Professional Documents

Culture Documents

Us 4284373

Uploaded by

emernelsonman0 ratings0% found this document useful (0 votes)

1 views6 pagesThis patent describes a working stand for electrical home machines without clamping necks. The stand has a moveable machine holder that can be fixed at different heights along a vertical guide column. The column has teeth that engage a gear driven by a hand crank. The machine holder has adjustable jaws that embrace the column. It has a vertical shaft for receiving the machine drive shaft above and allowing attachment of a drill chuck below via threads. Roller bearings mount the shaft within the holder.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a working stand for electrical home machines without clamping necks. The stand has a moveable machine holder that can be fixed at different heights along a vertical guide column. The column has teeth that engage a gear driven by a hand crank. The machine holder has adjustable jaws that embrace the column. It has a vertical shaft for receiving the machine drive shaft above and allowing attachment of a drill chuck below via threads. Roller bearings mount the shaft within the holder.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views6 pagesUs 4284373

Uploaded by

emernelsonmanThis patent describes a working stand for electrical home machines without clamping necks. The stand has a moveable machine holder that can be fixed at different heights along a vertical guide column. The column has teeth that engage a gear driven by a hand crank. The machine holder has adjustable jaws that embrace the column. It has a vertical shaft for receiving the machine drive shaft above and allowing attachment of a drill chuck below via threads. Roller bearings mount the shaft within the holder.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

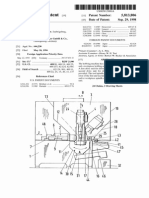

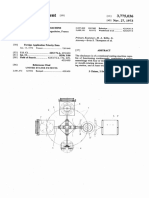

United States Patent (19) 11) 4,284,373

Wolff (45) Aug. 18, 1981

(54) WORKING STAND FOR NECKLESS Primary Examiner-Harrison L. Hinson

ELECTRICAL, HOME WORKER MACHINES Attorney, Agent, or Firm-Martin A. Farber

76 Inventor: Robert Wolff, im Kiesacker, 5446 57 ABSTRACT

Engeln, Fed. Rep. of Germany

A working stand for collarless electrical home worker

(21) Appl. No.: 74,277 machines, which machines have at the end of their drive

22 Filed: Sep. 11, 1979 shaft a threaded section for screwing on or attachment

of a drill chuck. A machine holder is moveable up and

51) Int. Cl......................... B23B39/00; B23B 47/00 down a vertical polygon guide column and can be fixed

52 U.S.C. ...................................... 408/87; 408/129; in position at whatever desired height. The guide col

408/135; 408/712 umn has a toothing, in which there engages a gear

58) Field of Search ..................... 408/87, 88,99, 111, which is driveable by means of a hand crank, the gear

408/129, 135, 136, 712 being mounted in the machine holder. The machine

56 References Cited holder has a pair of adjustable clamping jaws embracing

U.S. PATENT DOCUMENTS the polygon guide column. In the machine holder a

Re. 24,203 8/1956 Buck .................................... 408/712

vertical shaft is rotatably mounted, which shaft on the

l,794,149 2/1931 Collins ................................. 408/135 upper end has an axially interior threaded section for

2,642,760 6/1953 Goldberg ............................... 408/99 reception of the drive shaft of the machine and on the

2,719,461 10/1955 Hawker ................................ 408/111 lower end, which end projects from the machine

3,667,855 6/1972 Douglass .............................. 408/712 holder, has a threaded section for the screw-on attach

3,837,757 9/1974 Levine .... 408/136 ment of the drill chuck.

3,838,935 10/1974 Boyajian. ... 408/87

3,874,810 4/1975 Russell ... ... 408/99

4,012,162 3/1977 Warren .................................. 408/87 7 Claims, 2 Drawing Figures

U.S. Patent Aug. 18, 1981 Sheet 1 of 2 4,284,373

U.S. Patent Aug. 18, 1981 Sheet 2 of 2 4,284,373

4,284,373

1. 2

annular grooves or annular tee-slots (28, 29), in which

WORKING STAND FOR NECKLESSELECTRICAL clamping jaw pair (12, 13) the shaft (14) is clamped, the

HOME WORKER MACHINES shaft (14) being provided with two axially non-displace

able roller bearings (31, 32).

