Professional Documents

Culture Documents

8 Steps Nomura

8 Steps Nomura

Uploaded by

Endi KustamsiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8 Steps Nomura

8 Steps Nomura

Uploaded by

Endi KustamsiCopyright:

Available Formats

8-Step Procedure for Defect

Recurrence Prevention Activity

by Toyota veteran Sadoa Nomura

1 Actual defect

check

Immediately conducted

by the team leader (TL)

6 Standardization and

horizontal deployment

Conducted by TL

during the next day

Actual defective parts are checked to identify Determination of work procedures and basic

the process where the defect occurred. rules

Is there any work standard? Do they

2

understand it? Is just following it acceptable?

Stock check → If not, revise it immediately.

Conducted by TL

& sorting immediately If not available, create it immediately.

Make it simple to enable them to

Whether there are any other parts having the same

understand it at a glance.

defect in the stock shall be checked to make sure of

the beginning and ending of the defect occurrence. Listing of similar processes/items and

implementation of horizontal deployment

3

Zero defects cannot be achieved only by

improving the process where the defect

Cause Implemented by TL occurred.

investigation within the day

7

The cause investigation is conducted through GENCHI

GENBUTSU check. Also, the cause is investigated through Education Conducted by TL

interviews with the workers in the relevant process. and training during the next day

4

Education is to teach people what is

standardized.

Countermeasure Implemented by TL Training is to enable workers to do what they

implementation within the day

were taught correctly in real work.

Against the causes of defect occurrence and → TL must make them promise to do what

outflow, respective countermeasures are they were taught.

implemented. Those actually implemented are

written in the sheets on the Asaichi plastic board.

5 Asaichi report

Reported by TL at the

8 Daily management Checked by TL

every day

next Asaichi meeting TL checks whether members are actually

The relevant TL explains the cause and measures doing as they were instructed

to all the members in an easy-to-understand Check members’ work through GENCHI

manner, writes down any instruction or guidance GENBUTSU observation and make prompt

on the sheet, and conducts follow-up activities. corrections to defects if any.

Learn more from Nomura in his new

book available now at lean.org/nomura

You might also like

- Reverse PFMEA Worksheet 2Document1 pageReverse PFMEA Worksheet 2adochan92% (12)

- 8D Human Error Root Cause Analysis Worksheet Revision Date: 4/3/2018 Revision #: 1Document1 page8D Human Error Root Cause Analysis Worksheet Revision Date: 4/3/2018 Revision #: 1Thee Bouyy100% (1)

- 5S Audit SheetDocument2 pages5S Audit SheetSenthil_KNo ratings yet

- 6 - Kobayashi - 20 - Keys - Template EVALUACIONDocument4 pages6 - Kobayashi - 20 - Keys - Template EVALUACIONrmatum100% (2)

- The 8 Step Process 1670347137Document4 pagesThe 8 Step Process 1670347137ashutoshpal21No ratings yet

- 04 Auto MaintenanceDocument486 pages04 Auto Maintenanceanderson pariz100% (1)

- What Is Poka-YokeDocument114 pagesWhat Is Poka-YokeAdriano CarlosNo ratings yet

- Autonomous Maintenance Step 1 To Step 3Document14 pagesAutonomous Maintenance Step 1 To Step 3R.BALASUBRAMANINo ratings yet

- 2.4 ToolBox Meetings-2020-HandoutDocument5 pages2.4 ToolBox Meetings-2020-HandoutHeliNo ratings yet

- Step 0 and 1 Management Part 1Document14 pagesStep 0 and 1 Management Part 1murilocabriniNo ratings yet

- Tool Box Talk: Human Induced FailuresDocument1 pageTool Box Talk: Human Induced FailuresDIEGO A. TOVAR CHIANo ratings yet

- Maintenance Theory PDFDocument181 pagesMaintenance Theory PDFkaca82100% (2)

- Chapter 5. Jishu Hozen ManualDocument71 pagesChapter 5. Jishu Hozen ManualVivek Kumar100% (4)

