Professional Documents

Culture Documents

CORE 3 EIM

Uploaded by

kentcarlopaye08Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CORE 3 EIM

Uploaded by

kentcarlopaye08Copyright:

Available Formats

HOW TO USE THIS COMPETENCY BASED LEARNING MATERIAL

Welcome to the module in Installing wiring devices of floor and wall mounted

outlets, lighting fixtures/switches, and auxiliary outlets This module contains training

materials and activities for you to complete.

You are required to go through a series of learning activities in order to

complete each learning outcome of the module. In each learning outcome are

Information Sheets, Self-Checks, Operation Sheets and Job Sheets. Follow these

activities on your own. If you have questions, don't hesitate to ask your facilitator for

assistance.

The goal of this course is the development of practical skills. To gain these

skills, you must learn basic concepts and terminology. For the most part, you'll get

this information from the Information Sheets and multimedia materials.

This module was prepared to help you achieve the required competency, in

"Install Electrical lighting System on Auxiliary outlets and lighting fixtures."

This will be the source of information for you to acquire knowledge and skills in

this particular competency independently and at your own pace, with minimum

supervision or help from your instructor.

Remember to:

Work through all the information and complete the activities in each section.

Read information sheets and complete the self-check. Suggested references

are included to supplement the materials provided in this module.

Most probably your trainer will also be your supervisor or manager. He/she is

there to support you and show you the correct way to do things.

You will be given plenty of opportunity to ask questions and practice on the

job. Make sure you practice your new skills during regular work shifts. This way you

will improve both your speed and memory and also your confidence.

Use the Self-checks, Operation Sheets or Job Sheets at the end of each

section to test your own progress.

When you feel confident that you have had sufficient practice, ask your Trainer

to evaluate you. The results of your assessment will be recorded in your Progress

Chart and Accomplishment Chart.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 1 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

MODULE CONTENT

UNIT OF COMPETENCY : Install wiring devices of floor and wall

mounted outlets, lighting fixtures/switches,

and auxiliary outlets

MODULE TITLE : Installing wiring devices of floor and wall

mounted outlets, lighting fixtures/switches,

and auxiliary outlets

MODULE DESCRIPTOR : This unit covers the knowledge, skills and attitudes

on selecting and installing wiring devices, installing

lighting fixtures/switches and notifying completion

of work of floor and wall mounted outlets and

auxiliary outlets.

NOMINAL DURATION : 40 hrs.

CERTIFICATE LEVEL : NC II

PREREQUISITE :

LEARNING OUTCOMES:

Upon completion of this module, the trainee/student must be able to:

1. Select wiring devices

2. Install wiring devices

3. Install lighting fixtures/switches

4. Notify completion of work

Install wiring devices of floor and wall

RPTESDC Developed by: Page 2 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

LEARNING OUTCOME NO. 1 Select wiring devices

CONTENTS:

TECHNOLOGY:

• Selecting wiring devices

• GFCI protected outlets

SCIENCE:

Insulation of a conductors

ENVIRONMENTAL ISSUES AND OTHER CONCERNS:

CONDITIONS:

The students/trainees must be provided with the following:

Supplies and Materials Learning Materials

o Wiring devices o Learning elements

o Manuals

o Books and

o Philippine Electrical

Code/National Electric

Code, Latest Edition

METHODOLOGIES:

Demonstration

Discussion

Practical Exercises

Laboratory exercises

ASSESSMENT METHODS:

Demonstration

Direct observation and questioning

ASSESSMENT CRITERIA

Wiring devices are inspected for damage according manufacturer’s

specification.

Wiring devices are selected according to the job requirements.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 3 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

Learning Experience

Select wiring devices

Learning Activities Special Instructions

1. Read Information Sheet No. 3.1-1 In this learning outcome you shall

.Circuit breaker prepare tools and materials needed

Answer Self- Check No. 3.1-1 to select wiring devices.

Compare answers with answer key 3.1-1

2. Read Information Sheet No. 3.1-2 Study the Information Sheet and

Conductors and Insulation answer self-checks to ensure the

Answer Self- Check No. 3.1-2 knowledge of learning outcome are

Compare answers with answer key 3.1-2 acquired.

3. Read Information Sheet No. 3.1-3

Fuses Perform the task sheet, operation

Answer Self- Check No. 3.1-3 sheet and job sheet in order to meet

the needed skills required.

Compare answers with answer key 3.1-3

4. Read Information Sheet No. 3.1-4 If you have questions you could ask

GFCCP your facilitator/trainer.