The invention relates to a working stand for collarless 5 By this constructional assembly or mounting of the

electrical home worker machines, which machines have working stand a series of advantages are achieved. A

at the end of their drive shaft a threaded section for neckless home worker machine can easily be screwed

screwing on or attachment of a boring socket or drill into the upper end of the shaft with its threaded section,

chuck. which is located at the end of the drive shaft. The

The home worker machines which are found on the O screwing-on or fastening of the drill chuck to the lower

market are divided into two different basic types. Ma end of the shaft is equally simple, whereby the home

chines of one type have between the actual machine worker machine in connection with the working stand

body and the drill chuck a clamping neck of a standard becomes for instance a table drill machine, with which,

ized outer diameter of 43 mm, which clamping neck is because of the play-free abradant guiding along the

rigidly connected to the machine body, whereas with 15 polygon guide column, work can be done very exactly.

other machine types the drill chuck is joined directly to The two roller bearings which are provided nondis

the machine body. For the machines with the clamping placeably on the shaft are received by the annular

neck, in addition to other countless traditional or auxil grooves in the housing shells and permit a small-friction

iary or supplementary instruments, also drill stands running of the shaft and its fixed or secure mounting in

were developed, which drill stands, in case of the neck 20 the machine holder. The bearings assume the horizontal

less drilling machines, are not usable by themselves, or pressure, which occurs particularly with milling work,

alone, without utilization of an adapter part. so that the bearing of the drive shaft of the home

A tentering frame for neckless home worker machine worker machine is not loaded or stressed thereby.

is known, which frame is disposed or lies in a plane Furthermore in execution of the invention, on the

which contains the drive shaft, surrounds or encloses 25 machine holder (4) there can be arranged an abutment

the entire machine body and moreover has a bushing as stop (45) for arresting rotation of the machine (5), the

a clamping neck, which bushing surrounds the drive abutment stop (45) resting against the machine housing.

shaft, whereas on the opposite frame side there is pro Thereby it can be provided that the stop or abutment

vided a screw apparatus for gripping or clamping the (45) is formed as a fork (46) which encloses, frames or

frame to the machine body. Such a frame does indeed 30 embraces the machine housing, and the stem (44) of the

make possible the use or application of a known operat fork can be guided movably in the machine holder (4)

ing stand even with neckless home worker machines. It and can be attached firmly or secured with a clamping

is however disadvantageous that the tentering frame screw (47). By the stop or abutment the home worker

with neck provides no comparably stable mounting of machine is secured or held on the machine holder of the

the front end of the bearing shaft. Furthermore the 35 working stand without the entire machine being able

frame is also frequently obstructive during the handling during operation to go or shift into rotation. The dis

or working. placeability of the stop permits home worker machines

It is an object of the invention to create a working of differing construction to be able to be attached or

stand for neckless home worker machines, which stand mounted on the working stand.

has a high guide precision, which is easily handleable or For improved handling for example during the

manipulated and can be produced at optimum cost. screwing on of the chuck drill, furthermore it is pro

By the present invention this object is aided in its vided that between the two roller bearings (31, 32) the

solution, by the combination that a machine holder (4) is shaft (14) and the housing shells (6, 7) are provided with

moveable up and down a vertical polygon guide col a diametric bore (38, 37, 39) for insertion or a clamping

umn and can be fixed in position at whatever desired 45 or toggle tool.

height, the guide column (2) being provided with a Further in accordance with the invention it can be

toothing (3), in which toothing there engages a gear (10) provided that on the lower end of the shaft (14) directly

which is drivable or actuatable by means of a hand above the threaded section (35) there is arranged a

crank (21), the gear (10) being mounted in the machine polygon section (40) for the joining application of a

holder (4); the machine holder (4) has a pair of adjust 50 turning wrench (41).

able clamping jaws (16,17), the jaws (16,17) embracing By a tugging or jerking actuation of the turning

the polygon guide column (2), and in the machine wrench or turn handle which is joined or applied to the

holder (4) a vertical shaft (14) is rotatably mounted, polygonal section, even a connection between the work

which shaft on the upper end has an axially interior stand shaft and the drive shaft of the home worker

threaded section (33) for reception of the drive shaft 55 machine that has become very rigid in operation can be

(34) of the machine (5) and on the lower end, which end loosend or released. The threaded section can however

projects from the machine holder (4), has a threaded be used also for the locking or securing of the shaft

section (35) for the screw-on attachment of the drill during the screwing on of the drill chuck.

