Professional Documents

Culture Documents

5816n - Magnetico Inalambrico

Uploaded by

christian yelpoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5816n - Magnetico Inalambrico

Uploaded by

christian yelpoCopyright:

Available Formats

N6482V2 4/98 Rev.

D

ADEMCO 5816

Door/Window Transmitter

INSTALLATION AND SETUP GUIDE

NOTE

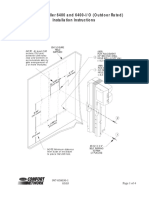

MAGNET ALIGNMENT STRIP LATCH

5816 HAS 2 UNIQUE ZONES

CASE ALIGN MAGNET

HOLDING WITH MARKS ON

POSTS (2) A CASE AND GUIDE

HOLES "A" (2)

+ ON MTG. PLATE

(SEE TEXT)

REED

SWITCH MAGNET

(INPUT 2) (OBTAIN

SEPARATELY)

PLATE ANTENNA

MOUNTING BATTERY

HOLES (2) – 1/2” MAX.

COVER

TAMPER

CONCEALED SWITCH

WIRING NOTE

ENTRY HOLE TYPICAL BREAKING GAP

COVER 1.36" (Wood & non-magnetic

HOLDING surfaces)

5816-002-V0

HOOKS (2) A 0.78" (Steel surfaces).

CASE

5816-001-V3

LOOP TERMINALS (INPUT 1)

LOCKING LOCKING TAB

TAB RELEASE BREAKOUT FOR SLOT FOR CONCEALED

WINDOW WIRING ACCESS

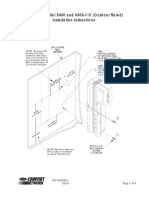

Diagram 1. Mounting Plate SURFACE WIRING

Diagram 2. Transmitter, Cover Removed

GENERAL INFORMATION Before mounting the transmitter permanently,

The 5816 Door/Window Transmitter has its own conduct Go/No Go tests (see control’s

unique serial number permanently assigned instructions) to verify adequate signal strength

during manufacture. You must “enroll” the and reorient or relocate the transmitter if

transmitter serial number in the control prior to its necessary.

usage in the system. Refer to the control unit’s 1. Remove the transmitter’s cover using the

installation instructions for further details. Note: finger latch.

During programming of the control unit, 5816 2. Disengage the supplied mounting plate

transmitters shall be treated as “RF” (i.e., from the unit by releasing the locking tab

supervised RF) Type (mandatory for UL while sliding the plate downward along the

installations). case back.

3. If a wired contact loop is to be used with

The 5816 has two unique zones; the first is for a concealed wiring, feed the wires through the

wired closed circuit contact loop and the second concealed wiring entry hole at one corner of

for its built-in reed switch (used in conjunction with the mounting plate.

a magnet as described below). Either or both For surface wiring entry, a thin “breakout”

zones may be used. For UL installations, a area is provided in the case wall. Wiring can

contact may not be more than 3 feet from the be run through this “breakout” in the case

transmitter. when attaching the case in step 5.

A built-in cover tamper switch is activated when 4. Install the mounting plate, with its case

the cover is removed. holding posts pointing up (in this example), in

the location selected as described in the

INSTALLATION control unit’s installation instructions. Use the

Mounting flat head screws supplied.

For proper orientation of the unit in relation to the 5. Attach the case back to the mounting plate

mounting plate, loop wiring, and/or magnet, read by sliding the keyhole slots in the case back

all of this section before installing the unit. down onto the mounting plate’s case holding

posts. The locking tab will click as the case

The description that follows assumes that the unit back locks in place.

will be mounted as shown in the diagrams, with 6. If the unit’s reed switch is to be used,

the magnet (if used) located to the unit’s right. The mount a No. 5899 Magnet (or equivalent;

unit may, however, be installed in any direction, obtain separately) adjacent to the alignment

as long as the relationship of the unit to its marks on the case and the mounting plate’s

mounting plate and (if used) magnet is alignment strip at maximum ½ inch separation

maintained. distance (see Diagram 2).

Although two holes are provided in the unit that Note:

would permit mounting directly to a surface (holes For wood & non-magnetic surfaces, the

‘A’ in Diagram 2) it is recommended that the typical breaking gap is 1.36 inches.

mounting plate be used, for ease in removing the For steel and other magnetic surfaces, the

unit for servicing should it become necessary. typical breaking gap is 0.78 inches.