Answer Self- Check No. 3.1-4

Compare answers with answer key 3.1-4

5. Read Information Sheet 3.1-5

Switches

Answer Self- Check No. 3.1-5

Compare answers with answer key 3.1-5

6. Read Information Sheet 3.1-6

Convenience Outlet

Answer Self- Check No. 3.1-6

Compare answers with answer key 3.1-6

7. Read Information Sheet 3.1-7

Incandescent/LED Lamp

Answer Self- Check No. 3.1-7

Compare answers with answer key 3.1-7

8. Read Information Sheet 3.1-8

Fluorescent Lamp

Answer Self- Check No. 3.1-8

Compare answers with answer key 3.1-8

Install wiring devices of floor and wall

RPTESDC Developed by: Page 4 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

INFORMATION SHEET NO. 3.1-1

CIRCUIT BREAKER

Introduction

• A circuit breaker is used to close and interrupt a circuit under both normal

conditions (for service) and abnormal conditions.

• A circuit breaker is designed to automatically open the circuit when it senses a

predetermined overload or fault current.

Number of Poles

Another characteristic shared by all product lines is that circuit breakers are available

with a varying number of poles, according to the number of phase conductors in the

protected circuit:

One (1) Pole Circuit Breaker

Used in a line to neutral electrical system, Provide a 115 volts

from a 230 volts source and provide also 230 volts from 460 volts.

One-pole circuit breakers are wired with one hot wire and one

neutral wire. When there is an overload in a single-pole breaker’s

circuit, only that particular breaker trips.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 5 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

Two (2) Pole Circuit Breaker

Used in a single phase electrical system. Unlike

the single-pole breaker, it services a 240-volt circuit by using

two spaces in the electrical panel. By utilizing both phases, you

are able to connect the circuit breaker to things like a 240-volt air

conditioner, an electric range, an electric water heater, or an electric

dryer. Double-pole breakers have two connection points used to

connect the electrical wires to them while snapping

into place within the electrical panel's bus.

Three-Pole Circuit Breaker

Used most often in a three-phase electrical system,

a three-pole circuit breaker connects three different conductors,

such as is often required by heavy duty industrial motors. When

a surge exists anywhere in the system, across one or more of the

conductors, the breaker trips, the power bridge collapses, and the

circuit opens.

Molded Case circuit Breaker

Molded case circuit breakers (MCCB) work on the same

principles of thermal-magnetic protection, but they offer

some additional features that are not available with CBs:

MCCBs have adjustable trip settings, so they are suitable

when the rated current of a circuit breaker must be

fine-tune according to the actual site conditions.

MCCBs have a much wider range of current ratings: they

can be found from ratings below 100 Amps to ratings

above 2500 Amps.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 6 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

Compared with CBs, molded-case circuit breakers are much larger, given that they

must accommodate an adjustable trip mechanism and, in many cases, larger

contacts for high-current applications. MCCBs are available in a wide variety of

voltage ratings:

240-277 V: , 480 V: 600 V

There are two sub-types of MCCBs that are used exclusively for electric motor

protection:

Motor protection circuit breaker (MPCB)

Motor circuit protectors (MCP)

Operating Characteristics of a Circuit Breaker

• When a breaker trips, it moves from the On

position to the middle (Tripped) position. To

reset the breaker, it is pushed beyond Off to the

Reset position and then back to the On position.

Circuit Breaker Current Rating

• The continuous current rating of a circuit

breaker is the maximum current that it can

carry continuously without exceeding the

allowable temperature rise.

• Continuous current ratings range from 15A

,20 ,25, 30, 35, 40, 45, 50, 60, 70, 80, 90,

100, 110,125, 150, 175, 200, 225, 250,

300, 350, 400, 450, 500, 600, 700, 800,

1000, 1200, 1600, 2000, 2500, 3000,

4000, 5000, 6000A.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 7 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

Normal Current Operation

• The amperage interrupting capacity (AIC) is the maximum short circuit current at

which the breaker will safely interrupt the circuit at the rated voltage and

frequency.

• Under normal operation, the load current is consistent and the protective device

will not trip.

Short Circuit Operation with Adequate Interrupting Rating

When the overcurrent device is sized correctly, it operates to protect the circuit and

downstream components.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 8 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

PARTS OF A CIRCUIT BREAKER

Install wiring devices of floor and wall

RPTESDC Developed by: Page 9 of

mounted outlets, lighting fixtures/switches, OMAR S.

-Cainta 105

and auxiliary outlets LAYNESA

SELF CHECK: 3.1-1

Circuit Breaker

1. What is a device designed to open a current carrying circuit without injury to itself under

abnormal conditions?

a. contactor b. circuit breaker

c. fuse d. control switch

2. Automatic circuit breaker is a device used to protect a circuit from

a. Over current b. Over load

c. Over voltage d. High resistance

3. A circuit breaker used in a line to neutral electrical system.

a. one (1) pole circuit breaker

b. two (2) pole circuit breaker

c. single phase circuit breaker

d. three phase circuit breaker

4. To switch on the tripped circuit breaker, first you have to .

a. pushed the switch beyond Off to the Reset position

b. pushed the switch to on position

c. pushed the switch to off position

d. pushed the switch to trip position

5. When the circuit breaker is sized correctly, it operates to protect the .

a. source

b. branch circuits

c. panel board

d. circuit and downstream components.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 10 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Answer Key 3.1-1

Circuit Breaker

1. b.

