Professional Documents

Culture Documents

515021&515022-PLT-DZ-077-2011 Replace FIP, Fuel Injector, and Turbo Charge of Dozer

Uploaded by

Muhammad Fatur Dipo GribaldyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

515021&515022-PLT-DZ-077-2011 Replace FIP, Fuel Injector, and Turbo Charge of Dozer

Uploaded by

Muhammad Fatur Dipo GribaldyCopyright:

Available Formats

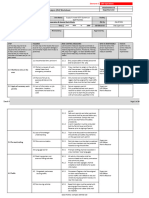

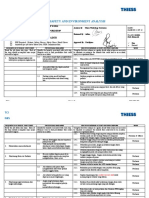

JOB SAFETY AND ENVIRONMENT ANALYSIS

Project: Location of Work: JSEA Number New Date: Page No

Melak Coal Mine Project Workshop / Field 515021&515022-PLT-DZ-077-

Revised Date: 05/04/2011 1 of 8

2011

Job Description: Reference Materials:

Replace F I P, Fuel Injector, and Turbo Charger of Dozer Isolation and Tag out, AMANKAN, PPE, Supporting load, Moving and parking

equipment around workshop area, Manual Handling

Operational Activity (Job Boundaries) JSEA Team Members

Parking unit until final check finished Name Position Signature

Hierarchy of Control to Manage Potential Hazards

1. Elimination

Remove the hazard so consequence is virtually zero. This is the most effective control measure

and should always be considered first.

2. Substitution

Substituting a less hazardous material, process or equipment so there is less consequence

(note that replacing often introduces a different hazard).

3. Isolation

Isolating the hazard from the person put at risk at the time of exposure. Reviewed by:

4. Engineering Name Position Signature

Reduce the likelihood of the unwanted event through hardware design. Ratno Mechanic Supv

5. Administration Eko Prasetyo Plant Safety

Reduce exposure to hazards through procedures, instructions, training and competency. Approved by

6. Personal Protective Equipment Name Position Signature

last line of defense should other controls prove ineffective, or used together with other control Gary Cooper Plant Manager

measures. Dapot Daulay Plant Supt

Specific Instruction: (e.g. emergency plan, lift study, etc.)

Work Permit Required: Yes No

Hot Work Permit Confined Space

Work At Height Other :

JSEA should be reviewed each time they are used

JSEA need to be reviewed if any changes in the work situation, following related incidents or changes in legislation

2010-01 Page 1 of 8 515021&515022-H&S-FO-085

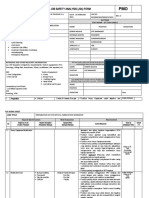

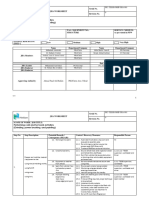

Project: Location of Work: JSEA No New Date: Page No

Revised Date: 05/04/2011 2 of 8

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of the Identify the hazards associated with each step. Using the first two columns as a guide, decide what actions are Responsible for carrying

steps should accomplish some major task and Examine each to find possibilities that could lead necessary to eliminate or minimize the hazards that could lead out/checking the action

be logical. to an accident. to an accident, injury or occupational illness.

1. Parking unit 1.1. Access sempit 1.1.1. Parkir di tempat yang luas Operator

Parking heavy equipment Narrow access Parking at large area

1.1.2. Gunakan traffic controller saat maju

mundur Traffic controller

Traffic controller is active during parking

1.1.3. Pastikan operator memiliki SIMPER

Ensure operator has SIMPER Operator

1.2. Area parkir tidak rata 1.2.1. Pastikan untuk memarkirkan di area Operator

Parking area not level yang rata

Ensure to park on level area

1.2.2. Matikan mesin dan aktifkan rem parkir Operator

Switch off the machine and parking

brake activated

1.2.3. Pasang ganjal saat memarkirkan unit Mechanic

minimum 2

Install wheel chock at least 2 ea when

parking

2. Mengisolasi Unit 2.1. Aliran listrik 2.1.1. Matikan kunci kontak Mechanic

Isolating Unit Electrical current Starter is turned off

2010-01 Page 2 of 8 515021&515022-H&S-FO-085

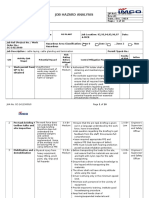

Project: Location of Work: JSEA No New Date: Page No

Revised Date: 05/04/2011 3 of 8

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of the Identify the hazards associated with each step. Using the first two columns as a guide, decide what actions are Responsible for carrying

steps should accomplish some major task and Examine each to find possibilities that could lead necessary to eliminate or minimize the hazards that could lead out/checking the action

be logical. to an accident. to an accident, injury or occupational illness.

