Professional Documents

Culture Documents

HCQXSeriesExtensionModuleHW INS V3 1 (En)

Uploaded by

Олег ЕфимовOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HCQXSeriesExtensionModuleHW INS V3 1 (En)

Uploaded by

Олег ЕфимовCopyright:

Available Formats

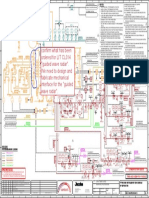

01 02 03 04 05 06 07 08

Indicates that incorrect handling may cause hazardous conditions, Symbo l Colo r Descriptio n Symbol Light color Channel description Mounting Symbol Light color Description QX-DA04

DANGER resulting in death or severe injury or significant property damage PWR Green The indicator show the current power supply status of the module

. The indicator show the current power supply status of the hook QX-AD04

P Green P Green The indicator shows the current power supply status of the module. P RUN

module. P RUN

RUN Red EC module running state. Lit means the module is in normal running state OD module running state. Lit means the module is in

Indicates that incorrect handling may cause hazardous conditions, RUN Red

QX-AD04 A1 Analog module running state. Lit means the module is in normal A1

WARNING MODEL:HCQX-EC01-D A1 Red Channel ACT/LINK indicator of PORT 1 normal running state A2

RUN Red running state

resulting in medium or slight personal injury or physical damage. POWER INPUT:DC24(-15%~+20%) 70mA(Typ.)

A2

A2 Red Channel ACT indicator of PORT 2 0 Red Output signal is detected by output channel 0. ER Note that the indicator Whether ESC channel 1 of analog input module can respond

POWER OUTPUT:12V 16W A1 Red ER

Indicates that incorrect handling may cause slight injury or property

AD

in the frame is not normally.

A3 Red Channel ACT/LINK indicator of PORT 3 1 Red Output signal is detected by output channel 1. Connector DA

CAUTION damage. de ned temporarily. A2 Red

Whether ESC channel 2 of analog input module can respond

L2 Red Channel LINK indicator of PORT 2 2 Red Output signal is detected by output channel 2 mounting normally.

S/N:Y2119557811 Indicators

hook

P/N:200019Y0852000000000 3 Red Output signal is detected by output channel 3. ER Red AD operation failure indication

Indicates that incorrect handling may cause damage to the

HCQX Remote Extension Modules Note environment / equipment or data loss MADE IN CHINA 2.2.2 Main view of digital input module HCQX-ID16-D 4 Red Output signal is detected by output channel 4. AD Red Connection failure indication between AD module and MCU Symbol Light color Description

5 Red Output signal is detected by output channel 5. Sheetmetal The indicator shows the current power supply status of the

Figure 1 Model name and nameplate description Mounting P Green

Hardware Instruction hook QX-ID16-D 6 Red Output signal is detected by output channel 6. Tips module.

Analog module running state. Lit means the module is in

P RUN 7 Red Output signal is detected by output channel 7. When the ESC channel in the indicator respond normally, it does not RUN Red

Key points or explanations to help with better operation and

QX-ID16-D

normal running state

P RUN

0 4 10 14 10 Red Output signal is detected by output channel 10. correspond to the specific channel of analog input. Whether ESC channel 1 of analog output module can respond

understanding of product.

0 4 10 14

1 5 11 15 A1 Red

①Model name normally.

1 5 11 15

Manual Number HPPP1220000EN Connector 2 6 12 16

11 Red Output signal is detected by output channel 11.

②Input voltage & current 3 7 13 17

2 6 12 16 Whether ESC channel 2 of analog output module can respond

mounting Input channel arrangements A2 Red

Manual Version V3.1 ③Output voltage & power hook 3 7 13 17 12 Red Output signal is detected by output channel 12. normally.

④Code, S/N &P/N, The rst four digits of the PN code are the version number. DI 0 10 13 Red Output signal is detected by output channel 13. 2.2.6 Main view of analog output module HCQX-DA04-D ER Red DA operation failure indication

Date 2021.8 1.1.2 Safety symbols

Eg: The version number in the gure above is V2.000. Indicators DI 1 11 14 Red Output signal is detected by output channel 14. DA Red Connection failure indication between DA module and MCU

⑤QR code (model name, serial number) Terminal block

STARTUP AND MAINTENANCE PRECAUTIONS DI 2 12 15 Red Output signal is detected by output channel 15. Mounting

Sheetmetal

DI 3 13 16 Red Output signal is detected by output channel 16. Common hook QX-DA04

When the ESC channel in the indicator respond normally, it does not

DANGER 2.1.2 Model name description for function modules DI 4 14

17 Red Output signal is detected by output channel 17. terminal P

A1

RUN

correspond to the specific channel of analog output.

1 Introduction

QX-DA04

DI 5 15 Note that the indicator

HC QX- ID XX- D

COM No indicator COM output common terminal

, connecting to 0V power A2

•Do not touch any terminal while the PLC's power is on. Doing so may cause electric shock or DI 6 16 in the frame is not

ER

malfunctions. COM No indicator COM output common terminal

, connecting to 0V power Figure 7 Analog input module inte aces diagram de ned temporarily.

DI 7 17 AD

Thank you for purchasing and using the Q series remote extension modules independently •Before cleaning or retightening terminals externally cut off all phases of the power supply. Common Connector

Failure to do so may cause electric shock. SS SS mounting

developed and produced by HCFA Corporation. terminal 2.2.4 Main view of digital I/O module HCQX-MD16-D

Company information Series name Function module Number of channels Power type Indicators 2.2.7 Main view for temperature measurement module HCQX-TS04-D

This Instruction will give the brief explanation for the following modules in the table: •Before modifying or disrupting the program in operation or Forced output, RUN, STOP etc., Name Terminal Name hook

HCFA QXslave Digital input * Channel arrangements is octal.

carefully read through this Instruction and the associated Instructions and ensure the safety of ID Number D DC powe Terminal block

QX XX V1- 0 9 V1+

the operation. An operation error may damage the machinery or cause accidents. terminal Digital output of ch. A AC power Mounting QX-MD16-D

OD/OC (Transistor Mounting

Name Module Version Power Description Common hook P RUN

/relay) Sheetmetal hook QX-TS04

terminal G 1 10 I1

STARTUP AND MAINTENANCE PRECAUTIONS MD Digital I/O Figure 4 Digital input module inte aces diagram QX-MD16-D 0 4 0 4

New Coupler Connect EtherCAT and EtherCAT terminal P RUN

1 5 1 5 Channel arrangements P RUN

HCQX-EC01-D V1.00 16W (digital, analog modules etc.) AD Analog input 0 4 0 4

module 1 5 1 5

2 6 2 6

QX-TS04 A1

Analog output DI 0 0 DO

CAUTION DA

2 6 2 6

Connect EtherCAT and EtherCAT terminal

3 7 3 7

3 7 3 7 V2- 2 11 V2+ A2

Coupler Symbol Light color Channel description I Q

HCQX-EC-D V1.30 8W MA Analog I/O Connector I Q

DI 1 1 DO

ER Note that the indicator

module (digital, analog modules etc.) mounting

P Green The indicator show the current power supply status of the module. Connector AD in the frame is not

•Do not disassemble or modify the PLC. Doing so may cause fire, equipment failures, or Temperature Indicators DI 2 2 DO G 3 12 I2

Connected to the local extension of main TS hook mounting de ned temporarily.

Digital malfunctions. measurement RUN Red ID module running state. Lit means the module is in normal running state

HCQX-ID16-D V1.10 0.78W unit or the back of coupler, cannot be used DI 3 3 DO hook Indicators

input modul For module repair, contact our HCFA distributor. 0 Red Input signal is detectedby input channel 0. Sheetmetal Terminal block

alone. NPN and PNP inputs are supported. V3- 4 13 V3+

DI 4 4 DO

•Turn off the power to the PLC before connecting or disconnecting any extension cable. Failure 1 Red Input signal is detectedby input channel 1.