chuck. (36). According to further features of the invention it can

The machine holder (4) has a two-shell parted hous be provided that the gear (10) and hand crank (21) are

ing which is divided in the center plane of the gear or in mounted fixed on only one shell (7) of the housing

a plane which is parallel to this, both housing shells (6, shells, whereas the other housing shell (6), provided

7) of the housing being clamped rigidly to one another; with a bearing bore (27) for the toothed wheel shaft

the rearward area of the two housing sheels is formed as (20), is formed as a cover, and the toothed gear shaft

the clamping jaw pair (16, 17), the clamping jaw pair 65 (20) is provided with an axially threaded bore and being

(16, 17) embracing the polygon guide column, and the surounded by one of the housing shells (7) is screwed

front area of the two housing shells (6, 7) being formed with the operating or control hand crank (21), and the

as clamping jaw pair (12, 13), the latter provided with housing shells (6, 7) are clamped or tightened together

4,284,373

3 4.

by a screw (11), the screw being arranged near the heel the shaft, which wide roller bearing then would be

of the clamping jaws (12, 13) for the shaft (14). This enclosed in a correspondingly widely formed annular

execution of the machine holder makes possible a favor groove between the housing shells 6, 7. The annular

able cost in production and simple mountability or as groove 30 serves for the free rotatability of the shaft 14,

semblability. the latter being somewhat smaller in diameter. The shaft

With the above and other objects and advantages in 14 is provided on one end with an interior threaded

view, the present invention will become more clearly section 33, into which section 33, there is screwed the

understood in connection with the detailed description end 34 of the drive shaft of the home working machine

of a preferred embodiment, when considered with the 5, which end 34 is provided with a threading. On the

accompanying drawings, of which: 10 lower end the shaft 14 carries a threaded section 35 for

FIG. 1 is an elevational side view of an operating screwing-on a drill chuck or boring socket 36. Between

stand or support in accordance with the invention; the two roller bearings 31, 32 the shaft 14 is provided

FIG. 2 is an exploded perspective illustration of the with a diametric bore 37, which bore can be aligned or

working stand. directed flushly with the through-holes 38, 39 in the

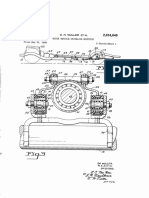

The working stand comprises a polygon guide col 15 housing shells 6, 7. For example a locking, toggle or

umn 2, standing on a base plate 1, which column 2 is clamping tool can be inserted through the bores 38, 37,

formed in the embodiment example as a hexagonal col 39, by means of which tool the shaft 14 is secured or

umn and carries a toothing 3. A machine holder 4 is locked during the screwing-on or unscrewing of the

arranged movable up and down on the guide column 2, drill chuck. At the lower end directly above the

the holder carrying on its front side a clamped-in or 20 threaded section 35 the shaft 14 is provided with a po

fixed home worker machine 5. lygonal section 40, on which section 40 a turning or turn

The housing of the machine holder 4 comprises two handle 41 can be applied or joined. With the turning

mirror image approximately equal or symmetrical hous wrench the shaft 14 either can be secured, or retained or

ing shells 6, 7, which in their center areas 8, 9 are di it can be released or loosened by a back-type jerking or

rectly tightened or clamped onto one another by means 25 tugging turning of the threaded section 34 of the home

of the screw 11 which is set through the two housing worker machine 5.

shells 6, 7, the shells 6, 7 enclosing a toothed wheel or Grooves 42, 43 are formed inclined in the housing

gear 10. In the front range lying over the base plate 1 shells 6, 7, which grooves serve to receive the stem 44

there is formed on or attached to each of the housing of an abutment or stop 45. The stop 45 is constructed in

shells 6, 7, respectively, one clamping jaw or cheek 12, 30 the form of a fork 46 embracing the machine housing of

13 for enclosing a shaft 14. The clamping jaws 12, 13 are the home worker machine 5 and serves to arrest the

cooperatively clamped or held together by means of a rotation of the home worker machine 5 itself. For the

screw 15. At the opposite end the housing shells 6, 7 are adjustment of the stop 45 to different home worker

provided with comparatively long prismatic clamping machines, the stem 44 is displaceably guided in the

jaws 16, 17, which clamping jaws 16, 17 together form 35 grooves 42, 43 and the stem 44 can be fixed on the

an inner profile which is adjusted or fitted to the hexag machine holder 4 by means of a clamping screw 47

onal guide column 2, whereby during the clamping two engaging the stem.

