Professional Documents

Culture Documents

AD-KPOC-KBB-PRO-DST-55014_F5

Uploaded by

FazliJaafarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AD-KPOC-KBB-PRO-DST-55014_F5

Uploaded by

FazliJaafarCopyright:

Available Formats

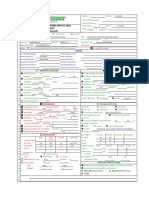

PROJECT DOCUMENT NO.

KBB NORTHERN HUB PROJECT AD-KPOC-KBB-PRO-DST-55014

TITLE ITEM NO ENGR PROJ JOB NO PAGE REV

PROCESS DATASHEET - DEMINERALIZER PACKAGE Z-5515 103347 2 OF 3 F5

JOB SPECIFICATION

CLIENT NAME

REV BY DATE CK'D DATE APP DATE REVISION

KEBABANGAN PETROLEUM F1 AFH 10.08.10 MYK 10.08.10 TPH 10.08.10 Discipline Internal Check (DIC)

OPERATING COMPANY (KPOC) F2 AFH 11.08.10 MYK 11.08.10 TPH 11.08.10 Inter-Discipline Checking(IDC)

F3 AFH 25.08.10 MM 25.08.10 TPH 25.08.10 Issued for Comments (IFC)

ORIGINATOR ORIG DATE F4 AFH 10.11.10 MM 10.11.10 TPH 10.11.10 Issued for Approval (IFA)

AFH 25.08.10 F5 MM 14.01.11 TPH 14.01.11 TPH 14.01.11 Issued for Bid (IFB)

1 P&ID NO.: AD-KPOC-KBB-PRO-PID-55008

2 UFD NO.: AD-KPOC-KBB-PRO-UFD-10059

3

4 LIQUID INLET FRESH WATER

5 OUTLET DEMINERALIZED WATER

6 PROCESS TYPE ION-EXCHANGE (MIXED BED) (NOTE 1)

7

8 FEEDWATER (NORMAL)

9 INLET SUPPLY PRESSURE Barg 4.0 (HOLD 1)

10 OPERATING TEMPERATURE °C 21-40

11 VISCOSITY cP 0.87

12 SPECIFIC GRAVITY @ PT 1.004

13 TOTAL DISSOLVED SOLIDS (TDS) ppm 400 MAX

14 CHLORIDE CONTENT ppm 200

15 pH - (NOTE 2)

16 SERVICE WATER SYSTEM

17 DESIGN PRESSURE Barg 16.0

18 DESIGN TEMPERATURE (MAX/MIN) °C 55 /18

19

20 PERMEATE (OUTLET)

21 FLOWRATE @ PT OF DEMINERALISED WATER

22 NORMAL Lit/h 50

23 RATED Lit/h 100

24 TOTAL DISSOLVED SOLIDS (TDS) ppm 5 max (NOTE 3)

25 CHLORIDE CONTENT ppm 0.5 max (NOTE 3)

26 STANDARD - (NOTE 3)

27

28 PERFORMANCE

29 POTABLE WATER INLET FLOW Lit/h 50

30 CHLORIDE INLET (MAX) ppm 250

31 OUTLET FLOW (MIN/MAX) Lit/h 50 - 100

32 RESIN CONSUMPTION RATE (MIN/MAX) Lit/Month 6 / 12 (NOTE 4) (HOLD 1)

33

34

35 NOTES:

36 1. THIS SYSTEM SHOULD BE CAPABLE TO REDUCE TDS AND CHLORIDE CONTENT IN THE WATER TO THE REQUIRED LEVEL.

37 ION EXCHANGE CONCEPT IS CONSIDERED WITH 2 TYPE OF ION EXCHANGE RESIN. VENDOR MAY PROPOSE ANY SUITABLE METHOD OF DEMINERALISATION

38 2. WHO GUIDELINES FOR DRINKING WATER QUALITY AS PER THE TABLE ATTACHED IN SHEET 3 OF 3.

39 3. THE QUALITY OF DEMINERALISED WATER REQUIRED IS AS PER THE TABLE ATTACHED IN SHEET 3 OF 3.

40 4. VENDOR SHALL ADVISE ON METHODS OF RESIN REPLACEMENT / REGENERATION.

41 5. PACKAGE TO INCLUDE A STORAGE TANK WITH WORKING CAPACITY OF (HOLD 2) LITRES.