Digital Connected to the local extension of main to do so may cause equipment failures or malfunctions MODEL:HCQX-ID16-D DI 5 5 DO

output HCQX-OD16-D V1.10 1.32W unit or the back of coupler, cannot be used INPUT:DC24V 5mA(Typ.) 2 Red Input signal is detectedby input channel 2. Common Sheetmetal

•Turn off the power to the PLC before attaching or detaching the following devices. Failure to DI 6 6 DO G 5 14 I3

module alone. NPN output is supported. QBUS OUTPUT:0.8W terminal

do so may cause equipment failures or malfunctions 3 Red Input signal is detectedby input channel 3. Figure 8 Analog output module inte aces diagram

DI 7 7 DO

Connected to the local extension of main -Display module, peripheral devices, expansion boards 4 Red Input signal is detectedby input channel 4. Common Common V4- 6 15 V4+

Digital I/O unit or the back of coupler, cannot be used S/N:Y2119557811 terminal I-COM Q-COM terminal

HCQX-MD16-D V1.10 1.032W -Extension blocks and special adapters P/N:200019Y0852000000000 5 Red Input signal is detectedby input channel 5.

module alone. NPN and PNP inputs are supported, MADE IN CHINA

NPN output is supp orted. -Battery, terminal block and memory cassette 6 Red Input signal is detectedby input channel 6. The COM for input/output should be G 7 16 I4 Name Terminal Name

independent of each other and don't

Analog input. Connected to the local extension Figure 3 Model name and nameplate description 7 Red Input signal is detectedby input channel 7. V1 0 9 G

DISPOSAL PRECAUTIONS

Analog of main unit or the back of coupler, cannot be Terminal block G 8 17 G

10 Red Input signal is detectedby input channel 10.

input HCQX-AD04-D V1.10 1.044W used alone. Support single-ended and Common Terminal block

module differential input and wide range of

current/voltage input signal.16bit resolution

CAUTION 11 Red Input signal is detectedby input channel 11. terminal I1 1 10 G

Common

① Model name 12 Red Input signal is detectedby input channel 12. Figure 6 Digital I/O module inte aces diagram

Terminal name Description terminal

② Input voltage & I/O current for normal operation of single channel 13 Red Input signal is detectedby input channel 13. V2 2 11 G

Analog output. Connected to the local •Please contact a certified electronic waste disposal company for the environmentally safe

Analog ③ Output powe V1- Voltage input (negative) of channel 1

extension of main unit or the back of coupler, recycling and disposal of your device. 14 Red Input signal is detectedby input channel 14.

output HCQX-DA04-D V1.40 1.056W ④ Code, S/N &P/N, The rst four digits of the PN code are the version number.

cannot be used alone. Supporting various V1+ Voltage input (positive) of channel 1

module Eg: The version number in the gure above is V2.000. 15 Red Input signal is detectedby input channel 15. I2 3 12 G

current/voltage output. 16bit resolution Symbol Light color Channel description Figure 9 Temperature measurement module inte aces diagram

⑤ QR code (model name, serial number) V2- Voltage input (negative) of channel 2

TRANSPORT AND STORAGE PRECAUTIONS 16 Red Input signal is detectedby input channel 16. P Green The indicator show the current power supply status of the module.

Temperature Connected to the local extension of main unit V2+ Voltage input (positive) of channel 2 V3 4 13 G

measurement HCQX-TS04-D V1.00 1W or the back of coupler, cannot be used alone. 17 Red Input signal is detectedby input channel 17. RUN Red MD module running state. Lit means the module is in normal running state

module Supports multiple sensor signal types. CAUTION 2.2 Part name description SS No indicator S/S input common terminal I0 Red Input signal is detected by input channel 0.

V3-

V3+

Voltage input (negative) of channel 3

Voltage input (positive) of channel 3 I3 5 14 G

Name Terminal Name

DC power To be To be SS No indicator S/S input common terminal B1/TC1+ 0 9 A1/TC1-

HCQX-PW01-D DC power supply module I1 Red Input signal is detected by input channel 1.

module launched launched V4- Voltage input (negative) of channel 4

•The PLC is a precision instrument. During transportation, avoid impacts larger than those 2.2.1 Main view for New coupler module HCQX-EC01-D

AC power To be To be specified in Section 3.1. Failure to do so may cause failures in the PLC. After transportation, verify I2 Red Input signal is detected by input channel 2. V4 6 15 G

HCQX-PW01-A 2.2.3 Main view of digital output module HCQX-OD16-D V4+ Voltage input (positive) of channel 4 B1 1 10

AC power supply module the operations of the PLC.

module launched launched I3 Red Input signal is detected by input channel 3.

I1 Current input of channel 1

Mounting hook Mounting hook I4 Red Input signal is detected by input channel 4. 14 7 16 G

Mounting I2 Current input of channel 2 B2/TC2+ 2 11 A2/TC2-

QX-OD16-D

Tips Indicators I5 Red Input signal is detected by input channel 5.

EC coupler channel hook I3 Current input of channel 3

When the user selects modules according to the power, part of the QX-OD16-D P RUN G 8 17 G

description P RUN I6 Red Input signal is detected by input channel 6. B2 3 12

power is reserved to avoid the loss during the signal transmission. 0 4 10 14 I4 Current input of channel 4

2 Product Overview Sheetmetal

0 4 0 4

1 5 1 5

Terminal No. Description 1 5 11 15 I7 Red Input signal is detected by input channel 7.

G AGND(Analog grounding,1、3、5、7、8、17 internal sho -circuited)

2 6 2 6

3 7 3 7

Po 3 2 6 12 16

13 Q0 Red Output signal is detected by output channel 0. Terminal name Description B3/TC3+ 4 13 A3/TC3-

Connector 3 7 13 17

Outputchannel arrangements

QBUS 12 V1 Channel 1 voltage output

mounting DO 0 10 Q1 Red Output signal is detected by output channel 1. Tips

Applicable readers 2.1 Model name description 11 hook Indicators 1 11 For current input, there is no need to short-circuit V+ and I, only I1 Channel 1 current output B3 5 14

10

DO Q2 Red Output signal is detected by output channel 2.

For the users of HCFA Q series extension modules, refer to this Instruction to perform the Sheetmetal DO 2 12 connect I and G. V2 Channel 2 voltage output

wiring, installation, diagnosis and maintenance and requires the users to have the certain 9 Q3 Red Output signal is detected by output channel 3.

2.1.1 Model name description for system modules Po 1 8

DO 3 13

I2 Channel 2 current output B4/TC4+ 6 15 A4/TC4-

knowledge of electrical and automation. 4 Q4 Red Output signal is detected by output channel 4.

DO 14

This Instruction gives the necessary information for the use of HCFA Q series extension EtherCAT IN 7

5

◆LED indicator arrangements for analog input module V3 Channel 3 voltage output

HC QX - EC01-D

DO 15 Q5 Red Output signal is detected by output channel 5.

modules, please read this Instruction carefully before use and make the correct operation with 6

24V DO 6 16 I3 Channel 3 current output B4 7 16

full attention to safety. 5 Q6 Red Output signal is detected by output channel 6.

DO 7 17 V4 Channel 4 voltage output

4

Terminal 0V Common COM Q7 Red Output signal is detected by output channel 7. I4 Channel 4 current output

Po 2 C+ 8 17 C-

1.1 Safety Precautions 3 COM

block terminal QX-AD04

Company information Series name Modules Power type EtherCAT OUT I-COM No indicator I-COM input common terminal G

2 PE AGND(Internal sho circuit at analog grounding G po )

HCFA QXslave EC EtherCAT coupler D DC powe 1

P RUN

QX Q-COM No indicator Q-COM output common terminal

1.1.1 Safety symbols terminal PD PD power extension A AC power Figure 3 Coupler module A1

◆LED indicator arrangements for analog output module

PF IO power extension A2

When using this product, please follow the following safety precautions and instructions strictly. Common 2.2.5 Main view of analog input module HCQX-AD04-D

TX ground terminal Terminal block ER

Users can check more specific safety guidelines in sections such as mounting, wiring, TX

extension terminal AD

communication, etc.

EC01 New EtherCAT coupler Figure 5 Digital output module inte aces diagram

In this Instruction, the following safety guidelines must be followed.