diametrically opposite edges of the guide column 2 are As immediately evident from FIG. 2, at first the en

received by V-grooves or slots of the clamping jaws 16, tire machine holder construction assembly can be

17. The strength of the clamping tension or tightening 40 mounted on the housing shell 7, whereby then in a final

for the clamping jaws 16, 17 is adjustable by means of working operation the other housing shell 6 is mounted

the screws 18, 19. on as a cover, whereby the hollow shaft 20 is received

The gear or toothed wheel 10, which toothwheel 10 by the bearing bore 27, the latter being encased with the

meshes into the toothing 3, is secured or fixed on a bearing bushing 26. The roller bearings 31, 32 lying in

hollow shaft 20, the latter being provided with an axi 45 the grooves 28, 29, are clamped or fastened by the

ally threaded bore. An angular or angle-shaped hand ciamping jaws 12, 13, and position the shaft 14 non-dis

crank 21 is inserted with its front end through a bore 23 placeable in the axial direction.

of the housing shell 7 (which bore is equipped or lined While I have disclosed embodiments of the invention,

with a bearing bushing 22), is screwed into the hollow these embodiments are given by example only and not

shaft 20 and is secured by means of a counter or cotter 50 in a limiting sense.

nut 24. On the outer side of the housing shell 7 on the I claim:

hand crank shaft a graduated collar 25 is seated, which 1. A working stand for collarless electrical home

collar is carried along during the rotation of the hand worker machines, which machines have at the end of

crank 21 by friction-tightness or a friction tight engage their drive shaft a threaded section for screwing on a

ment, yet it can be twisted or turned by hand upon 55 drill chuck, comprising

overcoming the friction. A bore 27 is formed in the a vertical guide column having a polygonal cross-sec

housing shell 6, the bore 27 being provided with a bear tion and a toothing,

ing bushing 26. The hollow shaft 20 is mounted in the a machine holder disposed moveably up and down

bore 27. said vertical guide column and fixable in position at

In the front area of the two housing shells 6, 7 there 60 any height on the guide column,

are respectively provided one half each of two horizon a gear mounted in said holder and engaging said

tal annular grooves 28, 29, which grooves are separated toothing, said gear constituting means actuatable

from one another by an annular groove 30 of smaller by a hand crank,

diameter. The annular grooves 28, 29 serve for the said machine holder comprises a pair of adjustable

reception of roller bearings 31, 32, which for example 65 clamping jaws embracing said guide column,

are shrunk-fit onto the shaft 14. The roller bearings can a vertical shaft is rotatably mounted in said machine

be formed as roller or ball bearings; instead of two roller holder, said shaft on an upper end has an axially

bearings one wide roller bearing could be provided on interior threaded section means for reception of the

4,284,373 6

5

drive shaft of the machines and said shaft on its 4. The working stand as set forth in claim 1, wherein

lower end has another threaded section means for between said two roller bearings, said shaft and said

screwing-on the drill chuck, said lower end of said two housing shells are formed with an aligned

shaft projects from the machine holder, diametric bore adapted for insertion of a toggle

said machine holder comprises a housing formed of 5 tool therein.

two housing shells, the housing being divided in a 5. The working stand as set forth in claim 4, wherein

center plane of the gear or in a plane which is a polygon section adapted to be joined with a turning

parallel to said center plane, both said shells of the wrench is disposed on the lower end of the shaft

housing are clamped rigidly to one another, directly above said another threaded section

a rearward area of said two housing shells is formed 10 e3S.

as said clamping jaws, said clampingjaws embrace 6. The working stand as set forth in claim 1, further

said guide column, and comprising

a front area of said two shells is formed as another a gear shaft disposed on said gear,

pair of clampingjaws, the latter being formed with a hand crank means operatively engages said gear for

annular grooves, said shaft is rotatably clamped in 15 driving and control of the latter,

said another pair of clamping jaws, said gear and said hand crank means are mounted

two axially non-displaceable roller bearings are dis firmly on only one of said two shells of the housing,

posed on said shaft and in said annular grooves. whereas the other of said two housing shells is