2. a.

3. a.

4. a.

5. d

Install wiring devices of floor and wall

RPTESDC Developed by: Page 11 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3.1-2

Conductors and Insulation

• Conductors are identified by size and insulation material.

• The size refers to the cross-sectional area of the current-carrying portion of the

wire and is expressed in American Wire Gauge (AWG) numbers.

• Conductor ampacity is affected by the conductor material and size, insulation,

and installation location.

Physical Factors that Affects/Determines the Resistance of a Conductor

1. Length of the conductor

- the greater the length of the conductor, the greater its resistance.

2. Cross-Sectional Area of the Conductor

- the greater the cross-sectional area of the conductor, the lesser its

resistance.

Conductors and Non-Conductors

Conductors - materials that easily facilitate the passage of free electrons. They

have less than 4 valence electron.

EX. Gold, Silver, Copper, Aluminium, etc.

Semi-Conductors - materials that neither is a good insulator or a good

conductor but becomes a very good insulator or conductor upon the

application of heat. They have 4 valence electron.

EX. Selenium, Germanium, Silicon.

Insulators- materials that hardly facilitate the passage of free electrons. They

have greater than 4 valence electron

EX. Paper, Plastic, Glass, Porcelain, Rubber, etc.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 12 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Wire Size Marking

For wire sizes larger than No. 16 AWG, the wire size is marked on the conductor

insulation.

Strand Configurations

• Wire stranding provides conductor flexibility for pulling.

• Wire sizes No. 18 to No. 2 have 7 strands.

• Wire sizes No. 1 to 4/0 have 19 strands.

• Wire sizes 250 kcmil to 500 kcmil have 37 strands.

(A kcmil is 1,000 circular mils or 0.001 inch.)

Install wiring devices of floor and wall

RPTESDC Developed by: Page 13 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Conductors are selected based on conductor material and the correct insulation for

the application. The insulation type is typically stamped on the wire.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 14 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Characteristic of selected insulated conductors for General Wiring

Trade Name Type Operating Application

Letter Temperature

Moisture and Heat

Resistant Rubber R.H.W 75 degrees Dry and Wet Location

Thermoplastic T 60 degrees Dry and Wet Location

Moisture Resistant T.W. 60 degrees Dry and Wet Location

Thermoplastic

Thermoplastic T.H.H.N. 90 degrees Dry Location

Heat

Resistant

Moisture and Heat T.H.W. 75 degrees Dry and Wet Location

Resistant

thermoplastic

Moisture and Heat THWN 75 degrees Dry Location

Resistant

thermoplastic

Moisture and Heat XHHW 90 degrees Dry Location

Resistant cross

linked

Thermosetting

Polyethylene 75 degrees Wet Location

Silicon asbestos SA 90 degrees Dry Location

Asbestos and AVA 110 degrees Dry Location

varnish

Cambric

Install wiring devices of floor and wall

RPTESDC Developed by: Page 15 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Ampacity; Conductor Material; Conductor Insulation

Ampacity is the safe current-carrying capacity of a conductor at a specified

temperature rating.

Conductors for General Wiring

Ampacities of insulated conductors rated 0 through 2000 volts, 60°C through

90°C not more than three current-carrying conductors in raceway, cable, or earth

(directly buried) based on ambient temperature of 30°C

60°C 75°C 90°C

Types Types Types

TW FEPW TBS,SA,SIS,FEP

UF RH, RHW, FEPB,MI,RHH,ZW-2

Conductor Size THW THHN, THHW

(mm², mm dia.) THWN THW-2,THWN-2

XHHW XHN, USE-2

USE,ZW XHHW,XHHW-2

Copper (Ampere)

2.0 (1.6) 20 20 25

3.5 (2.0) 25 25 30

5.5 (2.6) 30 35 40

8.0 (3.2) 40 50 55

14 55 65 70

22 70 85 90

30 90 110 115

38 100 125 130

50 120 145 150

60 135 160 170

80 160 195 205

100 185 220 225

125 210 255 265

150 240 280 295

200 280 330 355

250 315 375 400

325 370 435 470

400 405 485 515

250 445 540 580

Install wiring devices of floor and wall

RPTESDC Developed by: Page 16 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

SIZE OF WIRE

AMERICAN WIRE GAUGE (AWG) SQUARE Millimeter (mm²)

