Professional Documents

Culture Documents

Noi-Dc1-2f-L3-Br 2-Csu-2

Uploaded by

danishsaifi2007Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Noi-Dc1-2f-L3-Br 2-Csu-2

Uploaded by

danishsaifi2007Copyright:

Available Formats

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

COMMISSIONING METHOD STATEMENT

LEVEL 3

ST TELEMEDIA DATA CENTER, NOIDA

LEVEL 3

AHU STARTUP TEST

Page 1 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

CONTENTS

1. INTRODUCTION.......................................................................................................4

2. EQUIPMENT DETAILS.............................................................................................5

3. ON-SITE TEST...........................................................................................................5

4. TESTING & COMMISSIONING EQUIPMENT.........................................................6

5. SAFETY..................................................................................................................... 7

6. PRE-TEST CONDITION............................................................................................7

7. LEVEL 3 START UP TEST: -.....................................................................................8

7.1 GENERAL................................................................................................................8

7.2 AHU START-UP CHECKS.......................................................................................8

8. AHU STARTUP TEST RECORD...............................................................................9

8.1 AHU FUNCTIONAL VERIFICATION WITH BYPASS STARTER.........................9

8.2 AHU FUNCTIONAL VERIFICATION WITH VFD................................................10

8.2.1 VFD @ 50 HZ.......................................................................................................10

8.3 AHU PARAMETER VERIFICATION....................................................................12

8.4 AIR FLOW MEASUREMENT................................................................................13

8.5 AIR BALANCING.................................................................................................. 14

8.6 BMS - POINT VERIFICATION WITH BMS..........................................................16

9. LIST OF DOCUMENTATION TO BE SUBMITTED...............................................19

1. INTRODUCTION

ST Telemedia is in the process of building a new data centre at Noida sector 143. CBRE ICS has

been appointed by STT for providing 3 rd party testing & commissioning services for the project.

This document covers the commissioning requirement and acceptance criteria for the works

covered under the AHU System.

Page 2 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

2. EQUIPMENT DETAILS

General

Unit Make: ZECO

Model Number: ZDCSBD-30

Serial No: 212541-08-01

Manufacturer Source: ZECO

Equipment Label: NOI-DC1-2F-TR10-CSU-1

Design Information

AHU Type: CSAHU-02

AHU Capacity: 2750 CFM

Motor RPM: 1430 RPM

Motor Power: 1.5KW

Rated Voltage: 415 V

Rated Current: 3.47 AMP

dB Level: 72 dBA @ 1 meter

3. ON-SITE TEST

The following tests shall be performed and witnessed for AHU.

Sr. Test SAT Remarks

No. Description

1 Pre-Test Condition

2 Electrical parameter verification

3 Air side parameter verification

4 Chilled Water Flow Verification

5 Parameter verification with BMS

6 Alarm Interfacing with BMS

7 Sound and Vibration Check

4. TESTING & COMMISSIONING EQUIPMENT

Page 3 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

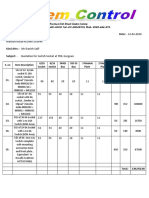

Calibration Date

Equipment Name Serial No.

Model

Issue Expiry

Digital clamp meter CM-2030AC 1310308 04-04-2023 03-04-2024

Tachometer DT-2234C L163216 04-04-2023 03-04-2024

Rotating Vane Anemometer AM-4201 T018682 04-04-2023 03-04-2024

Water flow meter (Ultrasonic) TUF-2000H D12345 04-04-2023 03-04-2024

Sling Psychrometer NA NA 04-04-2023 03-04-2024

dB meter HTC N1041319 04-04-2023 03-04-2024

Vibration meter VB-8205 N978180 04-04-2023 03-04-2024

Calibration requirement: - All equipment’s testing and commissioning shall be performed

with valid calibration certificates. All calibration certificates shall be submitted for CxA review

at least one week prior to each T&C activity being undertaken.

5. SAFETY

The following safety points must be taken care of while performing site acceptance test for AHU.

GC/Vendor should ensure to provide the Safety helmets and shoes for

individual protection while standing in the perimeter of AHU in

operation.

Areas of high risk must be properly secured.

The Site should have First Aid workers. In case of emergency, quick

medical assistance must be provided.

Before the Testing commences, the host must explain to all

individuals about the evacuation procedure in case of a fire or any

other incident.

