Professional Documents

Culture Documents

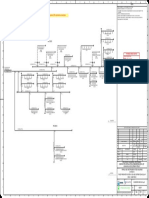

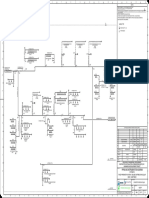

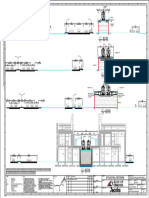

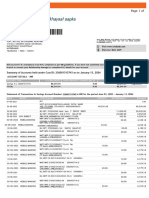

30lbe51br411-Rev 1

Uploaded by

Mohd Effiezool YaserOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

30lbe51br411-Rev 1

Uploaded by

Mohd Effiezool YaserCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

NPD Weight

Description Qty

[DN] [Kg]

N

A A

INSULATION:

INS_HC_180 INSULATION:

INS_HC_100

167MM BEND RADIUS 167

+X=-1160/13-30UMY01

+Y=+1619/B-30UMY01 7

26

B +Z=+1532 B

10 6

0

0 7.3 230

10

4

1.8

1.6 5

20

0 38

2.1 5

C C

30LBE51AA411

STEM S 88.57 U INSULATION:

07-0025-228 INS_HC_100

1.9

S5.1

INSULATION:

RH-02

08 230 INS_HC_50

28 S3.2

US-03A 1 PIPE-SMLS, S-STD, A335-P11, ASME-B36.10M 25 7.4 M 18.4

2 THROTTLE VALVE, CL1500, A182-F22, ASME B16.34 25 2 15.0

75 7 8 3 UNDER SUPPORT 25 2 -

167MM BEND RADIUS 21 4 GUIDE SUPPORT 25 1 -

+X=-4400/13-30UMY01 2.2 5 RIGID HANGER 25 1 -

+Y=+1619/B-30UMY01 30LBE51AA412 6 PIPE BEND 5D RADIUS (88.6 DEG), S-STD, A335-P11, 25 0.6 M 1.3

D +Z=+1613 STEM S 88.57 U ASME-B36.10M

D

14

07-0025-228 20 7 PIPE BEND 5D RADIUS (90.0 DEG), S-STD, A335-P11, 25 0.8 M 2.0

ASME-B36.10M

163

167

S4.1

7

66 GS-03A

163

167

E E

167MM BEND RADIUS

6.2 +X=-1160/13-30UMY01

10 +Y=-1075/B-30UMY01

0 +Z=+1464

40.0

PENGERANG POWER SDN BHD

7.2 (Company No. 1089490-K)

25NPD

626

Level 51, Tower 2, PETRONAS Twin Towers

1.11

Kuala Lumpur City Centre

3 50088 Kuala Lumpur, Malaysia

SEE ISO

F 30LBE51BR002 1.4 F

+X=+3650/12-30UMY01

+Y=+120/B-30UMY01 10 PETRONAS PETRONAS TECHNICAL SERVICES SDN BHD

66 TECHNICAL

+Z=+1961 (Company No. 347848-X)

CONN TO SERVICES

Tower 1, PETRONAS Twin Towers

30GMY10BZ002-H12 Kuala Lumpur City Centre

1 25, Loose connection

S3.1 50088 Kuala Lumpur, Malaysia

+X=-1160/13-30UMY01

US-03A

+Y=-1075/B-30UMY01

167MM BEND RADIUS +Z=+675

25NPD

40 167 +X=-4400/13-30UMY01

0 +Y=+120/B-30UMY01

+Z=+1650

G G

7.1

124

1.2 0

10

167

AG Malaysia Sdn Bhd MMC

H H

0 Siemens AG Siemens Malaysia Sdn. Bhd. MMC Engineering Services Sdn Bhd

6.1 52 Level 1, Reception, CP Tower unit 702, Level 7, Wisma Zelan

PG ES PM No. 11, Jalan 16/11 No. 1, Jalan Tasik Permaisuri 2

163 Pusat Dagang Seksyen 16 Bandar Tun Abdul Razak

63067 Offenbach, Germany 46350 Petaling Jaya, Malaysia 56000 Kuala Lumpur

Malaysia

SEONGHWA

167MM BEND RADIUS Industrial Co., Ltd

+X=+3650/12-30UMY01

163

+Y=+120/B-30UMY01 PCP-SAG-PIP-ISO-LBE-479533

+Z=+1674 Ursprung/Original Ursprung-Nr./Original-No. REV Urspr.-PKZ-Nr.