42

43

44

45

46

47 HOLDS:

48 1. VENDOR TO CONFIRM

49

50

51

52

53

54

55

56

57

58

AKER ENGINEERING MALAYSIA SDN BHD

P:\Process\Data Files\Datasheets\Demineraliser Package\Rev F5(IFB)\[AD-KPOC-KBB-PRO-DST-55014_F5_Demineralizer_Package.xls]3

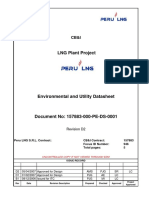

PROJECT DOCUMENT NO.

KBB NORTHERN HUB PROJECT AD-KPOC-KBB-PRO-DST-55014

TITLE ITEM NO ENGR PROJ JOB NO PAGE REV

PROCESS DATASHEET - DEMINERALIZER PACKAGE Z-5515 103347 3 OF 3 F5

JOB SPECIFICATION

CLIENT NAME

REV BY DATE CK'D DATE APP DATE REVISION

KEBABANGAN PETROLEUM F1 AFH 10.08.10 MYK 10.08.10 TPH 10.08.10 Discipline Internal Check (DIC)

OPERATING COMPANY (KPOC) F2 AFH 11.08.10 MYK 11.08.10 TPH 11.08.10 Inter-Discipline Checking(IDC)

F3 AFH 25.08.10 MM 25.08.10 TPH 25.08.10 Issued for Comments (IFC)

ORIGINATOR ORIG DATE F4 AFH 10.11.10 MM 10.11.10 TPH 10.11.10 Issued for Approval (IFA)

AFH 25.08.10 F5 MM 14.01.11 TPH 14.01.11 TPH 14.01.11 Issued for Bid (IFB)

1

2 DEMINERALISED WATER ANALYSIS (INFORMATION FROM THE GTG & GTC VENDORS)

3

4 LIMIT TEST METHOD

5 TOTAL SUSPENDED SOLIDS, mg/L , MAX 2.6 ASTM D5907, EPA 160.1&

6 TOTAL DISSOLVED SOLIDS, mg/L , MAX 5.0 EPA 160.2

7

pH 6.0 - 8.0 ASTM D5464 or EPA 150.1

8

9 CONDUCTIVITY, µ S/cm @ 25°C < 1.0 ASTM D5391

10 SODIUM + POTASSIUM , ppm , MAX SEE 3.3 EPA 200.7

11 SILICA (SiO2) , mg/L , MAX 0.1 EPA 200.7

12 ASTM D5542 ,

13 CLORIDES , mg/L , MAX 0.5 ASTM D4327 or

14 EPA 300.0

15 ASTM D5542 ,

16 SULFATES , mg/L , MAX 0.5 ASTM D4327 or

17 EPA 300.0

18

19

20

21 WHO GUIDELINES FOR DRINKING WATER QUALITY

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

AKER ENGINEERING MALAYSIA SDN BHD

P:\Process\Data Files\Datasheets\Demineraliser Package\Rev F5(IFB)\[AD-KPOC-KBB-PRO-DST-55014_F5_Demineralizer_Package.xls]3

You might also like

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Understanding Membrane Distillation and Osmotic DistillationFrom EverandUnderstanding Membrane Distillation and Osmotic DistillationNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Erbil Refinery Waste Water Pump Data SheetDocument5 pagesErbil Refinery Waste Water Pump Data SheetSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- 01-Apiflo Oh2 80-365-9-S-6-DS - RaDocument4 pages01-Apiflo Oh2 80-365-9-S-6-DS - RapaachangaNo ratings yet

- JI2048-977-MS-DAT-0041 - Rev002 (T-1020)Document9 pagesJI2048-977-MS-DAT-0041 - Rev002 (T-1020)Tech DesignNo ratings yet

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayNo ratings yet

- 2922-GAC-STA-DAS-000-1039 - B D4001 Column Top Condenser XE4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1039 - B D4001 Column Top Condenser XE4001 - TR-59RonggolaweNo ratings yet

- Duqm Project EPC 2 - Utilities and Offsites Data SheetDocument9 pagesDuqm Project EPC 2 - Utilities and Offsites Data SheetsudhirguduruNo ratings yet

- DMR-1. Dated 9-10-2022Document1 pageDMR-1. Dated 9-10-2022Gulzar AhmedNo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- (6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FDocument15 pages(6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FMohamed OuichaouiNo ratings yet

- MixerDocument4 pagesMixerMarcelo PerettiNo ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- SEL-TBD-O-CA-003 - R0 - Crude Oil Storage Tank Sizing-Signed PDFDocument16 pagesSEL-TBD-O-CA-003 - R0 - Crude Oil Storage Tank Sizing-Signed PDFahmad santosoNo ratings yet

- Mechanical Data Sheet for Diesel Engine Driven Fire Water PumpDocument5 pagesMechanical Data Sheet for Diesel Engine Driven Fire Water Pumpbubbles82No ratings yet