14 AWG 2.0mm²

12 AWG 3.5mm²

10 AWG 5.5mm²

8 AWG 8.0mm²

6 AWG 14mm²

4 AWG 22mm²

2 AWG 30mm²

1 AWG 38mm²

1/0 AWG 50mm²

2/0 AWG 60mm²

3/0 AWG 80mm²

4/0 AWG 100mm²

250 MCM 125mm²

300 MCM 150mm²

350 MCM 200mm²

400 MCM 250mm²

500MCM 325mm²

800 MCM 400mm²

1000 MCM 500mm²

Install wiring devices of floor and wall

RPTESDC Developed by: Page 17 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Self Check: 3.1-2

Conductor and Insulation

1. What is the maximum temperature rating of a TW insulated

conductor.?

a. 50°C b. 60°C

c. 75 °C d. 90°C

2. What material is a THHN made of?

a. thermoplastic b. rubber

c. asbestos d. synthetic

3. What ampere rating of circuit breaker is used to protect a 5.5 mm² TW?

a. 15 A b. 20A

c. 30 A d. 40 A

4. The minimum size of wire used in electrical wiring is the former number 14

AWG. Under the metric system now shown the new PEC, the diameter is,

a. 1.6 mm b. 2 mm

c. 2.6 mm d. 3.2 mm

5. Silver is a better conductor electricity than copper, However copper is generally

used as electrical conductors. The main reason for using copper instead of silver

is its

a. cost b. strength

c. weight d. melting point

6. Which of the following electric wires has the highest ampacity?

a. 22 mm² b. 14 mm²

c. 5.5 mm² d. 30 mm²

7. What is the largest size of commercially available solid conductor?

a. 3.0 mm b. 3.5 mm

c. 3.6 mm d. 3.2 mm

8. Which of the following materials is good conductor?

a. plastic b. rubber

c. iron d. copper

9. Materials that allow few free electrons

a. insulators b. inductors

c. capacitors d. conductors

10. In sizing feeder conductors in long feeder runs, one important factor to consider is

a. insulation b. feeder protection

c. voltage drop d. ground fault current

Install wiring devices of floor and wall

RPTESDC Developed by: Page 18 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Answer Key 3.1-2

Conductors and Insulation

1. b. 60°C

2. a. thermoplastic

3. c. 30 A

4. a. 1.6 mm

5. d. melting point

6. d. 30 mm²

7. d. 3.2 mm

8. d. copper

9. a. insulators

10. c. voltage drop

Install wiring devices of floor and wall

RPTESDC Developed by: Page 19 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3.1-3

Fuses

A fuse is the simplest type of over current protective device and consists of a fusible

link encapsulated in a tube or plug body

Fuse is an electrical safety device that operates to provide overcurrent protection of an

electrical circuit. Its essential component is a metal wire or strip that melts when too much

current flows through it, thereby interrupting the current. It is a sacrificial device; once a fuse

has operated it is an open circuit, and it must be replaced depending on type.

Cartridge Fuses for use in commercial, industrial, automotive, residential and agricultural

applications. Fuses come in a variety of sizes, amps and volt ratings.

CONSTRUCTION

A fuse consists of a metal strip or wire fuse element, of small cross-section compared to the

circuit conductors, mounted between a pair of electrical terminals, and (usually) enclosed by

a non-combustible housing.

PARTS OF A FUSE

INSULATIO

WEAK

CONTACT (METAL STRIP)

Install wiring devices of floor and wall

RPTESDC Developed by: Page 20 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Plug fuses are commonly used to protect appliances.

SCREW IN PLUG FUSES

Screw in plug type fuses, Plug fuses come in a screw-type configuration. They come with a

sight glass that shows if the fuse is blown or not. only allows you to screw the appropriate sized

fuse into the socket.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 21 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Self Check 3.1-3

Fuses

1. Weak link in a circuit which will break when too much current flows through it is a

a. relay b. circuit breaker

c. fuse d. control switch

2. A type of fuse are commonly used to protect appliances.

a. screw in flug fuses b. cartridge fuses

c. fuse link d. plug fuses

3. It come with a sight glass that shows if the fuse is blown or not.

a. screw in plug fuses b. cartridge fuses

c. fuse link d. plug fuses

4. A part of a fuse that melt when temperature increases due to high current.

a. housing b. insulation

c. metal strip d. contacts

5. A fuse is an electrical protective device which .

a. protects electrical equipment from incoming spike voltage

b. protects electrical equipment from current surges and overloads

c. breaks power flow when a very low voltage is encountered

d. trips off when a very low current is encountered

Install wiring devices of floor and wall

RPTESDC Developed by: Page 22 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Answer Key 3.1-3

Fuses

1. C. Fuse

2. D. Plug fuses

3. A. Screw in Plug Fuses

4. C. Metal Strip

4. B. Protects electrical equipment from current surges and overloads

Install wiring devices of floor and wall

RPTESDC Developed by: Page 23 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3.1-4

Ground Fault Current Circuit Protection

GFCIs are usually required by local laws to be installed in, kitchens, bathrooms,

unfinished basements, garages, outdoors, and anywhere near a sink. Notably, these

are all places where water may allow a short circuit to happen.

