Professional Documents

Culture Documents

PF-ZA-MINOI-SF-058 SGS Risk Assessment - Vessel Sampling

Uploaded by

qoyise.zamaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PF-ZA-MINOI-SF-058 SGS Risk Assessment - Vessel Sampling

Uploaded by

qoyise.zamaCopyright:

Available Formats

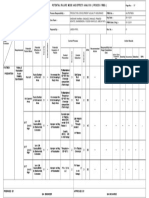

Form

PF-ZA-[MIN(OI)]SF-058

No.

SGS Risk Assessment – Minerals Issue

11/17

No.

Reference Number: OI-HSE- Revision Number: 001

Date of Assessment: Date of Sampling Inspection: 23rdJanuary`2024 Review Date: December`2026

Form Completion(Name): Sizwe Mtintsilana Business Unit: Mineral resources-Trade

Sampling of the stockpile of Manganese ore fines

Location BOT – PE Task/Process: for Moisture Determination and taking photos prior

to the loading of the vessel

Permit/s Required No N/A Other:

Does this task/process require multiple persons? YES Responsible Manager: Nigel Ramlall

INITIAL RISK HAZARD EXPOSURE AND

(Refer to RAM Guidance) ASPECT

FUTHER BARRIERS –

ACTIVITY EXISTING BARRIERS IN Frequency: Hours /week

ENVIRONMENT RESPONSIBILITY,

(Per geographical area and risk/impact)

REQUIRED OF HAZARD PLACE P = People IMPROVED RISK ALARP? H = >35 Hours

AL IMPACT E = Environment

ACTION AND MH = 27 - 35 Hours

TASK/PROCESS

A =Assets TIMESCALE M = 18 - 26 Hours

R =Reputation ML = 9 – 17 Hours

Reference Number

L = 0 – 8 Hours

Provide details of existing

Number of persons exposed

controls. Consider the Risk Detail barriers required to

Mitigation Hierarchy and the risk to ALARP.

describe fully all barriers NOTE: If further barriers

FREQUENCY

List the activities List the hazards against each Could there be a

Environment

applicable for each risk. For have been identified,

required to perform task with the potential to cause release to air, soil

Health

Safety

example if PPE is used as the these additional

the task/process in injury when the task is or water? Will a P E A R P E A R Y/N

barrier, it must be specifically resources/actions must

the sequence that it is performed. Could this hazard waste be

described. All barriers must be be realistic and

carried out hurt anyone working on site generated?

valid in that they reduce achievable. If no further

likelihood, severity or both. barriers have been

NOTE: Existing barriers may be identified, enter “N/A”.

ALARP.

Walk on barricaded area.

Sampling of Mn ore Moving Machinery- All machinery have

which injure a No hooters – communication 3C

BOT fines stockpiles from - 3C 3C - - - YES >35 L

the bins person with the driver.

Wear PPE- reflective

clothing.

Sampling of Mn ore Uneven Surface-

tripping and sharp No PPE provided –wear 3C

BOT fines stockpiles from - 3C 3C - - - YES >35 L

the bins end safety boots

Template PF-(RZA)-[GEN]QU-006 08/12 Page 1 of 3

Form

PF-ZA-[MIN(OI)]SF-058

No.

SGS Risk Assessment – Minerals Issue

11/17

No.

INITIAL RISK HAZARD EXPOSURE AND

(Refer to RAM Guidance) ASPECT

FUTHER BARRIERS –

ACTIVITY EXISTING BARRIERS IN Frequency: Hours /week

ENVIRONMENT RESPONSIBILITY,

(Per geographical area and risk/impact)

REQUIRED OF HAZARD PLACE P = People IMPROVED RISK ALARP? H = >35 Hours

AL IMPACT E = Environment

ACTION AND MH = 27 - 35 Hours

TASK/PROCESS

A =Assets TIMESCALE M = 18 - 26 Hours

R =Reputation ML = 9 – 17 Hours

Reference Number

L = 0 – 8 Hours

Provide details of existing

Number of persons exposed

controls. Consider the Risk Detail barriers required to

Mitigation Hierarchy and the risk to ALARP.

describe fully all barriers NOTE: If further barriers

FREQUENCY

List the activities List the hazards against each Could there be a

Environment

applicable for each risk. For have been identified,

required to perform task with the potential to cause release to air, soil

Health

Safety

example if PPE is used as the these additional

the task/process in injury when the task is or water? Will a P E A R P E A R Y/N

barrier, it must be specifically resources/actions must

the sequence that it is performed. Could this hazard waste be

described. All barriers must be be realistic and

carried out hurt anyone working on site generated?

valid in that they reduce achievable. If no further

likelihood, severity or both. barriers have been

NOTE: Existing barriers may be identified, enter “N/A”.

