6.9, 10.23, Clauses 6.10.3.1, 6.10.3.3 Date: July 28, 2023 Angle of Bend: 180 Degrees

NONDESTRUCTIVE EXAMINATION RESULTS

RadiographicResults

Radiographic Results:

: Report No. :

RadiographicTesting

Radiographic TestingConducted

ConductedBy:By:

WeldingWitnessed

Welding Witnessed By: Nevoe M. Bermejo

By: Haron Visual Inspection: Pass Fail (reason)

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with

the requirements of: AWSAWSD1.1 D1.1 - AWS B2.1 -

(2020 ed.) Other:

Date Qualified: July 28, 2023 ATF Name and Number: SUBNET SERVICES LTD. ATF No.: 120101

Signed By: HARON NEVOE M. BERMEJO CWI No. : 09051491

ATF WPQR Blank Form 2010-04-15 Rev. 1

ATF WPQR Blank Form 2010-04-15

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- WQT Form (AWS D1.1) 04-23Document1 pageWQT Form (AWS D1.1) 04-23hanz bermejoNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- WPQRDocument1 pageWPQRJBStringerNo ratings yet

- Computer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- WPQR SampleDocument1 pageWPQR SampleccbmitNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Hfy2 E1890 CPF1WT WLD SPC 0008Document3 pagesHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- NYX Ndustries ZC: Welder Performance Qualification RecordDocument1 pageNYX Ndustries ZC: Welder Performance Qualification RecordanoopkumarNo ratings yet

- Quy trình hàn vết nứt vành lò dùng que KNCF3 PDFDocument3 pagesQuy trình hàn vết nứt vành lò dùng que KNCF3 PDFDương Quang KhánhNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Wps Pqrwelding SCSP COUPON Phpapp02Document14 pagesWps Pqrwelding SCSP COUPON Phpapp02Oladimeji TaiwoNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- PWPS DonpyDocument1 pagePWPS DonpyANDINTA MUDA YUSUFNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Welders CertDocument11 pagesWelders CertAhmed GomaaNo ratings yet

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsDocument9 pagesWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamed100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pages(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023No ratings yet

- Asme WPS Demo 1Document3 pagesAsme WPS Demo 1venkateshNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- 3g Tar WPQTR Form Aws d1.1Document2 pages3g Tar WPQTR Form Aws d1.1Scott AdkinsNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Wps PQR A3620 PDFDocument5 pagesWps PQR A3620 PDFHamid MansouriNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (1)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Alumana Welder IDDocument7 pagesAlumana Welder IDZuberYousufNo ratings yet

- PQR 11 Noram GTDocument6 pagesPQR 11 Noram GTross anthonyNo ratings yet

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- WPQ 006Document1 pageWPQ 006vinuNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Welder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)Document3 pagesWelder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)SANUNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Welding Procedure Specification: Backing MaterialDocument2 pagesWelding Procedure Specification: Backing MaterialDiki ArmandoNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- C. 6GR Test Schedule (Mar. 13, 2023)Document1 pageC. 6GR Test Schedule (Mar. 13, 2023)hanz bermejoNo ratings yet

- AWS Maintenance-of-Welder-Certification-Form (01-2023)Document1 pageAWS Maintenance-of-Welder-Certification-Form (01-2023)hanz bermejoNo ratings yet

- AWS Certified-Welder-Application (01-2023)Document2 pagesAWS Certified-Welder-Application (01-2023)hanz bermejoNo ratings yet

- Tutorial How To Change The Sleep Settings On Your Acer Laptop ScreenshotsDocument3 pagesTutorial How To Change The Sleep Settings On Your Acer Laptop Screenshotshanz bermejoNo ratings yet

- Building Technology SbaDocument11 pagesBuilding Technology Sbatashoy clarkeNo ratings yet

- Testing Welders For Fusion Welding: Approval ofDocument26 pagesTesting Welders For Fusion Welding: Approval ofValter RamosNo ratings yet

- Welding SymbolsDocument60 pagesWelding Symbolsmitrasah50% (2)

- Bill of Material of Aeration Tank Phase III Air PipingDocument2 pagesBill of Material of Aeration Tank Phase III Air PipingPravin BoteNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Códigos de SoldagemDocument12 pagesCódigos de Soldagemvladimirsoler01No ratings yet

- GSI SLV Duisburg - International Welding Engineer-2015Document2,485 pagesGSI SLV Duisburg - International Welding Engineer-2015yutwelding83% (12)

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- H28 3Document31 pagesH28 3jwsiglerNo ratings yet

- Api 577Document6 pagesApi 577Mohammed YoussefNo ratings yet

- VM Vertical Inline Pump Parts ListDocument4 pagesVM Vertical Inline Pump Parts ListFiqri Permana MohamadNo ratings yet

- Standard Weld JointDocument3 pagesStandard Weld Jointtalparadipak100% (1)

- 20 MM Cement Plaster in Single Coat On Rough Side (1:4) (1 Cement: 4 Sand)Document2 pages20 MM Cement Plaster in Single Coat On Rough Side (1:4) (1 Cement: 4 Sand)Aman ThakurNo ratings yet

- Como Soldar 4140Document4 pagesComo Soldar 4140Luis Jose DuranNo ratings yet

- API 577 QuestionsDocument14 pagesAPI 577 QuestionsabdoNo ratings yet

- Hyundai Pricelist 2014Document1,438 pagesHyundai Pricelist 2014andrew candraNo ratings yet

- D1 3scopeDocument4 pagesD1 3scopeayub82No ratings yet

- Avit 2007 6.7 Afsa AfskDocument1 pageAvit 2007 6.7 Afsa AfskMohamed ElmakkyNo ratings yet

- Cross Sectional Assembly Drawing With Part ListDocument33 pagesCross Sectional Assembly Drawing With Part Listhuynhthanhtamga1981No ratings yet

- Karakteristik Kawat LasDocument36 pagesKarakteristik Kawat LasKen RanggaNo ratings yet

- Itp For Staircase HandrailDocument3 pagesItp For Staircase HandrailKishoreNo ratings yet

- Disassembly of Roberts RD50, and Similar Radio'sDocument6 pagesDisassembly of Roberts RD50, and Similar Radio'sAnthony RhodesNo ratings yet

- Blended Hydraulic Cements: Standard Specification ForDocument8 pagesBlended Hydraulic Cements: Standard Specification ForMartha Carolina Gomez Martinez100% (1)

- Wi sb4 16Document2 pagesWi sb4 16Ramdan Pramedis SetyaNo ratings yet

- Shielded Metal Arc Welding 2Document8 pagesShielded Metal Arc Welding 2Cold EnzethNo ratings yet

- Trainees Record Book (TRB)Document4 pagesTrainees Record Book (TRB)Edward LyleNo ratings yet

- Torque CalculatorDocument2 pagesTorque CalculatorDanhHoNo ratings yet

- Bolt Capacity HT Bolt & Anchor BoltDocument9 pagesBolt Capacity HT Bolt & Anchor BoltMadhava PadiyarNo ratings yet

- Welding Discontinuities: Porosity Undercut Incomplete FusionDocument1 pageWelding Discontinuities: Porosity Undercut Incomplete Fusionbrrrrzzzz100% (1)