Professional Documents

Culture Documents

Micron Coalecsing

Uploaded by

dieselmotorsbogotasasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micron Coalecsing

Uploaded by

dieselmotorsbogotasasCopyright:

Available Formats

1.

Introduction

Stanadyne has been making diesel fuel filters for over 30 years. Stanadyne’s “Square Filter” design filters, with

glass or metal cases, are still seen on many off and on-road applications.

But new technology and requirements from the market have resulted in a new generation of diesel fuel filters

known as Fuel Manager.

2. What isFuel Manager?

Fuel Manager is a diesel fuel filter/water separator system. It features a complete range of modules and features

to meet any diesel filtration need. The concept is to provide everything you need, but only what you need, using a

common range of interchangeable parts that can be added as needed to the basic header to provide specific

features to meet specific requirements. There are two versions of Fuel Manager.

• FM 100 Seriesis for engines with a total fuel flow of up to 80 US galls (300 liters)/hour, or about 350 HP.

• FM 1000 Seriesis for engines with a max. fuel flow of about 180 US gals (680 liters)/hour, or about 600 HP.

3. Fuel Managermodules and options.

• A Fuel Manager basic assembly consists of a cast aluminum header with two inlet and two outlet female

threaded ports for fuel line connections. Normally, only one inlet and one outlet are required. (The flexible

design offers a choice. Unused ports should be plugged). Attached to the header is the element, which

contains the media to remove water & other contaminants.

• The header features a choice of female threads for fuel line connections. Standard threads for FM 100 Series

are ¼” – 18 NPTF; 3/8” – 18 NPTF; ½” – 20 SAE ‘O’ ring; M12 x 1.5 ‘O’ ring; & M14 x 1.5’O’ ring. Standard

threads for FM 1000 Series are ½” – 14 NPTF; & 7/8” – 14 ‘O’ ring. Other threads are available.

• The element features a choice of four different media, all with water repelling treatment:

150 Micron Coalescing Pre-Filter/Water

Separator Element - Ideal for cold weather

applications, where the special nylon media

minimizes the risk of fuel wax choking.

Designed to provide extra protection and

remove most water and larger contaminants

before they choke the final (or secondary) filter.

30 Micron Pre-Filter/Water Separator Element

Using chemically treated paper media to repel

water, these elements offer very efficient primary

filtration. Designed to be used with a Final Filter,

a Pre-Filter will extend service intervals and

ensure optimum protection for the injection

system. Available in standard or extended duty

sizes.

2 or 5 Micron Final Filter/Water Separator Element

Providing the ultimate in protection, a Final (or

secondary) Filter can be used on its own or in

combination with either a 150 micron or 30 micron

Pre-Filter assembly for maximum service life. Final

Filter elements are available in a range of sizes for

different service interval requirements.

You might also like

- User's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemDocument5 pagesUser's Guide: Stanadyne Diesel Fuel Filter/Water Separator SystemMiguel RojasNo ratings yet

- Micron S602 ECODocument4 pagesMicron S602 ECOTan Kang YaoNo ratings yet

- Marco Osvaldo Vigueras ZunigaDocument8 pagesMarco Osvaldo Vigueras ZunigaAnonymous PkeI8e84RsNo ratings yet

- DonalsonDocument6 pagesDonalsonrockyttpmcNo ratings yet

- Max.e3 Technical Description ENGDocument5 pagesMax.e3 Technical Description ENGDamVent DamVentNo ratings yet

- Vantage UFI Feb2011 SiemensDocument4 pagesVantage UFI Feb2011 SiemenssirtrungNo ratings yet

- E7709 3 06 12 - RF3 - WebDocument8 pagesE7709 3 06 12 - RF3 - WebNicolas Alvarez GomezNo ratings yet

- Lista Filtros BOBCATDocument18 pagesLista Filtros BOBCATmadscoutNo ratings yet

- Filters and Strainers On A Ship: Mircea Cel Bătrân' Naval Academy, ConstantaDocument6 pagesFilters and Strainers On A Ship: Mircea Cel Bătrân' Naval Academy, ConstantaDulca StefanNo ratings yet

- 3M High Flow Series Filer SystemsDocument12 pages3M High Flow Series Filer SystemsRahimd Fox100% (1)

- Air Filter Leaflet 2009Document2 pagesAir Filter Leaflet 2009karthikraja21No ratings yet

- Filter Types, LocationsDocument5 pagesFilter Types, LocationsRevathy AarthyNo ratings yet

