Professional Documents

Culture Documents

Manufactured Boards

Uploaded by

api-6022373920 ratings0% found this document useful (0 votes)

22 views10 pagesOriginal Title

manufactured boards

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views10 pagesManufactured Boards

Uploaded by

api-602237392Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

Manufactured boards

Making boards and sheets from wood or wood

products

• Veneers

• Sawdust

• Wood fibers

• Wood strips

• Wood flakes

Manufactured boards

What are the properties of manufactured

boards?

• Large sheets

• Uniform thickness

• Smooth surfaces

• Strong boards

• Few defects

• Easy to work with

• Relatively cheap

• Can be finished with decorative veneer

• They reduce waste by using wood

efficiently

Plywood

Make-up of plywood: Cutting the

• Veneers at 90° to each other

veneer

• Odd number of layers (5/7)

Producing veneers

Cut from a log – two methods

Types of plywood

WBP

•Water and Boil

Proof

•Exterior grade

Marine plywood

•Boat building

•Exposed

situations, roofs

Blockboard

•Strips of softwood

glued together and

faced with veneers

•Does not split

easily

•Can screw into the

edge

•Wide sheets (8’ X

4’)

Pineboard/lamwood

•Made from thin

softwood strips, glued

together

•Makes a wide board in

softwood

•Uniform thickness (12

– 25mm)

•Boards tend to cup

•Useful for projects

•Hardwood examples

can be obtained

OSB – oriented strand board

•Made from wood

flakes/strands

bonded with resins

into a strong board.

•The strands are

arranged so they

overlap

•Standard sheet

sizes

•Used for flooring

and construction

Chipboard

• Wood chips are

glued

• Pressed into

sheets

• Often faced with

wood veneer or

plastic laminate

• Edges of the

board need to be

covered

Chipboard

You might also like

- Build Your Own Inexpensive Dollhouse: With One Sheet of 4' by 8' Plywood and Home ToolsFrom EverandBuild Your Own Inexpensive Dollhouse: With One Sheet of 4' by 8' Plywood and Home ToolsRating: 4.5 out of 5 stars4.5/5 (3)

- Engineered TIMBER PRODUCTSDocument9 pagesEngineered TIMBER PRODUCTSAr Ayoushika AbrolNo ratings yet

- Wood Finishes Final 24-08Document40 pagesWood Finishes Final 24-08Sanal SamsonNo ratings yet

- Manufactured BoardsDocument13 pagesManufactured Boardsapi-268923331No ratings yet

- manufactured boards mr flanneryDocument17 pagesmanufactured boards mr flanneryapi-548177991No ratings yet

- 873 - 52 - 473 - Module 1 Wood SubstitutesDocument18 pages873 - 52 - 473 - Module 1 Wood SubstitutesAlexNo ratings yet

- Presentation 23Document25 pagesPresentation 23Vivek MakadiaNo ratings yet

- Disadvantages of WPC BoardDocument32 pagesDisadvantages of WPC BoardvidhiNo ratings yet

- 07f Manufactured BoardsDocument29 pages07f Manufactured BoardsJim Jeus dela CruzNo ratings yet

- Essential Guide to Wood Products for Flooring, Siding, Ceiling, Trims and MouldingsDocument29 pagesEssential Guide to Wood Products for Flooring, Siding, Ceiling, Trims and MouldingsBackupFilesNo ratings yet

- Everything You Need to Know About Special Woods and Wood AlternativesDocument61 pagesEverything You Need to Know About Special Woods and Wood AlternativesnadiajmiNo ratings yet

- Sem 7 MMBC Module 1 - WoodsDocument8 pagesSem 7 MMBC Module 1 - WoodsARTFOLIO .49No ratings yet

- BT5 - WoodsDocument34 pagesBT5 - WoodsHatdugNo ratings yet

- Building MaterialsDocument37 pagesBuilding Materialsjeo TinioNo ratings yet

- Construction Materials: Interior Design 2Nd Semester 9782134439/9024262644Document45 pagesConstruction Materials: Interior Design 2Nd Semester 9782134439/9024262644DARSHAN SAVSAIYANo ratings yet