ALARP.

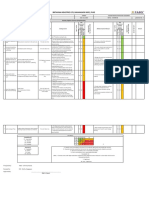

Dust Generated during

Sampling of Mn ore operation from

Manganese which Yes-air Awareness 3

BOT fines stockpiles from 3C 3C 3C - - - YES >35 L

the bins can cause lungs PPE provided C

problem

Don`t climb ontop of a

Material falling from stockpile with a stockpile a

Sampling of Mn ore

the stockpile can hit No Release

height of 2m max.If not

3C

BOT fines stockpiles from

a person during sample where it is safe - 3C 3C - - - YES >35 L

the bins

operation. Awareness training

Only sample inside the

container.

When crushing PPE provided, crushers

samples, the are covered with

Sample Sampling of Mn ore crushers can injure a protective guards and

person if it is No Release 4D

Prep fines stockpiles from have electrical insulators - 3C 3C - - - YES >35 L

SGS lab the bins unguarded, and if and are isolated when not

electrical wiring is in use.

exposed. Training provided.

BOT Sampling of Mn ore Manual handling-bending Manual handling training.

SGS fines from the bins Make sure a person does

while sampling.

Sample and transportation of

Weight of the sample collected

No release not carry above 20kg,if the 2D 2D 2D YES >35 L

Prep samples to SGS

in a bag. weight is above, put the

Lab Sample Prep Lab

samples on FEL.

Template PF-(RZA)-[GEN]QU-006 08/12 Page 2 of 3

Form

PF-ZA-[MIN(OI)]SF-058

No.

SGS Risk Assessment – Minerals Issue

11/17

No.

INITIAL RISK HAZARD EXPOSURE AND

(Refer to RAM Guidance) ASPECT

FUTHER BARRIERS –

ACTIVITY EXISTING BARRIERS IN Frequency: Hours /week

ENVIRONMENT RESPONSIBILITY,

(Per geographical area and risk/impact)

REQUIRED OF HAZARD PLACE P = People IMPROVED RISK ALARP? H = >35 Hours

AL IMPACT E = Environment

ACTION AND MH = 27 - 35 Hours

TASK/PROCESS

A =Assets TIMESCALE M = 18 - 26 Hours

R =Reputation ML = 9 – 17 Hours

Reference Number

L = 0 – 8 Hours

Provide details of existing

Number of persons exposed

controls. Consider the Risk Detail barriers required to

Mitigation Hierarchy and the risk to ALARP.

describe fully all barriers NOTE: If further barriers

FREQUENCY

List the activities List the hazards against each Could there be a

Environment

applicable for each risk. For have been identified,

required to perform task with the potential to cause release to air, soil

Health

Safety

example if PPE is used as the these additional

the task/process in injury when the task is or water? Will a P E A R P E A R Y/N

barrier, it must be specifically resources/actions must

the sequence that it is performed. Could this hazard waste be

described. All barriers must be be realistic and

carried out hurt anyone working on site generated?

valid in that they reduce achievable. If no further

likelihood, severity or both. barriers have been

NOTE: Existing barriers may be identified, enter “N/A”.

ALARP.