2.2. Unit dijalankan orang lain 2.2.1. Main switch harus di posisi off Mechanic

Unauthorized person operating Main switch should be off position

unit

2.2.2. Pasang isolation pad lock, dan personal

danger tag Mechanic

Install personal isolation and personnel

danger tag

3. Persiapan peralatan 3.1. Alat tidak sesuai untuk pekerjaan 3.1.1. Pastikan alat yang digunakan sesuai untuk Mechanic

Preparation of tools Improper tools used pekerjaan

Ensure only proper tools to be used for the

job

3.2. Kondisi alat tidak layak pakai 3.2.1. Pastikan alat yang digunakan layak pakai Mechanic

Tools condition is not good dan diperiksa sebelum memulai pekerjaan

Ensure the tools is good condition and

checked prior to start the job

3.3. Titik jepit 3.3.1. Perhatikan posisi jari jika melakukan Mechanic

Pinch point pengangkatan manual dan ikuti prosedur

manual handling

Keep watching the finger position if doing

manual lifting and follow handling manual

procedure

3.3.2. Gunakan sarung tangan standard yang

sesuai dengan pekerjaan

Wear appropriate standard handglove

according to the job

2010-01 Page 3 of 8 515021&515022-H&S-FO-085

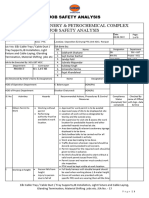

Project: Location of Work: JSEA No New Date: Page No

Revised Date: 05/04/2011 4 of 8

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of the Identify the hazards associated with each step. Using the first two columns as a guide, decide what actions are Responsible for carrying

steps should accomplish some major task and Examine each to find possibilities that could lead necessary to eliminate or minimize the hazards that could lead out/checking the action

be logical. to an accident. to an accident, injury or occupational illness.

3.4. Perlatan yang diangkat 3.4.1. Jangan berada di bawah material / perlatan Mechanic

Lifted tools yang diangkat

Do no stay under material being lifted

3.4.2. Hanya orang yang kompeten yang dapat

melakukan aktifitas pengangkatan

Lifting actifity can be performed by

competent personnel only

4. Melepas Turbo, Fuel Injector , 4.1. Panas 4.1.1. Pastikan turbo dalam keadaan dingin Mechanic

dan FIP Heat sebelum dilepas

Remove Turbo, Fuel Injector, Ensure turbo is not hot before removed

and FIP

4.1.2. Gunakan sarung tangan standar yang sesuai Mechanic

pada saat melakukan pekerjaan tersebut di

atas

Use standar handglove while doing activitie

above

4.2. Titik jepit 4.2.1. Gunakan stand untuk aktifitas melepas Mechanic

Pinch point suspensi

Use stand to remove suspension activity

4.2.2. Pastikan tanah untuk dudukan stand rata Mechanic

dank eras

Ensure hard and level soil for stand support

4.3. Tempat komponen sempit 4.3.1. Posisikan tubuh dengan aman saat bekerja Mechanic

Component place is narrow Keep body on safe position when working

2010-01 Page 4 of 8 515021&515022-H&S-FO-085

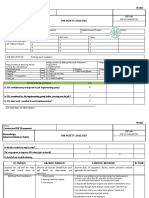

Project: Location of Work: JSEA No New Date: Page No

Revised Date: 05/04/2011 5 of 8

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of the Identify the hazards associated with each step. Using the first two columns as a guide, decide what actions are Responsible for carrying

steps should accomplish some major task and Examine each to find possibilities that could lead necessary to eliminate or minimize the hazards that could lead out/checking the action

be logical. to an accident. to an accident, injury or occupational illness.