09 10 11 12 13 14 15 16

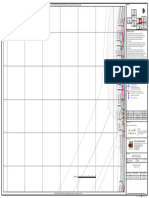

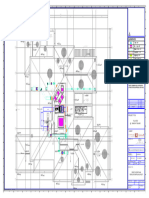

Terminal name Description 2.3 Product Dimensions 3 Installation Description 3.1.3 Digital input module specifications 3.1.5 Digital I/O module specifications ◆Status bit description 6030 Mini. value RO INT 0 Setting value

:

B1/TC1+ Sensor inte ace 1 of channel 1 Items HCQX-ID16-D speci cations 1 2 3 4 5 6 7 8..13 14 15 16 6040 Channel 2 status Mode 0:5000;

◆Product dimensions Items HCQX-MD16-D speci cations

Within Over Limit 1 Limit 2 Error Rese ed Rese ed Rese ed Rese ed

A1/TC1- Sensor inte ace 2 of channel 1 Number of input channels 16 range range 1 Within range RO BOOL FALSE Mode 1:Disabled user

3.1 Specifications Number of channels 8 input channels +8 output channels

scale mode::5000、

B1 Sensor inte ace 3 of channel 1 4.5 Input type Source/sink input 2 Over range RO BOOL FALSE

Input type Source/sink input ◆Parameter setting

3 Limit 1 RO BOOL FALSE Enabled user scale

B2/TC2+ Sensor inte ace 1 of channel 2 3.1.1 EC01 coupler module specifications Isolation method Photocoupler isolation Output type Sink output Sub- Default mode : User Scale

Index 5 Limit 2 RO BOOL

A2/TC2- Sensor interface 2 of channel 2 Input voltage DC24 V (-15% / +20%) Isolation method Photocoupler isolation index Description R/W Type Notes FALSE

(HEX) (HEX) (HEX)

Items Technical speci cations O set+1000~10000;

B2 Sensor inte ace 3 of channel 2 "0" signal voltage -3 V ... 5 V (EN 61131-2, Typ 1) 3.6mA Load type Resistive, inductive, lighting load 7 Error RO BOOL FALSE

Connect terminal module to 100BASE-TX 1000 Device type RO UDINT 5001 Mode 2:5000;

B3/TC3+ Sensor inte ace 1 of channel 3 Functions "1" signal voltage 15 V ... 30 V (EN 61131-2, Typ 1) 1.7mA Input/output voltage DC24V ( -15% / +20%) 6050 Digital value RO INT 0 12 User scale gain RW INT 5000

EtherCAT network 1001 Error register RO USINT 0 Rese e d Mode 3:5000;

A3/TC3- Sensor inte ace 2 of channel 3 Input response speed 1 ms Input "0" signal voltage -3V ... 5V (EN 61131 -2, Typ 1) 3.6mA 6060 Max. value RO INT 0

Max. extension slaves Max. 65535 STRING HCQX Mode 4:3000;

B3 Sensor inte ace 3 of channel 3 Input current typ. 5 mA (EN 61131-2, Typ 1) 1008 Device name RO 6070 Mini. value RO INT 0

Input "1" signal voltage 15V ... 30V (EN 61131 -2, Typ 1) 1.7mA (20) AD-04 Mode 5:Disabled user

35.4

Maximum acceptable data Max.4.2GB, I/O by assignable address

QBUS power 6080 Channel 3 status

100

B4/TC4+ Sensor inte ace 1 of channel 4 Input response speed 1ms 1009 Hardware version RO STRING(5) scale mode :20000、

Data transmission EtherNet/EtherCAT(at least CAT5),

shielded 0.8W (Typ.)

A4/TC4- Sensor inte ace 2 of channel 4 consumption Switching time(cycle) 1ms 1 Within range RO BOOL FALSE

Enabled user scale

100A Software version RO STRING(5)

Distance between stations Up to 100m

B4 Sensor inte ace 2 of channel 4 Electrical isolation 500 Ve (Backboard/Input inte ace

) Input current typ. 5 mA (EN 61131-2, Typ 1) 2 Over range RO BOOL FALSE

mode : User Scale

Restore default

Transmiss ion Weight About 90g 1011 3 Limit 1 RO BOOL FALSE

C+/C - External cold-end inte ace (2-wire PT100) EtherCAT/100Mbaud Max. output current 250mA settings O set+3000~20000;

protocol/transmission rate

Working temperature 0 °C ... + 55 °C QBUS power consumption 1W (Typ.) 1 Sub-index 1 RW BOOL FALSE 5 Limit 2 RO BOOL FALSE Mode 6:20000;

Delay About 1μs

Storage temperature -25 °C ... + 85 °C Electrical isolation 500 Ve (Backboard/input inte ace) 1C00 Sync manager type 7 Error RO BOOL FALSE Setting value

:

Tips Bus inte ace 2 x RJ45

Note The two-wire sensor is connected to terminal TC1+ and TC1-; The 49 71 Relative humidity 95%, no condensation Weight About 90g Master→slave Mailbox data 6090 Digital value RO INT 0 Mode 0:-32~Limit2-1;

Power supply DC24V(-15%~+ 20%) 1 Sub-index 1 RO USINT 1

three-wire sensor is connected to terminal TC1+, TC1 and B1. Dimensions About 15 mm x 100 mm x 70 mm( Width alignment: 12 mm) communication 60A0 Max. value RO INT 0 Mode 1:-32768~ Limit2-

Working temperature 0 °C ... + 55 °C

Figure 12 Installation dimemsion for system module (unit:mm) Power consumption 70mA+(∑ QBUS Current /4 )

Installation method On 35 mm DIN rail Comply withEN 50022 Slave→master Mailbox data 60B0 Mini. value RO INT 0 1;

Storage temperature -25 °C ... + 85 °C

QBUS load power Max.1750mA(-25°C~+55°C) Max.1333mA 16W)

( >+55°C) 2 Sub-index 2 RO USINT 2 Mode 2:-16384~ Limit2-

LED indicators arrangements for temperature measurement module Vibration/shock Relative humidity 95%, no condensation communication 60C0 Channel 4 status

Comply withEN 60068-2-6/EN 60068-2-27/29 13 Limit1 RW INT -32

Electrical isolation 500V(power contact/supply voltage/bus eld) 1;

resistance Master→slave Process data 1 Within range RO BOOL FALSE

14.7 Dimensions About 15 mm x 100 mm x 70 mm( Width alignment: 12 mm)

100.0 Dimensions About 100 mm x 49 mm x 71mm 3 Sub-index 3 RO USINT 3 Mode 3:-16~ Limit2-1;

QX-TS04 12.5 Anti-electromagnetic communication 2 Over range RO BOOL FALSE

Comply withEN 61000-6-2/EN 61000-6-4 Installation method On 35 mm DIN rail Comply withEN 50022

Weight About 150g Mode 4:-16~ Limit2-1;

P RUN inte erence Slave→master Process data 3 Limit 1 RO BOOL FALSE

4.5 Vibration/shock resistance Comply withEN 60068-2-6/EN 60068-2-27/29 RO USINT

Working /storage temperature 0°C~+55°C/-25°C~+75°C 4 Sub-index 4 4 Mode 5:-32~ Limit2-1;

A1 Protection level IP 20 communication 5 Limit 2 RO BOOL FALSE

Anti-electromagnetic inte erence Comply with EN 61000-6-2/EN 61000-6-4

A2 Relative humidity 95% , no condensation Mode 6:-32~ Limit2-1;

Installation location Not speci ed 1C13 TxPD O ass ignment 7 Error RO BOOL FALSE

Protection level IP 20

ER Protection level/Installation IP20/ Not speci ed Setting value

:

Ce i cate CE 1 Sub-index 1 RO UINT 1A00 60D0 Digitalvalue RO INT 0

AD Installation location Not speci ed Mode 0:

Ce i cate CE/UL

Ce i cate CE 2 Sub-index 2 RO UINT 1A01 60E0 Max. value RO INT 0

3.1.4 Digital output module specifications Limit1+1~32767;

3 Sub-index 3 RO UINT 1A02 60F0 Mini. value RO INT 0

Mode 1:

3.1.2 EC coupler module specifications

Symbol Light color Description Items HCQX-OD16-D speci cations 3.1.6 Analog input module specifications 4 Sub-index 4 RO UINT 1A03 Channel n input

Limit1+1~32767;

80n0 N=0、1、2、3

100 35.4 5 Sub-index 5 RO UINT 1A04 setting

The indicator shows the current power supply status of the Items Technical speci cations Output points 16 Mode 2:

P Green Items HCQX -AD04-D speci cations

module. 6 Sub-index 6 RO UINT 1A05 Setting value

:

Connect terminal module to 100BASE-TX Output type Sink output Limit1+1~16383;

The running state. Lit means the module is in normal running Functions Input channel 4(di erential)

RUN Red Isolation method Photocoupler isolation 7 Sub-index 7 RO UINT 1A06 Mode 0:0~10V、 14 Limit2 RW INT 32767 Mode 3:

state EtherCAT network

Signal voltage 0~10V、-10~10V、-5~5V、0~5V、1~5V Mode 1:-10~10V、

Data transmission EtherNet/EtherCAT(at least CAT5),

shielded Load type Resistive, inductive, lighting load 8 Sub-index 8 RO UINT 1A07 Limit1+1~16383;