- G8D - With CommentDocument10 pagesG8D - With CommentYoohyun LeeNo ratings yet

- Ebook On Call Guide PagerdutyDocument11 pagesEbook On Call Guide PagerdutyShiva KumarNo ratings yet

- Poka YokeDocument8 pagesPoka YokeFran JimenezNo ratings yet

- Preventive Vigilance in WorksDocument57 pagesPreventive Vigilance in WorksnitishNo ratings yet

- Root Cause Analysis & Corrective ActionsDocument29 pagesRoot Cause Analysis & Corrective ActionsOgheneruemu EtasNo ratings yet

- Gu 276Document19 pagesGu 276kattabommanNo ratings yet

- Management Safety Observation Tours Don'tsDocument3 pagesManagement Safety Observation Tours Don'tsTim813No ratings yet

- RCA 1 Day Course v1Document85 pagesRCA 1 Day Course v1abcxyxNo ratings yet

- WSH Guidelines For Investigating Workplace Incidents For SMEsDocument15 pagesWSH Guidelines For Investigating Workplace Incidents For SMEsandrewhw100% (1)

- Consolidated Question During The Orientation of Safety Seal Certification Program 03 June 2021Document4 pagesConsolidated Question During The Orientation of Safety Seal Certification Program 03 June 2021jigsespinaNo ratings yet

- nchi Genbutsu (現地現物: Toyota Production SystemDocument3 pagesnchi Genbutsu (現地現物: Toyota Production SystemcvikasguptaNo ratings yet

- Do-It-Yourself Cheat-Sheet For Continuous Process OptimisationDocument27 pagesDo-It-Yourself Cheat-Sheet For Continuous Process OptimisationMina RemonNo ratings yet

- Jisu Hozen PillarDocument98 pagesJisu Hozen PillarAndrei MarinNo ratings yet

- BBS ProgramDocument45 pagesBBS Programerryrahman72No ratings yet

- G8D FordDocument10 pagesG8D Fordapi-3856433100% (2)

- Managing Failure AnalysisDocument25 pagesManaging Failure AnalysisAndiNo ratings yet

- The Essence of Jidoka PDFDocument2 pagesThe Essence of Jidoka PDFJonathan DavisNo ratings yet

- Fundamentals of Troubleshooting: The Most Important Points For TroubleshootingDocument6 pagesFundamentals of Troubleshooting: The Most Important Points For TroubleshootingssendyosseNo ratings yet

- 5 Sand ProductivityDocument19 pages5 Sand ProductivityCarlo Sablaon CallosNo ratings yet

- Training On Root Cause Analysis / Problem Solving TechniquesDocument66 pagesTraining On Root Cause Analysis / Problem Solving TechniquesDINESH SHARMANo ratings yet

- Chapter 1Document3 pagesChapter 1Sherry SherNo ratings yet

- LCM Element 2Document22 pagesLCM Element 2Vincent Anthony MilitanteNo ratings yet

- 5 Why TrainingDocument38 pages5 Why Trainingliviu_din_codru100% (8)

- T09-MOTIVA Sample Continual Improvement ProcedureDocument9 pagesT09-MOTIVA Sample Continual Improvement ProcedurefarheenNo ratings yet

- Be SMARTDocument5 pagesBe SMARTYareni RosasNo ratings yet

- Types of Mistake PDFDocument2 pagesTypes of Mistake PDFAdita Yumanda100% (1)

- Assurance - Chapter 5 - ST - 2022Document40 pagesAssurance - Chapter 5 - ST - 2022Linh KhanhNo ratings yet

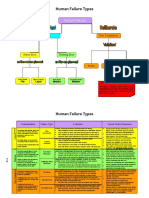

- Human Failure TypesDocument2 pagesHuman Failure TypesAhmed Al-aminNo ratings yet

- 54-57 - Tony McGrailDocument4 pages54-57 - Tony McGrailbenlahnecheNo ratings yet

- 8 8D Problem SolvingDocument24 pages8 8D Problem SolvingVincent FajardoNo ratings yet

- Autonomus Maintenance - Maintenance MonthDocument92 pagesAutonomus Maintenance - Maintenance MonthBakhsheesh100% (1)

