Professional Documents

Culture Documents

El240220 014

Uploaded by

Abdallah AbdallahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

El240220 014

Uploaded by

Abdallah AbdallahCopyright:

Available Formats

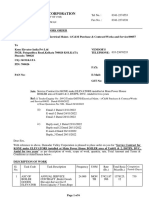

To company Oriental Weavers Carpet Date 23.02.

2024

10th Of Ramadan City

Cairo / EGYPT

Kind attention Mr. Amany AHMED Phone +20. 554410811

Fax no.

email Ahelmy@orientalWeavers.com

arranged by Mr. El MALIZI / mobil: +49.179.930.54.20 / email: elmalizi@bay-boiler.de

Offer no. EL240220-014 (please always state no. in correspondence)

Code Name Dampfkessel / STEAM BOILER

Your reference 23.02.2024

Dear Mr. AHMED,

Thanking you for your inquiry and the related confidence in our products. Subject to alteration without notice we are pleased to

submit thereafter the quotation according to your specifications with price overview and technical details. The tender is carried

out exclusively on the basis of our valid General Conditions of Sale and Delivery.

We trust that the quotation meets your requirements. Should you decide to favour us with your order, you may rest assured that

it will be handled with due care and delivered on time. Please feel free to contact Mr. Mostafa El MALIZI at the number

performed on top for any further queries.

Sincerely yours

BBS GmbH

Mostafa El MALIZI

This document was created electronically and is valid without signature

ATTACHMENT

Prices Overview (from page 2) and Technical Specifications (from page 3)

Data sheet for boiler, burner, pump … !!! Technical modifications reserved !!!

BBS General Conditions of Sale and Delivery (AGB), available online http://www.bay-boiler.com/de/agb/AGB_BBS_GmbH_de.pdf

PID diagram and informations concerning the prescriptions on request

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 1 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

PRICES OVERVIEW Date 23.02.2024

Item Qty DESCRIPTION Unit price Total price

(EURO)

1 unit BBS HIGH-PRESSURE STEAM BOILER 148.470,00 € 148.470,00 €

1.0.0.0 1 BOILER PRESSURE BODY, Stamp Pressure PS 12 bar g, 120 mm

HEAT INSULATED, MODEL HDK

- mainly equipped with the following accessories

1.1.0.0 1 BASIC FITTINGS / HDK 2500

1.2.0.0 1 SENSORIES for SAFETY and CONTROL

2.0.0.0 1 BOILER's FEED UNIT (SP) * 2 GRUNDFOS CENTRIFUGAL PUMPS

with VARIABLE FREQUENCY DRIVE (1 on duty, 1 on standby)

3.0.0.0 1 FIRING UNIT * 1 WEISHAUPT GAS BURNER Series MONARCH®

4.0.0.0 1 BBS CONTROL CABINET * FIRING POWER control, SENSORIES

in electric safety chain

# BOILER SPECIAL EQUIPMENT

1.9.0.0 1 BBS HEAT EXCHANGER ECOnomizer * Heat recovery from the OPTION 26.920,00 €

flue gas heat to preheat Medium SOFTWATER. Please pay

attention to the PAYBACK CALCULATION (item 1.9.2.0)

3.5.0.0 1 BURNER ACCESSORY * 1 GAS TRAIN FITTING 9.750,00 € 9.750,00 €

# PERIPHERAL DEVICES to operate with the BBS HIGH-

PRESSURE STEAM BOILER

16.0.0.0 1 SPARE PARTS 6.007,00 € 6.007,00 €

# TOTAL MATERIAL PRICE of the above installations OPTION not included 164.227,00 €

21.0.0.0 1 SHIPMENT / Place of lading D-71691 Freiberg

21.0.0.2 1 FOB EUROPEAN seaport 4.510,00 € 4.510,00 €

21.0.0.3 1 Cargo charge FOB EUROPEAN seaport to CFR seaport 7.140,00 € 7.140,00 €

ALEXANDRIA / EGYPT

23.0.0.0 1 COMMISSIONING 9.260,00 € 9.260,00 €

- EXPENSES: Hotel, food and traveling expenses by BBS / by

customer transit airport <-> hotel <-> boiler house

- IMPORTANT NOTE! The operation date should be agreed 14

days before execution. CONTACT: Mr. Mostafa El MALIZI,

phone: +49.7141.688986.23, email: elmalizi@bay-boiler.de

- Please pay attention to CUSTOMER DUTY ON-SITE /

COMMISSIONING, IMPORTANT NOTE! WEISHAUPT service

engineer for burner setting is to be ordered by customer

# TOTAL NET PRICE exclusive VAT OPTION not included 185.137,00 €

# FINAL PRICE OPTION not included 185.137,00 €

# DELIVERY TERMS (Incoterms® 2020) CFR seaport ALEXANDRIA / EGYPT

# PRICE VALIDITY after issue or revision date 90 days

# Due to the current situation of the projects it should be

advantageous to agree on time the LONG DELIVERY TERM

(generally 6 months)

- Expected time arrival to seaport ALEXANDRIA in case of Oktober 24 Week 42

Purchase Order within 4 weeks. IMPORTANT NOTE! The

delivery time refers to the date of RECEIPT of DOWN

PAYMENT and upon clearing all technical details

- Shipment schedule: Forward EX Freiberg to FOB / OCEAN 7 days 20 days

FREIGHT time

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 2 / 17

# NOTE! not included in this offer! Necessary PERIPHERAL

DEVICES to operate with the BBS HIGH-PRESSURE STEAM

BOILER + Final works on-site

- BBS SERVICE MODULE FEED WATER DEGASSING (SWE)

- BBS BLOW DOWN COOLER (MK) required in Germany

- FLUE GAS CHIMNEY SYSTEM

- On-site MECHANICAL and ELECTRICAL works such as wiring,

erection, pipeline construction and HEAT INSULATION

# TERMS of PAYMENT (to be agreed on later) / SUGGESTION

30% by SWIFT upon purchase order and down payment invoice

60% against shipping documents and by an irrevocable Letter of

Credit (L/C) by a FIRST CLASS BANK and confirmed through

BBS bank. Between L/C expiry date and latest date of

shipment must be at least 21 days!

10% against acceptance certificate and by an irrevocable Letter of

Credit (L/C) with confirmation by a FIRST CLASS BANK

- Time of payment: according L/C

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 3 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

1.0.0.0 1 BBS HIGH-PRESSURE STEAM BOILER Type HDK 2500

- FLAME/FIRE TUBE SHELL BOILER suitable to be fired with fuel

gas DVGW-work sheet G260 and for generating of

SATURATED STEAM

1.0.0.1 # ADVANTAGES of BBS HIGH-PRESSURE STEAM BOILER

- FABRICATION totally made in GERMANY. Wherever possible

the dimensions and connections shall be built tailor-made

according to customer requirements

- EASY HANDLING, LONG LIFETIME due to robust construction

and high safety reserve. With appropriate treatment, a

lifespan of 20 years to over 30 years is often the case.