J Orig.-PC J

MY1008-30LBE51-&MTB020-111492 00/00

PENGERANG COGENERATION PLANT MY1008

446539331 &MTC030

INCH-DIA

K 30LBE51BR411 K

SHOP 0 479533

FIELD 8.4 L/M SPISO PLMS-P

01_00 2016-07-01 S.W.Kim J.W.Han REVISED AS MARKED

THK THK THK FIELD SHOP 00_01 2016-04-21 S.W.Kim J.W.Han FIRST ISSUE

(mm) (mm) (mm) in% BW SW RFN FIL in% BW SW RFN FIL Definition 00_00 2016-05-26 S.W.Kim J.W.Han RELEASED FOR EXECUTION

1 25 F BW 33.4 3.38 No R 100 0 0 0 R 100 0 0 0 Radiographic Examination

2 25 F BW 33.4 3.38 No U 0 0 0 0 U 0 0 0 0 Ultasonic Examination.

80

3 25 F BW 33.4 3.38 No P P Liquid Penetration Examination

0 0 0 0 0 0 0 0

4 25 F BW 33.4 3.38 No - -

S 100 100 100 100 S 100 100 100 100 Magnetic Examination

5 25 F BW 33.4 3.38 No

L 6 25 F BW 33.4 3.38 No H 0 0 0 0 H 0 0 0 0 Hardness Testing

7 25 F BW 33.4 3.38 No M 10 0 10 10 M 10 0 10 10 Metascope or ferritic check 2016-04-21 M.J.Shin Piping

8 25 F BW 33.4 3.38 No V V Visual Examination 2016-04-21 S.W.Kim

Exportkennzeichnung AL: ECCN:

Remarks

100 100 100 100 100 100 100

The extent of NDE is mandatory for shop and field welds of the

100

2016-04-21 J.W.Han

Isometric 30LBE51BR411

respective piping system as a designated lot.

Bearbeitung dieses Dokumentes, Verwertung und Mitteilung

- Final dimensions of valves and in- line components to be

checked by erection contractor before installation. General Weld type Addition for extent of NDE below 100%: All materials, all nominal pipe sizes Building: 30UMY

gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz.

- Pipe routing NPS < 3" (DN80) should be Position number acc. partlist BW : Butt weld and all welders shall be considered for a random spot examination of welds

bzw bei Kennzeichen "AL:N" oder "ECCN:N", kann sich eine Genehmigungspflicht, unter anderem

checked by erection contractor at site Shop weld number SW : Socket weld Set of Rules for

oder Geschmacks-mustereintragung vorbehalten. Insulation 180 mm

- All pipes without fit-up allowance Field weld number O-LET : Weldolet, sockolet Construction

Transmittal, reproduction, dissemination and/or editing of this Export classification AL: ECCN: - Fit-up allowance of pipe = 150mm, Support type RFN : Reinforce Nozzle

Pipe Material Class A90A1RA0120 max. allow. work. Temperature 470 C 01_00

M document as well as utilization of its contents and Goods labeled with "AL not equal to N" are subject to European or German export authorization which is additional marked with "+150" KKS-support number FIL : Fillet

20

communication thereof to others without express authorization when being exported out of the EU. Goods labeled with "ECCN not equal to N" are subject to US - For Part No. only figure before dot to be Slope SF : Socket Fusion MY1008-30LBE51-&MTC030-479533

are prohibited. Offenders will be held liable for payment of matched with BOM Part No.

