Professional Documents

Culture Documents

RAMS For Concrete Pumping

Uploaded by

JohnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RAMS For Concrete Pumping

Uploaded by

JohnCopyright:

Available Formats

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Method Statement Title: Concrete Pumping

Method Statement No.: MS-0001

Date Compiled:

Review Date:

Expiry Date:

Compiled By:

Competency:

Main Contractor:

Site Managers:

Site Address:

Site Operatives:

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Truck Mounted Mobile Concrete Pump

Significant Risk Identification / Control Measure Statement

The mobile truck-mounted concrete pump is designed to convey concrete from the machine’s delivery hopper to a point designated by the hirer/site

management.

This is achieved via a hydraulically powered pump, through pipe sections attached upon an articulated boom, to a suspended flexible rubber delivery hose,

solid ‘tremmie’ pipe, or via a steel pipeline laid on the ground or fixed vertically.

Data Sheets detailing pump dimensions, outrigger loadings/ positioning, boom type/ reach, and pumping delivery pressures/ volume outputs are available

upon request from C&G Concrete Pumping Services, or from our website - www.cgconcretepumping.co.uk

Information, Instruction, Training, Monitoring - All C&G Concrete Pump Operators (C&GPO’s) are issued with a detailed Operators Procedure Guide (OPG).

Every C&GPO holds a current CPCS card/NPORS certificate for concrete pumping operations. C&GPO’s are assessed periodically, and are also subject to

unannounced ‘spot checks’, in order to ensure safety, quality, & operating standards are maintained and developed.

Encouragement by site management of this progress would be appreciated. This enables us as a company to comply with our employers legal

requirements.

British Standard BS 8476:2007 ‘Code of practice for the safe use of concrete pumps’ is recommended to hirers and interested parties as a reference

document detailing the general minimum requirements in respect of the operation of concrete pumping equipment. Copies of the standard are available

from BSI – www.bsi-global.com

Safe Systems of Work –C&G Concrete Pumping Ltd have assessed all aspects of its operations, and have developed procedures and safe systems of work

that aim to reduce and control risks to safety, health, and the environment.

Significant Risks As an overview, the significant risks that are present in respect of concrete pumping activities are noted below, along with appropriate

control measures. Any additional risks have been assessed and are recorded within our company (C&GCPS/RAMS/) Method Statement.

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

REFERENCE No. : MS- 0001

OPERATION: Concrete pumping using boom pump/ Line Pump

LOCATION:

NOTE: This method statement must be fully explained to all employees involved in the

operation prior to commencement of the works. They are to sign the signature box end

the end of the statement to acknowledge receipt of the information

1 Scope of Work

Description and sequence

Use of vehicle mounted boom pump for placement of concrete into floors above ground level.

Method

Before leaving depot

Walk-round inspection of vehicle, to ensure road worthiness, to include:- general visual check of

pump turret and fixed steel pipes, hydraulic hoses (to check for any leaks), tyres, mirrors & lights,

operation of remote control operator’s system, hopper guard grid is secure and serviceable.

Fill water tanks.

Defrost all windows (during winter conditions) to provide good all-round driving visibility.

Allow engine to “warm-up” and idle for 10mins prior to departure, to build up air reservoirs for

brakes.

Arrival on site

Park safely outside site and report to site manager.

Go through site induction process.

Fill out plant inspection record sheet/book.

Walk to area designated for pump setup area, and visibly assess environment. Check for ground

stability (responsibility for suitable preparation is down to the site manager/hirer); overhead

obstructions; visibility to work area; access conditions and route for delivery lorries.

Establish a code of signals between the pump operator and concrete laying gang/foreman prior to

commencement of pumping works.

Pump setup

Deploy machine stabilisers (using sole plates if necessary).

Level up and support the pump using the hydraulic jack stabilisers.

Unfurl boom and manoeuvre into pour starting position.

Check wire safety lanyards are attached between end of boom (knuckle bend) and first flexible

pipe.

Remove steel and rubber pipes (necessary to reach pour stating point) from bed of pump, and carry

to lay-out position.

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Layout necessary pipes in approximate assembly locations.

Join pipes together using couplings with rubber sealing rings.

Position any mobility pans under couplings (as necessary) to aid with hose movements during pour.

Fix suitable rope handling cord onto last section of pipework ready for work to commence.

Once all hoses have been connected, conduct a final walk-through check of all hoses and couplings

starting at point of pour and finishing at pump hopper.

