Professional Documents

Culture Documents

Sop D.G. Operation

Uploaded by

sapat309Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop D.G. Operation

Uploaded by

sapat309Copyright:

Available Formats

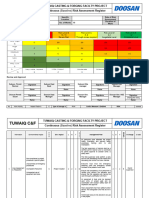

Engineering & Projects

DEPARTMENT / PROJECT DOC NO. MHS/SOP/1.1.8/01

SECTION/ SITE REVISION NO 01

JOB TITLE EFFECTIVE DATE

SUB LOCATION

S.No Activities / Sequence Work Instruction / Hazard & Safety Precautions Why Responsibility

Pre – Work/ Ensure site Safety Induction. Non-compliance of HSE Safety Supervisor

1. Obtaining Ensure familiarization with Life Saving Rules. Management System &

Authorization Ensure familiarization with Company rules. Procedures Electrician

Ensure to obtain all required permits (LOTO, etc)

prior to the work

Unauthorized area of work

2. Checking oil Ensure equipment is operated on a stable, level Fuel Spillage Safety Supervisor

level surface

Ensure to check machine daily for fuel and oil Electrician

leaks Contamination of soil

Switch engine off before refuelling and make

sure fuel cap is replaced

In contact with body parts

Dip tray should be placed to prevent soil

contamination by accidental spills.

Full sleeve clothing should be mandatory

Use of adequate PPEs.

Name Name Name

Date Date Date

E&P Departmental Representative/ Consultant E&P Safety Representative Working Agency / Contractor Representative

Remarks

1. 6 - direction hazards (Up/Down/Front/Back/Left/Right) of other jobs being done in close proximity have to be recorded daily and has to be discussed in the Tool Box Talk

2. Job specific SWP should be made and attached to this SWP with additional precautions for any additional activities (if any). This should be step by step including all steps.

3. The job specific SWP will be modified as and when the nature of job changes

4. Training on SWP to be given to all workmen by E&P Officer / Consultant at the start of the job and thereafter least once per year and by Contractor representative on a monthly basis. The monthly training record should be attached

with the monthly bill or Job Measurement Report.

5. Review on status of implementation shall be done through Job Cycle Check by Safety Supervisor / Consultant/ E&P Officer at least once per month

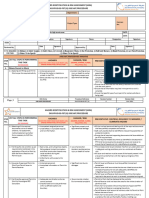

Engineering & Projects

DEPARTMENT / PROJECT DOC NO. MHS/SOP/1.1.8/01

SECTION/ SITE REVISION NO 01

JOB TITLE EFFECTIVE DATE

SUB LOCATION

S.No Activities / Sequence Work Instruction / Hazard & Safety Precautions Why Responsibility

3. Checking water Keep hands away from the hot surface & do not Hot surface

in radiator touch them with bare hands. Safety Supervisor

Let it cool first for some time after shutting down Hot water

of DG. Electrician

Usage of adequate PPEs( safety leather hand

gloves, safety goggles) during the checking

work.

Use full sleeve clothing while checking.

Pay attention to work

4. Checking All moving parts should be protected with guards Contact with moving Safety Supervisor

battery & fan or covers.

belt. Do not remove guards or covers. parts Electrician

Maintenance or repairing should be done by

competent personnel only Battery chemical

MSDS for battery chemicals should be displayed

with precautions at the work site.

Name Name Name

Date Date Date

E&P Departmental Representative/ Consultant E&P Safety Representative Working Agency / Contractor Representative

Remarks

1. 6 - direction hazards (Up/Down/Front/Back/Left/Right) of other jobs being done in close proximity have to be recorded daily and has to be discussed in the Tool Box Talk

2. Job specific SWP should be made and attached to this SWP with additional precautions for any additional activities (if any). This should be step by step including all steps.

3. The job specific SWP will be modified as and when the nature of job changes

4. Training on SWP to be given to all workmen by E&P Officer / Consultant at the start of the job and thereafter least once per year and by Contractor representative on a monthly basis. The monthly training record should be attached

with the monthly bill or Job Measurement Report.