Proper illumination and a dust-free environment should be provided

to carry out the test.

Lock-Out Tagout shall be provided for the charged equipment’s.

Page 4 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

6. PRE-TEST CONDITION

The following criteria shall be satisfied before the Testing & Commissioning can commence:

Inspection Status Remarks

Level 2 checks completed, and results found satisfactory Yes No N/A

Confirm all major snags highlighted during Level 2

Yes No N/A

testing are rectified

Confirm Level 2 completion tag (Yellow Tag) available

Yes No N/A

on AHU.

Confirm all necessary testing & commission equipment’s

are available on site During startup test. Ensure all T&C Yes No N/A

equipment’s are calibrated.

Confirm space is in good condition and fit for

Yes No N/A

commissioning to commence.

Clean and clear off any debris within the starter

Yes No N/A

compartment.

Confirm all AHU material is removed for the unit and

Yes No N/A

that air inlets and discharges are free from obstruction.

Check power supply available at the incoming of AHU

and verify the Yes No N/A

Voltage and Phase sequence.

7. LEVEL 3 START UP TEST: -

7.1 General

Page 5 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

Undertake all necessary checks and complete the Testing & Commissioning Record as per this

method statement.

Start Fan as per OEM's Recommendation.

7.2 AHU Start-Up Checks

Test the AHU by using the AHU by-pass starter, Star Delta or DOL starter. On

activating the motor starter at initial start.

The direction and speed of rotation of the motor shaft are correct.

The VCD full open condition.

The motor, blower, and drive are free from vibration and undue noise.

The sequence timing adjustment of star-delta starters (≥10s), auto-transformer

starters (≥15s), etc. is set in line of motor starting current.

The motor running current on all phases are balanced and do not exceed motor

nameplate rating. The discharge valve can be opened slowly and monitoring

the AHU running current is not over of the motor full load current.

Record the AHU running current, voltage, suction/ discharge.

There is no overheating of the motor.

There is no seepage of the lubricant from the housing.

The motor running current are matching with the speed as specified by manufacturer.

After tested the AHU by-pass starter, test the AHU with VFD control.

The VFD setting and all functional should be checked and tested with T&C

consultant during the SAT of MCC panel. The VFD shall be set at maximum

of 50 Hz while testing.

Run the AHU with at maximum 50Hz, record the AHU running current,

voltage, input power factor, input harmonic at different running frequency.

Check the motor, AHU and drive are free from vibration and undue noise.

8. AHU STARTUP TEST RECORD

8.1 AHU Functional Verification with bypass starter

Description Units Expected Act Result Remar

ual ks

Volumetric Flow Rate CFM 2750 3285 Pass Fail

Page 6 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

L1-L2 415 401 Pass Fail

(V)

Voltage

L1-L3 415 401 Pass Fail

(V)

L2-L3 415 401 Pass Fail

(V)

(Avg) 415 401 Pass Fail

(V)

L1 (A) 3.47 2.1 Pass Fail

At Design / Max Current L2 (A) 3.47 2.2 Pass Fail

running current of

motor L3 (A) 3.57 2.1 Pass Fail

(Avg) (I) 3.47 2.16 Pass Fail

Supply AIR (CFM) 2750 3197 Pass Fail

Return AIR (CFM) 2750 3285 Pass Fail

Control Panel: -

Description Pass / Fail

Power Healthy indication Lamps (L1/L2/L3) PASS FAIL N/A

Check Running Indication Lamps PASS FAIL N/A

Check Fault Indication Lamps PASS FAIL N/A

Check Motor Start push button PASS FAIL N/A

Check Motor Stop push button PASS FAIL N/A

Check Lamp Test push button PASS FAIL N/A

Check Auto / Off / Manual Switch operation PASS FAIL N/A

Check VFD / Bypass Switch operation PASS FAIL N/A

Fire integration PASS FAIL N/A

8.2 AHU Functional Verification with VFD

8.2.1 VFD @ 50 Hz

Description Units Expected Actual

Page 7 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

Volumetric Flow Rate CFM 2750 3159

L1-L2 415 390

(V)

Voltage

L1-L3 415 390

(V)

L2-L3 415 390

(V)