Acquire 50kg of cement (client to supply) for every 20m of pipeline to be used, for pipe grouting,

and position by hopper prior to delivery lorry arrival.

Priming hoses

On arrival of 1st delivery lorry, mix up grout for lining pump hoses.

Empty ½ a bag of cement into bucket containing @ 20lts. of water and mix using a small paddle to

combine water and cement into a flowable grout.

Pour mixture into top of connecting knuckle on rear of hopper.

Repeat above steps for remaining cement.

During works

Reverse concrete delivery lorry up to hopper ready for discharge.

Ensure that hopper grid is in lowered position, prior to approach of mixer lorry, and at all times

during discharge and pumping operations.

Allow delivery vehicle to agitate mixer drum for a couple of minutes to avoid initial aggregate

separation on discharge.

Discharge concrete into hopper to check slump and suitability of concrete prior to starting to pump

through hoses.

Establish a suitable position of work – to be able to see concrete discharge into hopper and point of

delivery from hose. This may involve the use of the remote control pack.

Should a remote control pack be used, then any other operating controls, mounted on the pump

body, must be disabled.

Commence pumping of concrete at a suitable rate to allow for site operators to spread concrete; and

for lorry to discharge concrete at a rate to keep hopper ¾ full.

Until concrete is flowing smoothly out of the end of the delivery hose, or when a blockage occurs

in the boom pipeline, all personnel should remain clear of the delivery hose and the placing boom.

(The danger zone is the area around the delivery hose in which the delivery hose can strike out. The

diameter of the zone is twice the length of the delivery hose).

If a blockage occurs during the pour, the concrete pump operator must stop pumping immediately

and instruct personnel to move to a safe position before attempting to remove the blockage.

If the concrete pump operator needs to open the delivery pipeline to clear a blockage, he must first

release the pressure inside the pipeline as much as possible, e.g. by reversing the pumping action.

The pipeline must be treated as being pressurised at all times. Appropriate and adequate eye

protection must be worn when opening the pipeline.

The hirer is to ensure that site personnel DO NOT under any circumstance open or attempt to open

the pipeline under pressure.

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Use horn to signal to concrete lorry driver to stop discharge if the need arises to move hoses,

disconnect hoses, or to stop pour for any other reason.

Move boom as necessary to making a suitable progress across pour area.

On completion of lorry discharge lower boom to allow end of delivery hose to rest on floor.

At the end of discharge of each load remove any disconnected hoses and wash out immediately to

avoid concrete drying inside hoses and pipes.

If the concrete pump has to be left unattended, the operation of the boom and pump must be

isolated.

Between concrete lorry deliveries

Agitate the contents of the hopper should the need arise – long intervals between delivery vehicles,

rise in ambient temperature, etc.

If the concrete in the pump should need circulating or boom should need moving to another part of

the site, correct blanking of boom should be used, i.e. blanking cap or squeeze bag activated if

fitted.

On completion of works.

Concrete in the hopper should be discharged until the only a small amount is left in the hopper (just

covering the ram inlet chambers)

The pressure in the pipeline should be released by retracting concrete into the hopper.

The access point in the rear knuckle (immediately after the hopper) should be opened, a wetted

sponge ball inserted into the line, and the access cover re-secured.

A cage, or protective back board, should be erected at the end of the delivery hose (to receive and

confine the cleaning ball).

The end of the discharge hose should be secured to avoid any whiplash.

All laying gang members should be moved away from the discharge hose, to a safe area.

The cleaning ball should then be advanced through the remaining pipes and hose, At reduced

engine revs, until it emerges at the discharge point.

The ball should then be recovered and thoroughly cleaned and washed off.

All hoses should be thoroughly washed out and stored on the lorry bed.

All couplings should be cleaned, washed and stored on the lorry bed.

The boom should then be retracted and stored on the purpose-made cradle on the lorry bed.

A suitable site for emptying the remaining concrete from the hopper should be identified, and the

pump moved to this location.

The retaining lever on the lower door of the hopper is then released, and the door swung away to

allow the remaining concrete to be discharged from the hopper.

Flush out all the intake rams, pistons and thoroughly rinse all concrete and grout from the hopper.

Once fully flushed, close the lower door of the hopper and secure with the retaining level.

Ensure all pipes, clips, hoses, wash out lines sole plates are stowed in their respective areas on the

2 lorry bed, and ready for road travel

Complete client receipt and present to client’s representative.

Sign out (if required) from site and return to depot.

Location

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Time/Duration

Access Routes

Access for Emergency Services and others.