- MINIMUM SPACE required through compact installation

- HIGH AVAILABILITY, OPERATIONAL SAFETY through use most

modern equipments and materials

1.0.0.2 # CUSTOMER'S REQUIREMENTS and SPECIFICATIONS please correct in case of discrepancy

- Required SATURATED STEAM rating 2.500 kg/h

- IMPORTANT NOTE! The above mentioned steam output does

not take into account the required steam rate to degas the

feed water for BBS HIGH-PRESSURE STEAM BOILER

- Required working pressure / saturated steam temperature 10,0 bar g 185 °C

- Feed water quality complied with EN 12953-10: Make-up

water is available on-site. A guideline for feed water quality to

BBS steam boiler is available on request

- Make-up water temperature as assumed (fully degassed) 20 °C (105,0 °C)

- Fuel supply on-site NATURAL GAS (LNG)

- Gas pressure upstream gas fitting as assumed. IMPORTANT 300 mbar

NOTE! Please confirm finally at time of order! The price can

be subject to modification

- On-site power supply: operating voltage / frequency 3~ 400 V 50 Hz

- The installation site is indoors, free from frost, dust and CAIRO / EGYPT

dripping water. Please confirm country of installation! The

price can be subject to modification

- Installation altitude above sea level MAX 500 m

- Temperature in boiler room normal / MIN (MAX) 25 °C 10 °C (50,0 °C)

- Installation site in HAZARDOUS areas NONE and SAFE

1.0.0.3 # TECHNICAL DATA / HDK 2500

- Nomimal steam mass flow 2.500 kg/h

- Nominal steam heat capacity 1.626 kW

- Stamp Pressure PS (set pressure of safety valve Psv) 12,0 bar g (12,0 bar g)

- Working pressure, factory set (MAX, adjustable downwards) 10,0 bar g (11,0 bar g)

- Hydraulic Test Pressure PT according PED

- Steam working temperature (design temperature TS) 184,6 °C (198,0 °C)

- Boiler feed water temperature downstream ECO into HDK 143 °C (105,0 °C)

(upstream ECO coming from feed tank, fully degassed)

- Fresh water flow rate required 1,4 m³/h

- Water volume up to lowest level mark WSTB-L 3,8 m³

- Water volume up from WSTB-L to WSTB-H (TOTAL) 0,2 m³ (4,1 m³)

- Steam space 0,7 m³

- Average speed at SATURATED STEAM FEEDING 31,7 m/s

- MAX resistance, flue gas side 6,1 mbar

1.0.0.4 # SCOPE of DELIVERY / DESIGN

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 4 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

1 PRESSURE BODY ELECTRIC WELDED by certified welders with

valid certificate

1 Model flue gas way in asymmetrical TRIPLE PASS technology

for a total combustion and ideal heat transfer

1 FLAME TUBE designed with optimal dimensions according to

the burner manufacturer matching a LOW POLLUTANT

EMISSION

1 INTERNAL water-flushed REVERSING CHAMBER (WET BACK),

with sight glass for flame observation

1 MUFFLE in the front, refractory lined, suitable for assembly

installation of FIRING UNIT

1 FRONT DOOR, HEAT INSULATED, gastight, can be EASILY

HINGED for flue gas-side maintenance work

1 Set MANHOLE / HEADHOLE, inspection access inside the

boiler shell

1 BBS HEAT EXCHANGER ECOnomizer, FLUE GAS BOX with OPTION

connecting mating flange

1 INSULATION / PAINTING / CORROSION PROTECTION

1 BASIC FITTINGS / HDK 2500

1 SENSORIES for SAFETY and CONTROL

1 BOILER's FEED UNIT (SP)

1 FIRING UNIT equipped with WEISHAUPT GAS BURNER Series

MONARCH®

1 BBS CONTROL CABINET with factory functional test and report

1 Set of SUPPORT LEGS welded to shell and bolted on skid for

dilatation compensation

1 IDENTIFICATION - NAMEPLATE

1 Set TRANSPORT LUGS / LIFTING EYE welded on the top as well

as down on skid

1 NDT welding quality control by SUPERSONIC on SHELL

(longitudinal seam and circumferential seam) according TUEV

GERMANY / TÜV SÜD Industrie Service GmbH

1 INSPECTION by THIRD PARTIES: Pre-shipment inspection will

be carried out by TUEV GERMANY / TÜV SÜD Industrie Service

GmbH. A report or CE Declaration of Conformity shall be

furnished to the purchaser respectively to end user

1.0.0.5 # FACTORY PACKAGE

1 HDK 2500 built on skid, SENSORY and BASIC FITTINGS built-on

1 Pre-assembly and testing of FIRING UNIT

1 BOILER's FEED UNIT (SP) built as a compact station and

delivered separately

- The interconnecting piping and wiring to HDK 2500 shall be

carried out on site by customer

1 BBS CONTROL CABINET delivered separately

- The wiring to devices such as burner, pump, sensory ... shall

be carried out on site by customer. Upon request, we supply

cables for a surcharge. In this case, please specify the required

cable length

1.0.0.6 # CODES / STANDARDS

- Fabrication in line with APPLICABLE European PED (Pressure EN 12953-3 // PED 2014/68/EU

Equipment Directive) and German Code AD 2000

- WELDER Examination Certificate DIN EN ISO 9606-1:2013

- Electric switch cabinet EN 50156-1 / GERMAN VDE 0116

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 5 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

- Quality management ISO 9001:2015 / Certificate no. IZ co2112031

- CONFORMITY assessment procedure CATEGORY IV, Module G / EC individual test

1.0.0.7 # DOCUMENTATION / CERTIFICATE

- According to EUROPEAN guidelines. Used language is ENGLISH

- Customs tariff number, HS code 8402 19 10

1 Hardcopy and digital saved on a CD-ROM or USB stick as final

documentation

1 CE Declaration of Conformity TUEV GERMANY

1 Drawings, stress calculation according to PED

1 Operating manual

1.0.0.8 # COMBUSTION DETAIL / FUEL PROPERTY

- Existing fuel NATURAL GAS (LNG)

- Efficiency determination based on German 1st BImSchV

- Temperature ambient air 25 °C

- Expected flue gas temperature at full load 265 °C

+ GASEOUS FUEL NATURAL GAS (LNG) (with ECO)

- MIN Efficiency according previously measured exhaust gas 88,3% (93,7%)

temperature and depending on working conditions

- MAX firing output 1.842 kW

- Gas pressure upstream the gas fittings 300 mbar

- Net calorific value LHV 10,0 kWh/m³

- Fuel consumption at 100% load (with ECO) 184 m³/h (173 m³/h)

- Exhaust gas mass flow / volume flow (T downstream ECO) 0,79 kg/s 3.570 m³/h (130,0 °C)

1.0.0.9 # EXHAUST EMISSION

- Evaluation of the emission, tolerance / measurement

incertitude according to EN 676 (GAS) / EN 267 (OIL)