5. Review on status of implementation shall be done through Job Cycle Check by Safety Supervisor / Consultant/ E&P Officer at least once per month

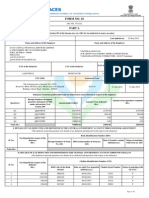

Engineering & Projects

DEPARTMENT / PROJECT DOC NO. MHS/SOP/1.1.8/01

SECTION/ SITE REVISION NO 01

JOB TITLE EFFECTIVE DATE

SUB LOCATION

S.No Activities / Sequence Work Instruction / Hazard & Safety Precautions Why Responsibility

DG should be equipped with spark arrestor exposure on body

Keep flammables away from the engine

Ensure to keep fire extinguisher at work site. parts.

Fire due to sparks

5. Press start button Report to Supervisor or Management Malfunction causing Safety Supervisor

immediately

In case of emergency or malfunction activate leak or fire Electrician

stop switch at D G set

Do not operate with wet hands, damp soil and Electric hazards

avoid inclement weather.

Rubber mat is suitable while operating. Noise

Ensure proper ELCB in place & earthing should

good enough.

Use ear protection device before operating.

Name Name Name

Date Date Date

E&P Departmental Representative/ Consultant E&P Safety Representative Working Agency / Contractor Representative

Remarks

1. 6 - direction hazards (Up/Down/Front/Back/Left/Right) of other jobs being done in close proximity have to be recorded daily and has to be discussed in the Tool Box Talk

2. Job specific SWP should be made and attached to this SWP with additional precautions for any additional activities (if any). This should be step by step including all steps.

3. The job specific SWP will be modified as and when the nature of job changes

4. Training on SWP to be given to all workmen by E&P Officer / Consultant at the start of the job and thereafter least once per year and by Contractor representative on a monthly basis. The monthly training record should be attached

with the monthly bill or Job Measurement Report.

5. Review on status of implementation shall be done through Job Cycle Check by Safety Supervisor / Consultant/ E&P Officer at least once per month

You might also like

- Gnostic BibleDocument867 pagesGnostic BibleThe Divine Eye100% (5)

- Tips For Pop ArrangingDocument6 pagesTips For Pop ArrangingPlosytre Grostuna100% (1)

- Jsa For HydrotestDocument10 pagesJsa For HydrotestAnonymous CcGYhZb080% (5)

- Jsa For Lifting Activities With Mechanical EquipmentDocument4 pagesJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalNo ratings yet

- James Ruse 2005 Biology Prelim HY & SolutionsDocument15 pagesJames Ruse 2005 Biology Prelim HY & SolutionsAnna Wong100% (1)

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- Mom 59Document14 pagesMom 59Anonymous kWfNFb100% (1)

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- Business Plan Aunt NewwwDocument10 pagesBusiness Plan Aunt NewwwpushpamaliNo ratings yet

- HT & PWHT JsaDocument3 pagesHT & PWHT JsaNature BeautiesNo ratings yet

- Contractor Method Statement (RL)Document8 pagesContractor Method Statement (RL)Shaikh Muhammad AteeqNo ratings yet

- HSE-RA-014 Using of Cutting Torch - Rev 0Document15 pagesHSE-RA-014 Using of Cutting Torch - Rev 0عمروNo ratings yet

- Unit Tests AnswersDocument24 pagesUnit Tests AnswersNanman Thaiman78% (9)

- Selenium PDFDocument90 pagesSelenium PDFSelvarajaguru RamaswamyNo ratings yet

- HSE-RA-029 Straight and Cut Operation - Rev 0Document8 pagesHSE-RA-029 Straight and Cut Operation - Rev 0عمروNo ratings yet

- HSE-RA-067 Threading Machine - Rev 0Document14 pagesHSE-RA-067 Threading Machine - Rev 0عمروNo ratings yet

- Up Dated Job Safety Analysis-Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis-Gypsum Plastering WorksAkhtar Ali100% (1)

- Company Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateDocument11 pagesCompany Instrumentation & Control Specialists, Inc Document ID No. Department/s Contractor Revision No Job Title Coring Works Effective DateJayson EscamillanNo ratings yet

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- Ug PipingDocument186 pagesUg PipingKepweng ManggagamotNo ratings yet

- HSE 10 Excavation PermitDocument1 pageHSE 10 Excavation PermitBa N Nhim100% (1)