• Standard circuit breakers cannot protect personnel from damaged or faulty

equipment because the current levels, while enough to harm or even kill a

person, are too low to trip a standard breaker.

• Ground fault circuit interrupters (GFCIs) are used to interrupt fault currents of

6mA or more.

Receptacle Type

This type of GFCI is used in place of the standard duplex

receptacle found throughout the house It fits into the

standard outlet box and protects you against "ground faults'

whenever an electrical product is plugged into the outlet.

Most receptacle-type GFCls can be installed so that they

also protect other electrical outletsfurther "down stream" in

the branch circuit

Install wiring devices of floor and wall

RPTESDC Developed by: Page 24 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Protection Against Ground Faults

Ground fault is any path (circuit) established unintentionally between a current

carrying conductor and ground, besides occurring in defective equipment, ground

faults can results when serviceable equipment is abused. Such as accidentally

setting or dropping an energize electric tool in water. Depending on and

conditions and the nature of the contact, a ground fault has either high or

low resistance. If it has a low resistance large of amount of current flow, and the fuse

blows or the circuit breaker trips to open the circuit.

Shock hazards are greater when the fault has a high resistance and not enough fault

current flows to blow the fuse or trip the circuit breaker. In such cases, a GROUND

FAULT CIRCUIT INTERRUPTER (GFCI) can protect you against shock.

Under normal conditions when no ground fault exist the GFCI does nothing .

Hot

FAULT

RE APPLIANC

Neutr SET

BALANCE CURRENT – Normal operation GFCI does nothing.

TEST

Install wiring devices of floor and wall

RPTESDC Developed by: Page 25 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

However the instant ground fault occurs, there is an inbalance of current between the

hot and neutral conductors.

FAULT

APPLIANCE

RE

SET

TEST

REDUCED CURRENT IN NEUTRAL WIRE due to current diverted through fault,

GFCI immediately opens circuit to stop current flow

Install wiring devices of floor and wall

RPTESDC Developed by: Page 26 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

A GFCI breaker is installed in the panel like any other breaker, except the white wire

pigtail is attached to the panel neutral assembly.

In homes equipped with circuit breakers rather than fuses, a circuit breaker GFCI

may be installed in a panel box to give protection to selected circuits. The circuit

breaker GFCI serves a dual purpose - not only will it shut off electricity in the event of

a "ground-fault," but it will also trip when a short circuit or an overload occurs.

Protection covers the wiring and each outlet, lighting fixture, heater, etc served by the

branch circuit protected by the GFCI in the panel box.

GFCI circuit breaker controls an entire circuit, and is installed as a replacement for a

Circuit breaker on your home's main circuit board. Some homes are wired so that all

bathrooms or all outdoor fixtures are on the same circuit. Rather than install multiple

GFCI outlets, one GFCI circuit breaker can protect the entire circuit.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 27 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Self Check 3.1-4

Ground Fault Current Circuit Protection

1. The type of receptacle outlet that is safe for bathrooms and outdoors like garage is

the

a. GFCI b. water proof

c. weather proof d. special purpose outlet

2. The GFCI under normal conditions when no ground fault exist the current

is .

a. unbalance b. reduce in neutral wire

c. balance d. over

3. The GFCI under abnormal conditions when there is ground fault occurs the current

is .

a. zero b. reduce in neutral wire

c. balance d. over

4. The GFCI under normal conditions when no ground fault exist the contact

is .

a. broken b. open

c. welded d. closed

5. A circuit breaker that can protect the entire circuit in a damp locations.

a. automatic circuit breaker b. GFCI circuit breaker

c. molded case circuit breaker d. 2 pole circuit breaker

Install wiring devices of floor and wall

RPTESDC Developed by: Page 28 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Answer key 3.1-4

Ground Fault Current Circuit Protection

1 .a

2. c

3. b

4. d

5. b

Install wiring devices of floor and wall

RPTESDC Developed by: Page 29 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3.1-5

Switches

A switch is an electrical component that can "make" or "break" an electrical circuit.

Like receptacles, switches are marked with the maximum voltage and amperage

(rated current and voltage), along with the type of wire to be used.

Light Switch

In building wiring, light switches are installed at convenient locations to control

lighting and occasionally other circuits. By use of multiple-pole switches, multiway

switching control of a lamp can be obtained from two or more locations, such as the

ends of a corridor or stairwell.