- Hydraulic Separator PDFDocument4 pagesHydraulic Separator PDFsloba68No ratings yet

- Hepa Filter Product-SummaryDocument8 pagesHepa Filter Product-Summaryphase_shekhar21No ratings yet

- Filtros RotatoriosDocument2 pagesFiltros RotatoriosManuel Alejandro Gonzalez AguayoNo ratings yet

- Septik TankDocument1 pageSeptik TankGabetsos KaraflidisNo ratings yet

- DeltaDocument20 pagesDeltaClaudio TurlherNo ratings yet

- Ecology Unit SpecificationsDocument3 pagesEcology Unit SpecificationsMotaz H OthmanNo ratings yet

- Sepura Oil Water Separator 4ppDocument4 pagesSepura Oil Water Separator 4ppmuppetscrapNo ratings yet

- Numatics FRLFlexiblok R072010Document33 pagesNumatics FRLFlexiblok R072010Oscar ZavaletaNo ratings yet

- Micro FiltrationDocument7 pagesMicro FiltrationEdwin CaleñoNo ratings yet

- AMSOIL BMK30 - Heavy-Duty Remote By-Pass Filtration SystemDocument2 pagesAMSOIL BMK30 - Heavy-Duty Remote By-Pass Filtration SystemamsoildealerNo ratings yet

- Cim-Tek CLMDocument14 pagesCim-Tek CLMAgung WidodoNo ratings yet

- Centurion CimtekDocument6 pagesCenturion CimtekAgung WidodoNo ratings yet

- Exporters Suppliers Exporter31627.650331 Pre Filter Rod Support Type - HTMLDocument3 pagesExporters Suppliers Exporter31627.650331 Pre Filter Rod Support Type - HTMLMukund JadavNo ratings yet

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009No ratings yet

- Operation and Maintenance Manual - Irrigation SystemsDocument13 pagesOperation and Maintenance Manual - Irrigation SystemsVinay Tunge75% (4)

- Maintenance of Hydraulic Filters 00.330 EN US PDFDocument2 pagesMaintenance of Hydraulic Filters 00.330 EN US PDFIvandro Dantas PantojaNo ratings yet

- Viledon MX85Document2 pagesViledon MX85msafwanizzudinNo ratings yet

- Water Filters Profine CatalogDocument20 pagesWater Filters Profine CatalogSinergroup Water Filters Water Purifiers Water SoftenersNo ratings yet

- GLV - Drum Filter (PGS) LR PDFDocument8 pagesGLV - Drum Filter (PGS) LR PDFSamuel MushakaNo ratings yet

- JCI Process Filter Separator Technical BrochureDocument8 pagesJCI Process Filter Separator Technical BrochureVAN_JCINo ratings yet

- E7200 10 02 08 - D Type FilterDocument8 pagesE7200 10 02 08 - D Type FiltermecambNo ratings yet

- Axminster 03 - Dust Extraction & Wood Waste - p109-p126Document18 pagesAxminster 03 - Dust Extraction & Wood Waste - p109-p126Pierre799esNo ratings yet

- Filson Product CatalogDocument9 pagesFilson Product CatalogDaniel Sandoval FernándezNo ratings yet

- Operation Manual: Jesma FilterDocument50 pagesOperation Manual: Jesma Filterdaniel100% (3)

- Ficha Tecnica Hepa 24x48x5 Tm2Document4 pagesFicha Tecnica Hepa 24x48x5 Tm2EDWLYCANNo ratings yet

- ABAC Formula 5 5 22kWDocument6 pagesABAC Formula 5 5 22kWsebastianNo ratings yet

- 10 - Filter ElementsDocument6 pages10 - Filter ElementsAalap DerasaryNo ratings yet

- Netzsch Improves Progressive Cavity Pumps 2006Document1 pageNetzsch Improves Progressive Cavity Pumps 2006jaccucv2150No ratings yet

- Water Purification Plant 1000 GPH Capacity SSDocument9 pagesWater Purification Plant 1000 GPH Capacity SSHaiDer J MarWatNo ratings yet

- Drip Irrigation BrochureDocument6 pagesDrip Irrigation BrochureHRagheb100% (1)

- New HEPA Al SepDocument2 pagesNew HEPA Al Seppham hoang quanNo ratings yet

- Filter BrochureDocument8 pagesFilter BrochurekalbrabazonNo ratings yet

- Ahucatlog - Doc JetDocument11 pagesAhucatlog - Doc JetDharmesh Nyak100% (1)