- The Resister, The Political Warfare Journal of The Special Forces UndergroundVolume I, Number 3 Winter 1994Document28 pagesThe Resister, The Political Warfare Journal of The Special Forces UndergroundVolume I, Number 3 Winter 1994Rmplstlskn100% (1)

- Mohamad FadliDocument6 pagesMohamad Fadlishamierrul shahliNo ratings yet

- Attachment - I: Pre Start-Up Safety Review Checklist - 1Document15 pagesAttachment - I: Pre Start-Up Safety Review Checklist - 1HamzaNoumanNo ratings yet

- Decision Making Using Financial Ratios PDFDocument107 pagesDecision Making Using Financial Ratios PDFOmkar Reddy Punuru100% (3)

- Work Order ProcedureDocument5 pagesWork Order ProcedureJames Reyes100% (1)

- HSE-RA-052 Repairs of Concrete Imperfections - Rev 0Document11 pagesHSE-RA-052 Repairs of Concrete Imperfections - Rev 0عمروNo ratings yet

- PTW - Electrical PermitDocument2 pagesPTW - Electrical PermitJahanzaib KhanNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- Is Sadhguru Jaggi Vasudev A ConmanDocument83 pagesIs Sadhguru Jaggi Vasudev A ConmanShanmugam Piramanayagam33% (6)

- Sumerian AchievementsDocument5 pagesSumerian AchievementsmagilNo ratings yet

- Grammar WIki Upper-Intermediate PDFDocument439 pagesGrammar WIki Upper-Intermediate PDFКатерина КотоваNo ratings yet

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- Seal Oil SystemDocument22 pagesSeal Oil SystemRaja VigneshNo ratings yet

- Work Permit ProcedureDocument2 pagesWork Permit Procedureवात्सल्य कृतार्थNo ratings yet

- 515021&515022-PLT-DZ-077-2011 Replace FIP, Fuel Injector, and Turbo Charge of DozerDocument8 pages515021&515022-PLT-DZ-077-2011 Replace FIP, Fuel Injector, and Turbo Charge of DozerMuhammad Fatur Dipo GribaldyNo ratings yet

- KITCHEN Maintenance JSEADocument7 pagesKITCHEN Maintenance JSEAWeru MorrisNo ratings yet

- Permit To Work Ref TemplateDocument2 pagesPermit To Work Ref Templatenatamas systemsNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- CommissioningDocument4 pagesCommissioningAldrien CabinteNo ratings yet

- PTW in Working at HeightDocument1 pagePTW in Working at Heightbach.pham0932719192No ratings yet

- 20.SOP For Boiler Initial Water FilllingDocument9 pages20.SOP For Boiler Initial Water FilllingRaja VigneshNo ratings yet

- JSA For Filter Cleaning by Steam and Water ManuallyDocument22 pagesJSA For Filter Cleaning by Steam and Water ManuallyThái Đạo Phạm LêNo ratings yet

- HSE-RA-055 Chiller Pipe Installation - Rev 0Document16 pagesHSE-RA-055 Chiller Pipe Installation - Rev 0عمروNo ratings yet

- Permit of WorkDocument24 pagesPermit of WorkSantanu SharmaNo ratings yet

- Hse Daily ObservationDocument1 pageHse Daily ObservationtinojNo ratings yet

- 17 Confined SpaceDocument1 page17 Confined SpaceMUhammad RanaNo ratings yet

- Rekayasa Industri: Daftar IsiDocument13 pagesRekayasa Industri: Daftar IsiArieNo ratings yet

- HSE-RA-054 HVAC Duct Installation Works - Rev 0Document13 pagesHSE-RA-054 HVAC Duct Installation Works - Rev 0عمروNo ratings yet

- Grinding Work JsaDocument2 pagesGrinding Work JsaAKBAR ALINo ratings yet

- 3.2d Airbag DisposalDocument1 page3.2d Airbag DisposalJaime jr MillanNo ratings yet

- Up Dated Job Safety Analysis Gypsum Plastering WorksDocument12 pagesUp Dated Job Safety Analysis Gypsum Plastering WorksshahbazchafekarNo ratings yet

- PnP4 - Preventive MaintenanceDocument1 pagePnP4 - Preventive MaintenanceKenneth Bryan VillagonezaNo ratings yet

- 001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)Document13 pages001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)NIdhinNo ratings yet