Single Pole Single Throw Switch

A single-pole, single-throw (SPST) switch is as simple as it gets. It’s got one output

and one input. The switch will either be closed or completely disconnected. SPSTs

are perfect for on-off switching. They’re also a very common form

of momentary switches. SPST switches should only require two terminals.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 30 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Duplex Switch/Two Gang Switch

Basically two SPST switches, which can control two separate circuits

LINE 1

Bulb 1 Bulb 2

LINE 2

LOCATION 1

S2

Triplex Switch/Three Gang Switch

Basically three SPST switches, which can control three separate circuits.

LINE 1

Bulb 1 Bulb 2 Bulb 3

LINE 2

LOCATION 1

S3

Install wiring devices of floor and wall

RPTESDC Developed by: Page 31 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Three Way Switch

An electric switch that has three terminals; used to control a circuit from two different

location. Three-way switches are normally used at the tops and bottoms of stairways

to control the light from either location.

Four Way Switch

An electric switch employed in house wiring, that makes it possible to turn a light on

or off at three or more location. A four-way switch may be used in conjunction with

two three-way switches to control a device from three locations.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 32 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Self Check 3.1-5

Switches

1. Which of the following electrical parameters apply or labelled to all kind of

switches?

a. Rated power and rated voltage

b. Rated resistance and rated current

c. Rated current and rated voltage

d. Rated power and rated current

2. What type of switch used to control one lamp from to locations.

a. Toggle Switch b. Three way switch

c. Single pole switch d. Triplex switch

3. An electrical component that can "make" or "break" an electrical circuit.

a. Switch b. Convenience outlet

c. Lamp d. Receptacle

4. A switch may be used in conjunction with two three-way switches to control a

device from three locations.

a. Four way switch b. Three way switch

c. Single pole switch d. Triplex switch

5. Basically two SPST switches, which can control two separate lamps.

a. Three gang switch b. Triplex switch

c. Single pole switch d. Duplex switch

Answer Key 3.1-5

Install wiring devices of floor and wall

RPTESDC Developed by: Page 33 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Switches

1. C. Rated current and rated voltage

2. B. Three way switch

3. A. Switch

4. A. Four way switch

5. D. Duplex switch

INFORMATION SHEET NO. 3.1-6

Install wiring devices of floor and wall

RPTESDC Developed by: Page 34 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Convenience Outlet

An electrical outlet or receptacle is a socket that connects an electrical device to

an electricity supply. In buildings, electrical outlets are usually installed in the wall,

although they can also be installed in the floor.

Different countries often have different outlet types, current and voltages.

Type A Type B Type G Type I

SPECIAL PURPOSE OUTLET

Special purpose outlet is an outlet used for purposes other than ordinary lighting and

power, usually fused separately. Most commonly used for electric range or clothes

dryers.

ACU OUTLET

Install wiring devices of floor and wall

RPTESDC Developed by: Page 35 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

An air conditioner outlet connects your air conditioner with the power source, and

such outlets are usually very different from the “usual”, conventional outlets. They

usually vary in current rating, as the air conditioner

requires higher current than usual. Thus, the choice of an

air conditioner outlet will depend largely on the power

your air conditioner needs. This means that you will need

to check the type of plug is on your air conditioner, as well

as compare it to the outlet on your wall.

POP UP OUTLET

The pop up was specifically designed to meet code for kitchen, floor and wet location

installations, it meets National Electrical Code (NEC) 406.5E for countertop use in the

USA and Canada. The outlet is tamper proof and is UL listed, the pop up as a

complete unit is ETL listed for USA installations, and cETL and CSA approved for

Canada installations. The pop up features an IP44 water rating, and is splash rated

for wet location installations, there is also a gasket under the bezel to keep water

from entering from the sides between the countertop and the base of the pop up

POP UP FLOOR OUTLET POP UP KITCHEN OUTLET

INDUSTRIAL SOCKET/PLUGS

Industrial and multiphase plugs and sockets provide a connection to the electrical

mains rated at higher voltages and currents than household plugs and sockets. They

are generally used in poly phase systems, with high currents, or when protection from

environmental hazards is required. Industrial outlets may have weatherproof covers,

waterproofing sleeves, or may be interlocked with a switch to prevent accidental

disconnection of an energized plug. Some types of connectors are approved for

Install wiring devices of floor and wall

RPTESDC Developed by: Page 36 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

hazardous areas such as coal mines or petrochemical plants, where flammable gas

may be present.

Industrial

Socket

(2P+E)

Almost all three-phase power plugs have an earth (ground) connection, but may not

have a neutral because three-phase loads such as motors do not need the neutral.