A1 Red Whether ESC channel 1 of the module can respond normally. Voltage input resistance > 200 kΩ

9 Sub-index 9 RO UINT 1A08 Mode 2:-5~5V、 Mode 4:

Distance betweenstations Up to 100m Rated load voltage DC24 V (-15% / +20%) 1 Input mode selection RW USINT 01

A2 Red Whether ESC channel 2 of the module can respond normally. Signal current 0~20mA、4~20mA Mode 3:0~5V、 Limit1+1~16383;

Transmission Low-level output voltage 1V A Sub-index 10 RO UINT 1A09

ER Red AD operation failure indication EtherCAT/100Mbaud Current input resistance 250Ω Mode 4:1~5V、

protocol/transmission rate Switching time (cycle) 1ms B Sub-index 11 RO UINT 1A0A Mode 5:

AD Red AD operates normally at ickering Input lter limit frequency 5Khz(second-order lter) Mode 5:0~20mA、

Bus inte ace 2 x RJ45 Max. output current(per channel) 250mA C Sub-index 12 RO UINT 1A0B Limit1+1~32767;

Common-mode voltage UCM Up to 35 V Mode 6:4~20mA Mode 6:

2.1 Power supply DC24V(-10%~+ 10%) D Sub-index 13 RO UINT 1A0C

Figure 13 Installation dimension for function module (unit:mm) QBUS power consumption 1.4W (Typ.)

Tips Resolution 16bit Setting value

:True、 Limit1+1~32767;

Current consumption 0.6A(Typ.) Electrical isolation 500 Ve (Backboard/input inte ace) E Sub-index 14 RO UINT 1A0D 9 Enabled channel RW BOOL FALSE

ESC indicates the EtherCAT slave controller chip. Channel data refresh time About fourchannels take 1ms False

QBUS load power 8W(Typ.) Setting value

:

Weight About 90g F Sub-index 15 RO UINT 1A0E 15 Filtering setting RW INT 0001

Measurement error(Total error range ) < ± 0,3 % ( full scale)0.8%(current) Enabled propo ion Setting value

:True、 0~4096;

Electrical isolation 500V(Backboard/Input power) Working temperature 0 °C ... + 55 °C 10 Sub-index 16 RO UINT 1A0F A RW BOOL FALSE

2.2.8 Right view for extension modules adjustment False

QBUS power consumption 1W (Typ.)

24.6 About 15 mm x 100 mm x 70 mm(Width Storage temperature -25 °C ... + 85 °C 1C33 SM input parameter

12.5

Dimension Electrical isolation 500 Ve (Backboard/Input inte ace) Enabled peak Setting value

:True、

19 alignment: 12 mm) 1 Sync. mode RW UINT 01 B RW BOOL FALSE

Mounting Relative humidity 95%, no condensation monitoring False

hook Weight About 90g Setting No need to set the address, can be con gured through CODESYS

Dimensions About 15 mm x 100 mm x 70 mm ( Width alignment : 12 mm) 7122000 SM communication cycle

Weight About 90g 2 Cycle time RO UDINT Setting value

:True、

Working /storage temperature 0°C~+55°C/-25°C~+75°C (DEC ) time(ns) C Enabled lter RW BOOL FALSE

Sheetmetal Installation method On 35 mm DIN rail Comply withEN 50022 False

Sheetmetal Working temperature 0 °C ... + 55 °C

Relative humidity 95% ,no condensation Suppo ed sync mode:

Vibration/shock resistance Comply withEN 60068-2-6/EN 60068-2-27/29 Setting value

:True、

Mounting Protection level/Installation IP20/ Not speci ed Storage temperature -25 °C ... + 85 °C Suppo ed sync

Connector 4 RO UINT 3 0x0001:FREE RUN D Enabled limit1 RW BOOL FALSE

connection hook Anti-electromagnetic inte erence Comply with EN 61000-6-2/EN 61000-6-4 False

Ce i cate CE Relative humidity 95%, no condensation mode

0x0002:SM

Protection level IP 20 Setting value

:True、

Dimension About 15 mm x 100 mm x 70 mm( Width alignment: 12 mm) 100000 E Enabled limit2 RW BOOL FALSE

Installationlocation Not speci ed 5 Mini. Cycle time RO UDINT (ns) False

Installation On 35 mm DIN rail Comply with EN 50022 (DEC )

Ce i cate CE Setting value

:

Vibration/shock resistance Comply withEN 60068-2-6/EN 60068-2-27/29 Calculation and copy

6 RO UDINT 0

Mode 0:0;

Anti-electromagnetic inte erence Comply withEN 61000-6-2/EN 61000-6-4 time

78.1

69.3

Mode 1:Disabled user

Protection level IP 20 8 Obtain cycle time RW UINT 0

Cable tie scale mode:0、Enabled

Installation location Not speci ed 9 Delay time RO UDINT 0

Figure 10 Function module inte ace diagram Figure 11 System module inte ace diagram user scale mode:0~User

Ce i cate CE A SYNC0 cycle time RW UDINT 0

Scale Gain-1000;

Name Description B SM event loss RO UINT 0

Mode 2:0;

Sheetmetal Transmits QBUS signal and control circuit current. Do not suppo hot swap. 3.1.7 Analog input configuration and parameter mapping C Cycle time toosmall RO UINT 0 11 User scale o set RW INT 00

Mounting hook Fix the module on the DIN rail Mode 3:0;

Connector

◆PDO mapping 20 SYNC error RO BOOL FALSE

Provide wiring device for easy wiring and module replacement Mode 4:1000;

connection Index Name Index Name 6000 Channel 1 status

Connector Fix the connector onto the module. Install and remove the connector Mode 5:Disabled user

mounting hook by this structure. 1A00 Channel 1 Status 1A08 Channel 3 Status 1 Within range RO BOOL FALSE scale mode :0、Enabled

Pass the cables through and x them to make the wiring more neat Figure 14 Installation dimension for connector (unit: mm)

Cable tie 1A01 Channel 1 Data (bipolar e ective) 1A09 Channel 3 Data (bipolar e ective) 2 Over range RO BOOL FALSE user scale mode :0~User

and convenient forfuture maintenance.

Terminal block Terminal block 1A02 Channel 1 Max. value(bipolar e ective) 1A0A Channel 3 Max. value(bipolar e ective) 3 Limit 1 RO BOOL FALSE Scale Gain-3000;

Common terminal Common terminal, internal connection 1A03 Channel 1 Mini. value(bipolar e ective) 1A0B Channel 3 Mini. value(bipolar e ective) 5 Limit 2 RO BOOL FALSE Mode 6:4000;

1A04 Channel 2 Status 1A0C Channel 4 Status 7 Error RO BOOL FALSE

1A05 Channel 2 Data (bipolar e ective) 1A0D Channel 4 Data (bipolar e ective) 6010 Digital value RO INT 0

1A06 Channel 2 Max. value(bipolar e ective) 1A0E Channel 4 Max. value(bipolar e ective) 6020 Max. value RO INT 0

1A07 Channel 2 Mini. value(bipolar e ective) 1A0F Channel 4 Mini. value(bipolar e ective)

17 18 19 20 21 22 23 24

3.1.8 Analog input value conversion and display 3.1.10 Analog output configuration and parameter mapping O set sho 3.1.11 Analog output conversion and display Measurement error TC :< ± 0,3 % ( for fullscale) ◆ Parameter setting Performance parameter 3. To remove the cable from the connector, insert the small screwdriver into the

D RO UDINT 0

counting (total error range) PT :<±0.5℃ Sampling speed outside square socket as Step 1, and then remove the cable from the

◆ PDO mapping ◆ User display Index Sub-index Default corresponding square socket.

20 Sync. error RO BOOL FALSE Internal Q bus power Description R/W Type Notes Disconnection detection OFF:

Index Name By Q-bus (HEX) (HEX) (HEX)

Channel 1 supply TC:100ms* Number of enabled channel* Filtering times of this channel

1600 Channel 1 output 1600 Channel 1

parameter Current consumption PT:200ms* Number of enabled channel* Filtering times of this channel

1601 Channel 2 output typ.180 mA

Output data by Q-BUS setting

Disconnection detection ON:

1602 Channel 3 output 1 Sub-index1 RO UDINT 70100110

mapping Electrical isolation 500 Ve (E-Bus/ Field potential) 1 Channel enabled RW USINT 0 Enabled by default Test once for 7 sampling cycles and each takes 450ms.