- JSP For SS No. 8 Installation of EOT CraneDocument28 pagesJSP For SS No. 8 Installation of EOT CraneJaafar LagayanNo ratings yet

- 03-Contoh JSA-OKEDocument2 pages03-Contoh JSA-OKEMaster AssassiNNo ratings yet

- Template Site Specific ESH Safety SSEP PlanDocument12 pagesTemplate Site Specific ESH Safety SSEP PlanNarendraNo ratings yet

- Jsa PDFDocument5 pagesJsa PDFVAMSINo ratings yet

- Old Parts Handling Procedure-ADocument3 pagesOld Parts Handling Procedure-AJoseph Emmanuel ParedesNo ratings yet

- JSEA-ICS-004 Cable Laying and PullingDocument17 pagesJSEA-ICS-004 Cable Laying and PullingJayson EscamillanNo ratings yet

- Epoxy Method StatementDocument8 pagesEpoxy Method StatementALLAN KIBIRIGENo ratings yet

- SOP - 6 - Coal Charging ActivityDocument7 pagesSOP - 6 - Coal Charging Activityfaraz ahmedNo ratings yet

- Confined Space EntryDocument9 pagesConfined Space EntryAldrien CabinteNo ratings yet

- RA 16 (Anchor Bolt Installation)Document7 pagesRA 16 (Anchor Bolt Installation)abdulthahseen007No ratings yet

- Format No. 13.01.05 F-03 Visual Felt Leadership - HSE Checklist R1 15.06.2020Document2 pagesFormat No. 13.01.05 F-03 Visual Felt Leadership - HSE Checklist R1 15.06.2020Aarti100% (1)

- PTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobDocument3 pagesPTA-JSA-001-Mobilization Deployment of Manpower & Beginning of The JobSaiyad RiyazaliNo ratings yet

- JSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaDocument11 pagesJSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- 2017-LPA KarachiDocument7 pages2017-LPA KarachiHammad RazaNo ratings yet

- Instrumen KSSR P.KHAS ENGLISH YEAR 1Document69 pagesInstrumen KSSR P.KHAS ENGLISH YEAR 1ain_fazillahNo ratings yet

- RRLDocument3 pagesRRLFrancis Calubayan100% (1)

- Chapter 2 CONSIGMENT - 084222Document9 pagesChapter 2 CONSIGMENT - 084222Priyanshu tripathiNo ratings yet

- Accommodation Costs 2023-2024 With Lease DatesDocument1 pageAccommodation Costs 2023-2024 With Lease DatesMadalongipolahaNo ratings yet

- The Values of An AugustinianDocument1 pageThe Values of An AugustinianCarla VirtucioNo ratings yet

- Ciclostomi FosiliDocument5 pagesCiclostomi FosiliAnca MihalcescuNo ratings yet

- Boss Me 30 PatchesDocument4 pagesBoss Me 30 PatchesAps BautistaNo ratings yet

- Research ProposalDocument4 pagesResearch ProposalAnonymous cm3q67h3MY100% (1)

- Mini Sprint Assisgnment Rubric 1Document3 pagesMini Sprint Assisgnment Rubric 1api-353324671No ratings yet

- Mentoring in Organizations SLIDESDocument17 pagesMentoring in Organizations SLIDESrangelj13No ratings yet

- GRG 4Document1 pageGRG 4egalNo ratings yet

- PDFDocument5 pagesPDFdhanu1434No ratings yet

- Ejercicios Voz PasivaDocument3 pagesEjercicios Voz Pasivasmary_20No ratings yet

- NandiniDocument28 pagesNandinianamica100% (1)

- Ashok Leyland Ltd-FY15Document157 pagesAshok Leyland Ltd-FY15Gautam DNo ratings yet

- Numerical Logic 2Document98 pagesNumerical Logic 2Rafe ANo ratings yet

- Online Book Store: Shashank Srivastava B.Tech: 4 Year Computer Science & Engineering 1014710027Document12 pagesOnline Book Store: Shashank Srivastava B.Tech: 4 Year Computer Science & Engineering 1014710027malik hadiaNo ratings yet

- Open Mind Upper Intermediate Unit 12 Wordlist - PortugueseDocument2 pagesOpen Mind Upper Intermediate Unit 12 Wordlist - PortugueseOmar MohamedNo ratings yet