Were all action reviewed and agreed upon by all If “No”, indicate

participants? YES reason/s

RISK ASSESSMENT TEAM TEAM MEMBER NAME SIGNATURE DATE

Ramitila Lerata

Aubrey Phaladi

Sizwe Mtintsilana

Nigel Ramlall

Template PF-(RZA)-[GEN]QU-006 08/12 Page 3 of 3

You might also like

- Prod-Fmea-01 PfmeaDocument1 pageProd-Fmea-01 Pfmeaumesh sengarNo ratings yet

- Risk Assessment Template For Combo Roof Waterproofing Work.Document14 pagesRisk Assessment Template For Combo Roof Waterproofing Work.Majaga MabhenaNo ratings yet

- D10369520ADocument4 pagesD10369520AQUALITY ControlNo ratings yet

- HIRA For PEB ShedDocument90 pagesHIRA For PEB ShedSanjeet SinghNo ratings yet

- Hazzard Identification & Risk Assesment SheetDocument1 pageHazzard Identification & Risk Assesment SheetAmit Kumar OjhaNo ratings yet

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Document4 pagesMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaNo ratings yet

- Diesel Generator Site Installation Method Statement: 7.8 Risk AssessmentDocument11 pagesDiesel Generator Site Installation Method Statement: 7.8 Risk AssessmentPowerand ControlNo ratings yet

- Personal Protective Equipment (PPE) Hazard Assessment Certificate InstructionsDocument6 pagesPersonal Protective Equipment (PPE) Hazard Assessment Certificate Instructionsmohammad QutubuddinNo ratings yet

- Working at Height Risk AssessmentsDocument1 pageWorking at Height Risk AssessmentsRajan GuptaNo ratings yet

- How To Report A Hazard in The WorkplaceDocument8 pagesHow To Report A Hazard in The WorkplaceKhey GambeNo ratings yet

- Plating FMEADocument1 pagePlating FMEAshiv jangale80% (5)

- Risk Assesment PresentationDocument26 pagesRisk Assesment Presentationdarius sutherlandNo ratings yet

- Potential Failure Mode and Effects Analysis (Process FEMA)Document1 pagePotential Failure Mode and Effects Analysis (Process FEMA)Asif Iqbal100% (2)

- HLTWHS002 Follow Safe Work Practices For Direct Client Care Resource InterCareDocument146 pagesHLTWHS002 Follow Safe Work Practices For Direct Client Care Resource InterCareSushant Shrestha100% (1)

- 04 - RISK ASSESSMENT CradleDocument5 pages04 - RISK ASSESSMENT Cradle287100% (4)

- OSHA Compliance Manual - Application of Key OSHA TopicsDocument1,138 pagesOSHA Compliance Manual - Application of Key OSHA TopicssalemNo ratings yet

- Risk Assessment For Drainage uPVC PipesDocument1 pageRisk Assessment For Drainage uPVC PipesZameer Basha Navzath AliNo ratings yet

- Itp - RoadDocument5 pagesItp - RoadBiswajit BarikNo ratings yet

- NO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionDocument123 pagesNO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionYoseph Maulana0% (1)

- Potential Failure Mode and Effect Analysis: (Process Fmea)Document9 pagesPotential Failure Mode and Effect Analysis: (Process Fmea)SACHIN KUMARNo ratings yet

- Appendix 1 - Inspection & Test PlanDocument2 pagesAppendix 1 - Inspection & Test Planwagwahkiabathe100% (1)

- Technology and Livelihood Education: Home Economics - Dressmaking Quarter 0 - Module 4Document22 pagesTechnology and Livelihood Education: Home Economics - Dressmaking Quarter 0 - Module 4Cynthia TulopNo ratings yet

- Legal Register ExampleDocument3 pagesLegal Register ExampleHnisjj100% (2)

- Group 5 (Training of Personnel On OSH) : Alpapara - Cabrera - Orate - SarsaDocument26 pagesGroup 5 (Training of Personnel On OSH) : Alpapara - Cabrera - Orate - SarsaKeisu ʚĩɞNo ratings yet

- NIOSH SHO 01-Historical Perspectives5Document22 pagesNIOSH SHO 01-Historical Perspectives5Msh SabriNo ratings yet

- SITXWHS002 003 Chetanjeet KaurDocument26 pagesSITXWHS002 003 Chetanjeet KaurSandeep KaurNo ratings yet

- Sme ManufacturersDocument23 pagesSme ManufacturersWorking Capital100% (2)

- RA 14 - Concrete WorksDocument5 pagesRA 14 - Concrete WorksKlizman AmineNo ratings yet