(Avg) (V) 415 390

L1 (A) 3.47 2.2

At Design / Max running Current L2 (A) 3.47 1.8

current of motor

L3 (A) 3.47 2.2

(Avg) (I) 3.47 2.06

Supply AIR (CFM) 2750 2893

Return AIR (CFM) 2750 3159

VFD

Description Record

Motor kW Setting YES NO NA

Full Load current Setting YES NO NA

Motor Voltage Setting YES NO NA

Maximum Operating frequency setting YES NO NA

Minimum Operating frequency setting YES NO NA

Ramp up Time setting YES NO NA

Ramp down Time setting YES NO NA

VFD Display and control button is normal operation YES NO NA

VFD Ventilation operating in normal condition YES NO NA

Fire integration YES NO NA

VFD modulation on Differential pressure YES NO NA

Page 8 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

8.3 AHU parameter Verification

Parameters Unit Design Data Test Result Remarks

Total Air Quantity CFM 2750 CFM 3159 CFM

Fresh Air Quantity CFM NA NA

Parameters (Air side)

Fan Static Pressure Drop

mm WC 45 35

(Discharge - Inlet)

Entering Air Dry Bulb Temp °C NA 23.5

Entering Air Wet Bulb °C

NA 17

Temp

Leaving Air Dry Bulb Temp °C NA 20.5

Leaving Air Wet Bulb Temp °C NA 16.5

Settings

Overload Setting A 80% 2.8 A

Tripping Time of Overload Sec NA NA

Rated Power kW 1.5 KW .55 KW

Emergency Stop NA NA NA

Filter

Type

Effective Area sq.ft NA 6.22

Velocity FPM NA

Cooling Coil

Inlet Water Temperature °C 19 19.0

Outlet Water Temperature °C 24 23.5

Inlet Water Pressure kg/cm2 NA 6.8

Outlet Water Pressure kg/cm2 NA 6.3

Chilled water flow M3/hr or GPM 10.94 11.5 (As per PICV settings)

Noise & Vibration

Noise Level dB 72 @ 1 57 dBA

Page 9 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

Parameters Unit Design Data Test Result Remarks

Meter

Vibration level mm/s 1.8 mm/s 1.31,0.69,0.88

VFD Modulation (Ramp

NA NA

up/down)

Filter Clog Status YES YES

Fan Running Status YES YES

Fire Tripping YES YES

Limit switch status NA NA

Inspection light status NA NA

UV light status NA NA

8.4 Air Flow Measurement

AHU TAG No NOI-DC1-L2-BR 2-CSU-2 Capacity: 2750 CFM

AHU Model No: ZDCSBD-30 AHU Location BATTERY ROOM

Air Flow Measurement at Return filters (ft/min)

VFD Speed: 50 Hz

517 482 505 535

525 529

510 495 485 497

Air Side

Calculations

508 FPM Voltage (V) Current (A)

Average

velocity : PF

6.22 sq.ft V VYB VBR IR IY IB

Filter Area : R

Y

Air-flow at 3159 cfm 390 390 390 2.2 1.8 2.2

Return(cfm) :

Page 10 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

Air-flow at

Power

Supply(CFM 2893 CFM 1.176 kW

consumption =

):

Design

2750 CFM % of deviation 5.2 %

Airflow

Result PASS FAIL

8.5 Air Balancing

Grill/

Sr. Velocity - Actual Flow Design Flow -

Diffuser – Area Deviation % Result

No. FPM - CFM CFM

Size

1 1180x280 3.55 815 2893 2750 5.2 %

Page 11 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

8.6 BMS - Point Verification with BMS

Sr.

I/O Parameters At Field At BMS

No Result Remarks

Status Value Status Value

1 Fan “ON” Command Yes No N/A Yes No N/A Pass Fail

2 Fan “OFF” Command Yes No N/A Yes No N/A Pass Fail

3 Fan Run Status Yes No N/A Yes No N/A Pass Fail

4 Fan Trip status Yes No N/A Yes No N/A Pass Fail

5 Fan “Auto” status Yes No N/A Yes No N/A Pass Fail

6 Fan “Manual” status Yes No N/A Yes No N/A Pass Fail

7 Filter Clean/Clog Status Yes No N/A Yes No N/A Pass Fail

Supply Air Temperature Pass Fail

8 Monitoring Yes No N/A Yes No N/A

Return Air Temperature Pass Fail

9 Monitoring Yes No N/A Yes No N/A

Chilled Water Control Valve Pass Fail

10 Modulation Command Yes No N/A Yes No N/A

Chilled Water Control Valve Pass Fail

11 Feedback Yes No N/A Yes No N/A

Page 12 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

Sr.