The works will not impact on access for the emergency services or others.

3 Lighting

All work is to be carried out in daylight hours. The hirer is to supply any additional lighting

required.

4 Plant and Equipment.

Schedule of equipment

Lorry mounted concrete pump

Test Certificates

Operator to possess either a CPCS or NPORS certificate for operation of concrete pumps

Specialist Equipment

N/A

5 Materials

Materials to be used

Ready mixed concrete

COSHH Implications

See attached COSHH data sheet

Fire Implications

N/A

6 Risks and Controls

See attached hazard identification sheet and control measures.

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

7 Training

All employees are to have this method statement, and associated risk, COSHH and manual handling

assessments explained to them prior to commencing work. The briefing register is to be signed by

each employee on all documents.

The pump operator is to be in possession of a valid training certificate.

8. Organisation

P. Johnson, L. Green , T Fletcher A Harding, J Simpson, D Cull, W Holden, N Grant

9. Housekeeping

Removal

All residual concrete shall remain on site and is the responsibly of the client to dispose of.

Resources

N/A

Frequency

N/A

Storage

N/A

10. Briefing Register

The briefing register for this operation is attached

11. Personal Protective Equipment

The following PPE will be worn by all operatives involved in this operation:

Safety Hats

High Visibility Vests

Safety Boots

Gloves

Safety glasses

Ear defenders (if required due to site conditions)

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Issue, Maintenance and Recall

All PPE will be issued to employees by the contracts Manager prior to their commencement on site.

The foreman is to inspect all employees PPE prior to the operation to ensure it is serviceable.

12. Power

N/A

13. Working Platforms

N/A

14. Welfare

Welfare facilities are provided by main contractor.

15. 3rd Party Protection

N/A

16. The Environment

Noise

See method statements

Air Omissions

N/A

Aqueous/effluent discharge

All concrete washed from hopper, pipes and hoses shall be contained on-site and not allowed to

contaminate any drains or water courses. The responsibility for this containment lies with the

client/hirer

Waste Generation

N/A

3rd Parties

N/A

17. Temporary Works

N/A

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

18. Monitoring

Air Sampling

N/A

Health Surveillance

N/A

Noise/Vibration Sampling

N/A

19. General

First Aid

The first aider for the project will be the site manager or a person appointed by the hirer.

Fire.

No fire risk will be present during this operation.

Exposure to hazardous substances

See COSHH assessments

Oxygen enriched / deficient atmosphere

N/A

Adverse weather conditions

Adverse weather conditions should not effect this operation

Spillage

Should any fuel or oil spillage occur it would be contained using subsoil which will

subsequently disposed of as contaminated waste.

20 Communications

Radio

N/A

Telephone

Mobile available with site foreperson and pump operative.

Verbal

This method statement and the associated risk assessment will be verbally explained to all

employees involved in the operation prior to its commencement.

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Hand Signals

All hand signals to reversing vehicles will be in accordance with the Health and Safety (Safety

Signs and Signals) Regulations 1996.

Code of hand signals between pump operator, lorry drivers and concrete laying gang members

to be agreed prior to works commencing.

HAZARD AND RISK IDENTIFICATION SHEET

EFFECTED AREA RISK VALUE

PROBABILITY

SEVERITY X

HAND/WRIST

PROBABILITY

SHOULDER

INTERNAL

SEVERITY

PUBLIC

TRUNK

OTHER

HAZARD

HEAD

FOOT

ARM

EAR

TOE

LEG

EYE

SERVICES

Overhead X X X X X X X X X 2 2 4

FALLS

From Height X X X X X X X X X 2 2 4

Same Level/Trip X X X X X X X X X 2 2 4

MACHINERY IN MOTION

Drawn in X X X X X X X X X 2 2 4

Flying objects X X X X X X X X X X X X X 3 3 9

VEHICLE IN MOTION

Fall From X X X X X X X X X X 3 2 6

Trapped Between Machinery/ X X X X X X X X X 3 2 6

Vehicles

Hit By Machinery/ Vehicles X X X X X X X X X 3 2 6

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Minmere Bungalow, Buckland Road Charney Bassett OXON OX12 0EL