2. The working stand as set forth in claim 1, further formed with a bearing bore for said gear shaft, the

comprising 20 latter is mounted in said bearing bore, said other of

an abutment stop means for arresting rotation of the said two shells is formed as a cover.

machines, said abutment stop means rests against a 7. The working stand as set forth in claim 6, wherein

housing of the machines and is mounted on said said gear shaft is formed with an axially threaded

machine holder. bore and is surrounded by said one of said two

3. The working stand as set forth in claim 2, wherein 25 housing shells, said hand crank means is screwed to

said abutment stop means is formed as a fork having said gear shaft, and

a stem of the fork displaceably guided in said ma screw means for clamping said two housing shells

chine holder, together, said screw means is arranged near a heel

a set screw means for fixing said abutment stop means of said another pair

ak

of clamping

it k is

jaws for said shaft.

in said machine holder. 30

35

45

55

65

You might also like

- Boxford Know Your LatheDocument108 pagesBoxford Know Your LatheRoy Masters75% (4)

- Instructions For Servicing The Necchi Supernova Sewing MachineDocument122 pagesInstructions For Servicing The Necchi Supernova Sewing MachineSteven McDonaldNo ratings yet

- Installation and Parts Manual D6R - D6TDocument23 pagesInstallation and Parts Manual D6R - D6TJUAN CARLOS PAZ100% (3)

- The Shaping MachineDocument104 pagesThe Shaping MachineJohn Smith90% (10)

- Practical 7 Lathe MachineDocument5 pagesPractical 7 Lathe MachineTendayiBonzo100% (7)

- Report On Four Bar Mechanism of Sewing MachineDocument8 pagesReport On Four Bar Mechanism of Sewing MachineshazedislamNo ratings yet

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualPeter Galuszka0% (1)

- Kearney and Trecker Installation ManualDocument12 pagesKearney and Trecker Installation Manualaa987100% (1)

- 7 Speed Dual Clutch Transmission 0gcDocument30 pages7 Speed Dual Clutch Transmission 0gcAntónio Fernandes100% (1)

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Raschel Machine With Stitch Comb and Knock-Over BarDocument6 pagesRaschel Machine With Stitch Comb and Knock-Over Barntd1011No ratings yet

- Maintainance ReportDocument17 pagesMaintainance ReportDinesh Kumar TailorNo ratings yet

- Impetus Metalmaster LatheDocument19 pagesImpetus Metalmaster LatheIan Foreman100% (1)

- Djj10033 Chapter 3Document50 pagesDjj10033 Chapter 3YogenNo ratings yet

- Lab ManualDocument43 pagesLab ManualTech OriginNo ratings yet

- Pneumatic Machining Time Reduction in ShaperDocument4 pagesPneumatic Machining Time Reduction in ShaperVamsi KrishnaNo ratings yet

- United States Patent (19) : Archie A. Hodge, Renton Thomas E. Belshaw John R. Hamblin, Both ofDocument8 pagesUnited States Patent (19) : Archie A. Hodge, Renton Thomas E. Belshaw John R. Hamblin, Both ofBeny StephenNo ratings yet

- Umted States Patent (191 (111 4,372,411: Flower ' (45) Feb. 8, 1983Document8 pagesUmted States Patent (191 (111 4,372,411: Flower ' (45) Feb. 8, 1983Sugarboy3 SurNo ratings yet

- M19 LatheDocument36 pagesM19 LatheVinay Kumar Neelam100% (1)

- US4827759Document7 pagesUS4827759jonyNo ratings yet

- Lathe TurretDocument17 pagesLathe TurretLove ReloadedNo ratings yet

- Construction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill BitsDocument8 pagesConstruction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill Bitsviruz2_09No ratings yet

- United States Patent (19) : Filed: Feb. 14, 1972Document5 pagesUnited States Patent (19) : Filed: Feb. 14, 1972zgregzNo ratings yet

- Mechanical Mounting and Dismounting TPI WL 80-56 EDocument36 pagesMechanical Mounting and Dismounting TPI WL 80-56 EAhmad MuchroniNo ratings yet

- Engine Lathe ProcessesDocument41 pagesEngine Lathe ProcessesMoe MyuNo ratings yet