I/O Parameters At Field At BMS

No Result Remarks

Status Value Status Value

12 CHW Inlet Temp. Monitoring Yes No N/A Yes No N/A Pass Fail

CHW Outlet Temp. Pass Fail

13 Monitoring Yes No N/A Yes No N/A

14 Return Air RH Monitoring Yes No N/A Yes No N/A Pass Fail

15 Filter Clean/ Clog Status Yes No N/A Yes No N/A Pass Fail

16 VFD Local/ Remote Status Yes No N/A Yes No N/A Pass Fail

17 VFD Fault Status Yes No N/A Yes No N/A Pass Fail

18 VFD Frequency Monitoring Yes No N/A Yes No N/A Pass Fail

VFD Motor Current Pass Fail

19 Monitoring Yes No N/A Yes No N/A

VFD Motor Voltage Pass Fail

20 Monitoring Yes No N/A Yes No N/A

VFD Power Consumption Pass Fail

21 Monitoring Yes No N/A Yes No N/A

22 VFD cumulative run hours Yes No N/A Yes No N/A Pass Fail

23 VFD Cumulative KWh Yes No N/A Yes No N/A Pass Fail

Page 13 of 14 Independent Commissioning Services

COMMISSIONING METHOD STATEMENT LEVEL -3

NOIDA – SECTOR 143

OBSERVATIONS IF ANY:

9. LIST OF DOCUMENTATION TO BE SUBMITTED

LIST OF DOCUMENTS

Verify that the following documentation has been received and stored with the project

documentation

Measuring Instruments Calibration Certificate Yes No N/A

GFC Drawing Yes No N/A

GA Drawing Yes No N/A

BOM Yes No N/A

FAT Report Yes No N/A

Level 2 Report Yes No N/A

Approved I/O Summary Yes No N/A

Technical Submittals Yes No N/A

Control Drawing Yes No N/A

Comments: if Any: -

Approval Signatures

This Level 3 Startup Test script is submitted for approval.

Vendor Bluestar Ltd Name Virendra P Signature Date 03/06/2023

CBRE

CBRE SAPL Name M Sartaj Signature Date 03/06/2023

PMC

CBRE CBRE SAPL - Name Husain A. Signature Date 03/06/2023

ICS ICS

STT STT GDC Name Rahul S. Signature Date 03/06/2023

Page 14 of 14 Independent Commissioning Services

You might also like

- Noi-Dc1-2f-L3-Br 1-Csu-2Document14 pagesNoi-Dc1-2f-L3-Br 1-Csu-2danishsaifi2007No ratings yet

- Pre-Commissioning Tests for SwitchgearDocument16 pagesPre-Commissioning Tests for SwitchgearVijaya KumarNo ratings yet

- Site Acceptance Test for Fire & Gas Detection PanelDocument17 pagesSite Acceptance Test for Fire & Gas Detection Panelluis HernandezNo ratings yet

- 00-SATP-busway, Rev01Document9 pages00-SATP-busway, Rev01islam mohamedNo ratings yet

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- J1525-HW2-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW2-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Checklist Testing and Inspection With Interconnection-Version 1 0 August 2015Document32 pagesChecklist Testing and Inspection With Interconnection-Version 1 0 August 2015Sunil SinghNo ratings yet

- J1525-NT8-010 SAT Procedure - Rev ADocument15 pagesJ1525-NT8-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- J1525-HW3-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW3-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingDocument9 pagesSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamNo ratings yet

- PRE Commissioning Procedures TR Rev01 PGCILDocument52 pagesPRE Commissioning Procedures TR Rev01 PGCILkrishnamanikandan100% (3)

- Ultrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Document26 pagesUltrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Taufik SantosoNo ratings yet

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDocument38 pagesD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- Saudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 ElectDocument3 pagesSaudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 Electkarthi51289No ratings yet

- Pressure ProcedureDocument4 pagesPressure ProcedureCitco IdfcNo ratings yet

- Pre Commissioning Procedures and Formats For Switchyard EquipmentsDocument218 pagesPre Commissioning Procedures and Formats For Switchyard EquipmentsSushant86% (7)