- NOx calculated as NO2 (dry flue gas), O2 concentration 3%

1.0.0.10 # MATERIAL / HDK 2500

- with mill test certificate according to EN 10.024-3.1

- Boiler shell made of CARBON STEEL

- Fire-tubes made of high heat-resistant CARBON STEEL

- Boiler end made of CARBON STEEL

- Flame tube made of CARBON STEEL

1.0.0.11 # PRELIMINARY DIMENSION / HDK 2500

- The informations are provisional only for planning. Valid

details will be provided at time of order

- On request possible partial adaptation of the dimensions

- Boiler layout HORIZONTAL

- Service access side, view from firing-side Variant A: on the LEFT SIDE

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 6 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

- NOTE! The service access side (variant A or B) should be

checked and must be confirmed before ordering. Subsequent

changes are only possible at extra cost. If not specified,

variant A applies

- Overall length 4.610 mm

- Overall width 2.110 mm

- Overall height for transport (with fittings approx.) 2.760 mm (3.400 mm)

- Shipping weight: Boiler body insulated, burner fitted, ECO 4.010 kg

fitted

- Operation weight, HDK filled 8.800 kg

- Proposal for boiler house sizing (length x width x height) 5.600 mm 4.300 mm 4.400 mm

including PERIPHERAL DEVICES such as feed pump unit, feed

tank, water treatment ...

1.0.0.12 # MAIN CONNECTION - BATTERY LIMIT / HDK 2500

- Connection points at delivery are welding flanges DIN / EN 1092-1

- Material of the V-flanges made of CARBON STEEL P250GH / EN10222-2 (1.0460)

1 SATURATED STEAM FEEDING DN 65 PN 16

1 DRAIN DN 20 PN 16

1 BLOW DOWN DN 20 PN 16

2 SAFETY VALVE DN 32 PN 16

1 BOILER FEED WATER INCOMING DN 25 PN 16

2 REFLECTION LEVEL GAUGE DN 20 PN 40

1 DESALTING DN 20 PN 16

1 WATER LEVEL CONTROLLER WSTR by COMPACT LEVEL DN 100 PN 40

ELECTRODE and MIN LEVEL LIMITER WSTB-L1

1 MIN LEVEL LIMITER WSTB-L2 DN 50 PN 40

1 STACK Ø350 mm PN 6

1.0.0.13 # INSULATION / PAINTING / CORROSION PROTECTION

1 HEAT INSULATION with high quality rock wool and

GALVANIZED sheet cladding

- Upon request, the cladding can be made of ALUMINIUM or

STAINLESS STEEL for an additional surcharge

- Boiler body and heat surface shall be specially insulated to

reduce radiation loss to a minimum

- Body parts, which can't be covered by the insulation, shall be

factory coated with a heat-resistant anti-corrosion paint

1.0.0.14 # WARRANTY

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 7 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

- The warranty period begin from the date of handing over of

the plant, however limited to MAX 36 months after delivery.

This requires a commissioning by our personnel or by BBS

authorized experts, also the maintenance work is performed

by specialists at the prescribed intervals.

- Warranty on boiler body 24 months

- Warranty for auxiliary part such as sensory … 12 months

- Regular wearing parts such as filter, lining … are excluded

from the warranty also damages by inappropriate operation

1.1.0.0 1 BASIC FITTINGS / HDK 2500

- consisting of

1.1.0.1 2 WIKA Reflection glass level gauge, marking WSTB-L

1.1.0.2 1 Test sampling cooler

- Welded construction with cooling coil, pre-assembled ready

for connection to wall mounting.

- Connections:

- Cooling water inlet G ½

- Cooling water outlet pipe 26.9 x 2.0

- Sample inlet cutting ring fitting for tube 8x1 mm

- Sample exit tube 8x1 mm

Conformity Assessment:

- Fluid group 2, Article 4, paragraph 3

The device meets the requirements of the Pressure

Equipment Directive 2014/68/EU.

1.1.0.3 1 ARI FABA®-Plus Stop Valve, maintenance free, bellows seal up

to 300°C, SATURATED STEAM FEEDING

1.1.0.4 1 GESTRA DISCO® Non-Return Valve, SATURATED STEAM

FEEDING

1.1.0.5 1 ARI STEVI® Smart Electric Control Valve in straight through

form

- Release OPEN/CLOSE to SATURATED STEAM FEEDING

- Flow medium SATURATED STEAM

- Spindle packing PTFE-V-ring unit up to +250 °C

- Flow characteristic OPEN / CLOSE

- Cone design Isolating cone

1 Electric actuator 220 V, Actuator force 5,0 kN

1.1.0.6 1 ARI FABA®-Plus Stop Valve, maintenance free, bellows seal up

to 300°C, DRAIN

1.1.0.7 1 GESTRA Quick-Closing Blow Down Valve with hand lever

without hand lever, DRAIN

- The automatic blowdown works with a pneumatic drive unit,

item 1.2.3.3

1.1.0.8 2 ARI SAFE Safety valve with flange according to VdTÜV Sheet

100, AD2000-A2 and EN ISO 4126-1

closed housing / closed ventilation

TÜV.SV.17-663.D/G

Inlet according to DIN PN40

Outlet according to DIN PN16

1.2.0.0 1 SENSORIES for SAFETY and CONTROL EN 12953-6,8,9

- consisting of

1.2.0.1 1 Set PRESSURE GAUGE, MANOSTATE COLLECTOR

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 8 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

1 3-way valve with test flange for connecting a calibrated

pressure gauge at hydraulic test PT by TUEV GERMANY

1.2.0.2 1 SAUTER Safety pressure switch MAX (PZA1+), MANOSTATE

COLLECTOR

- certified according to German VdTÜV Druck 100/1 switches

off the heating at increasing pressure

1.2.0.4 1 JUMO Pressure transmitter (PE1), MANOSTATE COLLECTOR

- Transmitter for Boiler PLC power logic controller (PIC1) to 0 … 16 bar

regulate the firing power, measuring range

- Output: 4 ... 20mA zl

Process connection: G1/2 DIN EN 837

Material process connection: CrNi (stainless steel)