Input/output signal Value 1603 Channel 4 output 0x8000

Channel 2 Weight About 90g 2 Sensor type RW USINT 0 K-type by default

HCQX -AD04-D HCQX-DA04-D Decimal Hexadecimal 1601 Note

parameter Working temperature 0 °C ... + 55 °C

◆ Parameter setting Filter word It is recommended to turn off the disconnection detection after the sensor Remove the cable from the square socket

10V 20mA 10V 20mA 32000 0x7D00 3 RW UINT 0 No lteringby default

Output data Input/output signal Values Storage temperature -25 °C ... + 85 °C

Index Sub-index Default 1 Sub-index1 RO UDINT 70100210 selection for AD is connected.

5V 5V 16000 0x3E80

Description R/W Type Notes mapping HCQX -AD04-D HCQX -DA04-D Decimal Hexadecimal Relative humidity 95%, no condensation

0x0001 (HEX) (HEX) (HEX) Channel 2 Apply a force of more than 10N

Channel 3 10V 20mA 10V 20mA 32000 0x7D00 Dimension About 15 mm x 100 mm x 70 mm( Width alignment: 12 mm)

0V 1V 0mA 4mA 0V 1V 0mA 4mA 0 0x0000 1000 Device type RO UDINT 5001 1602 setting Sampling accuracy

parameter 5V 5V 16000 0x3E80 Installation On 35 mm DIN rail Comply withEN 50022

0x0001 1001 Erroregister RO USINT 0 Rese ed TC:± full scale * 0.3%(No module connected to TS)

Output data 0x0001 1 Channel enabled RW USINT 0 Enabled by default

Vibration/shock

-5V -5V -16000 0xC180 Device STRING HCQX -DA- 1 Sub-index1 RO UDINT 70100310 Comply withEN 60068-2-6/EN 60068-2-27/29 0x8010 PT:±0.5°C

1008 RO mapping 0V 1V 0mA 4mA 0V 1V 0mA 4mA 0 0x0000 resistance 2 Sensor type RW USINT 0 K-type by default

-10V -10V -32000 0x8300 name (20) 04

Channel 4 0x0001 EMC resistance Filter word

Hardware STRING 1603 Comply withEN 61000-6-2/EN 61000-6-4 3 RW UINT 0 No lteringby default Note

1009 RO parameter -5V -5V -16000 0xC180 burst/static resistance selection for AD Excluding the error of connecting PT or TC sensor.

version (5) 4. After completing the wiring, provide 24VDC power to the analog module at the top

Output data -10V -10V -32000 0x8300 Protection level IP 20 TC error will exceed 0.3% when connecting TS to the module, so it is

Software STRING 1 Sub-index1 RO UDINT 70100410 Channel 3

100A RO mapping Installation place Not speci ed recommended to connect the TS at the end.

version (5) ◆ Figure as shown below: setting

7010 Output value Ce i cate CE /UL

Restore 1 Channel enabled RW USINT 0 Enabled by default

1 Channel 1 RW INT 0 0x8020

1011 default RW BOOL

2 Sensor type RW USINT 0 K-type by default

2 Channel 2 RW INT 0

settings

3 Channel 3 RW INT 0

3.1.13 Temperature measurement module configuration and parameter mapping

Filter word 3.2 Wiring Description

1 Sub-index1 RW BOOL FALSE 3 RW UINT 0 No lteringby default

4 Channel 4 RW INT 0 ◆ PDO mapping selection for AD

Sync 3.2.1 Cable selection and connector wiring

Chanel n Channel 4

1C00 manager Index Sub-index Default

80n0 output N=0、1、2、3 Description R/W Type Notes setting ◆ Cable selection

type (HEX) (HEX) (HEX) ① GND

Master→slave setting 1 Channel enabled RW USINT 0 Enabled by default

0: No 0x8030 ② 0V

1 Sub-index1 RO USINT 1 Mailbox data Output Setting value: K-type by default

Channel 1 disconnection or 2 Sensor type RW USINT 0

1 mode RW USINT 1 Mode 0:0~10V、 ③ 24V

communication

1 disconnection R BOOL 0 over-limit 1: Filter word

Slave→master selection Mode 1:- 3 RW UINT 0 No ltering by default

detection Disconnection or selection for AD

2 Sub-index2 RO USINT 2 Mailbox data Channel

2 RW BOOL TRUE over-limit

Cold-end OFF by

communication enabled 0x8040 Cold-end setting RW USINT 2

Channel 2 default

Master→slave User

2 disconnection R BOOL 0

3 Sub-index3 RO USINT 3 Process data Set temperature Connector installation

3 calibration RW BOOL FALSE Not suppo ed 0x8050 RW USINT 0 °C be default

detection unit

3.1.9 Analog output module specifications communication enabled

3.1.12 Temperature measurement module specifications Channel 3 Align the connector end with the extension module bottom. After aligning and

Slave →Master Disconnection inserting, press the terminal down in the B direction as shown below.

Scale 0x8060 RW USINT 1 Enabled by default

Items Description 3 disconnection R BOOL 0

4 Sub-index4 RO USINT 4 Process data detection switch

4 adjustment RW BOOL FALSE Not suppo ed Items HCQX -TS04-D speci cations Connector wiring

Output channels 4 detection

communication

enabled Input channel 4 0x1a00

Signal voltage 0~10V、-10~10V、-5~5V、0~5V Channel 4 Take out the small screwdriver in the package and insert it into the square

RxPDO

1C12 6 Watchdog RW UINT 0 Not suppo ed Power input(2-ch) 24VDC (±20%),by E-BUS(power consumption1W) 3.1.14 Measuring range and performance socket of the connector, applying a force of more than 10N . And then insert

Signal current 0~20mA、4~20mA assignment 4 disconnection R BOOL 0

the qualified cable from another square wiring socket (located inside the

Error/stop Thermocouple:K,J,E,T,N,B,R,S(K-type by detection

Accuracy ± 0.3 % , relative to full scale 1 Sub-index1 RO UINT 1600 module) ) to the bottom, loosen the screwdriver, gently pull the cable up and

7 output RW UINT 0 Not suppo ed default ) ◆ Temperature range for thermocouple down until the cable is clamped

Resolution 16bit 2 Sub-index2 RO UINT 1601 Signal voltage Channel 1 over-

mode Thermal resistance:PT100,PT1000,Ni100,Ni1000(PT100 by 5 R BOOL 0

Channel data refresh time 1ms 3 Sub-index3 RO UINT 1602 limit detection

default)3-wire

Voltage load > 5 kΩ 4 Sub-index4 RO UINT 1603 Output

8 RW UINT 0 Not suppo ed Channel 2 over- Type Range

value No need to set the address, it can be con gured by codesys; 6 R BOOL 0

Current load < 350Ω SM output limit detection B 250~1800 ℃

1C32 function include over -limit detection, disconnection detection,

QBUS ower consumption 1W (Typ.) parameter User scale Setting E -200~1000 ℃

9 RW INT 10000 Not suppo ed sampling periodsetting, sensor type setting, input lter setting and Channel 3 over- B

Electrical isolation 500 Ve (Backboard/input inte ace) 1 Sync mode RW UINT 1 o set 7 R BOOL 0

temperature unit conversion setting limit detection J -200~1200 ℃ Insert the qualified cable to

Process image bit width Output4 x 16 bit data 7122000 User scale K -200~1370 ℃ another square wiring socket

2 Cycle time RW UDINT A RW DINT 0 Not suppo ed Input lter limit Typical: 1Khz;Determined by sensor type, conversion time and Channel 4 over-

Setting No need to set the address, can be con gured through CODESYS (DEC ) gain 8 R BOOL 0 N -200~1300 ℃

frequency length limit detection

Weight About 90 g 3 O set time RO UDINT 0 User R 0~1768 ℃ Apply a force of more than 10N

Resolution 0.1 °C per digit ,0.1℉ per digit Channel 1 A

Working temperature 0 °C ... + 55 °C Suppo ed B correction RW INT 16000 Not suppo ed 0x1a01 R INT 0 10times agni cation S 0~1768 ℃