Wiring Connections SPECIFICATIONS

With the battery still not inserted, connect the Dimensions: 1-9/16”W x 3-1/16”H x 1-3/16”D

contact loop (if used) to the unit’s loop terminals (40mm x 78mm x30mm)

(see diagram). The contact loop must use closed Battery: 3V Lithium (see Note in step 2 of

circuit devices. The loop response time is a BATTERY INSTALLATION/REPLACEMENT)

nominal 100mSec.

Note: If the contact loop is not to be used, no

connection is needed across its terminals. BATTERY CAUTION: Risk of fire, explosion

and burns. Do not recharge, disassemble, heat

above 212 F (100 C) or incinerate. Dispose of

BATTERY INSTALLATION/REPLACEMENT

used batteries promptly. Keep away from

1. Remove the transmitter’s cover (if it is not

children.

already off) as described in Mounting Step 1.

2. Observe correct polarity and insert the

battery provided into the battery holder (see

Diagram 2). Take care not to bend the

antenna.

Note: Replace battery only with:

Panasonic CR123A, Duracell DL123A,

or ADEMCO 466.

3. To replace the cover, engage the hooks

along one edge and snap shut.

FEDERAL COMMUNICATIONS COMMISSION STATEMENTS: The user shall not make any changes or

modifications to the equipment unless authorized by the Installation Instructions or User's Manual. Unauthorized

changes or modifications could void the user's authority to operate the equipment.

FCC/IC NOTICE: This device complies with Part 15 of the FCC Rules, and RSS 210 of IC. Operation is subject to

the following two conditions: (1) This device may not cause harmful interference (2) This device must accept any

interference received, including interference that may cause undesired operation.

Cet appareil est conforme à la partie 15 des règles de la FCC & de RSS 210 des Industries Canada. Son

fonctionnement est soumis aux conditions suivantes: (1) Cet appareil ne doit pas causer d' interferences nuisibles.

(2) Cet appareil doit accepter toute interference reçue y compris les interferences causant une reception indésirable.

TO THE INSTALLER: Regular maintenance and inspection (at least annually) by the installer and frequent testing

by the user are vital to continuous satisfactory operation of any alarm system. The installer should assume the

responsibility of developing and offering a regular maintenance program to the user, as well as acquainting the user

with the proper operation and limitations of the alarm system and its component parts. Recommendations must be

included for a specific program of frequent testing (at least weekly) to insure the system’s operation at all times.

REFER TO THE INSTALLATION INSTRUCTIONS FOR THE CONTROL WITH WHICH THIS DEVICE IS

USED, FOR DETAILS REGARDING LIMITATIONS OF THE ENTIRE ALARM SYSTEM.

For Warranty Information on this product, please see:

http://www.honeywell.com/security/hsc/resources/wa

ÊN6482V2bŠ 2 Corporate Center Drive, Suite 100

N6482V2 4/98 Rev. D P.O. Box 9040, Melville, NY 11747

Copyright © 2008 Honeywell International Inc.

www.honeywell.com/security

You might also like

- 320E L Plano Electrico SISDocument33 pages320E L Plano Electrico SISelvis100% (2)

- Renr9959 00Document2 pagesRenr9959 00Ahmer CamdzicNo ratings yet

- Diagrama Eléctrico de Cargador Compacto 906Document2 pagesDiagrama Eléctrico de Cargador Compacto 906Claudio Jofre Gordillo100% (1)

- PDF Electrical Layout 1Document1 pagePDF Electrical Layout 1Goldie Gail EndozoNo ratings yet

- Wire Cable/ Wire Cable/: NotesDocument10 pagesWire Cable/ Wire Cable/: Notesmahesh reddy mNo ratings yet

- Diagrama Electrico D6NDocument20 pagesDiagrama Electrico D6NKeiber Bastos100% (3)

- 307D, 311D, 312D, 315D, 319D, 320D, 323D, M313D, M315D, M316D, M318D, and M322D Excavators Ai R Conditioning Electrical SystemDocument2 pages307D, 311D, 312D, 315D, 319D, 320D, 323D, M313D, M315D, M316D, M318D, and M322D Excavators Ai R Conditioning Electrical SystemDed IvanovichNo ratings yet

- Alvarez Engr. Catibayan: Riser Diagram 1 3Document1 pageAlvarez Engr. Catibayan: Riser Diagram 1 3Grizzly BearNo ratings yet