Internal Coating max. allow. work. Pressure 67 bar

reexport authorization. Even without a label, or with label "AL:N" or"ECCN:N", authorization may be Flow direction F : Field weld

damages. All rights created by patent grant or registration of a - For shop pre-fabrication Referance S : Shop weld

utility model or design patent are reserved.

required due to the final whereabouts and purpose for which the goods are to be used.

drawing no. External Coating MY1008-61810-&MDC080-484504 Test Pressure 100.5 bar 1 /1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

You might also like

- Fidelity Bond Application Form FBAFDocument2 pagesFidelity Bond Application Form FBAFMark Idaloy0% (1)

- Golden Joint Procedure Rev1Document9 pagesGolden Joint Procedure Rev1Mohd Effiezool Yaser100% (3)

- HK Kumar Digest of Important LawsDocument233 pagesHK Kumar Digest of Important Lawshello100% (1)

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- Project Specification Piping Class SummaryDocument41 pagesProject Specification Piping Class SummaryMohd Effiezool YaserNo ratings yet

- Rio Tinto Standard DetailsDocument34 pagesRio Tinto Standard DetailsHCStepNo ratings yet

- Asme Section Ix InterpretationsDocument77 pagesAsme Section Ix Interpretationsहेमंत कुमार मीणाNo ratings yet

- Sample Request Letter For Authority To Practice The Legal ProfessionDocument3 pagesSample Request Letter For Authority To Practice The Legal ProfessionJOHN VINCENT S FERRER100% (1)

- 30LBF11BR411 - 2Document1 page30LBF11BR411 - 2Mohd Effiezool YaserNo ratings yet

- Iso 20lae05aa101Document1 pageIso 20lae05aa101Mohd Effiezool YaserNo ratings yet

- 30lbe51br303 - Rev 0Document1 page30lbe51br303 - Rev 0Mohd Effiezool YaserNo ratings yet

- 30lbe51br302 - Rev 0Document1 page30lbe51br302 - Rev 0Mohd Effiezool YaserNo ratings yet

- 30lbe51br002-Rev 1Document1 page30lbe51br002-Rev 1Mohd Effiezool YaserNo ratings yet

- 30lbe51br301 - Rev 0Document1 page30lbe51br301 - Rev 0Mohd Effiezool YaserNo ratings yet

- 10lab12br001-Rev 1 - 2Document1 page10lab12br001-Rev 1 - 2Mohd Effiezool YaserNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- A Detail: Piping Isometric BuildingDocument1 pageA Detail: Piping Isometric BuildingMohd Effiezool YaserNo ratings yet

- 10lab12br001-Rev 1 - 1Document1 page10lab12br001-Rev 1 - 1Mohd Effiezool YaserNo ratings yet

- Pile DrawingDocument1 pagePile DrawingAri AdityaNo ratings yet

- SP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Document1 pageSP0793-6186-15-0020 - PVDC EXPANSION PROJECT LIME STONE MILLING BALL OFFLOADING CONCRETE LAYOUT AND DETAILS Rev.1Hector HernandezNo ratings yet

- 05-KSCPP-B-1906 - A - Code 2Document1 page05-KSCPP-B-1906 - A - Code 2Mohd KhaidirNo ratings yet

- TECHNICALPart 5Document1,521 pagesTECHNICALPart 5সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Section Detail: J-DmsDocument1 pageSection Detail: J-DmsMary DenizeNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Mohd KhaidirNo ratings yet

- B01 TL103P1Document1 pageB01 TL103P1alysamir.eetdNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- GT A GT B GT D GT F GT G GT E GT C: 400Kv Switchyard EquipmentDocument1 pageGT A GT B GT D GT F GT G GT E GT C: 400Kv Switchyard EquipmentS Rao CheepuriNo ratings yet

- B011 000 16 50 01205 - Rev 2Document1 pageB011 000 16 50 01205 - Rev 2GLOBUS ENGINEERSNo ratings yet

- M007 MML Arc DWG Ucstedu CL 00201 - Rev4.0Document1 pageM007 MML Arc DWG Ucstedu CL 00201 - Rev4.0whalet74No ratings yet

- Rbs College StationDocument1 pageRbs College StationPooja waniNo ratings yet

- Section A-A: Issued For ConstructionDocument1 pageSection A-A: Issued For ConstructionjafarNo ratings yet