Seal: FPM

Electr. connection: cable socket DIN EN 175301-803, form A

Nominal size pressure connection: G1/2

Measuring range unit: bar

Power supply: DC10..30V

1.2.0.5 1 MANOSTATE COLLECTOR

- fixing the SENSORY DEVICES

1.2.1.0 1 BOILER WATER LEVEL CONTROL, TYPE TESTED GESTRA

- consisting of

1.2.1.1 1 WATER LEVEL CONTROLLER WSTR

1 COMPACT LEVEL ELECTRODE

- Compact System for Level Monitoring working acc. to the

capacitance measurement principle. The level transmitter

translates the level changes into a level-dependent current

signal of 4-20 mA, with the length of the electrode rod

determining the measuring range. The transmitter can be

used for water level limiting or for highlevel alarm

- 4 switch points adjustable during operation

- Pump ON

- Pump OFF

- Pre-alarm water shortage

- Pre-alarm water overfill

1 Flange fixing COMPACT LEVEL ELECTRODE and MIN LEVEL

LIMITER WSTB-L1

1.2.1.2 1 LEVEL LIMITER LOW WATER WSTB-L1 / L2

1 MIN LEVEL LIMITER WSTB-L1

- The electrode is used as water level limiter for steam boiler

plant and (pressurised) hot water installation. The electrode

operation is based on the conductive measuring principle. The

self-monitoring function ensures that an alarm will also be

triggered if the electrode insulation is contaminated or has

developed a leak and/or if there is a malfunction in the

electrical connection

1 MIN LEVEL LIMITER WSTB-L2

- The electrode is used as water level limiter for steam boiler

plant and (pressurised) hot water installation. The electrode

operation is based on the conductive measuring principle. The

self-monitoring function ensures that an alarm will also be

triggered if the electrode insulation is contaminated or has

developed a leak and/or if there is a malfunction in the

electrical connection

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 9 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

1 LEVEL SWITCH (LZA1-) / (LZA2--) for 2 electrodes

- with periodic self-checking and Safety Integrity Level (SIL3)

according to IEC 61508

- 1st limiter / 2nd limiter switches off the heating when the

water level falls below the set minimum level WSTB-L1/L2

1 Flange fixing MIN LEVEL LIMITER WSTB-L2

1.2.2.0 1 SURFACE DESALTING GESTRA

- consisting of

1.2.2.1 1 CONTINUOUS SURFACE DESALTING

- Due to the continuous evaporation process in the steam

boiler the density hence the Total Dissolved Solid (TDS)

concentration of boiler water is increased. The TDS level must

remain within the limits specified by TRD guideline.

- SCOPE of DELIVERY / CONTINUOUS SURFACE DESALTING

1.2.2.2 1 Conductivity electrode

- The conductivity electrode is used as conductivity limiter and

continuous blowdown controller in steam boilers. The

electrode works according to the conductivity measurement

principle and, in conjunction with conductivity switches or

controllers, monitors the conductivity in fluids. A short circuit

or wire breakage in the conductivity electrode will trigger an

error message in the conductivity switch or controller

- Electrode is fitted inside of the boiler

1.2.2.3 1 Desalting controller integrated in control cabinet

- The conductivity controller is used as conductivity controller

and limit switch in steam boilers, hotwater installations as

well as condensate and feedwater tanks. The conductivity

controller indicates when the MAX conductivity limit is

reached and opens or closes a continuous blowdown valve

1.2.2.4 1 GESTRA Servo Motorized Blow Down Valve Reaktomat®

1.2.2.5 1 T piece fixing Reaktomat <-> HDK

1.2.3.0 1 SEDIMENTS BOTTOM BLOW DOWN SYSTEM GESTRA

- consisting of

1.2.3.1 1 PERIODIC BLOW DOWN

- Sludge sediments, which are accumulated precipitates from

boiler water that settle at the bottom of the boiler, will be

removed from the boiler with the aid of quick-closing blow

down valve. This valve gives a short blow at regular intervals,

thereby discharging accumulated sludge and sediments.

- SCOPE of DELIVERY / PERIODIC BLOW DOWN

1.2.3.2 1 Auto Timed blow down cycle

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 10 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

- Electronic unit for the generation of periodic pulses to initiate

a blowdown cycle. The equipment meets the German

regulation for use in steam-boiler plants operating without

constant supervision or with limited supervision. The cycling

timer generates a control pulse which, after the preset

blowdown interval, operates the three-way solenoid valve.

This in turn actuates the rapid-action blowdown valve by

means of compressed air or pressurized water and closes it

again at the end of the pulse duration. The blowdown interval

and the pulse duration can be coarsely preset with a code

switch. Final adjustment with aid of 2 potentiometers

1.2.3.3 1 Diaphragm pneumatic unit to actuate the GESTRA Quick-

Closing Blow Down Valve with hand lever without hand lever,

DRAIN (Item 1.1.0.7)

1.2.3.4 1 Three-way solenoid valve 230 V AC / 50 Hz with accessories

1.2.3.5 1 Y-Strainer, red bronze, sieve SS, thread ISO 228/1

1.9.0.0 1 BBS HEAT EXCHANGER ECOnomizer OPTION

- Heat recovery from the flue gas heat to preheat Medium

SOFTWATER

- This recovering process succeed in gaining a higher boiler

efficiency (additional energy savings) as well as in minimizing

the pollutant emission

1.9.1.0 # SCOPE of DELIVERY / DESIGN

- Customs tariff number, HS code 8404 10 00

- Fabrication in line with APPLICABLE European PED (Pressure EN 13445-3 // PED 2014/68/EU

Equipment Directive) and German Codes AD 2000

- Heat transfer by principle of CROSS-CURRENT flow

1 HOUSING INTEGRATED on boiler, REMOVABLE OPENING for

repair works, material made of CARBON STEEL

1 REPLACEABLE ribbed tubes register. The ribs are wound up

under tension / Material made of CARBON STEEL

1 HEAT INSULATION with high quality rock wool and

GALVANIZED sheet cladding

1 EQUIPMENT / BBS HEAT EXCHANGER ECOnomizer / Medium

SOFTWATER (COLD SIDE)

1 INSPECTION by THIRD PARTIES: Pre-shipment inspection will

be carried out by TUEV GERMANY / TÜV SÜD Industrie Service

GmbH. A report or CE Declaration of Conformity shall be

furnished to the purchaser respectively to end user

1.9.2.0 # PAYBACK CALCULATION

- Yearly running hours 2.000 h 4.000 h 6.000 h

+ Fuel saving p.a. by GASEOUS FUEL 22.164 m³ 44.328 m³ 66.491 m³

- converted in MWh 222 MWh 443 MWh 665 MWh

- Estimated current fuel price 0,04 €/kWh

- Money Saving in (EURO) 8.866 € 17.731 € 26.597 €

- PAYBACK of the investment within (approx.) 1109 days 555 days 370 days

1.9.3.0 # TECHNICAL DATA / BBS HEAT EXCHANGER ECOnomizer

- Heat capacity / Energy gain @ GASEOUS FUEL 111 kW 4,26%

- Stamp Pressure PS 12,0 bar g

- Hydraulic Test Pressure PT according PED

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 11 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

+ Medium FLUE GAS

- HOT SIDE Flow around the ribbed tubes

- Temperature ECO INCOMING (T OUTGOING -> STACK) 264,6 °C (130,0 °C)

+ Medium SOFTWATER

- COLD SIDE Flow in the tubes

- Temperature ECO INCOMING (T OUTGOING -> HDK) @ 105,0 °C (142,9 °C)

GASEOUS FUEL

1.9.5.0 1 EQUIPMENT / BBS HEAT EXCHANGER ECOnomizer / Medium

SOFTWATER (COLD SIDE)