- CB Testing and Commissioning 76-92Document17 pagesCB Testing and Commissioning 76-92Vijaya KumarNo ratings yet

- Pre-Commissioning Tests for Circuit BreakersDocument17 pagesPre-Commissioning Tests for Circuit BreakersVijaya Kumar100% (2)

- MOTOR PROTECTION RELAYdocxDocument7 pagesMOTOR PROTECTION RELAYdocxPandrayar Maruthu100% (3)

- Ocef Relay TestingDocument6 pagesOcef Relay TestingPandrayar MaruthuNo ratings yet

- Ultrasonic Phased Array Inspection for Pipe WeldsDocument25 pagesUltrasonic Phased Array Inspection for Pipe WeldsphanthanhhungNo ratings yet

- Paut Procedure - Asme 31.3 Process PipingDocument26 pagesPaut Procedure - Asme 31.3 Process PipingKarthikeyan Ganesan100% (3)

- CSU Vibration Acceptance Criteria ProcedureDocument9 pagesCSU Vibration Acceptance Criteria ProcedureDaniel Erasmo Avellaneda Sanchez100% (1)

- Idle TestDocument5 pagesIdle TestKshitiz RastogiNo ratings yet

- Testing Procedures Inspection TestsDocument45 pagesTesting Procedures Inspection TestspaolaNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportSino hydroNo ratings yet

- LV Controller Calibration Test ResultsDocument3 pagesLV Controller Calibration Test ResultsMa.socorro SaballaNo ratings yet

- Saudi Aramco LV Panelboard TestingDocument4 pagesSaudi Aramco LV Panelboard TestingheikelNo ratings yet

- Saudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstDocument16 pagesSaudi Aramco Test Report: Fire Alarm System - Control Panel - Pre-Commissioning Test SATR-B-6101 24-Jul-18 InstnadeemNo ratings yet

- 1744 - UT PROCEDURE (For Final) PDFDocument27 pages1744 - UT PROCEDURE (For Final) PDFpvdang8453100% (1)

- Saudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Document6 pagesSaudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Ma.socorro SaballaNo ratings yet

- Ultrasonic ProcedureDocument12 pagesUltrasonic ProceduremnmsingamNo ratings yet

- Shop Maintenance Guide Screw Conveyor Auger Inspection Service Test ReleaseDocument3 pagesShop Maintenance Guide Screw Conveyor Auger Inspection Service Test ReleaseIdowu MayowaNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- TB-2100 Operational and Maintenance Manual Rev C OptimiseDocument224 pagesTB-2100 Operational and Maintenance Manual Rev C OptimisearnaudmarielNo ratings yet

- Aries Netlink™ Configuration Tool (ACT8000) : User's GuideDocument178 pagesAries Netlink™ Configuration Tool (ACT8000) : User's GuideGilberto GuerreroNo ratings yet

- Dole-Oshc Tower Crane Inspection ReportDocument6 pagesDole-Oshc Tower Crane Inspection ReportDaryl HernandezNo ratings yet

- PAUT Procedure EEISDocument13 pagesPAUT Procedure EEISZakirUllahNo ratings yet

- Ultrasonic Testing ProcedureDocument17 pagesUltrasonic Testing ProcedureTg TarroNo ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- SML 1000D Commissioning & Service ManualDocument34 pagesSML 1000D Commissioning & Service Manualmarine ShanghaiNo ratings yet

- Method of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorDocument9 pagesMethod of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorPandrayar MaruthuNo ratings yet

- Ut Procedure OnsDocument10 pagesUt Procedure OnsPARTHNo ratings yet

- Saudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116zhangNo ratings yet

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289No ratings yet

- Quy Trinh T&C BMS Cho MVAC - Tham KhaoDocument79 pagesQuy Trinh T&C BMS Cho MVAC - Tham Khaovin ssNo ratings yet

- Saudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand TestingDocument10 pagesSaudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand Testingkarthi51289No ratings yet

- Checklist for BNWAS RequirementsDocument4 pagesChecklist for BNWAS RequirementsNgoHaiNo ratings yet

- Pre Commissioning Procedures TR Rev01 Pgcil PDFDocument52 pagesPre Commissioning Procedures TR Rev01 Pgcil PDFChandraNo ratings yet