Telephone: 01235 868855

Mobile: 07766503595

www.cgconcretepumping.co.uk Email:- paul@cgconcretepumping.co.uk

Hit By Burst Hoses/ Flying X X X X X X X X X X X X X 3 2 6

Material

COSHH

Irritant X X X X X X X 4 4 16

GENERAL

Manual handling X X X X X X X X X 2 2 4

Explosions

Electricity X X X X X X X X X X 2 2 4

Hand tools X X 1 2 2

Noise X 2 2 4

Falling objects X X X X X X X X X X X 3 3 9

Hazard Severity & Probability

Severity Probabilty

1 Negligible 1 Not likely

2 Slight 2 Possible

3 Moderate 3 Quite possible

4 High 4 Likely

5 Severe 5 Almost a certainty

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon. SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Rosecroft New Road Charney Bassett OXON OX12 0ER

Telephone: 01235 868855

Mobile: 07766503595

Risk Professional Control Site Management and Hirer Considerations &

Controls

Contact with overhead power cables C&G Pumping follow industry guidance (GS6) – Ensure the pump is sited so that neither the pump, or

6m from electric services mounted on wooden boom, encroaches within these limits.

poles and 11m from services mounted on metal

pylons.

Fall from height whist checking pump, filling Ensure footwear is clean and free from mud, Keep site clean as practicable.

water tanks, unloading pipes debris, etc. Short duration tasks only (retrieving Do not allow non C&GPO operatives to access the pump

fittings, et.c). Long duration tasks (changing seals, deck of the lorry.

etc. require a harnace and separate method

statementUnload pipes, 1 at a time, from side of

lorry.

Collapse or settlement of pump due to ground Sole plates are provided for placement below Ensure ground conditions at set-up position are adequate

conditions/ inadequate ground support outrigger feet to support the pumps outriggers/ for

reduce surface damage imposed load of pump

these are designed for use on firm, level provide sufficient extra support (timbers, steel sheets,

etc.) as

standing

Drawn into machinery in motion Ensure hopper grating is lowered and secured Keep unauthorised personnel away from working area

during pumping operations

Vehicle Movements (reversing) – crushing / Where possible the C&GPO will direct the mixer Provide a competent banksman to direct concrete mixer

trapping of persons by delivery vehicles truck during the manoeuvre onto the concrete trucks (especially when the C&GPO is required to

pump hopper operate the boom/pump.

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon, SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Rosecroft New Road Charney Bassett OXON OX12 0ER

Telephone: 01235 868855

Mobile: 07766503595

Risk Professional Control Site Management and Hirer Considerations &

Controls

Injury to people, or property from spillage/splatter Pump all concrete from hoses prior to moving Ensure suitable edge protection to slab/pour. Recet debris

from hoses boom. Lower boom so hose sits on floor between netting is likelihood of overspill or splatter.

loads. Direct hose away from edge of shutters, etc.

whilst discharging concrete

Potential blockage at start or restart of pump Agitate concrete in hopper between loads

Hose “whipping” when flexible hose used off end C&GPO request everyone remain clear end of Ensure laying gang members keep clear of end of hose

of boom discharge hose on restart. Steel security lanyard on restart.

used on joint between boom and flexible hose.

Only single ended hose used off boom

Bursting of pipelines under pressure Only pipes, hoses & clips of sufficient safety

rating to be used. Wear and damage to hoses and

pipes should be checked frequently and replaced

as necessary.

Forceful ejection of concrete from end of hose Pipe seals maintained correctly. Level of concrete If C&GPO operates pumps using remote control unit a

in hopper controlled correctly secondary banksman should be appointed to watch levels

of concrete in hopper ( to avoid air being pumped into

pipework)

Pressurised concrete release – dismantling hoses Release pressure in pipeline before releasing Non C&GPO operatives NOT to release clips without

joining clips C&GPO instruction/ direction/

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon, SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Rosecroft New Road Charney Bassett OXON OX12 0ER

Telephone: 01235 868855

Mobile: 07766503595

Risk Professional Control Site Management and Hirer Considerations &

Controls

COSHH: Cement - Irritant Gloves to be worn when handling pipe, hoses,

grout or washing out.

Blockages (and why they occur)

Segregation of aggregate during pumping Use appropriate amount of primer / grout to line Consider length of pipeline used (site setup position of

pipeline pump)

Inappropriate concrete mix Check and adjust slump as necessary Ensure “pump mix” specification on design mix.

Stiffening of concrete in boom pipeline, water C&GPO shall agitate concrete in hopper and move Deliveries should be time managed to avoid delays or

bleeds from concrete, incorrect dosage of concrete in pipeline if delays are envisaged waiting times

plasticiser (flash set)

Flexible hoses kinked or trapped Suspend vertically if off the boom and layout

straight if used as horizontal pipework

Foreign objects delivered form mixer drum Monitor the discharge of the concrete into the Banksman to assist if C&GPO is using pump via remote

hopper control box.