- consisting of

1.9.5.7 1 Set TEMPERATURE GAUGE, ECOnomizer INLET

1.9.5.8 1 Set TEMPERATURE GAUGE, ECOnomizer OUTLET

1.9.5.15 1 Unlockable Interconnecting Piping (Medium SOFTWATER) BBS

HEAT EXCHANGER ECOnomizer <-> BBS HIGH-PRESSURE

STEAM BOILER HDK 2500

2.0.0.0 1 BOILER's FEED UNIT (SP)

- consisting of

2.1.0.0 2 GRUNDFOS CENTRIFUGAL PUMPS with VARIABLE

FREQUENCY DRIVE

- 1 on duty, 1 on standby

- Vertical, multistage centrifugal pump with suction and

discharge ports on the same level. The pump head and base

are in cast iron, all other wetted parts are in stainless steel

- Pumping medium: Make-up water, Tmax 120 °C

- Nominal rated flow (allowable MIN stable flow rate for 3,0 m³/h (1,25 m³/h)

continuous operation at speed control down to 25 Hz)

- Actual calculated flow rate / TDH dynamic head 3,2 m³/h 11,0 bar g

- Motor rated power P2 2,20 kW

- Drive Motor: Rated voltage / FREQUENCY CONTROLLED 3~ 400 V 50 Hz

(common inverter driving the 2 pump motors)

- Power reserve according to ISO 5199 / Motor speed / 30,9% 2.900 min-1 IE3

Efficiency class according to IEC60034-30-1

- NPSH required 5m

2.2.0.0 1 BASIC FITTINGS / BOILER's FEED UNIT (SP)

- consisting of

2.2.0.1 2 ARI FABA®-Plus Stop Valve, maintenance free, bellows seal up

to 300°C, PUMP FEED SIDE

2.2.0.2 2 GESTRA DISCO® Non-Return Valve, PUMP FEED SIDE

2.2.0.3 2 Set PRESSURE GAUGE, PUMP FEED SIDE

2.2.0.4 2 ARI FABA®-Plus Stop Valve, maintenance free, bellows seal up

to 300°C, PUMP SUCTION SIDE

2.2.0.5 2 ARI Y-Strainer, sieve and basket made of SS up to 300°C,

PUMP SUCTION SIDE

2.2.0.6 2 Set VACUUM PRESSURE GAUGE, PUMP SUCTION SIDE

2.2.0.11 1 Compact installation on skid as feed station ready to be

interconnected HDK 2500 <-> FEED TANK (SWT)

3.0.0.0 1 FIRING UNIT

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 12 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

- consisting of

3.1.0.0 1 WEISHAUPT GAS BURNER Series MONARCH®

- Fully automatic sliding two stage or modulating depending on

rating regulation

- Monobloc burner construction can be hinged open to the left

or right, protection type IP54, type approval according EN

676. Consisting of the following parts:

- Flow favourable, compact housing for large ratings range and

high flame stability. Integrated intake sound absorber for

noise emission reduction in the boiler room.

- Digital combustion manager for start control, flame

monitoring and valve proving with stepping motors for air

damper and gas butterfly on correcting elements

- Input for fuel quantity determination. Basic parameter pre-

setting by factory. Display and operat. unit (ABE) with single

line digital display as well as e-Bus and Modbus interface

- Air and gas pressure switches. Electronic ignition unit. Motor

with integrated contactor.

- All burner components are connected via plug. Plug

connection for motor available at extra price.

- Gas valve trains consisting of: Double solenoid valve cl. A,

elbow and connecting parts. Burner is type tested to EN 676.

NOx in accordance with Emissions Class 2 (N-Gas)

- Heat Power for gas firing: MIN (MAX) / nominal 350 kW (2.600 kW) 1.842 kW

- Turn down ratio gas-side MAX 1:6

- MAX total smoke resistance 6,1 mbar

3.1.1.0 # SPECIAL VERSION

3.1.1.14 1 Integral capacity controller with analogue signal convertor

3.1.1.15 1 Firing manager W-FM suitable for continuous operation, start

sequence control, flame monitoring and valve proving for gas

valves

3.1.1.17 1 MAX gas pressure switch for low pressure supply

3.1.1.26 1 Pressure switch GW 150 A5 instead of GW 50 A5

3.1.1.34 1 Valve train complete preassembled from DMV to burner and

electrically wired for right+left installation

3.1.1.38 1 Premounting from ball valve to DMV inlet

3.1.1.45 1 Oil meter VZO20 fitted to the burner with low-frequency

teletransmitter for external wiring

3.1.2.0 # BURNER with the following CONFIGURATIONS

- National execution EGYPT

- LANGUAGE on Display and Operating unit (ABE) ENGLISH / West Europe 1: DE, GB, FR, Italian,

Spanish, Portuguese

- Type of gas NATURAL GAS (LNG)

- Main voltage 400 V 50 Hz

- Motor start DOL

- Burner Management W-FM 100

3.5.0.0 1 BURNER ACCESSORY * 1 GAS TRAIN FITTING

- Gas fittings ramp, accessory components with shut-off

devices, gas filter, pressure monitoring as well as assembly

and connection parts, mainly consisting of:

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 13 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

3.5.1.0 1 GAS CONTROL SECTION / LOW PRESSURE

3.5.1.1 1 Gas valve train: DMV double electromagnetic valve, class A,

DIN EN 161, 230V / 50Hz

3.5.1.4 1 Ball valve set for gas

3.5.1.5 1 Filter Set WF for gas

3.5.1.6 1 Reducing set

3.5.1.7 1 GAS FLOW METER

- Turbine flow meter, with temperature and pressure

compensation, local display for instantaneous and total value

(m³), LF/HF pulse transmitter

1 Set interconnecting parts, reducing flanges for gas meter

3.5.1.9 1 Low pressure governor

- Gas pressure upstream the gas fittings 300 mbar

3.5.1.10 1 Pressure gauge with push-button valve

3.5.1.11 1 Pressure gauge fitted to DMV, with GW...A6 additionally

3.5.1.12 1 Test burner

3.5.1.14 1 Axial compensator set

3.5.1.15 1 Bend set

3.5.1.16 1 Set Bracket, Mounting rail, Support …

# IMPORTANT NOTE! FUEL SUPPLY by CUSTOMER ON-SITE

- FUEL GAS: Delivery limit is the ball valve. Gas installation to

the GAS CONTROL SECTION according the local directives is

to be carried out by customer including EMERGENCY STOP

outside of boiler house EMERGENCY STOP required in EU countries

4.0.0.0 1 BBS CONTROL CABINET

- FIRING POWER control, SENSORIES in electric safety chain

- Wiring shall be made from cable ducts with marked and

numbered terminals on mounting plates and connection to

the devices mounted on the door.