- May 13, 1958 G. H. Muller Etal 2,834,640: Filed May 31, 1955 2 Sheets-Sheet LDocument4 pagesMay 13, 1958 G. H. Muller Etal 2,834,640: Filed May 31, 1955 2 Sheets-Sheet LKeval KamaniNo ratings yet

- Colchester Dominion Lathe-ManualDocument35 pagesColchester Dominion Lathe-ManualTony FitzgeraldNo ratings yet

- 412 MM CH09 PDFDocument8 pages412 MM CH09 PDFpancaNo ratings yet

- Milling Machine Operations: Subcours E Editio N OD1644 8Document46 pagesMilling Machine Operations: Subcours E Editio N OD1644 8deepak100% (1)

- Experiment NoDocument8 pagesExperiment NoNavin YadavNo ratings yet

- United States Patent: Kronseder (45) Date of Patent: Oct. 4, 2005Document14 pagesUnited States Patent: Kronseder (45) Date of Patent: Oct. 4, 2005DANESINo ratings yet

- United States Patent (19) : Felix-DalichowDocument5 pagesUnited States Patent (19) : Felix-DalichowBarmak CheraghiNo ratings yet

- Gec 218 Module Three - Machine TechnologyDocument17 pagesGec 218 Module Three - Machine TechnologyOyedotun TundeNo ratings yet

- Manufacturing Technology Ii Assignment I: Batch 10Document11 pagesManufacturing Technology Ii Assignment I: Batch 10sh_nk2010No ratings yet

- Design and Function ....................................................................................................... 4.3Document14 pagesDesign and Function ....................................................................................................... 4.3Miguel MartínezNo ratings yet

- Automatic Drawbar ManualDocument24 pagesAutomatic Drawbar Manualjason mossNo ratings yet

- Machine Stops-Trips and Locking Devices 1913 PDFDocument52 pagesMachine Stops-Trips and Locking Devices 1913 PDFjohn silverNo ratings yet

- EP0744338A1Document16 pagesEP0744338A1雷黎明No ratings yet

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Document3 pagesUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06No ratings yet

- US20110274550A1Document9 pagesUS20110274550A1雷黎明No ratings yet

- Report On Cascading TransformersDocument28 pagesReport On Cascading Transformerspalak yadavNo ratings yet

- Wa0002Document7 pagesWa0002محمد باسلNo ratings yet

- Chapter 4 LatheDocument10 pagesChapter 4 LatheDipayan DasNo ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- MP-I - Lab Manual DarshanDocument159 pagesMP-I - Lab Manual DarshanNitinGothiNo ratings yet

- Vertical Turret Lathe & Horizontal Boring MillDocument12 pagesVertical Turret Lathe & Horizontal Boring MillALLEN FRANCISNo ratings yet

- Unit-II The LatheDocument14 pagesUnit-II The LatheThulasi RamNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Ingram Cactus - Exact 15 Universal Slim-Hole Wellhead SystemDocument5 pagesIngram Cactus - Exact 15 Universal Slim-Hole Wellhead SystemYougchu LuanNo ratings yet

- United States Patent (19) : WalkerDocument8 pagesUnited States Patent (19) : Walker155No ratings yet

- United States Patent (19) : Dec. 10, 1991 (45) Date of PatentDocument4 pagesUnited States Patent (19) : Dec. 10, 1991 (45) Date of PatentKeval KamaniNo ratings yet

- Machine Tools: Lathe & Lathe WorkDocument35 pagesMachine Tools: Lathe & Lathe WorkRahul Deb PalNo ratings yet

- Manual de La Bop 3.06 15M PDFDocument28 pagesManual de La Bop 3.06 15M PDFJack FosterNo ratings yet

- Diseño ElectricoDocument5 pagesDiseño ElectricoemernelsonmanNo ratings yet

- Documents - MX Pragati BTP Turret Manual - PDFDocument31 pagesDocuments - MX Pragati BTP Turret Manual - PDFPetar Petrovic100% (3)

- Meccanismo T.R.Document6 pagesMeccanismo T.R.Marco Raneo PezzanoNo ratings yet

- 002005ea 5Document42 pages002005ea 5AliArababadiNo ratings yet

- Lathe Machine PrinciplesDocument15 pagesLathe Machine Principlesscratch89No ratings yet

- Actuator 657Document24 pagesActuator 657DineshNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- D166 Gate Crane+FS DS 0922Document1 pageD166 Gate Crane+FS DS 0922ธนาธิป 002No ratings yet