- 915 11531 - Rev 4Document1 page915 11531 - Rev 4Sonu KumarNo ratings yet

- Ed 0900 PRS Pid 000 09041CDocument1 pageEd 0900 PRS Pid 000 09041CMohamed ArafaNo ratings yet

- B01 TL101P2Document1 pageB01 TL101P2alysamir.eetdNo ratings yet

- Longprofile Priok - Muara Tawar T.18 - 19Document1 pageLongprofile Priok - Muara Tawar T.18 - 19Faiz LidinillahNo ratings yet

- 100 S 2021 Standard Details 10 (RC) r0Document1 page100 S 2021 Standard Details 10 (RC) r0HiubartNiponMurmuNo ratings yet

- P4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011Document1 pageP4c02-Snw-Tv-Mec-Sgt-Sho-2010 - Ecs-Street Level Ducting Layout Key Plan-P4c02-Snw-Tv-Mec-Sgt-Sho-2011ManojNo ratings yet

- 07Document1 page07camilo andres cutiva caraballoNo ratings yet

- Nomenclature:: - 31710MM - 31710MMDocument1 pageNomenclature:: - 31710MM - 31710MMjoselito navarroNo ratings yet

- Vu 1108 070822Document1 pageVu 1108 070822api-3698996No ratings yet

- B01 TL102P1Document1 pageB01 TL102P1alysamir.eetdNo ratings yet

- B01 TL101P1Document1 pageB01 TL101P1alysamir.eetdNo ratings yet

- X0231 PDW Ecb DG 20003 AaDocument1 pageX0231 PDW Ecb DG 20003 AajianranrenNo ratings yet

- Notes:-: Timber Doors Key PlanDocument1 pageNotes:-: Timber Doors Key PlanKumudu PereraNo ratings yet

- Existing - Earthing - Layout For Bogra 230kV SubstationDocument1 pageExisting - Earthing - Layout For Bogra 230kV SubstationRashad SarwarNo ratings yet

- Legend: Project Name: LPIC EPC1 SCUDocument1 pageLegend: Project Name: LPIC EPC1 SCUjeswinNo ratings yet

- A2 Km. 186+580 ST PDFDocument1 pageA2 Km. 186+580 ST PDFciciNo ratings yet

- Nabil Abbas: New Ikea StoreDocument1 pageNabil Abbas: New Ikea Storewalid MegahedNo ratings yet

- Detail Buttress (4X) Section 4 - 4 Detail Buttress (4X) Section 5 - 5Document1 pageDetail Buttress (4X) Section 4 - 4 Detail Buttress (4X) Section 5 - 5joselito navarroNo ratings yet

- 15PG-09-LB - MDD-IBE-160 Rev 6 P&ID. Steam SystemDocument4 pages15PG-09-LB - MDD-IBE-160 Rev 6 P&ID. Steam SystemAssdfNo ratings yet

- SGH-P900 Schematics PDFDocument8 pagesSGH-P900 Schematics PDFWilinton PissoNo ratings yet

- TT18J E 00 - Circuit (20120229)Document6 pagesTT18J E 00 - Circuit (20120229)kelmal KELMALLNo ratings yet

- 02 Planos Estructurales CF001Document1 page02 Planos Estructurales CF001GERARDO PINCAY BRAWNNo ratings yet

- Va 1302 070822Document1 pageVa 1302 070822api-3698996No ratings yet

- D038 Evs Co000 1091 - 00Document1 pageD038 Evs Co000 1091 - 00Mussarat BabasahebNo ratings yet

- 3-ModelDocument1 page3-Modeljoselito navarroNo ratings yet

- Balcon C1Document1 pageBalcon C1Laura GeorgianaNo ratings yet

- JFN01 05 027 CDocument1 pageJFN01 05 027 Cluca.laniNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- 0-ModelDocument1 page0-Modeljoselito navarroNo ratings yet

- 01-T.C.-1 NIVEL (18462) - Layout1Document1 page01-T.C.-1 NIVEL (18462) - Layout1samuel hernandezNo ratings yet