4 RO UINT 3 Warm-up time during temperature

sync mode 30mins

Storage temperature -25 °C ... + 85 °C value TC test T -200~400 ℃

Mini. Cycle Channel 2 10 times After inserting the connector successfully, press it in the “C” direction until

Relative humidity 95%, no condensation User maxim- Absolute maximum 0x1a01 R INT 0

5 RO UDINT 100000 C Not suppo ed temperature magni cation you hear the “click”, then connector installation has been completed.

time um correction RW INT 0 ±150mV

Dimensions About 15 mm x 100 mm x 70 mm (Width alignment: 12 mm) rating

value ◆ Temperature range for Thermal resistance

Calculation Channel 3 10 times

Installation On 35 mm DIN rail Comply withEN 50022 6 RO UDINT 0 About 100ms~1.3s. According to the con guration and lter 0x1a01 R INT 0

andcopy time temperature magni cation

Vibration/shock resistance Comply withEN60068-2-6/EN 60068-2-27/29 settings,disconnection detection will take 460ms (default ON) 2. After completing the wiring of the connector, use a cable tie to fix the cables

Obtain through the hole at the bottom of the connectors and cut off the excess

EMC resistance burst/static 8 RW UINT 0 TC time:100ms* Number of enabled channel* Filtering times of Channel 4 10 times

Comply withEN 61000-6-2/EN 61000-6-4 cycle time Conversion time 0x1a01 R INT 0 Type Range cable tie.e screwdriver, gently pull the cable up and down until the cable is

resistance this channel temperature magni cation clamped

9 Delay time RO UDINT 0 PT100 -200~850 ℃

Protection level IP 20 PT time:200ms* Number of enabled channel * Filtering times of

PT1000 -200~850 ℃

A SYNC0 time RW UDINT 0

Installation Not speci ed this channel

Ni100 -60~250 ℃

SM event

Ce i cate CE Within the range de ned for the sensor in each case ;

loss Ni1000 -60~250 ℃

B RO UDINT 0

Temperature range TC is default toK:-200~1370 ℃,-7~55mV;

ounting

PT is default to PT100:-200~850℃,18~391Ω。 C

Cycle over

C RO UDINT 0

counting

Use a cable tie to fix the cables

through the hole at the bottom of

the connectors

25 26 27 28 29 30 31 32

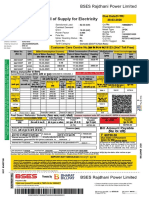

Remove the connector 3.2.4 Digital input module wiring description 0V

FG 3.2.9 Temperature measurement module wiring description 6)Right-click EtherCAT Master SoftMotion to select the scan device and for the 2)Follow the CODESYS guide, select the target device and main program 7)Use ST programming language to define two groups of INT variables in

24V module, which works normally and has established communication, find it in the PLC_PRG programming language. Q1 device is not installed by default, so you PLC_PRG, and map them to the corresponding input variables.

AA The temperature measurement module, as the remote extension module of the “Scan device” and click the “Copy all devices to the project” in the lower right need to install the device description file first, otherwise the correct target

+15V

Insert the screwdriver into the upper side of the connector in the “A” +24V corner to add the module to the project. device cannot be selected.

Q series CPU unit, cannot work alone and needs to be connected to the EC

direction, and gently push it downward in the “B” direction to unlock the

DC24V coupler or the right side of the CPU unit. The module provides two wiring

buckle

Internal 24V methods of two-wire system and three-wire system to match different types of

circuit DC/DC 0V

DC24V DC24V Filter sensors. Wiring diagrams are as follows.

conve er GND

-+ + - SS

Photocoupler

isolation

AGND

-15V AGND 8)Map the two groups of channels of HCQX-AD04-D to the variables

A NPN PNP iAnaloginput1_V and iAnaloginput1_A defined in the program, respectively, as

Temperature

measurement module follows:

Figure 13 Wiring diagram for digital input module HCQX-TS04-D

Figure18 Module load power supply diagram

B

3.2.5 Digital output module wiring description

2)Follow the CODESYS guide, select the target device and main program

PLC_PRG programming language. Q1 device is not installed by default, so you

Tips need to install the device description file first, otherwise the correct target

The analog signal cable adopts twisted-pair shielded wire device cannot be selected.

Load Equipotential is needed for the signal to be measured and“ AGND” 3)Double click Device→Scan network, then select the Q1 device and click

7) Use ST programming language to define two groups of BYTE variables in

“OK”.

+ PLC_PRG, and map them to the corresponding input variables.

- DC24V NPN wiring diagram

2. After unlocking the connector, remove the connector from the module in the Sink output, 3.2.8 Analog output module wiring description

com

“C” direction. Internal circuit low level is e ective

The analog output module, as the remote extension module of the Q series CPU

unit, cannot work alone and needs to be connected to the EC coupler or the 9)After no error for compiling, log in and run the program, and Set the current

Figure 14 Wiring diagram for digital output module right side of the CPU unit. It supports both current and voltage output. HCFA channel operating mode according to signal type to be measured. First, select

offers varieties of output ranges and the working range can be modified online the channel to be set, and then tick "Enable Expert Mode" in “General”.

through SDO or COE, where the output signal can be directly used as the

3.2.6 Digital I/O module wiring description control signal of the motor or drive.

*1 *2

A Motor, drive, module etc.

Internal 1KΩ 8) Map the two groups of channels of HCQX-ID16-D to the variables DI_0 and

circuit V+ Figure 26 Temperature measurement module wiring diagram

C to DI_1 defined in the program, respectively, as follows:

GND

1MΩ

Internal

circuit FG

DC24V DC24V

◆ At the top of analog I/O module, 24VDC needed to be connected.The wiring diagram 3) Double click Device→Scan network, then select the Q1 device and click “OK”. 4)After communicating with Q1 device,click Device→Add device→EtherCAT

Master SoftMotion

-+ + - SS

Photocoupler shown as below:

isolation Figure 19 Internal circuit diagram of voltage output

A NPN PNP FG 10)Set the working mode for the module under the CoE online page 16#

0V

At the top of analog I/O module, 24VDC needed to be connected. The wiring 24V 0x80N0:01 and confirm that the channel 16# 0x80N0:09 is turned ON(make sure

diagram shown as below: +15V that 24VDC is supplied normally). For more specific parameter setting, refer to

+24V section 3.2.

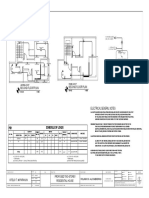

3.2.2 EC01 coupler module wiring description

DC24V

External wiring description Load FG 24V

0V

24V DC/DC 0V

conve er Filter GND

As a remote extension coupler of Q series PLC, EC module provides 24V power +

- DC24V NPN wiring diagram

supply for other extension modules through its side metal sheet. Unlike other +15V

Sink output, +24V AGND

remote extension I/O modules, it's not necessary for EC module to use all the com

AGND

Internal circuit low level is e ective -15V

ports. The wiring diagram is shown as below: 9) After no error for compiling, log in and run the program, and observe

DC24V

24V whether the value change of the input variable corresponds to the input signal

Figure 15 Wiring diagram for digital output module DC/DC 4)After communicating with Q1 device,click Device→Add device→EtherCAT

0V to the corresponding input channel in the program.

Filter Master SoftMotion

conve er GND Figure 27 Module load power supply diagram

5)Double click EtherCAT Master SoftMotion,and find the "Source Address

3.2.7 Analog input module wiring description AGND (Mac)" under the "General" on the right and select the correct EtherCAT network

-15V AGND

card.

The analog input module, as the remote extension module of the Q series CPU

unit, cannot work alone and needs to be connected to the EC coupler or the 4.2 Programming example for analog module

right side of the CPU unit. It supports both current and voltage input. HCFA Figure 25 Module load power supply diagram Wiring precautions

offers varieties of input ranges and the working range can be modified online ① Distinguish the input/output cables and make the wiring separately. This example uses the CPU unit HCQ1-1300-D + coupler module HCQX-EC +

through SDO or COE, where voltage input supports single –ended and analog module HCQX-AD04-D as an example to illustrate: (Q1 connection has

② If the power cable is close to I/O signal cable, error may occur because of high-

differential input. been described briefly. For more details, refer to Q1 Software Manual.)

voltage/current. The distance between I/O signal cable and power cable should

Di erential be more than 100mm. 1)Open CODESYS V3.5 SP14,select New project.