- Calibration ProcedureDocument5 pagesCalibration ProcedureManu SharmaNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportMa.socorro SaballaNo ratings yet

- Generator Commissioning ChecklistDocument11 pagesGenerator Commissioning ChecklistzainahmedscribdNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection & Verification of MPT Equipment & Materials SAIC-MPT-2003 3-Jul-18 NdeDocument6 pagesSaudi Aramco Inspection Checklist: Inspection & Verification of MPT Equipment & Materials SAIC-MPT-2003 3-Jul-18 Ndekarthi51289No ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289No ratings yet

- Construction Leak Test ProcedureDocument6 pagesConstruction Leak Test Procedurezack zeeartNo ratings yet

- UT Procedure Rev.8Document15 pagesUT Procedure Rev.8kalaiselvanNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Signed Inventory of Electrical Wok at Admin. BuildingDocument6 pagesSigned Inventory of Electrical Wok at Admin. Buildingdanishsaifi2007No ratings yet

- Summary 3Document1 pageSummary 3danishsaifi2007No ratings yet

- Read MeDocument49 pagesRead MePriyawan SukisnoNo ratings yet

- Pending Work at Minto PressDocument1 pagePending Work at Minto Pressdanishsaifi2007No ratings yet

- Read MeDocument49 pagesRead MePriyawan SukisnoNo ratings yet

- Electrical System Supply Delivery ChallanDocument1 pageElectrical System Supply Delivery Challandanishsaifi2007No ratings yet

- Vol-Abc-El-607 Schematic Diagram For Power Panel Distribution - Phe and Elevator Tower-Abc-Abc-El-607Document1 pageVol-Abc-El-607 Schematic Diagram For Power Panel Distribution - Phe and Elevator Tower-Abc-Abc-El-607danishsaifi2007No ratings yet

- Coordination With Other DepartmentDocument3 pagesCoordination With Other Departmentdanishsaifi2007No ratings yet

- Arna Engineering Bill Final BillDocument2 pagesArna Engineering Bill Final Billdanishsaifi2007No ratings yet

- Electrical Rising MainDocument5 pagesElectrical Rising Maindanishsaifi2007No ratings yet

- PipingDocument3 pagesPipingdanishsaifi2007No ratings yet

- Electrical System Supply Delivery ChallanDocument1 pageElectrical System Supply Delivery Challandanishsaifi2007No ratings yet

- ME2J 87007 (3) (AutoRecovered)Document232 pagesME2J 87007 (3) (AutoRecovered)danishsaifi2007No ratings yet

- TRIL SwitchDocument2 pagesTRIL Switchdanishsaifi2007No ratings yet

- Smart Brains Institute of Engineering Design & Research: Cabling SystemDocument11 pagesSmart Brains Institute of Engineering Design & Research: Cabling SystemAshwin SevariaNo ratings yet

- Resignation LatterDocument1 pageResignation Latterdanishsaifi2007No ratings yet

- Etap Course ConteinDocument1 pageEtap Course Conteindanishsaifi2007No ratings yet

- Basics of Structural Engineering Analysis & Design of Structures Steel Frame ConnectionDocument1 pageBasics of Structural Engineering Analysis & Design of Structures Steel Frame Connectiondanishsaifi2007No ratings yet

- Command On ExcelDocument3 pagesCommand On Exceldanishsaifi2007No ratings yet

- Calculate PVC Trunking Size for Power CablesDocument2 pagesCalculate PVC Trunking Size for Power Cablesdanishsaifi2007100% (1)

- Earthing Control Room Ams Cal 29 SeptDocument6 pagesEarthing Control Room Ams Cal 29 Septdanishsaifi2007No ratings yet

- Resignation LatterDocument1 pageResignation Latterdanishsaifi2007No ratings yet

- PdlicelllDocument1 pagePdlicellljhonmatinxNo ratings yet

- Equipment ListDocument14 pagesEquipment Listdanishsaifi2007No ratings yet

- AnsysDocument7 pagesAnsysdvarsastryNo ratings yet

- Interrio DesignerDocument2 pagesInterrio Designerdanishsaifi2007No ratings yet

- Hazardous Area ClassficationDocument22 pagesHazardous Area Classficationdanishsaifi2007No ratings yet