- Annexure IDocument22 pagesAnnexure IHareramShahNo ratings yet

- Stage 1 - Noddy GuideDocument3 pagesStage 1 - Noddy Guidegeorge moyoNo ratings yet

- Gemba Checklist: Area: Date: Leader NameDocument1 pageGemba Checklist: Area: Date: Leader NameDeepanshu SewakNo ratings yet

- Analysing and Investigating Road Traffic CrashesDocument5 pagesAnalysing and Investigating Road Traffic CrashesErrezaHardianNo ratings yet

- 2020.09.23 Annexes of 6th MR. ResearchDocument2 pages2020.09.23 Annexes of 6th MR. ResearcharacelipunoNo ratings yet

- Chapter 9. Failure Root Cause PreventionDocument23 pagesChapter 9. Failure Root Cause PreventionAbdirahman Ali mohamudNo ratings yet

- 5S ModulDocument20 pages5S ModulnursaidahNo ratings yet

- Title: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveDocument7 pagesTitle: Standard Operating Procedure For Investigation Sop No Version No.: 02 Page No. 1 of 8 Effective Date: Review Date: 1.0 ObjectiveBRIJENDRA KUMAR SINGHNo ratings yet

- Internal Investigations-Compliance Action Plan PDFDocument5 pagesInternal Investigations-Compliance Action Plan PDFAhsan ul haqNo ratings yet

- Govt Office HoursDocument12 pagesGovt Office HoursKaren GarciaNo ratings yet

- CQI 12 ExcelIndoc AsssementDocument2 pagesCQI 12 ExcelIndoc AsssementMilan PrajapatiNo ratings yet

- Unit 3 Maintenance ChecklistDocument18 pagesUnit 3 Maintenance ChecklistMABR 19No ratings yet

- Appendix J Risk Management SupplementsDocument7 pagesAppendix J Risk Management SupplementsGregory FernandezNo ratings yet

- 5 Why Global Standard - FCADocument8 pages5 Why Global Standard - FCAmagudeeshNo ratings yet

- Identifying Phenomena For Minor StopsDocument8 pagesIdentifying Phenomena For Minor StopsMadanKarkiNo ratings yet

- Jidoka: The Toyota Principle of Building Quality into the ProcessFrom EverandJidoka: The Toyota Principle of Building Quality into the ProcessRating: 4 out of 5 stars4/5 (2)

- BIQ r3Document15 pagesBIQ r3Endi KustamsiNo ratings yet

- Right Person, Right MethodDocument8 pagesRight Person, Right MethodEndi KustamsiNo ratings yet

- So You Want To Be A Change AgentDocument46 pagesSo You Want To Be A Change AgentEndi KustamsiNo ratings yet

- ADM QCC - Taman Mimpi PDFDocument29 pagesADM QCC - Taman Mimpi PDFEndi KustamsiNo ratings yet

- 4-Quick Changeover - Updated June2010Document47 pages4-Quick Changeover - Updated June2010Endi KustamsiNo ratings yet

- A Factory of One - Applying Lean Principles To Banish Waste and Improve Your Personal Performance PDFDocument166 pagesA Factory of One - Applying Lean Principles To Banish Waste and Improve Your Personal Performance PDFEndi Kustamsi100% (1)

- Group 2: Jackline Cletus Mcharo Halima Yusuff Hussein Michonjo James Evelyn Shaibu Makenjura Mosses Ben Device MshoboziDocument32 pagesGroup 2: Jackline Cletus Mcharo Halima Yusuff Hussein Michonjo James Evelyn Shaibu Makenjura Mosses Ben Device MshoboziralphNo ratings yet

- Suhanya Sundaran CVDocument5 pagesSuhanya Sundaran CVapi-426615858No ratings yet

- Condensation Heat Transfer in The Presence If A Ioocosifcisalle GasDocument7 pagesCondensation Heat Transfer in The Presence If A Ioocosifcisalle GasArchit ChandorkarNo ratings yet

- Statics of Rigid Bodies 1Document3 pagesStatics of Rigid Bodies 1Rosette de AsisNo ratings yet