4.4. Benda tajam 4.4.1. Selalu gunakan handglove standard Mechanic

Sharp materiall Always wear standardhandglove

4.5. Komponen tidak sesuai 4.5.1. Pastikan perkerja mengetahui dan Mechanic

Unappropriate component memehami prosedur kerja

Ensure mechanic know and understand

about procedure of working

Mechanic

4.5.2. Komunikasi yang baik harus dijaga antar tim

Keep team in good communication

4.6. Kontaminasi terhadap tanah 1.1.1. Pastikan kondisi selang dalam keadaan baik Mechanic

Contamination to soil Ensure condition of hose is good

1.1.2. Pastikan sambungan selang tidak ada

kebocoran dan dilengkapi klem pengaman Mechanic

jika tidak ada

Ensure hose connection is not leak and

completed with clamp if nothing

1.1.3. Siapkan oil spill kit di dekat area

pemindahan

Provide oil spill kit near with transfer area

Mechanic

1.1.4. Buang sisa kain lap yang terkontaminasi oli

ke dalam wadah khusus

Throw residue of contaminated rag into Mechanic

special container

2010-01 Page 5 of 8 515021&515022-H&S-FO-085

Project: Location of Work: JSEA No New Date: Page No

Revised Date: 05/04/2011 6 of 8

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of the Identify the hazards associated with each step. Using the first two columns as a guide, decide what actions are Responsible for carrying

steps should accomplish some major task and Examine each to find possibilities that could lead necessary to eliminate or minimize the hazards that could lead out/checking the action

be logical. to an accident. to an accident, injury or occupational illness.

5. Memasang Turbo, Fuel 5.1. Titik jepit 5.1.1. Gunakan stand untuk aktifitas melepas Mechanic

Injector , dan FIP Pinch point suspensi

Install FIP Use stand to remove suspension activity

5.1.2. Pastikan tanah untuk dudukan stand rata Mechanic

dank eras

Ensure hard and level soil for stand support

5.2. Tempat komponen sempit 5.2.1. Posisikan tubuh dengan aman saat bekerja Mechanic

Component place is narrow Keep body on safe position when working

5.3. Benda tajam 5.3.1. Selalu gunakan handglove standard Mechanic

Sharp materiall Always wear standardhandglove

5.4. Komponen tidak sesuai 5.4.1. Pastikan perkerja mengetahui dan Mechanic

Unappropriate component memehami prosedur kerja

Ensure mechanic know and understand

about procedure of working

Mechanic

5.4.2. Komunikasi yang baik harus dijaga antar tim

Keep team in good communication

2010-01 Page 6 of 8 515021&515022-H&S-FO-085

Project: Location of Work: JSEA No New Date: Page No

Revised Date: 05/04/2011 7 of 8

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of the Identify the hazards associated with each step. Using the first two columns as a guide, decide what actions are Responsible for carrying

steps should accomplish some major task and Examine each to find possibilities that could lead necessary to eliminate or minimize the hazards that could lead out/checking the action

be logical. to an accident. to an accident, injury or occupational illness.

5.5. Kontaminasi terhadap tanah 1.1.5. Pastikan kondisi selang dalam keadaan baik Mechanic

Contamination to soil Ensure condition of hose is good

1.1.6. Pastikan sambungan selang tidak ada

kebocoran dan dilengkapi klem pengaman Mechanic

jika tidak ada

Ensure hose connection is not leak and

completed with clamp if nothing

1.1.7. Siapkan oil spill kit di dekat area

pemindahan

Provide oil spill kit near with transfer area

Mechanic

1.1.8. Buang sisa kain lap yang terkontaminasi oli

ke dalam wadah khusus

Throw residue of contaminated rag into Mechanic

special container

6. Kebersihan 6.1. Area kerj a licin 6.1.1. Konsentrasi, dan berhati-hati Mechanic

House keeping Slippery work area Concentration and be careful

6.1.2. Perhatikan jalan saat melangkah

Keep eye on path when walking Mechanic

6.2. Benda tajam 6.2.1. Selalu gunakan APD yang sesuai dengan Mechanic

Sharp material standard

Always wear appropriate PPE and standard

2010-01 Page 7 of 8 515021&515022-H&S-FO-085

Project: Location of Work: JSEA No New Date: Page No

Revised Date: 05/04/2011 8 of 8

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of the Identify the hazards associated with each step. Using the first two columns as a guide, decide what actions are Responsible for carrying

steps should accomplish some major task and Examine each to find possibilities that could lead necessary to eliminate or minimize the hazards that could lead out/checking the action

be logical. to an accident. to an accident, injury or occupational illness.