- DH PEP PPS PR 001 Process DescriptionDocument6 pagesDH PEP PPS PR 001 Process Descriptionfadli arsyadaNo ratings yet

- SFCCL Reformer DCI R1Document38 pagesSFCCL Reformer DCI R1maheshNo ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- BFW Cooler Datasheet Rev 2Document3 pagesBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNo ratings yet

- IONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 TransmittalDocument10 pagesIONE-1B03-SP-PR-0002 PROCESS PROCESS DESCRIPTION For UNIT 03 Rev.0 Code 2 Transmittalyusuf.yuzuakNo ratings yet

- IONE-5D34-SP-PR-0002 PROCESS DESCRIPTION For UNIT 34 Rev.0Document8 pagesIONE-5D34-SP-PR-0002 PROCESS DESCRIPTION For UNIT 34 Rev.0yusuf.yuzuakNo ratings yet

- Solvent Recovery Bottoms Pumps (09P007A/B) : Data SheetDocument6 pagesSolvent Recovery Bottoms Pumps (09P007A/B) : Data SheetAthiphap SrisupareerathNo ratings yet

- MY-SK410B-LLCPP-ME-DS-0036-00 Rev F0 - Fuel Gas TreatmentDocument48 pagesMY-SK410B-LLCPP-ME-DS-0036-00 Rev F0 - Fuel Gas TreatmentkelburnNo ratings yet

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 pagesN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridNo ratings yet

- TECNICAS REUNIDAS PROPERTY AND CONFIDENTIALITY NOTICEDocument8 pagesTECNICAS REUNIDAS PROPERTY AND CONFIDENTIALITY NOTICEAlonso1593No ratings yet

- Flow Switch Data Sheet for Project MAQUIDocument1 pageFlow Switch Data Sheet for Project MAQUIlamisma09No ratings yet

- P4 - Ion Exchange-Process Data Sheet For Reject Water Transfer PumpDocument5 pagesP4 - Ion Exchange-Process Data Sheet For Reject Water Transfer Pumpsumit kumarNo ratings yet

- Ehs-E076-Ics-Das-Cnl-0000-90011-00 G02Document8 pagesEhs-E076-Ics-Das-Cnl-0000-90011-00 G02Okoro KennethNo ratings yet

- Daharki Combined Cycle Power PlantDocument77 pagesDaharki Combined Cycle Power Plantmuhammad abdulrehmanNo ratings yet

- SindhDocument2 pagesSindhzahid latifNo ratings yet

- NHT Heater API DatasheetDocument9 pagesNHT Heater API DatasheetAravind AravindNo ratings yet

- Centrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorDocument2 pagesCentrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorJuan José Grajeda AguayoNo ratings yet

- RFCC1Document35 pagesRFCC1alexHuy88No ratings yet

- Design CalculationsDocument43 pagesDesign CalculationsRanjan Rahi100% (1)

- Water Sprinker System Design Report - BPCLDocument32 pagesWater Sprinker System Design Report - BPCLbecpavanNo ratings yet

- Data Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / BeyDocument8 pagesData Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / Beyrajindo1No ratings yet

- Fire Water Sprinker System DesignDocument8 pagesFire Water Sprinker System DesignbecpavanNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray NozzlebecpavanNo ratings yet

- Calculation of Shell Plate Thickness for DCU Feed Storage TankDocument25 pagesCalculation of Shell Plate Thickness for DCU Feed Storage TankSachinNo ratings yet

- Cover Sheet - : Liquid Carbon Dioxide (LCD) 1Document13 pagesCover Sheet - : Liquid Carbon Dioxide (LCD) 1Miki TodevskiNo ratings yet

- Phase1 Hassi Bir Rekaiz Field DevelopmentDocument4 pagesPhase1 Hassi Bir Rekaiz Field Developmentahmed.njahNo ratings yet

- P2 - Ion Exchange-A2-Process Data Sheet of NF Feed PumpDocument5 pagesP2 - Ion Exchange-A2-Process Data Sheet of NF Feed Pumpsumit kumarNo ratings yet

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- 000 Pe DS 0001Document5 pages000 Pe DS 0001Dar FallNo ratings yet

- Project / Projet: REVIN Pump Turbine / Turbine PompeDocument1 pageProject / Projet: REVIN Pump Turbine / Turbine PompeMarcoNo ratings yet

- B-63.888 - B - Operational Test Procedure For Lifting Stations (Ls 1-5)Document39 pagesB-63.888 - B - Operational Test Procedure For Lifting Stations (Ls 1-5)onome ohwerhiNo ratings yet