+15V Tips

Figure 16 Wiring diagram for new coupler module input 200Ω

The analog signal cable adopts twisted-pair shielded wire ③ 24VDC I/O cable should be laid separately from AC power cable. The user can select the project type they want, enter the name and save path,

V+

④ When using piping for wiring, make sure that the piping is well-grounded. and then click “OK”.

V-

200Ω

Equipotential is needed for the signal to be measured and “ AGND” 11)After the configuration completion, check the current input channel values

GND *1

AGND -15V under the EtherCAT I/O mapping.

3.2.3 EC coupler module wiring description +15V

200Ω

Single-ended +

input

50Ω

+15V AGND

200Ω GND

*1 -15V

V+

4 Module programming examples 5) Double click EtherCAT Master SoftMotion,and find the "Source Address

200Ω

DC24V DC24V GND *1 V-

AGND -15V *1 Equipotential (Mac)" under the "General" on the right and select the correct EtherCAT network 6)Right-click EtherCAT Master SoftMotion to select the scan device and for the

bonding card. module, which works normally and has established communication, find it in the

FG “Scan device” and click the “Copy all devices to the project” in the lower right

FG

corner to add the module to the project.

Figure16 Figure17

4.1 Programming example for digital module

Internal circuit diagram for voltage Internal circuit diagram for

The 2 channels of EC module

di erential and single-ended input current input This example uses the CPU unit HCQ1-1300-D + coupler module HCQX-EC +

are internally connected, so

digital module HCQX-ID16-D as an example to illustrate: (Q1 connection has

just connect 24VDC to one been described briefly. For more details, refer to Q1 Software Manual.)

channel. At the top of analog I/O module, 24VDC needed to be connected. The wiring

diagram shown as below:

1)Open CODESYS V3.5 SP14,select New project The user can select the

project type they want, enter the name and save path, and then click “OK”.

Figure 17 Wiring diagram for old coupler module

You might also like

- 312 BDocument2 pages312 BДрагиша Небитни Трифуновић50% (2)

- Schematic 966G Series 1 PDFDocument2 pagesSchematic 966G Series 1 PDFcandra purnama100% (1)

- 12V WallchartDocument2 pages12V WallchartkjsjnjdujshskkhdhNo ratings yet

- 966G and 972G Wheel Loaders Electrical System: Machine Harness Connector and ComponentDocument2 pages966G and 972G Wheel Loaders Electrical System: Machine Harness Connector and ComponentPutra JawaNo ratings yet

- P94-1986 Inversor NGPDocument2 pagesP94-1986 Inversor NGPGonzalo GalvezNo ratings yet

- 928G 6XR ElectricoDocument4 pages928G 6XR ElectricoRodney Richardson100% (3)

- Aprilia Shiver 750 Wiring DiagramDocument1 pageAprilia Shiver 750 Wiring Diagrammylitter539140% (5)

- Area ClassificationDocument71 pagesArea ClassificationFaiqoh NahareyNo ratings yet

- Flaring and Venting PhilosophyDocument10 pagesFlaring and Venting PhilosophyRexx Mexx100% (1)

- Kenr1302 PDFDocument2 pagesKenr1302 PDFalfonso pachecoNo ratings yet

- Oxygen From Air by Pressure Swing Adsorption PDFDocument162 pagesOxygen From Air by Pressure Swing Adsorption PDFkalai0% (1)

- PP Aaa PP1 124Document19 pagesPP Aaa PP1 124Rabah AmidiNo ratings yet

- Esquema Electrico RetroexcavadoraDocument12 pagesEsquema Electrico RetroexcavadoraRamiro Castro Pacheco100% (1)

- Flycolor 45A ManualDocument2 pagesFlycolor 45A ManualTopan LaksanaNo ratings yet

- SDJ4000 - Exploded ViewDocument1 pageSDJ4000 - Exploded ViewRudi RenderNo ratings yet

- Mob SM Co SD GR 105Document1 pageMob SM Co SD GR 105Pharaoh GloriesNo ratings yet

- LI4278 - User Manual 1579980Document2 pagesLI4278 - User Manual 1579980xebigo7728No ratings yet

- For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-003 & 004Document1 pageFor Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-003 & 004naveenNo ratings yet

- Schedule of Loads PB1: Electrical General NotesDocument1 pageSchedule of Loads PB1: Electrical General NotesLady Mae BrigoliNo ratings yet

- Tabg Jec 0 000 Pro Pid 0012 - GDocument1 pageTabg Jec 0 000 Pro Pid 0012 - GAfif FadhliNo ratings yet

- L.O.W L.O.W: Limit of SubmissionDocument1 pageL.O.W L.O.W: Limit of SubmissionnaveenNo ratings yet

- Wistron DW40 - 50 Winery14 - 48.4es06.0sa 09630-Sa - Io BoardDocument6 pagesWistron DW40 - 50 Winery14 - 48.4es06.0sa 09630-Sa - Io BoardWillian AngeloNo ratings yet

- MT6169 - MT6158 - R2008 CT - Phase-2 - Ref - SCH - V1.1Document8 pagesMT6169 - MT6158 - R2008 CT - Phase-2 - Ref - SCH - V1.1carver_uaNo ratings yet

- Power Input Power Control For Single 12V 2in1 PowerDocument12 pagesPower Input Power Control For Single 12V 2in1 PowerMargarita GarittaNo ratings yet

- Product Manual - R 3EL 125 - PO 8584Document71 pagesProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNo ratings yet

- 735, 740 and 740E Articulated Truck Electrical SystemDocument2 pages735, 740 and 740E Articulated Truck Electrical SystemElie AbisaadNo ratings yet

- 83 Plano Elec PDFDocument6 pages83 Plano Elec PDFManuel CanazaNo ratings yet

- AVH-P4300DVD AVH-3300BT: Selecting The SourceDocument8 pagesAVH-P4300DVD AVH-3300BT: Selecting The SourceAriel FrimermanNo ratings yet

- Grundig-Beko fsp115-3f02 PsuDocument3 pagesGrundig-Beko fsp115-3f02 Psumustafa akanNo ratings yet

- From April 2007-03-01Document1 pageFrom April 2007-03-01martin ortizNo ratings yet

- Cab Access Door Headliner: 793F Off-Highway Truck Electrical SystemDocument6 pagesCab Access Door Headliner: 793F Off-Highway Truck Electrical SystemdarwinNo ratings yet

- 1102 K/ Internal: StatusDocument9 pages1102 K/ Internal: StatusJefte UnimetaisNo ratings yet

- SBSP - Pukra 2a Rwy 17rDocument1 pageSBSP - Pukra 2a Rwy 17rVinicius LinsNo ratings yet

- SBGR Rnav-Cgo-1c - Isimu-1c-Rwy-09l - 09r - Sid - 20190131Document1 pageSBGR Rnav-Cgo-1c - Isimu-1c-Rwy-09l - 09r - Sid - 20190131Rodrigo HalzenthNo ratings yet

- Lampu lt.1Document1 pageLampu lt.1Muhammad Reza RasyidNo ratings yet

- AVA4 Analog PDFDocument1 pageAVA4 Analog PDFSérgio SilvaNo ratings yet

- SM-G531M Esquematico Completo Anibal Garcia IrepairDocument7 pagesSM-G531M Esquematico Completo Anibal Garcia IrepairJuan David DelgadoNo ratings yet

- Electircal SLDDocument25 pagesElectircal SLDEzhu MalaiNo ratings yet

- 2SD 2017 PDFDocument1 page2SD 2017 PDFtabassam7801No ratings yet

- RTD2660 RTD2660: Debug InterfaceDocument1 pageRTD2660 RTD2660: Debug InterfaceWiebren van Erve100% (1)

- 14664ger CD 1-510173-3 E1Document2 pages14664ger CD 1-510173-3 E1pareek hansrajNo ratings yet

- TCL 40-Mt5603-Mad2hg Mainboard SCHDocument9 pagesTCL 40-Mt5603-Mad2hg Mainboard SCHJuly DemariaNo ratings yet

- Honey Well Valve Schmectic DrawingDocument1 pageHoney Well Valve Schmectic DrawingSingh MastermindNo ratings yet

- Circuit Diagrams and PWB Layouts: Power Board: Power, 32"Document2 pagesCircuit Diagrams and PWB Layouts: Power Board: Power, 32"HeronCesarVieiraNo ratings yet

- LG KF390 SchematicDocument17 pagesLG KF390 Schematichernandezemilio1981No ratings yet