Such plugs have only four prongs (earth, and the three phases). An example of a

socket with neutral is the L21-30 (30 A) and the L21-20 (20 A) both of which have five

pins (earth, neutral, and X, Y, Z phases).

Industrial

Socket

(3P+E)

While some forms of power plugs and sockets are set by international standards,

countries may have their own different standards and regulations. For example, the

colour-coding of wires may not be the same as for small mains plugs.

Industrial

Socket

(4P+E)

Self Check 3.1-6

Convenience Outlet

Install wiring devices of floor and wall

RPTESDC Developed by: Page 37 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

1. An outlet used for electric range or clothes dryer.

a. Industrial socket b. Special purpose outlet

c. A.C.U. outlet d. Pop out outlet

2. Which of the following electrical parameters apply or labelled to all kind of

outlet?

a. Rated power and rated voltage

b. Rated resistance and rated current

c. Rated current and rated voltage

d. Rated power and rated current

3. An outlet that can be installed in the floor.

a. Industrial socket b. Special purpose outlet

c. A.C.U. outlet d. Pop out outlet

4. A socket rated at higher voltages and currents than household outlet.

a. Industrial socket b. Special purpose outlet

c. A.C.U. outlet d. Pop out outlet

5. A socket used in a three (3) phase system

a. Industrial socket b. Special purpose outlet

c. A.C.U. outlet d. Pop out outlet

Answer Key 3.1-6

Convenience Outlet

Install wiring devices of floor and wall

RPTESDC Developed by: Page 38 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

1. b. Special purpose outlet

2. c. Rated current and rated voltage

3. d. Pop out outlet

4. a. Industrial socket

5. a. Industrial socket

Install wiring devices of floor and wall

RPTESDC Developed by: Page 39 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3.1-7

Incandescent / LED Lamp

HISTORY AND DEVELOPMENT OF INCANDESCENT LAMP

The first incandescent electric light was made in 1800 by Humphry Davy, an

English scientist. He experimented with electricity and invented an electric battery.

When he connected wires to his battery and a piece of carbon, the carbon glowed,

producing light. This is called an electric arc.

Much later, in 1860, the English physicist Sir Joseph Wilson Swan (1828-

1914) was determined to devise a practical, long-lasting electric light. He found that a

carbon paper filament worked well, but burned up quickly. In 1878, he demonstrated

his new electric lamps in Newcastle, England.

The inventor Thomas Alva Edison (in the USA) experimented with thousands

of different filaments to find just the right materials to glow well and be long-lasting. In

1879, Edison discovered that a carbon filament in an oxygen-free bulb glowed but did

not burn up for 40 hours. Edison eventually produced a bulb that could glow for over

1500 hours.

Lewis Howard Latimer (1848-1928) improved the light bulb by inventing a

carbon filament (patented in 1881); Latimer was a member of Edison's research

team, which was called "Edison's Pioneers." In 1882, Latimer developed and

patented a method of manufacturing his carbon filaments.

In 1903, Willis R. Whitney invented a treatment for the filament so that it

wouldn't darken the inside of the bulb as it glowed. In 1910, William David Coolidge

(1873-1975) invented a tungsten filament, which lasted even longer than the older

filaments. The incandescent bulb revolutionized the world.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 40 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Incandescent Lamp

An incandescent light bulb, incandescent lamp or incandescent light globe is an

electric light with a wire filament heated to such a high temperature that it glows with

visible light (incandescence). The filament is protected from oxidation with a glass or

fused quartz bulb that is filled with inert gas or a vacuum. In a halogen lamp, filament

evaporation is slowed by a chemical process that redeposits metal vapor onto the

filament, thereby extending its life.

Parts of an Incandescent Bulb

Coiled tungsten filament - the metal wires

that glow brightly when electricity flows

through them.

Connecting wires - The wires that carry

electricity from the bulb's electrical contact to

the filament.

Electrical contacts - the metallic base of the

bulb, which connects to the electrical contacts

of the lamp when the bulb is in the lamp.

Glass envelope - The thin layer of glass that

surrounds the light bulb mechanism and the

inert gases.

Glass fuse enclosure - glass that insulates the bulb's fuses - located in the stem of

the bulb.

Mixture of inert gases at low pressures - the bulb is filled with inert (non-reactive)

gases.

Screw cap - the threaded base of the bulb that secures it to a lamp.

Support wires - wires that physically hold up the filament.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 41 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

What makes a light bulb glow?

The thin wire, or filament, inside a light bulb resists the flow of current through

it. When electricity is passed through the bulb, the filament becomes hot and glows

brightly. To prevent the filament burning away completely, the glass bulb filled with a

mixture of inert gas (usually argon and nitrogen). The filament in most light bulbs is

made of tungsten.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 42 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

LED LAMP

A LED lamp or LED light bulb is an electric light for use in light fixtures that produces

light using light-emitting diode (LED). LED lamps have a

lifespan many times longer than equivalent

incandescent lamps, and are significantly more efficient

than most fluorescent lamps, with some LED chips able

to emit up to 303 lumens per watt (as claimed by Cree

and some other LED manufacturers).