- Contract: API 610 Vertical Centrifugal Pump DataDocument7 pagesContract: API 610 Vertical Centrifugal Pump DataNAHASALI11No ratings yet

- Process Design Basis FOR Unit 05 - Kerosene Hydrodesulphurization UnitDocument18 pagesProcess Design Basis FOR Unit 05 - Kerosene Hydrodesulphurization Unitdhiaa mohammedNo ratings yet

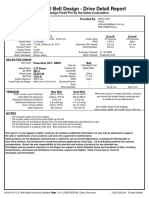

- Drive Design X-2410 & X-2420Document1 pageDrive Design X-2410 & X-2420FazliJaafarNo ratings yet

- Drive Design X-2307Document1 pageDrive Design X-2307FazliJaafarNo ratings yet

- Drive Design X-2307Document1 pageDrive Design X-2307FazliJaafarNo ratings yet

- Gas Turbine Power GenerationDocument4 pagesGas Turbine Power GenerationFazliJaafarNo ratings yet

- SM 81320_A_1Document11 pagesSM 81320_A_1FazliJaafarNo ratings yet

- Wpa Po727582 (U4)Document2 pagesWpa Po727582 (U4)FazliJaafarNo ratings yet

- Changing The Dates On Multiple Measurements in SKF @ptitude Analyst Using SQLDocument2 pagesChanging The Dates On Multiple Measurements in SKF @ptitude Analyst Using SQLFazliJaafarNo ratings yet

- X 4605 4608ADocument1 pageX 4605 4608AFazliJaafarNo ratings yet

- SteamTurbines 10308766Document282 pagesSteamTurbines 10308766FazliJaafarNo ratings yet

- AutocorrelationDocument43 pagesAutocorrelationpondpakkaNo ratings yet

- K-39 Fan Measurement Report SummaryDocument4 pagesK-39 Fan Measurement Report SummaryFazliJaafarNo ratings yet

- Vibration Report - M-39-01-B2 - Bearings DefectDocument4 pagesVibration Report - M-39-01-B2 - Bearings DefectFazliJaafarNo ratings yet

- Pod 1655929516Document1 pagePod 1655929516FazliJaafarNo ratings yet

- Performance - Monitoring - of - Vibration - in - Belt Conveyor SystemDocument11 pagesPerformance - Monitoring - of - Vibration - in - Belt Conveyor SystemFazliJaafarNo ratings yet

- P9902B Final Alignment ReportDocument3 pagesP9902B Final Alignment ReportFazliJaafarNo ratings yet

- The Creative Art of Blogging BriefingDocument4 pagesThe Creative Art of Blogging BriefingFazliJaafarNo ratings yet

- PowerMI Vibration Analysis 08112022Document5 pagesPowerMI Vibration Analysis 08112022FazliJaafarNo ratings yet

- Vibration Report - #3-301019-P3903ADocument2 pagesVibration Report - #3-301019-P3903AFazliJaafarNo ratings yet

- Vibration Analysis Report - K-39-01 P2 Motor Bering DefectDocument4 pagesVibration Analysis Report - K-39-01 P2 Motor Bering DefectFazliJaafarNo ratings yet

- Vibration Analysis Report - K-13-01-PM2 Bearing DefectDocument5 pagesVibration Analysis Report - K-13-01-PM2 Bearing DefectFazliJaafarNo ratings yet

- LGAST - Vibration Monitoring Preliminary ReportDocument2 pagesLGAST - Vibration Monitoring Preliminary ReportFazliJaafarNo ratings yet

- Cekd Ipo 20210914Document10 pagesCekd Ipo 20210914FazliJaafarNo ratings yet

- Vibration Report - 04-P3903A-121119 - Bearing DefectDocument1 pageVibration Report - 04-P3903A-121119 - Bearing DefectFazliJaafarNo ratings yet

- Order Details Billing Summary: Sold-To Bill-To Service Usage AddressDocument2 pagesOrder Details Billing Summary: Sold-To Bill-To Service Usage AddressFazliJaafarNo ratings yet

- PETRONAS CHEMICALS FERTILISER SABAH VIBRATION REPORT ON PM-37-04A ROTORDocument5 pagesPETRONAS CHEMICALS FERTILISER SABAH VIBRATION REPORT ON PM-37-04A ROTORFazliJaafarNo ratings yet

- CECON Cluthes Service ManualDocument6 pagesCECON Cluthes Service ManualFazliJaafarNo ratings yet

- CECON Cluthes Service ManualDocument6 pagesCECON Cluthes Service ManualFazliJaafarNo ratings yet

- Price VolumeDocument3 pagesPrice VolumeCryptoFX96% (24)