- Triangle - Brdge Class-D 1200WDocument1 pageTriangle - Brdge Class-D 1200WZamfir VanguNo ratings yet

- SBSP - Pukra 2f Rwy 35l 35r - Sid - 20200102Document1 pageSBSP - Pukra 2f Rwy 35l 35r - Sid - 20200102mike jackNo ratings yet

- Kakamanana PDFDocument1 pageKakamanana PDFAnonymous BZQOJwWIh6No ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar TransistorFábio PellegattiNo ratings yet

- Uvls.2 Uqair-A.12Document1 pageUvls.2 Uqair-A.12Anonymous BZQOJwWIh6No ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument8 pagesJeppview For Windows: List of Pages in This Trip KitcorreomailantonioNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2389)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2389)Gilberto DiazNo ratings yet

- Dorsoduro 1200 ABS: Bi V/Bi V Bi/BDocument1 pageDorsoduro 1200 ABS: Bi V/Bi V Bi/Brudi heriantoNo ratings yet

- Flow Chart of Troubleshooting: 9-1. Power OnDocument29 pagesFlow Chart of Troubleshooting: 9-1. Power OnRiza VirsadaNo ratings yet

- 521F Plans 84564186-Linked PDFDocument4 pages521F Plans 84564186-Linked PDFAudrey ThébergeNo ratings yet

- Dell Inspiron N5110 (Wistron Queen 15) SSID VIDEODocument1 pageDell Inspiron N5110 (Wistron Queen 15) SSID VIDEOrodrigoNo ratings yet

- Component Locations: 345D and 349D Excavator Accugrade Electrical SystemDocument2 pagesComponent Locations: 345D and 349D Excavator Accugrade Electrical SystemRodrigo EvaristoNo ratings yet

- CH 08 PowDocument1 pageCH 08 PowRUBEN DARIO SandovalNo ratings yet

- Ven - GF-FF-RF R.00-RFDocument1 pageVen - GF-FF-RF R.00-RFAnsinNo ratings yet

- PDFDocument2 pagesPDFBadarpur SchoolNo ratings yet

- Changing RoomDocument4 pagesChanging RoomComin AsiaNo ratings yet

- Telegram Listing Radar Sensor Rms320 en Im0080472Document45 pagesTelegram Listing Radar Sensor Rms320 en Im0080472Олег ЕфимовNo ratings yet

- Dynamic Pop UpDocument5 pagesDynamic Pop UpОлег ЕфимовNo ratings yet

- Emotas Sae j1939 Stack User Manual EnglishDocument22 pagesEmotas Sae j1939 Stack User Manual EnglishОлег ЕфимовNo ratings yet

- Technical Information Rms3xx Regulatory Compliance Information en Im0080254Document1 pageTechnical Information Rms3xx Regulatory Compliance Information en Im0080254Олег ЕфимовNo ratings yet

- Canopen EngDocument57 pagesCanopen EngОлег ЕфимовNo ratings yet

- DSP404Document184 pagesDSP404Олег ЕфимовNo ratings yet

- SSCi User Manual EN - V1.0 - 210503Document22 pagesSSCi User Manual EN - V1.0 - 210503Олег ЕфимовNo ratings yet

- Macro VariableDocument60 pagesMacro VariableОлег ЕфимовNo ratings yet

- SSCe User Manual EN - V1.0 - 210503Document20 pagesSSCe User Manual EN - V1.0 - 210503Олег ЕфимовNo ratings yet

- Syntec G&M Code MacroDocument6 pagesSyntec G&M Code MacroОлег ЕфимовNo ratings yet

- B01-FC-C-03 - FC-Serial Axis Controller Basic Installation Instructions - ENGDocument2 pagesB01-FC-C-03 - FC-Serial Axis Controller Basic Installation Instructions - ENGОлег ЕфимовNo ratings yet

- 4730-3 BLUM IF59 Installation Instructions 180168 Rev0-2 0-2Document48 pages4730-3 BLUM IF59 Installation Instructions 180168 Rev0-2 0-2Олег ЕфимовNo ratings yet

- 4726-2 Blum Novotest ZX-Speed Manual EnglishDocument28 pages4726-2 Blum Novotest ZX-Speed Manual EnglishОлег ЕфимовNo ratings yet

- Tips and Tricks Vivid t8 Rev4Document126 pagesTips and Tricks Vivid t8 Rev4Roberta KalasauskaiteNo ratings yet

- Rytec Tormax Imotion Install Owner 07 26 10 PDFDocument42 pagesRytec Tormax Imotion Install Owner 07 26 10 PDFabden66No ratings yet

- Coco Startup 1Document12 pagesCoco Startup 1Fabio Alejandro MeloNo ratings yet

- SC18GH Heat Pump Compressor R134a 220-240V 50/60Hz: CompressorsDocument2 pagesSC18GH Heat Pump Compressor R134a 220-240V 50/60Hz: CompressorsWiyatnox JapolNo ratings yet

- CABLE CalculaDocument2 pagesCABLE CalculaJayashree ShewareNo ratings yet

- Lda AssignmentDocument9 pagesLda AssignmentDee RajanNo ratings yet

- Camless EngineDocument19 pagesCamless EngineNitesh GoelNo ratings yet

- Floor Fryer: 40 Lb. Stainless Steel Liquid Propane or Natural GasDocument2 pagesFloor Fryer: 40 Lb. Stainless Steel Liquid Propane or Natural GasJose SavinonNo ratings yet

- Material Product Data Sheet: Tungsten Carbide - 12% Cobalt PowdersDocument4 pagesMaterial Product Data Sheet: Tungsten Carbide - 12% Cobalt Powdersİrem Şebnem SorucuNo ratings yet

- Fisher 377 Trip Valve: FeaturesDocument12 pagesFisher 377 Trip Valve: FeaturesGOPIKRISHNAHPTNo ratings yet

- Brosur DJI Mavic 3 Enterprise SeriesDocument2 pagesBrosur DJI Mavic 3 Enterprise SeriesAnas DickyNo ratings yet

- Two Sides For Every Story: Bridgestone/ FordDocument6 pagesTwo Sides For Every Story: Bridgestone/ FordKimberly HolcombNo ratings yet

- PSD of Modulated SignalsDocument22 pagesPSD of Modulated SignalsnathanamarNo ratings yet

- Walbro Carburetor WA-133-1 Parts Diagram For WA-133-1 PARTS LISTDocument3 pagesWalbro Carburetor WA-133-1 Parts Diagram For WA-133-1 PARTS LISTRoberto ZilianiNo ratings yet

- Tadiran Coral IPX NewDocument48 pagesTadiran Coral IPX NewYuvrajsinh ChauhanNo ratings yet

- Simplicity Soverign ManualDocument54 pagesSimplicity Soverign Manualcoyote556No ratings yet

- Neutrosophic TopologyDocument6 pagesNeutrosophic TopologyMia AmaliaNo ratings yet

- Bruker: Technical ManualDocument27 pagesBruker: Technical ManualFer GuNo ratings yet

- Kevin Dalimunthe PBC NewDocument31 pagesKevin Dalimunthe PBC Newapi-295590351No ratings yet

- OPTIMIZATION OF EDM PROCESS PARAMETERS ON ALUMINIUM ALLOY 6061/5% SiC COMPOSITEDocument4 pagesOPTIMIZATION OF EDM PROCESS PARAMETERS ON ALUMINIUM ALLOY 6061/5% SiC COMPOSITEIJORATNo ratings yet

- A Study of HR Practices in ITC-Synopsis-EditDocument2 pagesA Study of HR Practices in ITC-Synopsis-EditNageshwar singhNo ratings yet

- ROLL - UP.100: ManualDocument11 pagesROLL - UP.100: ManualRoberto VelascoNo ratings yet

- Datacell Brochure Batteries Bdc-101-01Document1 pageDatacell Brochure Batteries Bdc-101-01bacardieNo ratings yet

- Transformatory Germetizirovannye EI48x20.5-12VA Importer BelTerraTrans (Proizvoditel' Thai Lin Radio)Document4 pagesTransformatory Germetizirovannye EI48x20.5-12VA Importer BelTerraTrans (Proizvoditel' Thai Lin Radio)DontazavrNo ratings yet

- 1.1 Basic ConceptDocument20 pages1.1 Basic ConceptTomashita ArenasNo ratings yet

- DC卷筒联轴器 coupling-20141022104458Document15 pagesDC卷筒联轴器 coupling-20141022104458Ashley DeanNo ratings yet