- Air Sentry Dessicant Breathers BrochureDocument14 pagesAir Sentry Dessicant Breathers BrochureNelson PeraltaNo ratings yet

- Inline Process FiltersDocument7 pagesInline Process FiltersDenis JimenezNo ratings yet

- Ficha Técnica 150-040Document8 pagesFicha Técnica 150-040manuelaNo ratings yet

- Parts CatalogueDocument44 pagesParts CatalogueAlzieNo ratings yet

- Gas Turbine Air Filter System OptimizationDocument10 pagesGas Turbine Air Filter System Optimizationsevero97No ratings yet

- Filter ElementsDocument8 pagesFilter ElementsSheikh ZakirNo ratings yet

- Donaldson WixDocument8 pagesDonaldson WixdionymackNo ratings yet

- Filters and Strainers On A Ship: Mircea Cel Bătrân' Naval Academy, ConstantaDocument6 pagesFilters and Strainers On A Ship: Mircea Cel Bătrân' Naval Academy, ConstantaDulca StefanNo ratings yet

- Technical Proposal For Olympic Pool PDFDocument10 pagesTechnical Proposal For Olympic Pool PDFAlma DerajNo ratings yet

- Filtration With Offline Oil Filters SDN Rev Feb 2013 01Document7 pagesFiltration With Offline Oil Filters SDN Rev Feb 2013 01Dian Purwa Dewa (Babeh)No ratings yet

- 1cgde09jv 337626Document4 pages1cgde09jv 337626Fati ZoraNo ratings yet

- Caterpillar Filter ไส้กรอง กรองลม กรองน้ำมันDocument19 pagesCaterpillar Filter ไส้กรอง กรองลม กรองน้ำมันParinpa KetarNo ratings yet

- 39CQDocument10 pages39CQAnonymous yPWi8p3KkANo ratings yet

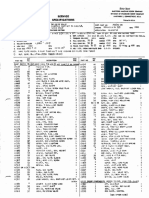

- Micron CoalecsingDocument1 pageMicron CoalecsingdieselmotorsbogotasasNo ratings yet

- Model: Pump Injection SpecificationDocument2 pagesModel: Pump Injection SpecificationdieselmotorsbogotasasNo ratings yet

- DCGFC 629-Z Ap: Model "Document2 pagesDCGFC 629-Z Ap: Model "dieselmotorsbogotasasNo ratings yet

- Modeldbgfc 6i37-49a J: Injection Pump Specification Customer Part No. 4515115Document2 pagesModeldbgfc 6i37-49a J: Injection Pump Specification Customer Part No. 4515115dieselmotorsbogotasasNo ratings yet

- Injection Pump Model Diesel Systems Specification Nay514958Document2 pagesInjection Pump Model Diesel Systems Specification Nay514958dieselmotorsbogotasasNo ratings yet

- ,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955Document2 pages,5 (-J - $438 DBGFC 631-44AJ: I Customer Part No., Y51 q955dieselmotorsbogotasasNo ratings yet

- Model: - OBGFC637 - ISA.1Document2 pagesModel: - OBGFC637 - ISA.1dieselmotorsbogotasasNo ratings yet

- 00877Document2 pages00877dieselmotorsbogotasasNo ratings yet

- Model Bbkvct63L - Lit P: Catalog NoDocument2 pagesModel Bbkvct63L - Lit P: Catalog NodieselmotorsbogotasasNo ratings yet

- ShaftDocument2 pagesShaftdieselmotorsbogotasasNo ratings yet

- 00866Document2 pages00866dieselmotorsbogotasasNo ratings yet

- Imjectlqn PU: 1545 K.P.M. / r-1 4. Keducr SPC - Ed Co I R T C"1 8Document2 pagesImjectlqn PU: 1545 K.P.M. / r-1 4. Keducr SPC - Ed Co I R T C"1 8dieselmotorsbogotasasNo ratings yet

- DBGVCC631 2apDocument2 pagesDBGVCC631 2apdieselmotorsbogotasasNo ratings yet

- Dbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3Document2 pagesDbgvcc431-: Ca-Ialog Pagt No: S 0 - 2 3 5 3dieselmotorsbogotasasNo ratings yet

- Installation Instructions - 4450410 Horno WhirpoolDocument5 pagesInstallation Instructions - 4450410 Horno WhirpoolfelipeNo ratings yet

- Agitatoare Electrice GracoDocument2 pagesAgitatoare Electrice GracoDanaNo ratings yet