Flexible hoses kinked or trapped Suspend vertically if off the boom and layout

straight if used as horizontal pipework

Foreign objects delivered form mixer drum Monitor the discharge of the concrete into the Banksman to assist if C&GPO is using pump via remote

hopper control box.

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon, SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

C&G Concrete Pumping Ltd

Rosecroft New Road Charney Bassett OXON OX12 0ER

Telephone: 01235 868855

Mobile: 07766503595

This is to certify that I have read and understood the above method statement, risk assessment and control measures.

PRINT NAME SIGNATURE DATE PRINT NAME SIGNATURE DATE

Site Address:

Reg’d Office: Vicarage Court, 160 Ermin Street, Stratton, Swindon, SN3 4NE

Company No: 6494408 VAT Reg. No. 930 4008 65

You might also like

- NKBA Kitchen and Bath WorkbookDocument20 pagesNKBA Kitchen and Bath WorkbookJohnNo ratings yet

- Pipeline Execution PlanDocument23 pagesPipeline Execution PlanRawnakul Islam Opu100% (1)

- Rs Concrete Pumping Risk Assessment 2015Document3 pagesRs Concrete Pumping Risk Assessment 2015api-301780442100% (1)

- Method Statement For Concrete RepairingDocument13 pagesMethod Statement For Concrete RepairingMihirdutta100% (3)

- Erection of DPC Clinker Silo Extraction-2Document7 pagesErection of DPC Clinker Silo Extraction-2RajuNo ratings yet

- A Simple Guide To Concrete Cube TestingDocument4 pagesA Simple Guide To Concrete Cube TestingmsohaibazizNo ratings yet

- Saudi Arabia Concrete Products (SACOP)Document24 pagesSaudi Arabia Concrete Products (SACOP)Mohammad Jaradeh100% (1)

- Concrete Pre Pour Planning For Civil ProjectsDocument6 pagesConcrete Pre Pour Planning For Civil ProjectshemantrulzNo ratings yet

- Cased Crossing ProcedureDocument8 pagesCased Crossing ProcedureRehan sheikh0% (1)

- Method Statment (Structural Works)Document9 pagesMethod Statment (Structural Works)Hazem Shaker Abu Shaaban100% (2)

- Method Statement: (Continuous Flight Auger)Document15 pagesMethod Statement: (Continuous Flight Auger)sawkariqbal100% (1)

- Bridge DesignDocument265 pagesBridge DesignJohnNo ratings yet

- 06 Handling Hauling & Stringing of Line Pipes - REV BDocument6 pages06 Handling Hauling & Stringing of Line Pipes - REV Bmaneesh singh100% (1)

- Girder Casting MethodologyDocument5 pagesGirder Casting MethodologyAkhilesh Dwivedi50% (2)

- Rs Concrete Pumping Method StatementDocument3 pagesRs Concrete Pumping Method Statementapi-301780442100% (1)

- Construction Project Risk ManagementDocument14 pagesConstruction Project Risk ManagementAdriano ZvNo ratings yet

- @method Statement For Static Load TestDocument76 pages@method Statement For Static Load TestTrương Văn ĐồngNo ratings yet

- Method Statement WideningDocument13 pagesMethod Statement WideningAMA MUTTAHIZI AHADAN AUHANNo ratings yet

- 9.625 CSG TallyDocument2 pages9.625 CSG TallyAdeel Safdar NenseyNo ratings yet

- Sewer DescriptionDocument27 pagesSewer Descriptionroco_3213No ratings yet

- Scope of Work For Mining Contractor & Coal Production Schedule - Rev.1Document15 pagesScope of Work For Mining Contractor & Coal Production Schedule - Rev.1setiawannm100% (1)

- Method of Statement Road Drain RockDocument6 pagesMethod of Statement Road Drain RockAlister PangNo ratings yet

- Tenchlees Piping Tech ReportDocument14 pagesTenchlees Piping Tech ReportTharun ReddyNo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- MOS - PipeBridge SG SebatangDocument13 pagesMOS - PipeBridge SG Sebatang7e1a8821100% (1)

- Analysis and Design of Bridge Substructures PDFDocument195 pagesAnalysis and Design of Bridge Substructures PDFsuheilbugs100% (1)

- BSI - Erection ManualDocument55 pagesBSI - Erection ManualRicardo Jesus Mallma CubasNo ratings yet