- Workplot: Not For ProductionDocument1 pageWorkplot: Not For ProductionOmkar TodkarNo ratings yet

- 5S4 Pipe Support DrawingDocument1 page5S4 Pipe Support DrawingMohd Effiezool YaserNo ratings yet

- Proposed PipeDocument1 pageProposed PipeMohd Effiezool YaserNo ratings yet

- PTS Vs IP & JotunDocument8 pagesPTS Vs IP & JotunMohd Effiezool YaserNo ratings yet

- 001-FP 001Document2 pages001-FP 001Mohd Effiezool YaserNo ratings yet

- MTW NOVATORK AR040983 20-100N.m 12 OCT 22Document2 pagesMTW NOVATORK AR040983 20-100N.m 12 OCT 22Mohd Effiezool YaserNo ratings yet

- Pipe Bend ReportDocument1 pagePipe Bend ReportMohd Effiezool Yaser100% (1)

- 30lae25br005-Rev 2Document1 page30lae25br005-Rev 2Mohd Effiezool YaserNo ratings yet

- 30lbe51br001-Rev 2 - 2Document1 page30lbe51br001-Rev 2 - 2Mohd Effiezool YaserNo ratings yet

- MTW KING TOYO 438745 50-300N.m 14 JAN 23Document2 pagesMTW KING TOYO 438745 50-300N.m 14 JAN 23Mohd Effiezool YaserNo ratings yet

- PCP Sag Pip DWG 480460Document2 pagesPCP Sag Pip DWG 480460Mohd Effiezool YaserNo ratings yet

- 30lbf11br001-Rev 2Document1 page30lbf11br001-Rev 2Mohd Effiezool YaserNo ratings yet

- Markup Finding CCC (Insulated)Document1 pageMarkup Finding CCC (Insulated)Mohd Effiezool YaserNo ratings yet

- 30LBF11BR411 - 1Document1 page30LBF11BR411 - 1Mohd Effiezool YaserNo ratings yet

- Welding Olet As ASME B31.3Document1 pageWelding Olet As ASME B31.3Mohd Effiezool YaserNo ratings yet

- Markup Finding PCC (Insulated)Document1 pageMarkup Finding PCC (Insulated)Mohd Effiezool YaserNo ratings yet

- Markup Finding PL (Insulated)Document1 pageMarkup Finding PL (Insulated)Mohd Effiezool YaserNo ratings yet

- Jotun LatterDocument1 pageJotun LatterMohd Effiezool YaserNo ratings yet

- Welding Olet As PTSDocument1 pageWelding Olet As PTSMohd Effiezool YaserNo ratings yet

- Mandatory Appendix 5 - Guideline On The Approval of New Materials Under The ASME BPV CodeDocument4 pagesMandatory Appendix 5 - Guideline On The Approval of New Materials Under The ASME BPV CodeMohd Effiezool YaserNo ratings yet

- Product Data BulletinDocument2 pagesProduct Data BulletinMohd Effiezool YaserNo ratings yet

- Piping Standard and SpecificationDocument22 pagesPiping Standard and SpecificationMuhamad Firdaus Bin Azizan100% (5)

- Practical Plate InspectionDocument8 pagesPractical Plate InspectionMohd Effiezool Yaser100% (1)

- ANSI Vs APIDocument2 pagesANSI Vs APIMohd Effiezool YaserNo ratings yet

- Appendix D - Specification For Coating & Wrapping of Underground PipiDocument13 pagesAppendix D - Specification For Coating & Wrapping of Underground PipivgestantyoNo ratings yet

- Underground PipingDocument27 pagesUnderground PipingMohd Effiezool Yaser100% (1)

- EconomicDevelopment MainsDocument4 pagesEconomicDevelopment MainsUtsav NishantNo ratings yet

- ICICI - Naveen ChandaDocument8 pagesICICI - Naveen Chandawintage23No ratings yet