6.3. Debu 6.3.1. Selalu gunakan APD yang sesuai dengan Mechanic

Dust standard

Always wear appropriate PPE and

standard

2010-01 Page 8 of 8 515021&515022-H&S-FO-085

You might also like

- RA For Man Lift OperationDocument6 pagesRA For Man Lift Operationalla malikNo ratings yet

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- JHA Development MatrixDocument20 pagesJHA Development MatrixShah Aizat Razali100% (2)

- Manage risks with safety proceduresDocument22 pagesManage risks with safety proceduresfadli.lpgNo ratings yet

- JHA For Manual Excavation Near On Control RoomDocument9 pagesJHA For Manual Excavation Near On Control RoomFrancis Enriquez Tan100% (1)

- RA For MPI TestDocument3 pagesRA For MPI TestLu Min Han100% (1)

- HPCL - Task Based Risk Assessment TemplateDocument37 pagesHPCL - Task Based Risk Assessment TemplateErnesto FariasNo ratings yet

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- Safe Work Method Statement for Metal Column, Rafter, Purlin InstallationDocument12 pagesSafe Work Method Statement for Metal Column, Rafter, Purlin Installationsasi kumar100% (1)

- Date Jsa Team (Name List) Name Position & SignatureDocument8 pagesDate Jsa Team (Name List) Name Position & SignatureMuralimohan PandianNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970No ratings yet

- Risk Assessment 53 Light TowerDocument18 pagesRisk Assessment 53 Light TowerAchmad ChusnadiNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- 03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressDocument16 pages03 Jha For Cable Laying Cable Glanding and Terminationdocx - CompressSavio SunnyNo ratings yet

- Door Window and Roller ShutterDocument7 pagesDoor Window and Roller Shuttershamierrul shahliNo ratings yet

- SS JSP - 063 Testing and Pre-Commissioning WorksDocument9 pagesSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahNo ratings yet

- Job Safety Analysis PSA-MailDocument50 pagesJob Safety Analysis PSA-MailechaNo ratings yet

- DROPS Recommended Practice 2017Document62 pagesDROPS Recommended Practice 2017TobeFrankNo ratings yet

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- Mohamad FadliDocument6 pagesMohamad Fadlishamierrul shahliNo ratings yet

- Earthworks Safety AnalysisDocument7 pagesEarthworks Safety AnalysisGeml TrinidadNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- ISO 45001 PRESENTATION SLIDE - Compressed PDFDocument147 pagesISO 45001 PRESENTATION SLIDE - Compressed PDFAyman Ali100% (1)

- JSA Site Office Prep & Fabrication WHDocument9 pagesJSA Site Office Prep & Fabrication WHArib RahmanNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- PRO-00714 Corporate Safety - Working On, in or Near Water ProcedureDocument18 pagesPRO-00714 Corporate Safety - Working On, in or Near Water ProcedureMatthew StephanNo ratings yet

- Work at Height Training Module: Safety FirstDocument15 pagesWork at Height Training Module: Safety FirstMiguel Gonzales100% (2)

- Hira Training 190407052212Document44 pagesHira Training 190407052212Aakanksha GahlautNo ratings yet

- Pre Job Hazard Assessment (PJHA) FORM: CAN-EHS-F-05 Revision: 15/09/17Document3 pagesPre Job Hazard Assessment (PJHA) FORM: CAN-EHS-F-05 Revision: 15/09/17Dharma Nayak0% (1)

- Job Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCDocument4 pagesJob Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCChukwuma Emmanuel Onwufuju0% (1)

- JHA For Cable Laying, Cable Glanding and TerminationDocument12 pagesJHA For Cable Laying, Cable Glanding and TerminationFrancis Enriquez Tan100% (2)

- Shuttering WorksDocument5 pagesShuttering Worksprasanna okNo ratings yet

- Hazard Identification Risk Assessment and Determine Control (HIRADC)Document28 pagesHazard Identification Risk Assessment and Determine Control (HIRADC)Shida ShidotNo ratings yet

- Hazard AnalysisDocument79 pagesHazard AnalysisRamónNo ratings yet

- Substation Earth Testing Job Safety AnalysisDocument5 pagesSubstation Earth Testing Job Safety AnalysishkaruvathilNo ratings yet

- 6.JSA of Batching Plant InstallationDocument4 pages6.JSA of Batching Plant InstallationNitesh Kumar100% (1)