- Methodology For PIpe Culvert, Box-Culvert, Slab Drain, Minor Bridge & Major Bridge.Document57 pagesMethodology For PIpe Culvert, Box-Culvert, Slab Drain, Minor Bridge & Major Bridge.Abhi100% (1)

- Dokumen - Tips - Bsi Standards Publication 2019 12 13 Bs 59752019 A Tracked Changes ComparesDocument21 pagesDokumen - Tips - Bsi Standards Publication 2019 12 13 Bs 59752019 A Tracked Changes ComparesJohnNo ratings yet

- Method Statement - Upvc Piping - Rev 01Document10 pagesMethod Statement - Upvc Piping - Rev 01Tamil Da RasckalzNo ratings yet

- Pipeline Coating ProcessDocument34 pagesPipeline Coating Processzenisler100% (2)

- TC 0120211127001523 1Document2 pagesTC 0120211127001523 1John100% (1)

- METHOD STATEMENT Conduits For Power OutletsDocument12 pagesMETHOD STATEMENT Conduits For Power OutletsVenkatKakarlaNo ratings yet

- MWP-C-CS-PC-0009 Tank Erection Procedure-BDocument17 pagesMWP-C-CS-PC-0009 Tank Erection Procedure-BKing王No ratings yet

- D5918Document12 pagesD5918grats_singcoNo ratings yet

- Pipelaying WorkDocument9 pagesPipelaying Workbee_imranNo ratings yet

- Mayur Electric Works Q2Document4 pagesMayur Electric Works Q2Voltonix InfratechNo ratings yet

- Technical Specification - Concrete WorksDocument5 pagesTechnical Specification - Concrete Workshendra djangNo ratings yet

- Project - Construction of Over Head ReservoirDocument9 pagesProject - Construction of Over Head ReservoirAkash MallickNo ratings yet

- Load Test BalajiDocument2 pagesLoad Test BalajisenthilNo ratings yet

- Method NSG H For Beam or SlabDocument3 pagesMethod NSG H For Beam or SlabDave Robert HasibuanNo ratings yet

- MS For Reinforcement Cement ConcretingDocument6 pagesMS For Reinforcement Cement ConcretingShan THALANo ratings yet

- TDS AddCrete SC 1100engDocument1 pageTDS AddCrete SC 1100engEldin PepelarNo ratings yet

- TDS AddCrete SC 1100engDocument1 pageTDS AddCrete SC 1100engNedim HrustićNo ratings yet

- Improvements To Internal Raods of Manyata Embassy Bussiness Park BangaloreDocument6 pagesImprovements To Internal Raods of Manyata Embassy Bussiness Park BangaloreHarish KulkarniNo ratings yet

- A223 6 44 0074Document15 pagesA223 6 44 0074mishtinilNo ratings yet

- Cleaning and Cement LiningDocument8 pagesCleaning and Cement LiningLudi D. LunarNo ratings yet

- GDP 25NotesforworkingsnearGTPDocument4 pagesGDP 25NotesforworkingsnearGTPtmarizNo ratings yet

- 35 (V) - Concrete PumpDocument9 pages35 (V) - Concrete PumpPrasanta ParidaNo ratings yet

- Narrative ConcretingDocument3 pagesNarrative ConcretingJune Mark AwingNo ratings yet

- B. Das & Associates - P - Ltd. - Dankuni - Chandannagar, - 22.07.2019 PDFDocument4 pagesB. Das & Associates - P - Ltd. - Dankuni - Chandannagar, - 22.07.2019 PDFRaju Aich100% (1)

- Method Statment For Diverted Vally Water-Realigned Access Road-N301Document7 pagesMethod Statment For Diverted Vally Water-Realigned Access Road-N301vinayp talpadaNo ratings yet

- Section P3001 Particular Concrete RequirementsDocument2 pagesSection P3001 Particular Concrete RequirementsClark HonradoNo ratings yet

- Sop For Set Up & Operation of Concrete PumpDocument3 pagesSop For Set Up & Operation of Concrete Pumplelu ojhaNo ratings yet

- Section 5-Part 8-Transportation and Placing of ConcreteDocument6 pagesSection 5-Part 8-Transportation and Placing of ConcreteAdamNo ratings yet

- Qcs 2010 Section 5 Part 8 Transportation and Placing of ConcreteDocument7 pagesQcs 2010 Section 5 Part 8 Transportation and Placing of Concretebryanpastor106No ratings yet