- Manufactured BoardsDocument29 pagesManufactured Boardsapi-341200208No ratings yet

- Particle BoardDocument51 pagesParticle BoardNUR MAZIAH ATIQAH JAININo ratings yet

- Isd.l1.sem3.sub 1.lakshya Patel PDFDocument20 pagesIsd.l1.sem3.sub 1.lakshya Patel PDFlakshya patelNo ratings yet

- Pre - Engineered Materials and StructuresDocument61 pagesPre - Engineered Materials and Structurescristian santillanNo ratings yet

- Introduction to MDF: Medium Density FiberboardDocument20 pagesIntroduction to MDF: Medium Density Fiberboardanon_414184376No ratings yet

- Veneers and LaminatesDocument31 pagesVeneers and LaminatesVijaya Ratna MNo ratings yet

- Wood#1Document21 pagesWood#1Keith DavisNo ratings yet

- Lec-6 Building Materials - TimberDocument25 pagesLec-6 Building Materials - TimberMr. Shahriar MahmudNo ratings yet

- Manufactured BoardsDocument12 pagesManufactured Boardsapi-381307435No ratings yet

- CARPENTRY AND MASONRY SKILLSDocument49 pagesCARPENTRY AND MASONRY SKILLSFerlynNo ratings yet

- Timber Product Stage 1Document68 pagesTimber Product Stage 1Ayush GuptaNo ratings yet

- Wood Substitutes - Industrial Products As Substitutes ForDocument19 pagesWood Substitutes - Industrial Products As Substitutes ForkunjuvavuNo ratings yet

- Roofing Material Options for Steel StructuresDocument8 pagesRoofing Material Options for Steel StructuresSaliha KabeerNo ratings yet

- 5.e. Plywood, Boards PDFDocument36 pages5.e. Plywood, Boards PDFBASMA FAHIM SIDDIQUINo ratings yet

- Carpentry and Masonry Defects of WoodsDocument8 pagesCarpentry and Masonry Defects of WoodsPamela MarieNo ratings yet

- Advance Construction and MaterialsDocument23 pagesAdvance Construction and MaterialsSaki Saki SakiNo ratings yet

- Tle NotesDocument69 pagesTle NotesDolly Grace GantalaoNo ratings yet

- Building Materials2Document51 pagesBuilding Materials2jeo TinioNo ratings yet

- Veneers: Types, Manufacturing Process & ApplicationsDocument23 pagesVeneers: Types, Manufacturing Process & Applicationsyashaswini100% (2)

- Chapter 10 Manufactured BoardsDocument5 pagesChapter 10 Manufactured Boardsapi-528243784No ratings yet

- BCM-V U1 Part-B 21.06.2021Document44 pagesBCM-V U1 Part-B 21.06.2021hyperloop707 designNo ratings yet

- Lecture 1 Nordic Wood ProductsDocument23 pagesLecture 1 Nordic Wood Productshudco kaamNo ratings yet

- Wood PresentationDocument32 pagesWood PresentationSuBchooNo ratings yet

- MCT SEM 4 Engineer WoodDocument16 pagesMCT SEM 4 Engineer WoodKhushi ChauhanNo ratings yet

- Veneer and Laminates in Residential Construction PresentationDocument36 pagesVeneer and Laminates in Residential Construction PresentationVishakhaBhardwajNo ratings yet

- Bay15 16 PDFDocument23 pagesBay15 16 PDFBob CalebNo ratings yet

- Flooring Materials: 3.04 Understand Materials and Finishes of Residential DesignDocument19 pagesFlooring Materials: 3.04 Understand Materials and Finishes of Residential DesignXiao MaiNo ratings yet

- PPT M.F. TIMBERDocument14 pagesPPT M.F. TIMBERpoojajain8804No ratings yet

- Module 5 Compressive and Flexural Strength of Wood NewDocument31 pagesModule 5 Compressive and Flexural Strength of Wood NewEUREKA JANAH MENDOZANo ratings yet