- RXD-V333/V333S/V535/V535-GR/V535S/ V535S-H/V636/V737/V737S: Service ManualDocument43 pagesRXD-V333/V333S/V535/V535-GR/V535S/ V535S-H/V636/V737/V737S: Service ManualKasun Chamara PrathapasinghaNo ratings yet

- CA3094 CopiarDocument1 pageCA3094 CopiarWashington ConceicaoNo ratings yet

- The Arctic Shutter - Thermal Window Shutter For Cold ClimatesDocument1 pageThe Arctic Shutter - Thermal Window Shutter For Cold ClimatesKhanh DamNo ratings yet

- Jce 67 2015 8 4 1361 enDocument1 pageJce 67 2015 8 4 1361 enSilviuSNo ratings yet

- Undervoltage Sensing Circuit: Semiconductor Technical DataDocument8 pagesUndervoltage Sensing Circuit: Semiconductor Technical DataFran Javi Vila DiazNo ratings yet

- 3-Terminal Positive Linear Regulator Az78LxxDocument17 pages3-Terminal Positive Linear Regulator Az78LxxkeisinhoNo ratings yet

- D D D D D: SN74LVC1G86 Single 2-Input Exclusive-Or GateDocument6 pagesD D D D D: SN74LVC1G86 Single 2-Input Exclusive-Or GateJose M PeresNo ratings yet

- Westinghouse Ds 416 PDFDocument28 pagesWestinghouse Ds 416 PDFLuiz_F_A_ViannaNo ratings yet

- Kenwood rxd303Document36 pagesKenwood rxd303André LeftNo ratings yet

- Imag Diagramas 7Document1 pageImag Diagramas 7BG JluisNo ratings yet

- Borehole 6 Project Electrical Installation: Floor PlanDocument1 pageBorehole 6 Project Electrical Installation: Floor PlanbekeleNo ratings yet

- Borehole 6 Project Electrical Installation: Floor PlanDocument1 pageBorehole 6 Project Electrical Installation: Floor PlanbekeleNo ratings yet

- Borehole 6 Project Electrical Installation: Floor PlanDocument1 pageBorehole 6 Project Electrical Installation: Floor PlanbekeleNo ratings yet

- Az1084s2 Adje1Document21 pagesAz1084s2 Adje1Altamiro RochaNo ratings yet

- 5A Low Dropout Linear Regulator Az1084Document15 pages5A Low Dropout Linear Regulator Az1084Marco MoralesNo ratings yet

- Ee-6 (Building Design)Document1 pageEe-6 (Building Design)Ken Joshua VidaNo ratings yet

- 1A Low Dropout Linear Regulator Az1117Document25 pages1A Low Dropout Linear Regulator Az1117DJALMA MOREIRANo ratings yet

- Kfss 1: Deyu CaiDocument1 pageKfss 1: Deyu CaiSKYLERNo ratings yet

- Enclosure A - MAXtension Guardrail Configurations JustificationDocument29 pagesEnclosure A - MAXtension Guardrail Configurations JustificationStephen EimersNo ratings yet

- 5324 DP-4090 5090 D-S300Document28 pages5324 DP-4090 5090 D-S300roca9oNo ratings yet

- Banga School Electrical - 2Document1 pageBanga School Electrical - 2santosmichael.rrfcNo ratings yet

- 3-Terminal Positive Linear Regulator Az78LxxDocument18 pages3-Terminal Positive Linear Regulator Az78LxxCesarNo ratings yet

- Max9708-1292336 - 20-40W Class D Amplifier FilterlessDocument23 pagesMax9708-1292336 - 20-40W Class D Amplifier FilterlessAnderson G SNo ratings yet

- Comfort Controller 6400 and 6400-I/O (Outdoor Rated) Installation InstructionsDocument4 pagesComfort Controller 6400 and 6400-I/O (Outdoor Rated) Installation Instructionslecau50cdlNo ratings yet

- Comfort Controller 6400 and 6400-I/O (Outdoor Rated) Installation InstructionsDocument4 pagesComfort Controller 6400 and 6400-I/O (Outdoor Rated) Installation InstructionsMurilo MachadoNo ratings yet

- LT-UNIT Series: AC Powered Low-Cost Type. Conforming To IEC 60688Document1 pageLT-UNIT Series: AC Powered Low-Cost Type. Conforming To IEC 60688asenk cincaulaNo ratings yet