- 36CBM SK RBDocument13 pages36CBM SK RBJayadev KarthaNo ratings yet

- NHConcrete Pump NewsflashDocument5 pagesNHConcrete Pump Newsflashmelo1No ratings yet

- Kick-Off Meeting - Pipe CulvertsDocument12 pagesKick-Off Meeting - Pipe CulvertsShabbar Abbas MalikNo ratings yet

- Eoecdo 6 H 2 RW 65 DelDocument64 pagesEoecdo 6 H 2 RW 65 Delsreejukumar27No ratings yet

- Method of Bored Piling Work Botanica Residence Project: Proposal Bore PileDocument3 pagesMethod of Bored Piling Work Botanica Residence Project: Proposal Bore PileNurfandy DewantoNo ratings yet

- Improper Practices On SiteDocument1 pageImproper Practices On SiteFranklin BasconNo ratings yet

- viewNitPdf 1454067Document8 pagesviewNitPdf 1454067laxmiccNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument8 pagesPDF Created With Pdffactory Pro Trial VersionSeán Mc CannNo ratings yet

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001No ratings yet

- Name of Work:-Providing Irrigation Facilities To SC Farmers by Construction of Open Well & Pump House in Sy - No.86 & 126 of Kantisangavi Village of Jewargi Taluka. Ra Bill First & PartDocument9 pagesName of Work:-Providing Irrigation Facilities To SC Farmers by Construction of Open Well & Pump House in Sy - No.86 & 126 of Kantisangavi Village of Jewargi Taluka. Ra Bill First & PartshivapannaleNo ratings yet

- Gavel Packer Technical GP Proposal Bengala 5 V1Document16 pagesGavel Packer Technical GP Proposal Bengala 5 V1Cerón Niño SantiagoNo ratings yet

- Sewer Connection Application Guidance PDFDocument7 pagesSewer Connection Application Guidance PDFSamuel FuentesNo ratings yet

- Pre-Purchased Fuel Oil Tank and Pump Set Shop Drawing (RWC)Document16 pagesPre-Purchased Fuel Oil Tank and Pump Set Shop Drawing (RWC)Arm WarriorNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- RT Tunnel - BA Anchors-ModelDocument1 pageRT Tunnel - BA Anchors-ModelJohnNo ratings yet

- Raisebore Stability Assessment of An Upcast Ventilation ShaftDocument11 pagesRaisebore Stability Assessment of An Upcast Ventilation ShaftJohnNo ratings yet

- U 1 01 15Document1 pageU 1 01 15JohnNo ratings yet

- U 1 01 02Document1 pageU 1 01 02JohnNo ratings yet

- DOKA Concrete RevolverDocument1 pageDOKA Concrete RevolverJohnNo ratings yet

- Ijciet 07 03 019Document9 pagesIjciet 07 03 019JohnNo ratings yet

- 54593+89+BIF BAF+Chemical+Free+Iron+Filter+ManualDocument40 pages54593+89+BIF BAF+Chemical+Free+Iron+Filter+ManualJohnNo ratings yet

- SR2211120689893Document3 pagesSR2211120689893JohnNo ratings yet

- As Q Luko Risk Management Part 1Document8 pagesAs Q Luko Risk Management Part 1JohnNo ratings yet

- Is 12918 1990Document11 pagesIs 12918 1990JohnNo ratings yet

- Processes 10 01376Document18 pagesProcesses 10 01376JohnNo ratings yet

- Fence Opt-2Document1 pageFence Opt-2JohnNo ratings yet

- Dyuthi T0355 PDFDocument253 pagesDyuthi T0355 PDFJohnNo ratings yet

- VR 20220425 Geostructural Industrial PDFDocument6 pagesVR 20220425 Geostructural Industrial PDFJohnNo ratings yet

- FCS JV Office PDFDocument356 pagesFCS JV Office PDFJohnNo ratings yet

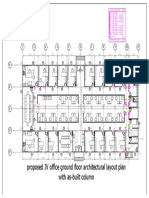

- JV Office As-Built Columns Layout Plan - 03-08-2023Document1 pageJV Office As-Built Columns Layout Plan - 03-08-2023JohnNo ratings yet

- 10005VSA Otc11bDocument46 pages10005VSA Otc11bJohnNo ratings yet

- Self Healing ConcreteDocument15 pagesSelf Healing ConcreteJohnNo ratings yet

- 2.15. Risk ScheduleDocument33 pages2.15. Risk ScheduleJohnNo ratings yet

- Mvu l95 Data Sheet Eng 395238Document8 pagesMvu l95 Data Sheet Eng 395238JohnNo ratings yet