- ARC5031 - Lesson 2 The Development and Theoretical Knowledge of ConservationDocument19 pagesARC5031 - Lesson 2 The Development and Theoretical Knowledge of ConservationMukhammadjonNo ratings yet

- Anil AnilDocument6 pagesAnil AnilSaket RaiNo ratings yet

- Mini AT User Manual v3.03Document154 pagesMini AT User Manual v3.03alicardozoNo ratings yet

- Partnership Lesson PlanDocument6 pagesPartnership Lesson Planapi-667746318No ratings yet

- (IIC 2021) Official BookletDocument11 pages(IIC 2021) Official BookletKhue NguyenNo ratings yet

- 3.3 Replacement Analysis and Sensitivity AnalysisDocument5 pages3.3 Replacement Analysis and Sensitivity Analysisrobel popNo ratings yet

- TF5420 TC3 Motion Pick-And-Place enDocument139 pagesTF5420 TC3 Motion Pick-And-Place enKenneth Thoft AndersenNo ratings yet

- Sol3e Int U3 Short Test 1bDocument2 pagesSol3e Int U3 Short Test 1bАлександра БабычNo ratings yet

- Ships and Shipping - Handbook - 1903Document142 pagesShips and Shipping - Handbook - 1903Clyde Steamers100% (13)

- B e BmeDocument42 pagesB e BmeRAMESHKUMAR.S MCE-LECT/MECHNo ratings yet

- How To Build A Position II - Done (Lecture Notebook)Document2 pagesHow To Build A Position II - Done (Lecture Notebook)Mary De JesusNo ratings yet

- LEEA Correspondence Courses: Assignment 1.8Document3 pagesLEEA Correspondence Courses: Assignment 1.8Primelift Safety Resources LimitedNo ratings yet

- Scientific Computing - LESSON 1: Computer Arithmetic and Error Analysis 1Document10 pagesScientific Computing - LESSON 1: Computer Arithmetic and Error Analysis 1Lee Hei LongNo ratings yet

- 11 Work and Energy For ParticlesDocument28 pages11 Work and Energy For ParticlesNina MabantaNo ratings yet

- DLP ScienceDocument5 pagesDLP ScienceRochelle Ann Ramilo GonzalesNo ratings yet

- RFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREADocument4 pagesRFI HPR FORM - 12E-C01-CE-0084 - 3rd LAYER BACFILLING AT PROJECT F 9 AROUND OFFICE AND LAY DOWN AREAAbdul Hannan100% (1)

- 28303-3 MID 128 PID 412 EGR Temperature CheckDocument6 pages28303-3 MID 128 PID 412 EGR Temperature CheckTun Tun Win Kse100% (1)

- Study of Defect Characteristics Essential For ET UT RTDocument58 pagesStudy of Defect Characteristics Essential For ET UT RTaldeanucu100% (2)

- Photovoltaic and Solar Thermal Modeling With The Energyplus Calculation EngineDocument8 pagesPhotovoltaic and Solar Thermal Modeling With The Energyplus Calculation EngineKevin AnandaNo ratings yet

- Remon Ahdy ,: Professional Diplomas in Sales Management and MarketingDocument60 pagesRemon Ahdy ,: Professional Diplomas in Sales Management and Marketingcmrig74No ratings yet

- Elastic Potential EnergyDocument17 pagesElastic Potential EnergyAlther AlitaoNo ratings yet

- English 10 Performance TaskDocument4 pagesEnglish 10 Performance TaskJello Perez CastañosNo ratings yet

- Making An Impact With Your PosterDocument15 pagesMaking An Impact With Your PosterHadrowi Dwi Putra RapikNo ratings yet

- Designand Analysisof Piercing ToolsDocument6 pagesDesignand Analysisof Piercing Toolsviju143No ratings yet

- Hand Splint A ReviewDocument15 pagesHand Splint A ReviewIJRASETPublicationsNo ratings yet

- Codes Needed For Entries 2019 MayDocument3 pagesCodes Needed For Entries 2019 MaycmhajxweqgzjbzhpfaNo ratings yet