- Examination of all functions by switch cabinet connection to

the simulation facilities

- Wiring plan and test reports enclosed in switch cabinet

- consisting of

4.1.0.0 1 RITTAL PANEL

1 Housing made of CARBON STEEL SHEET, pulverized coating, RAL 7035

painted

1 Protection class IP54 / IP55

1 Installation type: floor mounting

- Lettering language on CABINET DOOR ENGLISH

- Main power 3~ 400 V 50 Hz

- Control power 220 V 24 V DC

- Electricity feed-in with 20% reserve / Consumption 7,0 kW 20,1 A

- Star-delta starting from 11,0 kW

4.2.0.0 # SWITCHES / CONTROL UNITS on CABINET DOOR

- brand / make of field instruments, switches, pins, relays … BBS STANDARD

1 Main switch 0-1 (DIN VDE 0113 / EN 60204 part 1)

- without locking at tension drop

1 Emergency cut-out push-button

- Redundancy boiler interlocking

- Release through push-button reset

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 14 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

4.3.0.0 # CONTROL / DISPLAY / SIGNAL INTERCHANGE

4.3.1.0 # CONTROL and SAFETY DEVICES

1 Boiler PLC power logic controller (PIC1) EATON MFD-Titan

- Control parameter: STEAM PRESSURE, control range 0 … 16 bar

- Power controller type modulation

- programmable device that provides HMI, switching, closed-

loop and open-loop control functions, and can be used to

replace relay and contactor controls as well as being used as

an MFD device. Protection class to IP65

- with the following features:

• Logic functions

• Timing relay and counter functions

• Time switch functions

• Arithmetic functions

• PID controllers

• Operator and display functions

1 SAUTER Safety pressure switch MAX (PZA1+), MANOSTATE

COLLECTOR

1 WATER LEVEL CONTROLLER WSTR

1 LEVEL SWITCH (LZA1-) / (LZA2--) for 2 electrodes / LEVEL

LIMITER LOW WATER WSTB-L1 / L2

1 Desalting controller

4.3.2.0 # DISPLAY

- Plain text display of operating and malfunction messages of all

pending measured values and states relevant to operation,

mainly for the following devices

1 WEISHAUPT GAS BURNER Series MONARCH®

2 GRUNDFOS CENTRIFUGAL PUMPS with VARIABLE FREQUENCY

DRIVE / BOILER's FEED UNIT (SP)

1 SAUTER Safety pressure switch MAX (PZA1+), MANOSTATE

COLLECTOR

1 WATER LEVEL CONTROLLER WSTR

1 LEVEL SWITCH (LZA1-) / (LZA2--) for 2 electrodes / LEVEL

LIMITER LOW WATER WSTB-L1 / L2

4.3.3.0 # COMMUNICATION / SIGNAL INTERCHANGE / INTERFACE

- Signals are provided available to potential free terminals in

the control cabinet. On request a signals list can be fixed

exactly with a surcharge

- Input and output analog / binary 4 … 20 mA 0 … 10 V DC

1 Linking up into a master control system, all operating data

transmission, remote control and local setting e. g. via PROFIBUS DP

- ALARM in case of malfunctions, following 4 OPTIONS for an

additional charge:

1. Pure alarm via SMS (up to 10 alarms) = 650€

2. Alarm via SMS (up to 10 alarms) + remote maintenance =

950€

3. Alarm and monitoring via app (up to 10 alarms and up to

5 monitoring values) with visualization = 1350€

4. Alarm and monitoring via app (up to 10 alarms and up to

5 monitoring values) with visualization + remote

maintenance = 1650€

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 15 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

4.3.4.0 1 PRE-PROGRAMMING with REMOTE CONTROL

4.3.4.1 1 Pre-programming factory standby of the boiler automatically

on weekends and on Monday to full load

4.3.4.2 1 Extension for time-dependent switching of the pumps (for

example every 2 days ...)

4.3.4.3 1 Remote control, signaling of operating data, remote

maintenance via modem, on-off via an external timer

16.0.0.0 1 SPARE PARTS

- consisting of

16.1.0.0 1 BOILER ACCESSORIES and SENSORIES for SAFETY and

CONTROL

16.1.1.0 2 Gasket / headhole cover 320x220x25x10 mm novaSEAL

16.1.2.0 1 Gasket / manhole cover 420x320x25x10 mm novaSEAL

16.1.7.0 1 Boiler pressure gauge / 0 … 16 bar / NG160 - G1/2B bottom

16.1.8.0 1 SAUTER Safety pressure switch MAX (PZA1+), MANOSTATE

COLLECTOR / DSH 152 F001 / 2 … 16 bar

16.1.9.0 1 JUMO Pressure transmitter (PE1), MANOSTATE COLLECTOR /

0 … 16 bar

16.1.10.0 1 COMPACT LEVEL ELECTRODE / NRGT26-2 - SPECTORcompact

230 VAC, 4 … 20 mA, G1

16.2.0.0 1 SWITCH CABINET

16.2.1.0 1 Motor protection switch / pump

16.2.3.0 1 Relay safety chain K12 Siemens

16.2.4.0 1 Relay safety chain K11 Möller

16.3.0.0 1 PUMP

16.3.2.0 1 Set of gasket CR EPDM

16.4.0.0 1 BURNER

16.4.3.0 1 Flange gasket 380 x 302.5

16.4.10.0 1 Ignitor type W-ZG02 230V 110 VA

16.4.18.0 2 Ignition electrode WM-G (L) 20/30 ZM

23.0.0.0 1 COMMISSIONING

- consisting of

23.1.0.0 # SCOPE of DELIVERY / EXECUTION

- The COMMISSIONING shall be carried out as belows

- Factory location is CAIRO / EGYPT

1 BBS electrician

1 COLD CHECK of the MOUNTED ARRANGEMENT

- Mechanical, examination of the proper installations as well as

piping construction

- Electrotechnical, signal trim of the SENSORY

- Checking the firing unit and the gas, oil, electric supply

- For gas burners, a gas meter must be installed on site

1 START-UP and TEST RUN

- Start-up according to the agreed operating datas and

optimizing under the production conditions

- Functional test and safety check as well as instruction of the

customer staff during the checking

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 16 / 17

To company Oriental Weavers Carpet Offer from BBS GmbH

Kind attention Mr. Amany AHMED arranged by Mr. El MALIZI

Code Name Dampfkessel / STEAM BOILER Offer no. EL240220-014

TECHNICAL SPECIFICATION Date 23.02.2024

Item Qty DESCRIPTION Technical Data

- Instruction of the customer staff in the service and

maintenance of the delivered arrangement

- Safety-technical instruction with the help of the manual

- Confirmation of training signed by the instructed staff

23.2.0.0 # CUSTOMER DUTY ON-SITE / COMMISSIONING

- IMPORTANT NOTE! WEISHAUPT service engineer for burner

setting is to be ordered by customer

- Fuel supply to burner according to local prescriptions

- Electric main supply to the control panel

- Fuel and power (electricity) must be available in sufficient

quantity. Ongoing heat consumption must be assured.

- The arrangement must be installed ready to operation and

filled with boiler feed water.

- The safety testing and/or burner inspection by the TÜV or

other inspection companies must be ordered on time. The

costs for this are to be borne by the customer.