- 001 Removal - of - Iron - From - Industrial - Ground - WaterDocument5 pages001 Removal - of - Iron - From - Industrial - Ground - WaterJohnNo ratings yet

- Project Job Number Engineer: Error: Section Overstressed Warning: KL/R 200 (AISC E2)Document2 pagesProject Job Number Engineer: Error: Section Overstressed Warning: KL/R 200 (AISC E2)JohnNo ratings yet

- KENT Iron Removal Filter ManualDocument9 pagesKENT Iron Removal Filter ManualJohnNo ratings yet

- Fire Safety Solutions For Tunnels - Siemens Building TechnologiesDocument2 pagesFire Safety Solutions For Tunnels - Siemens Building TechnologiesJohnNo ratings yet

- Counter WT Slab CracksDocument161 pagesCounter WT Slab CracksJohnNo ratings yet

- Functional Evaluation of Change Order and Invoice Management Processes Under Different Procurement Strategies: Social Network Analysis ApproachDocument12 pagesFunctional Evaluation of Change Order and Invoice Management Processes Under Different Procurement Strategies: Social Network Analysis ApproachJohnNo ratings yet

- Stop Gates and Bar ScreenDocument4 pagesStop Gates and Bar ScreenGauravNo ratings yet

- Materials Selection For A Carbon Fibre FrameDocument11 pagesMaterials Selection For A Carbon Fibre FramePablo Jaramillo100% (1)

- A4. Force - CE Marking of Attached Steel Components On Storage TanksDocument16 pagesA4. Force - CE Marking of Attached Steel Components On Storage Tanksmarin cristianNo ratings yet

- Deep BeamDocument16 pagesDeep BeamrajasekharNo ratings yet

- John Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialsDocument8 pagesJohn Harvey and Samantha Birch: Important Factors in The Selection of Steel Ladle Lining MaterialssadhuNo ratings yet

- Bahay Pare Bridge: Department of Public Works and Highways Region IiiDocument21 pagesBahay Pare Bridge: Department of Public Works and Highways Region IiimacNo ratings yet

- IVAMA Association - List of Technical WebinarsDocument4 pagesIVAMA Association - List of Technical Webinarsaakash kumarNo ratings yet

- Disassembly of Screw JackDocument1 pageDisassembly of Screw JackSantosh KonduskarNo ratings yet

- CertificateDocument28 pagesCertificateKhaldi KaisNo ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForDocument11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForDalberto RamirezNo ratings yet

- Chapter 4 Metal Craft IiaDocument3 pagesChapter 4 Metal Craft IianicoleNo ratings yet

- Reinforced Concrete Design For Thermal Effects On Nuclear Power Plant StructuresDocument30 pagesReinforced Concrete Design For Thermal Effects On Nuclear Power Plant StructuresFred PrzNo ratings yet

- PHB 2018 GBDocument196 pagesPHB 2018 GBDareyoss NegussieNo ratings yet

- SmartPlant Instrumentation FlierDocument2 pagesSmartPlant Instrumentation Fliertexwan_No ratings yet

- Scroll: Packaged & Split-SystemsDocument24 pagesScroll: Packaged & Split-SystemsDavid SanchezNo ratings yet

- Accepted Manuscript: 10.1016/j.polymertesting.2015.01.020Document32 pagesAccepted Manuscript: 10.1016/j.polymertesting.2015.01.020Dharun TNo ratings yet

- Building TechnologyDocument3 pagesBuilding TechnologyClaro III TabuzoNo ratings yet

- Table of Content:: Mechanics of A Lamina Fibre Composites, FS20 Masoud Motavalli 1Document81 pagesTable of Content:: Mechanics of A Lamina Fibre Composites, FS20 Masoud Motavalli 1Joshua KarthikNo ratings yet

- Data Sample HondaDocument183 pagesData Sample HondaBilal Khan BangashNo ratings yet

- Presentation 2Document20 pagesPresentation 2Arvee VillamorNo ratings yet

- Cross-Section Properties: GeometryDocument2 pagesCross-Section Properties: GeometryFilip StojkovskiNo ratings yet

- Hpac - 201301Document69 pagesHpac - 201301Antonio LebrunNo ratings yet

- C Range Anchor: CompositionDocument1 pageC Range Anchor: CompositionDejan JanevNo ratings yet