- Vibration Report - PM3401A - Bearings DefectDocument3 pagesVibration Report - PM3401A - Bearings DefectFazliJaafarNo ratings yet

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument4 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton mirandaNo ratings yet

- Herose CryogenicDocument366 pagesHerose Cryogenicstphn_maturinNo ratings yet

- Ra 9275Document19 pagesRa 9275Calvin Jr. Wong100% (2)

- Manual and Solenoid Actuated 2-Way ValvesDocument12 pagesManual and Solenoid Actuated 2-Way ValvesElias100% (1)

- Analysis and Performance of Centrifugal Pump ImpellerDocument7 pagesAnalysis and Performance of Centrifugal Pump ImpellerMarcelo MachadoNo ratings yet

- Thermal Distillation Technology For Management of Produced Water and Frac Flowback WaterDocument12 pagesThermal Distillation Technology For Management of Produced Water and Frac Flowback WaterSebastián Arboleda PalaciosNo ratings yet

- Exp 1 PhenDocument5 pagesExp 1 Phensoran najebNo ratings yet

- 200 MW - Unit, Generator Seal Oil SystemDocument3 pages200 MW - Unit, Generator Seal Oil SystemNikhilNo ratings yet

- Dvigateli Hpi Serii 0 1 2 25 3 KatalogDocument375 pagesDvigateli Hpi Serii 0 1 2 25 3 KatalogТоп РемNo ratings yet

- Centrifugal Pump Envelope: Problem StatementDocument5 pagesCentrifugal Pump Envelope: Problem StatementPIDNo ratings yet

- No. Content 1. 1 2. Objective 2 3. Apparatus 2 4. Procedure 3-4 5. Result 4-5 6. Analysis 6-8 7. Discussion 9 8. Conclusion 9 9. References 10Document3 pagesNo. Content 1. 1 2. Objective 2 3. Apparatus 2 4. Procedure 3-4 5. Result 4-5 6. Analysis 6-8 7. Discussion 9 8. Conclusion 9 9. References 10Zaffira RahmanNo ratings yet

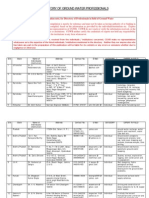

- Directory of GROUND WATER Professionals PDFDocument10 pagesDirectory of GROUND WATER Professionals PDFSathenapalle Kiran BabuNo ratings yet

- NameDocument16 pagesNameAfro BertNo ratings yet

- S770 Hyd Std-Op V-1676Document2 pagesS770 Hyd Std-Op V-1676Teknik MakinaNo ratings yet

- F2 2I UpdatedddDocument17 pagesF2 2I UpdatedddMohd Nik Harith FawwazNo ratings yet

- Manual LabDocument75 pagesManual LabAhmad JaradatNo ratings yet

- Continuity and Energy EquationsDocument53 pagesContinuity and Energy Equationssushil.vgiNo ratings yet

- Bell Helicopter Consumables ListDocument4 pagesBell Helicopter Consumables ListElias ZabanehNo ratings yet

- Models: D35, G35: Installation, Operation & MaintenanceDocument25 pagesModels: D35, G35: Installation, Operation & MaintenanceyuanNo ratings yet

- WfiDocument4 pagesWfiDevii RachmaaNo ratings yet

- FMC Flow Rates at 40 FPSDocument1 pageFMC Flow Rates at 40 FPSpaulegi5No ratings yet

- (ME LAB 1) Activity No. 04Document3 pages(ME LAB 1) Activity No. 04Gonzales Craezylyn D.No ratings yet

- Case StudyDocument3 pagesCase Studyzadbiel itai cruz tecuapachoNo ratings yet

- Pneumatic Ata 36Document2 pagesPneumatic Ata 36Muhammad ShoaibNo ratings yet

- Presentation (Flood Routing)Document24 pagesPresentation (Flood Routing)Vinay ChandwaniNo ratings yet

- Blasius Boundary Layer - WikipediaDocument6 pagesBlasius Boundary Layer - Wikipediarpraj3135No ratings yet

- Resume Buku Karangan William C Dunn Chapter LevelDocument4 pagesResume Buku Karangan William C Dunn Chapter LevelJeri AlexNo ratings yet

- CFD Manual FluentDocument82 pagesCFD Manual FluenttfemilianNo ratings yet

- Stream Flow MeasurementsDocument31 pagesStream Flow MeasurementsJohn Reymer V. SaplanNo ratings yet

- CM&CD works on Canals and Design of Lift Irrigation SchemesDocument126 pagesCM&CD works on Canals and Design of Lift Irrigation Schemessri sri sai traders kadapaNo ratings yet