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Jsa For Tie-In Tp-950Document11 pagesJsa For Tie-In Tp-950rexivyNo ratings yet

- 515021&515022-PLT-EX-076-2011 Replace FIP, Fuel Injector, and Turbo Charger of ExcavatorDocument8 pages515021&515022-PLT-EX-076-2011 Replace FIP, Fuel Injector, and Turbo Charger of ExcavatorMuhammad Fatur Dipo GribaldyNo ratings yet

- BTU Inpections and ReplacementDocument3 pagesBTU Inpections and Replacementshadrack.xuluNo ratings yet

- JSA-Replacement of GD, FD & MCP - Rev.00Document7 pagesJSA-Replacement of GD, FD & MCP - Rev.00Muhammad Umar GondalNo ratings yet

- No. Tower Crane ErectionDocument8 pagesNo. Tower Crane Erectionsreejukumar27No ratings yet

- AB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main DeckDocument2 pagesAB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main Deckvikrant911No ratings yet

- SWMS LV Switchboard Aux BoillerDocument5 pagesSWMS LV Switchboard Aux BoillerDangolNo ratings yet

- Job Safety and Environment Analysis: Remove Engine GraderDocument13 pagesJob Safety and Environment Analysis: Remove Engine GraderAhmad RozaliNo ratings yet

- Opertaing Window LimitsDocument6 pagesOpertaing Window LimitshejaNo ratings yet

- JHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLDocument8 pagesJHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLOmkar MishraNo ratings yet

- SOP D.G. OPERATIONDocument3 pagesSOP D.G. OPERATIONsapat309No ratings yet

- JSEA Project Cleaning and PaintingDocument6 pagesJSEA Project Cleaning and PaintingazerNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- JSA Q05 TEG Q05 Increase The CP Potential DFN# 80091611Document6 pagesJSA Q05 TEG Q05 Increase The CP Potential DFN# 80091611ibaig1970No ratings yet

- Jha JiggingDocument4 pagesJha Jiggingsyed aquibNo ratings yet

- 2017 - Handout - Equipment Preparer - ENG - 07 - N°01Document66 pages2017 - Handout - Equipment Preparer - ENG - 07 - N°01Jean fulgence RANDRIAMANDIMBYNo ratings yet

- Day 3 Job Hazard Analysis (Handout)Document6 pagesDay 3 Job Hazard Analysis (Handout)mike camsNo ratings yet

- JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDocument2 pagesJSA - 008 - Hydraulic Rig and Mobile Crane MarchingAhmed AlderbiNo ratings yet

- BSI-MEM-ANC-MEC-JSEA-0008 - Monthly Inspection Forklift BobcatDocument6 pagesBSI-MEM-ANC-MEC-JSEA-0008 - Monthly Inspection Forklift BobcatAlvin AntoniNo ratings yet

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument3 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument2 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- JSA For Filter Cleaning by Steam and Water ManuallyDocument22 pagesJSA For Filter Cleaning by Steam and Water ManuallyThái Đạo Phạm LêNo ratings yet

- TESSB-JHA-MHP (Grinding, Power Brushing & Painting) Area 3ADocument5 pagesTESSB-JHA-MHP (Grinding, Power Brushing & Painting) Area 3AAlif HafiziNo ratings yet

- TESSB-JHA-MHP (Grinding, Power Brushing & Painting) Area 3A MFARDocument5 pagesTESSB-JHA-MHP (Grinding, Power Brushing & Painting) Area 3A MFARAlif HafiziNo ratings yet

- JSA Form English - ExampleDocument9 pagesJSA Form English - ExampleMaulan FaNo ratings yet

- Emergency Air FailureDocument17 pagesEmergency Air Failureabhrrajjit SANo ratings yet

- Safe Operation of Excavator (SWMSDocument11 pagesSafe Operation of Excavator (SWMSAmit BhattNo ratings yet

- Substation Earth Testing JSADocument5 pagesSubstation Earth Testing JSApartho banerjeeNo ratings yet

- Grinding Work JsaDocument2 pagesGrinding Work JsaAKBAR ALINo ratings yet

- JSA for Scaffolding erection dismantling and modification workDocument17 pagesJSA for Scaffolding erection dismantling and modification workshane.ramirez1980No ratings yet

- HPWC Job QualificationDocument2 pagesHPWC Job QualificationGuruh SuprayitnoNo ratings yet