- Check List and Testing ProcedureDocument3 pagesCheck List and Testing ProcedureSheikh Shoaib RezaNo ratings yet

- Case Study: Desalinated Water Powers China's Economic GrowthDocument2 pagesCase Study: Desalinated Water Powers China's Economic Growthmona aminNo ratings yet

- Normal Distribution - ExerciseDocument8 pagesNormal Distribution - Exerciseaman KumarNo ratings yet

- Ficha Técnica Motor 1 11-16 Ss 2019Document1 pageFicha Técnica Motor 1 11-16 Ss 2019Gina Vanessa Quintero CruzNo ratings yet

- Inverter Quick GuideDocument52 pagesInverter Quick GuidePAOLO ODORICONo ratings yet

- 8-EE - Scheme Syllabus VII-VII FinalDocument18 pages8-EE - Scheme Syllabus VII-VII FinalGoriparthi SambasievaraavNo ratings yet

- RENEWABLEMEET2022 Albedo Program V003Document8 pagesRENEWABLEMEET2022 Albedo Program V003Aleksandar Rudnik MilanovicNo ratings yet

- Umsl LTD,: Ref - UMERKOTE SITE / Industrial Oxygen GAS RequirementDocument2 pagesUmsl LTD,: Ref - UMERKOTE SITE / Industrial Oxygen GAS RequirementAkhilesh SinghNo ratings yet

- RM ST40Document2 pagesRM ST40LUIS SLEITER NAPÁN HUAMANÍNo ratings yet

- 9702 Physics Theory ZNOTESDocument19 pages9702 Physics Theory ZNOTESanushaNo ratings yet

- 2022 Acdelco Training Course CatalogDocument81 pages2022 Acdelco Training Course CatalogWilliam Orozco LópezNo ratings yet

- Science10Q2 TestBankDocument8 pagesScience10Q2 TestBankCrisante MaruquinNo ratings yet

- RES - Module 1Document82 pagesRES - Module 1B.R. RESHMANo ratings yet

- SDP PDFDocument1 pageSDP PDFCRIS JOHN MANZANILL0No ratings yet

- TAMU - Pemex Offshore Drilling: Lesson 20 Horizontal WellsDocument54 pagesTAMU - Pemex Offshore Drilling: Lesson 20 Horizontal Wellsdriller22100% (1)

- 500 Words EssayDocument4 pages500 Words EssayPRIYAL GOTMARENo ratings yet

- Project: Layyah Combined Cycle Power Plant: Sub Station: Equipment: Panel Type BAY Ref: DateDocument3 pagesProject: Layyah Combined Cycle Power Plant: Sub Station: Equipment: Panel Type BAY Ref: DatesamlashNo ratings yet

- Instructions - Sun 12 16k sg01lp1 Eu - 240203 - enDocument48 pagesInstructions - Sun 12 16k sg01lp1 Eu - 240203 - enf789sgacanonNo ratings yet

- Heat and Phase ChangeDocument12 pagesHeat and Phase ChangeStephanie Cui SilvaNo ratings yet

- Đề phủ kiến thức - Tiếng AnhDocument5 pagesĐề phủ kiến thức - Tiếng AnhNgô Anh ThưNo ratings yet

- Control Estrela Triangulo SiemensDocument8 pagesControl Estrela Triangulo SiemensKenneth ThomasNo ratings yet

- Hoisting and Mounting The Engine For Installation1Document5 pagesHoisting and Mounting The Engine For Installation1SantiagoDaFornoAmorochoNo ratings yet

- MMSP-MCET-106-ZWD-MTG-Z-000324 - MoM No. 25 POW Regular Coordination MeetingDocument18 pagesMMSP-MCET-106-ZWD-MTG-Z-000324 - MoM No. 25 POW Regular Coordination Meetingdarktronic1988No ratings yet

- Ev ChargingDocument6 pagesEv ChargingVishal PatilNo ratings yet

- Lecture 8 - Week10Document51 pagesLecture 8 - Week10bettieboomNo ratings yet

- Worksheet Ac XiiDocument4 pagesWorksheet Ac XiiYug GandhiNo ratings yet

- Example 3500 - 1600kVA Oil TX-Liquid Distribution Transformer Data SheetDocument4 pagesExample 3500 - 1600kVA Oil TX-Liquid Distribution Transformer Data SheetSlick72No ratings yet

- User's Manual: RefrigeratorDocument31 pagesUser's Manual: RefrigeratorPrashanth VenkataramanaNo ratings yet