- Lesson 2.6 - Suppy-Demand and Philippine Economic Problems-GENES, IGNACIO, MAY and OQUENDODocument20 pagesLesson 2.6 - Suppy-Demand and Philippine Economic Problems-GENES, IGNACIO, MAY and OQUENDOAndrea Nicole HernandezNo ratings yet

- General Duty Medical OfficerDocument3 pagesGeneral Duty Medical OfficerTopRankersNo ratings yet

- Computer Application Notes 2024 Cabutinaira MiyakaDocument5 pagesComputer Application Notes 2024 Cabutinaira Miyakajucar fernandezNo ratings yet

- Immigration ReceiptDocument2 pagesImmigration Receipthenry okilaNo ratings yet

- Macroeconomics 9th Edition Mankiw Solutions ManualDocument35 pagesMacroeconomics 9th Edition Mankiw Solutions Manualmargaretjacksonch3nin100% (25)

- Shreveport City Council Agenda For October 26 2021Document13 pagesShreveport City Council Agenda For October 26 2021Curtis HeyenNo ratings yet

- Public EnterpriseDocument43 pagesPublic EnterpriseFarah Raihana522No ratings yet

- Cynamid Phil V Ca Tax Case DigestDocument1 pageCynamid Phil V Ca Tax Case DigestchablNo ratings yet

- Hotel White OakDocument1 pageHotel White OakCA Udit HurkatNo ratings yet

- Fingerprinting InstructionsDocument1 pageFingerprinting InstructionsTimothy WilliamsNo ratings yet

- ABAKADA VS ERMITA Case SyllabusDocument15 pagesABAKADA VS ERMITA Case SyllabusWræn ŸåpNo ratings yet

- Od 329783056775680100Document1 pageOd 329783056775680100adityashastrakar6No ratings yet

- Ingat Angat: Safety Seal: April 2021Document27 pagesIngat Angat: Safety Seal: April 2021Maria Fiona Duran MerquitaNo ratings yet

- Mtb-Mle: Quarter 1-Module 1, Week 1: Saken Ago So Pamiliya AkenDocument22 pagesMtb-Mle: Quarter 1-Module 1, Week 1: Saken Ago So Pamiliya AkenFahadNo ratings yet

- PYBOM00347440000064737 NewDocument4 pagesPYBOM00347440000064737 New4608 VANSHIKA SHARMANo ratings yet

- Kyc Info Sheet - Neurónio Do Tempo, LdaDocument3 pagesKyc Info Sheet - Neurónio Do Tempo, LdaSerRiquinhoNo ratings yet

- Memorandum: Nihon Sekkei, Inc. - 1Document7 pagesMemorandum: Nihon Sekkei, Inc. - 1Son PhanNo ratings yet

- Laporan Jualan Tiket Ets KTM BULAN 2/20 Padang Besar - KL Sentral - GemasDocument5 pagesLaporan Jualan Tiket Ets KTM BULAN 2/20 Padang Besar - KL Sentral - Gemasazlina osmanNo ratings yet

- EnrollmentDocument38 pagesEnrollmentSachin SharmaNo ratings yet

- I Disagree with-WPS OfficeDocument3 pagesI Disagree with-WPS OfficeLeighsen VillacortaNo ratings yet

- Morocco MIDDLE EAST AND NORTH AFRICA P151169 Supporting The Economic Inclusion of Youth Procurement PlanDocument4 pagesMorocco MIDDLE EAST AND NORTH AFRICA P151169 Supporting The Economic Inclusion of Youth Procurement Planrabhi fouadNo ratings yet

- Chapter 2 - National Difference in Political EconomyDocument52 pagesChapter 2 - National Difference in Political EconomyTroll Nguyễn VănNo ratings yet

- Final Details For Order #407-5078757-1351518: Dispatched On 21 June 2020Document1 pageFinal Details For Order #407-5078757-1351518: Dispatched On 21 June 2020Rishav RajNo ratings yet

- The General Concept of Auditing in EthioDocument20 pagesThe General Concept of Auditing in Ethioh84% (19)

- SPA - Seller's Authorized Representative (Clean)Document2 pagesSPA - Seller's Authorized Representative (Clean)Ellaine D RamirezNo ratings yet