- Dms - Cruching IbraDocument5 pagesDms - Cruching Ibrakmohamedkeita906No ratings yet

- Adfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R07 PDFDocument6 pagesAdfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R07 PDFIbrahim EsmatNo ratings yet

- Adfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R5 PDFDocument6 pagesAdfi-Eme-Gfts Ces - Ra-03 - R07 - Water Leakage Test R5 PDFIbrahim EsmatNo ratings yet

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pages017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- OMV Operations PUNCH LIST: Nawara and South Tunisia Development Central Process Facilities (CPF) Flowlines and WellpadsDocument1 pageOMV Operations PUNCH LIST: Nawara and South Tunisia Development Central Process Facilities (CPF) Flowlines and WellpadsAbderrazak ChaabiniNo ratings yet

- CPF2-PAUT For Heat Medium Heater A (H-25630A)Document10 pagesCPF2-PAUT For Heat Medium Heater A (H-25630A)Yasir MohammedNo ratings yet

- Tank ErectionDocument3 pagesTank ErectionPrasanth BharathNo ratings yet

- Construction Method For FoundationDocument3 pagesConstruction Method For Foundationdownload dokumenNo ratings yet

- SKH Metals LTD.: Process Control StanderdDocument2 pagesSKH Metals LTD.: Process Control StanderdshinuNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Lampiran - IKA CM Rotating EquipmentDocument1 pageLampiran - IKA CM Rotating Equipmentahmadalfan662No ratings yet

- SID-WRA-02 - Utility Pipeline Fabrication WorkDocument2 pagesSID-WRA-02 - Utility Pipeline Fabrication Workcnanda89No ratings yet

- 901 DesledgingDocument16 pages901 DesledgingLala KamarudheenNo ratings yet

- Hira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraDocument4 pagesHira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraZuberYousufNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Plumbing WorkDocument16 pagesPlumbing WorkTayib JabbarNo ratings yet

- Pfmea Review StatusDocument31 pagesPfmea Review StatusSamadhan MoreNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- F-PD-06 PfmeaDocument1 pageF-PD-06 PfmeaTrivesh SharmaNo ratings yet

- RA - ExcavationDocument3 pagesRA - ExcavationKlizman AmineNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- (Project Name) : Inspection Checklist - External PlasteringDocument2 pages(Project Name) : Inspection Checklist - External PlasteringMohd TameziNo ratings yet

- Temporary Structure Erection Work Risk AssessmentsDocument2 pagesTemporary Structure Erection Work Risk Assessmentshussein aliNo ratings yet

- SID-WRA-06 - Pipeline Erection & HydrotestingDocument2 pagesSID-WRA-06 - Pipeline Erection & Hydrotestingcnanda89No ratings yet

- LNGI-RA-HEC-398-Fabrication Works (Welding, Cutting, Grinding, Drilling, Threading, Support, and Power Tools Operations) Rev.3Document2 pagesLNGI-RA-HEC-398-Fabrication Works (Welding, Cutting, Grinding, Drilling, Threading, Support, and Power Tools Operations) Rev.3Ramesh arumugam0% (1)

- Crane SafetyDocument9 pagesCrane SafetyAzadh MoosaNo ratings yet

- Emmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Document1 pageEmmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Satya PalNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Aspect Impact-PUP - Aug.2011Document1 pageAspect Impact-PUP - Aug.2011Surendran ANo ratings yet

- WATER PROOFING-Jan-2019Document2 pagesWATER PROOFING-Jan-2019Hafiz M WaqasNo ratings yet

- Nawara and South Tunisia Development Central Process Facilities (CPF) Flowlines and WellpadsDocument1 pageNawara and South Tunisia Development Central Process Facilities (CPF) Flowlines and WellpadsZouhair BenmabroukNo ratings yet

- 02 - JSA CAR-002 Electrical, Mechanical (Revised)Document8 pages02 - JSA CAR-002 Electrical, Mechanical (Revised)rigig007No ratings yet

- Tower Crane Telescoping Work (Self-Jumping Work) Risk AssessmentDocument3 pagesTower Crane Telescoping Work (Self-Jumping Work) Risk AssessmentMontadhar HaithamNo ratings yet