- E&I - 13, JSA for Separation & Drying AreaDocument8 pagesE&I - 13, JSA for Separation & Drying AreaNikunja mohantyNo ratings yet

- SOP - 6 - Coal Charging ActivityDocument7 pagesSOP - 6 - Coal Charging Activityfaraz ahmedNo ratings yet

- Ar-001 02Document2 pagesAr-001 02orisNo ratings yet

- INSTALASIDocument1 pageINSTALASIMuhammad Fatur Dipo GribaldyNo ratings yet

- CRI-EnG06.2 DisassyAssy FuelPumpDocument63 pagesCRI-EnG06.2 DisassyAssy FuelPumpMuhammad Fatur Dipo GribaldyNo ratings yet

- Engine Return Fuel Blacking NoticeDocument4 pagesEngine Return Fuel Blacking NoticeMuhammad Fatur Dipo GribaldyNo ratings yet

- RnI KIT Cabin, Vessel, Fuel Tank RD2223Document1 pageRnI KIT Cabin, Vessel, Fuel Tank RD2223Muhammad Fatur Dipo GribaldyNo ratings yet

- Contoh Tugas Akhir Alif Dukti (Poltekba 2017)Document65 pagesContoh Tugas Akhir Alif Dukti (Poltekba 2017)Muhammad Fatur Dipo GribaldyNo ratings yet

- Contoh Tugas Akhir Alif Dukti (Poltekba 2017)Document65 pagesContoh Tugas Akhir Alif Dukti (Poltekba 2017)Muhammad Fatur Dipo GribaldyNo ratings yet

- JSA External Window Cleaning To 2 Story Building Simplified ReportDocument10 pagesJSA External Window Cleaning To 2 Story Building Simplified ReportMaja DakicNo ratings yet

- BSBWHS308Document40 pagesBSBWHS308Pragati AryalNo ratings yet

- 1st Year ReviewerDocument14 pages1st Year ReviewerArabella VillaruzNo ratings yet

- Risk Management in The National System: A Practical GuideDocument16 pagesRisk Management in The National System: A Practical GuideNyadroh Clement MchammondsNo ratings yet

- PJ 2329 Shoring Msra Rev 01 (RCV TSC Mss S 010 Rev 01)Document33 pagesPJ 2329 Shoring Msra Rev 01 (RCV TSC Mss S 010 Rev 01)MANAS K. DUTTANo ratings yet

- Sitxwhs006 - Appendix ADocument4 pagesSitxwhs006 - Appendix AChemistry SoniaNo ratings yet

- Implement and Monitor Infection Control PoliciesDocument53 pagesImplement and Monitor Infection Control PoliciesMa. Angelica MarquezNo ratings yet

- Work Methodology Statement: Maglev Air Conditioning Corp. Kim Nassorada Replacement of VTT Compressor of Ch#4Document4 pagesWork Methodology Statement: Maglev Air Conditioning Corp. Kim Nassorada Replacement of VTT Compressor of Ch#4Mayan FellerNo ratings yet

- Safe - Work - Method - Statement - Roof - Truss - Installation V1.0Document8 pagesSafe - Work - Method - Statement - Roof - Truss - Installation V1.0hurairamughal666No ratings yet

- AHA - Asbestos Abatement-11-11-2019Document7 pagesAHA - Asbestos Abatement-11-11-2019Eyal BabuNo ratings yet

- Annexure-I Hira For Upvc & PP Piping Works.Document2 pagesAnnexure-I Hira For Upvc & PP Piping Works.Dhananjai TiwariNo ratings yet

- BSBWHS501 At2Document14 pagesBSBWHS501 At2Utpann Solutions100% (3)

- Serious Injury and Fatality PreventionDocument20 pagesSerious Injury and Fatality PreventionISRAEL TOLANONo ratings yet

- Mod14 Risk AssessmentDocument23 pagesMod14 Risk AssessmentMhanna AYNo ratings yet

- Basics of Risk Management Article GuideDocument157 pagesBasics of Risk Management Article Guidemohammed minhajNo ratings yet

- JSEA Risk Assessment for External Window CleaningDocument12 pagesJSEA Risk Assessment for External Window CleaningPinuram PutrojoyoNo ratings yet

- Risk Assessment Template: For Student Work Experience PlacementsDocument4 pagesRisk Assessment Template: For Student Work Experience PlacementsHung PhamNo ratings yet