- " Power Details ": Project NameDocument18 pages" Power Details ": Project NameEdmar BataqueNo ratings yet

- Service Parts List: 54-30-0152 Mag Stand Control PanelDocument2 pagesService Parts List: 54-30-0152 Mag Stand Control PanelJavier SilvaNo ratings yet

- Tda 3629 Tym 118Document28 pagesTda 3629 Tym 118jamorNo ratings yet

- Cafterial SDB Electrical PLanDocument1 pageCafterial SDB Electrical PLanAmos KormeNo ratings yet

- Sigorta Fuse: Alternator and Main Power Connection Kit Various ApplicationsDocument4 pagesSigorta Fuse: Alternator and Main Power Connection Kit Various ApplicationstrentNo ratings yet

- RXD-303 353 503 553Document36 pagesRXD-303 353 503 553の選択 ウィルNo ratings yet

- Electrical Plan-20x301233Document1 pageElectrical Plan-20x301233Jom AsagraNo ratings yet

- Processor Intel Merom: 852balls TEBGADocument38 pagesProcessor Intel Merom: 852balls TEBGAAmin Udin100% (3)

- ISD715 Transport Magnetic Antenna (Active) : Installation GuideDocument2 pagesISD715 Transport Magnetic Antenna (Active) : Installation GuideravikkotaNo ratings yet

- Tumbler Switch: XS/XST SeriesDocument1 pageTumbler Switch: XS/XST Seriescv.samir.rodriguezNo ratings yet

- S1317 - Sun-Balete-MalabananDocument15 pagesS1317 - Sun-Balete-MalabananEdmar BataqueNo ratings yet

- 103 QInstGde Minipack 1U PSS IntDistr 1v0 Draft5Document4 pages103 QInstGde Minipack 1U PSS IntDistr 1v0 Draft5Edwin David ColqueNo ratings yet

- STB24N60M2, Sti24n60m2, STP24N60M2, STW24N60M2Document21 pagesSTB24N60M2, Sti24n60m2, STP24N60M2, STW24N60M2Fabio CaetanoNo ratings yet

- Samsung Sa-750 v14Document6 pagesSamsung Sa-750 v14Anderson GonçalvesNo ratings yet

- " Power Details ": Project NameDocument18 pages" Power Details ": Project NameEdmar BataqueNo ratings yet

- Plano 930E 4Document40 pagesPlano 930E 4Anais Alexandra Pereira ReyesNo ratings yet

- D D D D D D D D D: Description/ordering InformationDocument13 pagesD D D D D D D D D: Description/ordering InformationAdilson ToledoNo ratings yet

- STB10N60M2, STD10N60M2, STP10N60M2, Stu10n60m2Document24 pagesSTB10N60M2, STD10N60M2, STP10N60M2, Stu10n60m2Luis M GonzálezNo ratings yet

- WD0297 A Advent XT2 Block DiagramDocument1 pageWD0297 A Advent XT2 Block DiagramNicolae RaduleaNo ratings yet

- D PRXDocument1 pageD PRXDiana ArredondoNo ratings yet

- Wiring Digram For ACDocument3 pagesWiring Digram For ACahmed HOSNYNo ratings yet

- STAHL 8082 - 1 N.O and N.C Ignition SwitchDocument6 pagesSTAHL 8082 - 1 N.O and N.C Ignition SwitchazilahnazriNo ratings yet

- FS8860Document14 pagesFS8860RED KaromiNo ratings yet

- Az1117rev1.1 - 591 - Similar H16A 1117-3.3vDocument16 pagesAz1117rev1.1 - 591 - Similar H16A 1117-3.3vDiego CapezioNo ratings yet

- Simplex 4098 9788 Smoke Detector Base Installation Instructions 1208476539Document2 pagesSimplex 4098 9788 Smoke Detector Base Installation Instructions 1208476539mohamed.resco100% (1)

- Planos 930e-4seDocument36 pagesPlanos 930e-4seYvàn Renato Vigil LozanoNo ratings yet

- Signa Twinspeed Acgd Gradient Output Cable Installation InstructionsDocument4 pagesSigna Twinspeed Acgd Gradient Output Cable Installation InstructionsRogerio CastroNo ratings yet

- Basic Network DiagramDocument1 pageBasic Network Diagramsuman.k.das83No ratings yet