- Now and Get: Best VTU Student Companion You Can GetDocument7 pagesNow and Get: Best VTU Student Companion You Can GetLokesh KNo ratings yet

- Fiberspar LinePipe TM The Leader in Spoolable Pipeline Systems. Full Reel Program Certified Installer Training. Tuesday, December 07, 2010Document165 pagesFiberspar LinePipe TM The Leader in Spoolable Pipeline Systems. Full Reel Program Certified Installer Training. Tuesday, December 07, 2010jhon alexanderNo ratings yet

- 2023 Rockshox Spare Parts CatalogDocument235 pages2023 Rockshox Spare Parts CatalogDavidNo ratings yet

- Steam Turbine CalculationsDocument9 pagesSteam Turbine CalculationsShankarMukherjeeNo ratings yet

- Development of Cross Flow Turbine For Pico HydroDocument9 pagesDevelopment of Cross Flow Turbine For Pico HydroLAURO AUGUSTONo ratings yet

- The Large Mass Method in Direct Transient and Direct Frequency ResponseDocument3 pagesThe Large Mass Method in Direct Transient and Direct Frequency ResponsenetkasiaNo ratings yet

- Polymers: Fabrication and Characterization of Aluminum Nanoparticle-Reinforced CompositesDocument10 pagesPolymers: Fabrication and Characterization of Aluminum Nanoparticle-Reinforced CompositesTRNADEWNo ratings yet

- Iso 898 2紧固件的机械性能.第2部分有规定的检验载荷值的螺母.粗牙螺纹Document19 pagesIso 898 2紧固件的机械性能.第2部分有规定的检验载荷值的螺母.粗牙螺纹Pamela Saavedra MoyaNo ratings yet

- Sany S800S ReviewDocument11 pagesSany S800S ReviewJuna PasaribuNo ratings yet

- Nebula SentinelDocument4 pagesNebula SentinelDominic Viverra LouzadoNo ratings yet

- Superheat Sujay Steel GripDocument9 pagesSuperheat Sujay Steel Gripdebjit123No ratings yet

- 451 Smart Quick Manual (451 Smart Fortwo / 2008 Smart Car / Smart 451)Document22 pages451 Smart Quick Manual (451 Smart Fortwo / 2008 Smart Car / Smart 451)451s.com / 451 smart fortwo / 2008 smart car100% (2)

- Propulsion For: System UAVDocument25 pagesPropulsion For: System UAVQuraisy AmriNo ratings yet

- Bag Filter ComponentsDocument6 pagesBag Filter ComponentsAhmad Dagamseh100% (2)

- IC Engine QuestionsDocument18 pagesIC Engine QuestionswasemNo ratings yet

- ForgingDocument58 pagesForgingSamir Bose100% (4)

- ME3431-part 1Document107 pagesME3431-part 1tfhfnrnNo ratings yet

- Manual 120726 Imc5050 Carton SealerDocument9 pagesManual 120726 Imc5050 Carton SealerTheodora StefanNo ratings yet

- DesuperheatersDocument6 pagesDesuperheaterskparthypan100% (1)

- Produklinienbroschuere DryCoolersAndRadiators View EnglDocument15 pagesProduklinienbroschuere DryCoolersAndRadiators View EnglTansu MavunacıNo ratings yet

- Cat Extreme Application Grease - ArcticDocument2 pagesCat Extreme Application Grease - ArcticvNo ratings yet

- The Critical State of Sand: Géotechnique January 1991Document27 pagesThe Critical State of Sand: Géotechnique January 1991Jacky_LEOLEONo ratings yet

- BS en 13480-8-2012Document42 pagesBS en 13480-8-2012A.A0% (1)

- Thermochemistry: - The Study of The Heat ChangesDocument54 pagesThermochemistry: - The Study of The Heat ChangesFaZe BrAnDoNNo ratings yet

- Front Shovel enDocument15 pagesFront Shovel enAlejandro RodriguezNo ratings yet

- Propulsion 1Document64 pagesPropulsion 1jtradio13100% (1)

- 1 PDFDocument3 pages1 PDFedyNo ratings yet

- Daikin Engineering Data Packaged Air Conditioners PDFDocument176 pagesDaikin Engineering Data Packaged Air Conditioners PDFR'n'R Batam100% (2)