- Introduction To Plywood IndustryDocument9 pagesIntroduction To Plywood IndustryShakeel AhamedNo ratings yet

- Corian & WoodDocument68 pagesCorian & WoodMuhammad SohailNo ratings yet

- BLOCKBOARDDocument9 pagesBLOCKBOARDANJALI GAUTAM100% (1)

- Wood Substitutes - Industrial Products As Substitutes ForDocument18 pagesWood Substitutes - Industrial Products As Substitutes ForashimaNo ratings yet

- Plywood Types and ApplicationDocument3 pagesPlywood Types and ApplicationVibhor AgrawalNo ratings yet

- Wooden Floors and WallsDocument23 pagesWooden Floors and WallsMuhammad SohailNo ratings yet

- WoodDocument52 pagesWoodMoulya RajuNo ratings yet

- Types of Timber and their UsesDocument35 pagesTypes of Timber and their UsesYash SutharNo ratings yet

- Materials of ConstructionDocument35 pagesMaterials of ConstructionHoney de la TorreNo ratings yet

- Timber: Name:-Yash.H.SutharDocument35 pagesTimber: Name:-Yash.H.SutharYash SutharNo ratings yet

- Wood, Ferrocement - StoneDocument52 pagesWood, Ferrocement - StoneYadhu .msa17No ratings yet

- Interior Material StudyDocument37 pagesInterior Material StudyMaira NoorNo ratings yet

- Wood Composites: By: John Ralph A. MagbanuaDocument13 pagesWood Composites: By: John Ralph A. MagbanuaJohn Ralph A. MagbanuaNo ratings yet

- TreesDocument34 pagesTreesapi-544824973No ratings yet

- Carpentry and MasonryDocument81 pagesCarpentry and MasonryCassandra Noreen Pacayra SantosNo ratings yet

- Week 5 ReflectionsDocument3 pagesWeek 5 Reflectionsapi-602237392No ratings yet

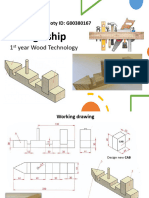

- tutorial paper 2 david culloty g00380167Document3 pagestutorial paper 2 david culloty g00380167api-602237392No ratings yet

- Week 5 ReflectionsDocument3 pagesWeek 5 Reflectionsapi-602237392No ratings yet

- CV - David CullotyDocument2 pagesCV - David Cullotyapi-602237392No ratings yet

- Week 8 ReflectionsDocument2 pagesWeek 8 Reflectionsapi-602237392No ratings yet

- Skills One PowerpointDocument4 pagesSkills One Powerpointapi-602237392No ratings yet

- Week 5 ReflectionsDocument3 pagesWeek 5 Reflectionsapi-602237392No ratings yet

- Week 5 ReflectionsDocument3 pagesWeek 5 Reflectionsapi-602237392No ratings yet

- House SurveyDocument18 pagesHouse Surveyapi-602237392No ratings yet

- Developoments 1 PowerpointDocument36 pagesDevelopoments 1 Powerpointapi-602237392No ratings yet

- Output 2 - ModelsDocument8 pagesOutput 2 - Modelsapi-602237392No ratings yet

- Pictorial DrawingDocument39 pagesPictorial Drawingapi-602237392No ratings yet

- Developoments 1 PowerpointDocument36 pagesDevelopoments 1 Powerpointapi-602237392No ratings yet

- Pictorial DrawingDocument39 pagesPictorial Drawingapi-602237392No ratings yet

- Second Year WT Planning GridDocument6 pagesSecond Year WT Planning Gridapi-602237392No ratings yet

- Cargo Ship PowerpointDocument8 pagesCargo Ship Powerpointapi-602237392No ratings yet

- Paper Towel Holder PowerpointDocument8 pagesPaper Towel Holder Powerpointapi-602237392No ratings yet

- New WT A Planning GridDocument7 pagesNew WT A Planning Gridapi-602237392No ratings yet

- Second Year WT Planning GridDocument6 pagesSecond Year WT Planning Gridapi-602237392No ratings yet