EL240220-014.xlsx / HDK-Angebot *** Seite(Page ) 17 / 17

You might also like

- Invoice EB19316-2-1 - 05.03.2020 With LPODocument5 pagesInvoice EB19316-2-1 - 05.03.2020 With LPODumindu Chandana PunchihewaNo ratings yet

- Vol-II Section 2 DTS Mechanical - R0Document605 pagesVol-II Section 2 DTS Mechanical - R0Pradeepta 3ANo ratings yet

- 000917a - V-Mark - BM 2000 T 30cm Extruder-1Document12 pages000917a - V-Mark - BM 2000 T 30cm Extruder-1hungthienphu999No ratings yet

- OICO - EDC Technical Offer - 05390-22Document2 pagesOICO - EDC Technical Offer - 05390-22MohammadNo ratings yet

- V1 Tour B 220317Document6 pagesV1 Tour B 220317chida mohaNo ratings yet

- CITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)Document4 pagesCITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)FarisNo ratings yet

- Gharissa Ice Mante 20 - 60 Mixpasto 120 Qatar P.kuwait PDFDocument5 pagesGharissa Ice Mante 20 - 60 Mixpasto 120 Qatar P.kuwait PDFSanu PhilipNo ratings yet

- MPS-Lab D.O.O. Sarajevo: Project Uw Kenmerk Offertenummer DatumDocument2 pagesMPS-Lab D.O.O. Sarajevo: Project Uw Kenmerk Offertenummer DatumHi ParphNo ratings yet

- Sodimex FR S.A.: InquiryDocument2 pagesSodimex FR S.A.: InquiryGunawan WibowoNo ratings yet

- PODocument5 pagesPOSiva ChalicheemalaNo ratings yet

- Quotation Gas Js 2023Document188 pagesQuotation Gas Js 2023logisticsNo ratings yet

- D190808-0 - Saj Engineering & Trading CompDocument3 pagesD190808-0 - Saj Engineering & Trading CompRazibul Saj EngineeringNo ratings yet

- By Regd. Post With Ack. Due & MailDocument17 pagesBy Regd. Post With Ack. Due & MailTender 247No ratings yet

- Wa0138.Document1 pageWa0138.Manish KumarNo ratings yet

- A0 Dieffenbacher Commercial Offer 387151 - 01 With CPS+ 265-56m 20210601Document10 pagesA0 Dieffenbacher Commercial Offer 387151 - 01 With CPS+ 265-56m 20210601Long Đặng HoàngNo ratings yet

- Devis Faiz ImportDocument6 pagesDevis Faiz Importlords alorNo ratings yet

- Qtn. #26 Abb Circuit Breaker PDFDocument3 pagesQtn. #26 Abb Circuit Breaker PDFfares hammoudNo ratings yet

- Offer For Aux EngineDocument16 pagesOffer For Aux EngineJackNo ratings yet

- O F F E R No. 322021 /45: Nabertherm GMBH Bahnhofstr 20 28865 Lilienthal/BremenDocument26 pagesO F F E R No. 322021 /45: Nabertherm GMBH Bahnhofstr 20 28865 Lilienthal/Bremenjuan Carlos espinozaNo ratings yet

- Gharissa Ice Mante 20 - 60 Mixpasto 120 Qatar P.kuwait PDFDocument6 pagesGharissa Ice Mante 20 - 60 Mixpasto 120 Qatar P.kuwait PDFSanu PhilipNo ratings yet

- RFQ Golden Gate (Alu - Redcon) 20-11-2023Document2 pagesRFQ Golden Gate (Alu - Redcon) 20-11-2023esomalk1No ratings yet

- QTN Hoffman UAEDocument18 pagesQTN Hoffman UAEmotionNo ratings yet

- Auftrag GA1000825Document2 pagesAuftrag GA1000825miiroowNo ratings yet

- Project Specific Details - JBRDocument13 pagesProject Specific Details - JBRRaad BaniyaseenNo ratings yet

- Quotation - Gas Piping 2023 - PaDocument358 pagesQuotation - Gas Piping 2023 - PalogisticsNo ratings yet

- Offer 3Document8 pagesOffer 3dubai eyeNo ratings yet

- Catalogo Horno de CopelacionDocument13 pagesCatalogo Horno de CopelacionFernando MarcosNo ratings yet

- Quotation: Promass 200 Spare PartsDocument4 pagesQuotation: Promass 200 Spare PartsHisham ABD ALRASOULNo ratings yet

- Petrol & Gas Construction Co. Your QEMS Contact: QuotationDocument2 pagesPetrol & Gas Construction Co. Your QEMS Contact: QuotationjabirNo ratings yet

- RG-2012024-III AGC Brazil InstallationDocument3 pagesRG-2012024-III AGC Brazil InstallationranishNo ratings yet

- Mtcs-Boq-190-1125 - Viproom - Artmind VarDocument5 pagesMtcs-Boq-190-1125 - Viproom - Artmind Varsyed WajihNo ratings yet

- LV Offer Ycic A8Document3 pagesLV Offer Ycic A8HaikalNo ratings yet

- Proforma Invoice: Document Number: Date: Customer Number: Our ReferenceDocument6 pagesProforma Invoice: Document Number: Date: Customer Number: Our ReferenceArafat SaleheenNo ratings yet

- Al Madina Hypermarket DibbaDocument3 pagesAl Madina Hypermarket DibbamuhammedkuttyNo ratings yet

- IVD 21 BQ 195 AGOCO Nafoora Metering SkidsDocument7 pagesIVD 21 BQ 195 AGOCO Nafoora Metering Skidsnader mahfoudhiNo ratings yet

- Inv 2424476 Konvex 1Document1 pageInv 2424476 Konvex 1Rade ArsenijevicNo ratings yet

- 1209 - Skyline Consultant - Revised-0355 PDFDocument3 pages1209 - Skyline Consultant - Revised-0355 PDFKline Sky J LineNo ratings yet

- Request For Quotation - P00292Document1 pageRequest For Quotation - P00292Ahmed Abdel-AzizNo ratings yet

- Bosch Offer1169073653-377Document59 pagesBosch Offer1169073653-377Ramy Mahmoud0% (1)

- RB Catalogo Subasta Septiembre 2023Document199 pagesRB Catalogo Subasta Septiembre 2023Osvaldo RoccaNo ratings yet

- Company Concern Offer No Offer Date Model/Capacity::Dalo Company:Mustafa Dalo: VM2021-C875-R3: 12.11.2021:100 m3/sDocument18 pagesCompany Concern Offer No Offer Date Model/Capacity::Dalo Company:Mustafa Dalo: VM2021-C875-R3: 12.11.2021:100 m3/sResul AkkurtNo ratings yet

- RFQ 292020 Mamba Sector AccomodationDocument7 pagesRFQ 292020 Mamba Sector AccomodationlibanpiresNo ratings yet