- NDT Aspects and Hazards Register - BN Rev.05Document2 pagesNDT Aspects and Hazards Register - BN Rev.05Juliyanto STNo ratings yet

- OHS Risk Assessment Form 03 ForDocument32 pagesOHS Risk Assessment Form 03 ForSohail khanNo ratings yet

- Daily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateDocument1 pageDaily Activity Records: Sheet: of Section: Valenzuela Viaduct Diary DateVWSSI Technical TeamNo ratings yet

- Appendix 1 - Inspection & Test PlanDocument4 pagesAppendix 1 - Inspection & Test PlanwagwahkiabatheNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Cargo Operations - ContainerDocument15 pagesCargo Operations - ContainerleNo ratings yet

- Job Safety Analysis / Risk Assessment Form: CementingDocument4 pagesJob Safety Analysis / Risk Assessment Form: CementingPelin giang ho vung tau PhamNo ratings yet

- Net Fix&dismat Outer PeriferyDocument3 pagesNet Fix&dismat Outer PeriferyMontadhar HaithamNo ratings yet

- 23 Risk Assessment Scaffold Erection Dismantling - HVACDocument5 pages23 Risk Assessment Scaffold Erection Dismantling - HVACBalongNo ratings yet

- 23 Risk Assessment Scaffold Erection Dismantling Fire FightingDocument5 pages23 Risk Assessment Scaffold Erection Dismantling Fire FightingBalongNo ratings yet

- Session 1 - Intro To Managing People - 5f41fd1b67eb4Document27 pagesSession 1 - Intro To Managing People - 5f41fd1b67eb4IreshaNadeeshaniNo ratings yet

- MSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementDocument6 pagesMSHEM-02.11-C Level 2 JSA - Veolia - RO Units Pipes Repairing and ReplacementAbdullah AbedNo ratings yet

- Name of Substance 2. Hazards For Workers and Environment: Handling InstructionDocument1 pageName of Substance 2. Hazards For Workers and Environment: Handling InstructionSayed SalahNo ratings yet

- Safety Data Sheet Evo-Stik Glasticord 400 Grey: According To Regulation (EC) No 1907/2006Document5 pagesSafety Data Sheet Evo-Stik Glasticord 400 Grey: According To Regulation (EC) No 1907/2006kamau kariukiNo ratings yet

- Chapter 1 Opm538Document4 pagesChapter 1 Opm538Yuyu ComelNo ratings yet

- Diisopropyl Ether: Safety Data SheetDocument5 pagesDiisopropyl Ether: Safety Data SheetFelix Vejar ZepedaNo ratings yet

- 1 Identification: Safety Data SheetDocument6 pages1 Identification: Safety Data SheetDental OutletNo ratings yet

- BRICKWORKDocument3 pagesBRICKWORKvicNo ratings yet

- MSDS - Trilite Amp26Document5 pagesMSDS - Trilite Amp26hilyaNo ratings yet

- X-Pando Pipe Joint Compound SDS (Us) 3-9-16Document5 pagesX-Pando Pipe Joint Compound SDS (Us) 3-9-16StevenFerrelNo ratings yet

- F03 Vendor Quarterly Compliance InspectionDocument2 pagesF03 Vendor Quarterly Compliance Inspectionsalman ahmedNo ratings yet

- Module 8 Dressmaking 7Document20 pagesModule 8 Dressmaking 7Arlie Jean Bioneda AbilaNo ratings yet

- Handouts EIM SS1. Week 10Document1 pageHandouts EIM SS1. Week 10myco sauraNo ratings yet

- PINE DISINFECTANT Safety Data SheetDocument7 pagesPINE DISINFECTANT Safety Data SheetDaniel IdongesitNo ratings yet

- Deleg WSH Cetsp01 326406 7Document30 pagesDeleg WSH Cetsp01 326406 7Việt Đặng XuânNo ratings yet

- First Aid NeedsDocument6 pagesFirst Aid NeedsMuhammad RamzanNo ratings yet

- SDS Cristal400 RenewDocument10 pagesSDS Cristal400 RenewsriNo ratings yet