- New Text DocumentDocument1 pageNew Text Documentdanishsaifi2007No ratings yet

- SP18368 Automotive Radar Comparison 2018 Sample 2Document33 pagesSP18368 Automotive Radar Comparison 2018 Sample 2Chipisgood YuNo ratings yet

- Usg Iom PDFDocument56 pagesUsg Iom PDFAnonymous 7xHNgoKE6eNo ratings yet

- BA Anchor Data SheetDocument17 pagesBA Anchor Data SheetbrodieNo ratings yet

- SG PB Imds1350Document103 pagesSG PB Imds1350zky0108No ratings yet

- Hospitality Case StudiesDocument26 pagesHospitality Case StudiesKarthik PalaniswamyNo ratings yet

- Performance Analysis of Cooling TowerDocument7 pagesPerformance Analysis of Cooling TowerIbrahim Al-MutazNo ratings yet

- Scania Rear View Mirror Removal and InstallationDocument8 pagesScania Rear View Mirror Removal and InstallationRuanNo ratings yet

- Hydrocarbon ReactionsDocument2 pagesHydrocarbon ReactionsJessa Libo-onNo ratings yet

- Heidegger and RhetoricDocument202 pagesHeidegger and RhetoricMagda AliNo ratings yet

- Shell Marine Pocketbook For International MarineDocument60 pagesShell Marine Pocketbook For International MarineGage Cendk HNo ratings yet

- Kant ParadigmDocument265 pagesKant ParadigmkairospandemosNo ratings yet

- 5 Commandments of DatingDocument8 pages5 Commandments of DatingBariki MwasagaNo ratings yet

- Interview Questions - Godrej Technical & HR Interview QuestionsDocument9 pagesInterview Questions - Godrej Technical & HR Interview Questionssasithar jaisankaranNo ratings yet

- GynecologyDocument24 pagesGynecologylovelots1234No ratings yet

- Gardening Tool Identification QuizDocument3 pagesGardening Tool Identification Quizcaballes.melchor86No ratings yet

- Replacing The Volvo Oil Trap and Oil Pan SumpDocument6 pagesReplacing The Volvo Oil Trap and Oil Pan SumpsaifrulNo ratings yet

- Power Systems Analysis Short Ciruit Load Flow and HarmonicsDocument1 pagePower Systems Analysis Short Ciruit Load Flow and HarmonicsJurij BlaslovNo ratings yet

- Cats Meow Edition 3 PDFDocument320 pagesCats Meow Edition 3 PDFbrunokfouriNo ratings yet

- Mx81x Mx71x Service ManualDocument834 pagesMx81x Mx71x Service ManualCarlosNey0% (1)

- Taoism and The KabbalahDocument26 pagesTaoism and The KabbalahJim Weaver100% (2)

- VTBS 20-3DDocument1 pageVTBS 20-3Dwong keen faivNo ratings yet

- Assignment 1 (Total Marks: 70) EEE 323: Power System IIDocument2 pagesAssignment 1 (Total Marks: 70) EEE 323: Power System IIShahriar SauravNo ratings yet

- DE712-014 Parts Manual - 712014 1 en Rev 1Document248 pagesDE712-014 Parts Manual - 712014 1 en Rev 1Emi DominguezNo ratings yet

- Formulation Development and Evaluation of Sustained Release Tablets of AceclofenacDocument128 pagesFormulation Development and Evaluation of Sustained Release Tablets of Aceclofenacraju narayana padala0% (1)

- CRRT (RVS) One Day TrainingDocument46 pagesCRRT (RVS) One Day TrainingwantoNo ratings yet

- B. Ingg Paket BDocument14 pagesB. Ingg Paket BAsep Fajar IrawanNo ratings yet

- Ajuste IAC and TPSDocument17 pagesAjuste IAC and TPSLuis Ignacio SilvaNo ratings yet

- 4.5.1.1 Inside and Outside Control Instructions - IG PDFDocument4 pages4.5.1.1 Inside and Outside Control Instructions - IG PDFMaksim Korsakov100% (4)

- AmadiDocument18 pagesAmadijawad bello aNo ratings yet

- Pulsar220S PLANOS PDFDocument32 pagesPulsar220S PLANOS PDFJuan Jose MoralesNo ratings yet