- 1117H PDFDocument24 pages1117H PDFThe RedfireNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- 6160CR 2 TecladoDocument1 page6160CR 2 Tecladochristian yelpoNo ratings yet

- 5809-Detector Termico InalambricoDocument2 pages5809-Detector Termico Inalambricochristian yelpoNo ratings yet

- Dual Zone Outdoor Pir: MS-12TE & MS-12FEDocument8 pagesDual Zone Outdoor Pir: MS-12TE & MS-12FEchristian yelpoNo ratings yet

- UD29348B A - Baseline - DS K1T502 Series Access Control Terminal - Quick Start Guide - V1.0 - 20221129Document2 pagesUD29348B A - Baseline - DS K1T502 Series Access Control Terminal - Quick Start Guide - V1.0 - 20221129christian yelpoNo ratings yet

- 793F Plano HidraulicoDocument10 pages793F Plano HidraulicoSam B VladNo ratings yet

- 216, 226, 228, 236, 246, and 248 Skid-Steer Loader Electrical SystemDocument2 pages216, 226, 228, 236, 246, and 248 Skid-Steer Loader Electrical SystemLiliana Rebeca Santos santos100% (1)

- Magnetic Sensing in Washing Machines: Application NoteDocument4 pagesMagnetic Sensing in Washing Machines: Application NoteMuhamad Fahri RamdaniNo ratings yet

- 623G Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsDocument4 pages623G Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsMauricio BellidoNo ratings yet

- 3500, C27, C32, and C175 Generator Set Modular Controls Electrical System (Interactive) (Function Isolation), 491-3960-05 (UENR8299)Document28 pages3500, C27, C32, and C175 Generator Set Modular Controls Electrical System (Interactive) (Function Isolation), 491-3960-05 (UENR8299)Zaid AlhakeemNo ratings yet

- C13 XQ350 Power Module Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesC13 XQ350 Power Module Electrical System: Harness and Wire Electrical Schematic SymbolsMian MubasharNo ratings yet

- RI-80 SMD Series Dry Reed SwitchDocument2 pagesRI-80 SMD Series Dry Reed Switchmicimacko_No ratings yet

- Table DLB00174 Ap655 Man225 PDFDocument4 pagesTable DLB00174 Ap655 Man225 PDFRafik MessaNo ratings yet

- Component Locations: 345D and 349D Excavator Accugrade Electrical SystemDocument2 pagesComponent Locations: 345D and 349D Excavator Accugrade Electrical SystemRodrigo EvaristoNo ratings yet

- 908H Serie LMD02385Document4 pages908H Serie LMD02385electricista85No ratings yet

- Reed Sensor For Bypass Level Indicators Model BLR Reed-Messwertgeber Für Bypass-Niveaustandsanzeiger Typ BLRDocument36 pagesReed Sensor For Bypass Level Indicators Model BLR Reed-Messwertgeber Für Bypass-Niveaustandsanzeiger Typ BLRDil NawazNo ratings yet

- Hvac Cab - Bottom View Cab - Left Rear View: Electrical System MD6310 Rotary DrillDocument12 pagesHvac Cab - Bottom View Cab - Left Rear View: Electrical System MD6310 Rotary DrillPedro ArancibiaNo ratings yet

- OHD Thermal Guard: ApplicationsDocument11 pagesOHD Thermal Guard: ApplicationsJoseNo ratings yet

- Bistable Switches For ElevatorsDocument46 pagesBistable Switches For ElevatorsFERNSNo ratings yet

- QM/33, QM/34Document4 pagesQM/33, QM/34Altemir PimentelNo ratings yet

- Cylinder Sensor Brochure UKDocument16 pagesCylinder Sensor Brochure UKifm electronicNo ratings yet

- C1.1, C2.2, C3.3, C4.4, C7.1, C9, C9.3, Electrical System PL444 Telematics Device C13, C15, and C18 Generator Set WithDocument2 pagesC1.1, C2.2, C3.3, C4.4, C7.1, C9, C9.3, Electrical System PL444 Telematics Device C13, C15, and C18 Generator Set WithalexliemNo ratings yet

- Overhead Door Magnetic Contacts: SM-226LQ / SM-226L-3QDocument2 pagesOverhead Door Magnetic Contacts: SM-226LQ / SM-226L-3QFabianAldanaHerreraNo ratings yet