- BOQ-Hvac Hall - 24.06.23 FinalDocument19 pagesBOQ-Hvac Hall - 24.06.23 FinalAnkit AgarwalNo ratings yet

- BBGC QS RR-302 07 2023 Water ProofDocument7 pagesBBGC QS RR-302 07 2023 Water ProofChikku NiyasNo ratings yet

- Kone 57Document6 pagesKone 57ARGHA SANANo ratings yet

- 3760 LT LPG Domestic TankDocument5 pages3760 LT LPG Domestic TankDaniel Edward Omondi100% (1)

- Corelio 30804 Grafisch-En-Papier UKDocument53 pagesCorelio 30804 Grafisch-En-Papier UKcombiliftforkliftNo ratings yet

- Fco Ulsd 10PPM BLM - Mep 200K TtoDocument6 pagesFco Ulsd 10PPM BLM - Mep 200K TtoAnugerah KalimantanNo ratings yet

- Cazan Installation-Manual-FbgDocument20 pagesCazan Installation-Manual-FbgCretu Stefan-DanielNo ratings yet

- NIT For JOJOBERA E&C U2 BOP-2021-07-20-08 39 51Document108 pagesNIT For JOJOBERA E&C U2 BOP-2021-07-20-08 39 51Instrument CandidatesNo ratings yet

- Steel Gate IHGDocument2 pagesSteel Gate IHGseyed sulthanNo ratings yet

- O F F E R No. 313232 /32: Nabertherm GMBH Bahnhofstr 20 28865 Lilienthal/BremenDocument15 pagesO F F E R No. 313232 /32: Nabertherm GMBH Bahnhofstr 20 28865 Lilienthal/BremenRidouane EL HAJJINo ratings yet

- Request For Quotation - P00292Document1 pageRequest For Quotation - P00292Ahmed Abdel-AzizNo ratings yet

- Silangan Fit OutDocument5 pagesSilangan Fit OutNova CastyNo ratings yet

- Qt-05-Casa Milano-Doha-Qatar-07.12.2023Document4 pagesQt-05-Casa Milano-Doha-Qatar-07.12.2023ipmx16075No ratings yet

- Samsung Brand VRF AC Offer: Submitted byDocument8 pagesSamsung Brand VRF AC Offer: Submitted bymustaqim. hvacNo ratings yet

- Budget Quotation OPP00001706-EV-BQR4Document3 pagesBudget Quotation OPP00001706-EV-BQR4Eusebio Castillo MejiaNo ratings yet

- 2310 D305 TA Rev00Document2 pages2310 D305 TA Rev00tamtour7No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- En US-AF Privacy NoticeDocument1 pageEn US-AF Privacy NoticeAbdallah AbdallahNo ratings yet

- Abdelaziz Abdallah AbdelazizDocument2 pagesAbdelaziz Abdallah AbdelazizAbdallah AbdallahNo ratings yet

- Boiler KpiDocument2 pagesBoiler KpiAbdallah AbdallahNo ratings yet

- User Manual Xiaomi Redmi Note 11S (English - 59 Pages)Document3 pagesUser Manual Xiaomi Redmi Note 11S (English - 59 Pages)Abdallah AbdallahNo ratings yet

- Model Papers - Cryogenic I SemesterDocument34 pagesModel Papers - Cryogenic I Semesterrajraj3550No ratings yet

- SRU UnitDocument33 pagesSRU UnitCenk Yağız ÖzçelikNo ratings yet

- Actual Methods For Obtaining Vegetable Oil From Oil SeedsDocument7 pagesActual Methods For Obtaining Vegetable Oil From Oil SeedsSally Polo PiedrahitaNo ratings yet

- The Emperor's Wrath 2Document10 pagesThe Emperor's Wrath 2Александр КурочкинNo ratings yet

- Tutorial 3 PDFDocument3 pagesTutorial 3 PDFWan NorfarhanaNo ratings yet

- PSAII Final EXAMDocument15 pagesPSAII Final EXAMdaveadeNo ratings yet

- Y Strainer CatalogDocument2 pagesY Strainer CatalogLandung GumilangNo ratings yet

- Floating LNG Technology For Abadi Field Development: IPA09-E-158Document12 pagesFloating LNG Technology For Abadi Field Development: IPA09-E-158REandoNo ratings yet

- CMC (Coordinated Master Control)Document28 pagesCMC (Coordinated Master Control)Anoop Kumar Allanki100% (4)

- Bartlesville Project U. S. Department of Energy Bartlesville, KlahomaDocument445 pagesBartlesville Project U. S. Department of Energy Bartlesville, KlahomaGabriel EduardoNo ratings yet

- 2013Document31 pages2013Narayanan SrinivasanNo ratings yet

- Egypowpd Module3Document52 pagesEgypowpd Module3Jas PayaNo ratings yet

- Boiler Emergency OperationsDocument55 pagesBoiler Emergency OperationsbajrangNo ratings yet

- Heat Balance & Thermal Power Plant Performance (MDT)Document44 pagesHeat Balance & Thermal Power Plant Performance (MDT)Anita BaitadeNo ratings yet

- 44 Uc Irvine's Combined Heat Power PlantDocument48 pages44 Uc Irvine's Combined Heat Power Plantparklane79No ratings yet

- 6 44 0005 A2Document25 pages6 44 0005 A2S.selvakumarNo ratings yet

- Power Stations: Section One: Reading ComprehensionDocument7 pagesPower Stations: Section One: Reading Comprehensionعلیرضا جعفرنژادNo ratings yet

- Alfa VapDocument2 pagesAlfa Vapkresimir.mikoc9765No ratings yet

- JPCL - TaqiDocument22 pagesJPCL - TaqiAsad UllahNo ratings yet

- Economiser LiteratureDocument7 pagesEconomiser LiteratureSteve M D'souzaNo ratings yet

- CH-14 Design Fundamentals of BoilerDocument15 pagesCH-14 Design Fundamentals of BoilerRavi ShankarNo ratings yet

- PPE NotesDocument30 pagesPPE NotesmeenaNo ratings yet

- Boiler AnnexDocument66 pagesBoiler Annexrenjithv_4No ratings yet

- 5 09 E Adcamat APST Automatic Pump and Steam Trap DN40x50Document5 pages5 09 E Adcamat APST Automatic Pump and Steam Trap DN40x50lesonspkNo ratings yet

- Statement of PurposeDocument6 pagesStatement of PurposeMichelleMich Mangubat Descartin50% (2)

- Electrical Thermal Power Generation MCQ'sDocument13 pagesElectrical Thermal Power Generation MCQ'ssalman bhattiNo ratings yet

- Millennium B Bplus and B2 ManualDocument102 pagesMillennium B Bplus and B2 ManualMohamed Choukri Azzoula60% (5)

- Flour Siever / Flour Sifter: SpecificationDocument9 pagesFlour Siever / Flour Sifter: SpecificationJustine AbanadorNo ratings yet

- HW4Document1 pageHW4Shanka UdugampolaNo ratings yet