However, LED lamps require an electronic LED driver circuit when operated from

mains power lines, and losses from this circuit mean the efficiency of the lamp is

lower than the efficiency of the LED chips it uses. The most efficient commercially

available LED lamps have efficiencies of 200 lumens per watt (lm/w).Commercially

available LED chips have efficiencies of over 220 lm/w.[citation needed]

The LED lamp market is projected to grow by more than twelve-fold over the next

decade, from $2 billion in the beginning of 2014 to $25 billion in 2023, a compound

annual growth rate (CAGR) of 25%.As of 2016, LEDs use only about 10% of the

energy an incandescent lamp requires.

Similar to incandescent lamps and unlike most fluorescent lamps (e.g. tubes and

compact fluorescent lamps or CFLs), LEDs come to full brightness without need for a

warm-up time; the life of fluorescent lighting is also reduced by frequent switching on

and off. The initial cost of LED is usually higher. Degradation of LED dye and

packaging materials reduces light output to some extent over time.

Some LED lamps are made to be a directly compatible drop-in replacement for

incandescent or fluorescent lamps. An LED lamp packaging may show the lumen

output, power consumption in watts, color temperature in kelvins or description (e.g.

"warm white", "cool white" or "daylight"), operating temperature range, and

sometimes the equivalent wattage of an incandescent lamp of similar luminous

output.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 43 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Self Check 3.1-7

Incandescent / LED Lamp

.1. Most of the required electrical parameters apply to an incandescent bulb are

a. Rated power and rated voltage

b. Rated resistance and rated current

c. Rated current and rated voltage

d. Rated power and rated current

2. A lamps, have a lifespan many times longer than equivalent incandescent lamps, and are

significantly more efficient than most fluorescent lamps.

a. Indicating lamp b. LED lamp

c. Mercury lamp d. CFL Lamp

3. Parts of an incandescent lamp that glow brightly when electricity flows through them.

a. Support wire b. Connecting wire

c. Coiled tungsten filament d. Screw cap

4. A lamp with a wire filament heated to such a high temperature that it glows with

visible light.

a. Incandescent lamp b. LED lamp

c. Mercury lamp d. CFL Lamp

5. A lamp that use only about 10% of the energy an incandescent lamp requires.

a. Fluorescent lamp b. LED lamp

c. Mercury lamp d. CFL Lamp

Install wiring devices of floor and wall

RPTESDC Developed by: Page 44 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Answer Key 3.1-7

Incandescent / LEDLamp

1. a. Rated power and rated voltage

2. b. LED lamp

3. c. Coiled tungsten filament

4. a. Incandescent lamp

5. b. LED lamp

Install wiring devices of floor and wall

RPTESDC Developed by: Page 45 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3 .1-8

Fluorescent Lamp

FLUORESCENT LAMP

A fluorescent lamp or a fluorescent tube is a low pressure mercury - vapor gas-discharge

lamp that uses fluorescence to produce visible light.

It is extremely in common use, second only to incandescent lamp. Fluorescent lamps are

adaptable to residential interior for both seeing and decorative purposes, because of their

shape, coolness and hign efficiency. Fluorescent lamps are manufactured as tubular and

circular in shape and of various lengths and wattages.

TUBULAR CIRCULAR

Parts and Functions of Fluorescent Lamp

1. Fluorescent tube –is a circular bulb containing mercury vapor and inert gas with phosphor

coating inside.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 46 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

The rare gas (argon) as a result of voltage illuminates and becomes a conductor, Like every

conductor carrying a current. This generated heat maintains the filamint at a certain

temperature and volatiles the few drops of mercury while filling the tube with mercury vapor.

The filament, like all conductors, has the property of emitting electrons when they reach a

certain temperature.

These electrons meet the mercury vapor, the resulting shock can force the fluorescent

material to emit light.

The interior of the glass tube of a fluorescent tube is covered with fluorescent powder which

under the effect of the ultra violet rays give illumination.

2. The Fluorescent Starter

Current moves in ulilizing the rare gas as conducting means and the rare gas produces a

“GLOW” the glow generates heat and causes the bimetallic blade to expand.

The bimetallic blade, because it is heated, changes shape and touches the fixed contact.

The close contact of the two starter contacts produce an path for current flow.

Parts of a Starter

GLASS BULB

CONDENSER/ BIMETALLIC

CAPACITOR

BLADE

RARE GAS

ARGON GAS

Install wiring devices of floor and wall

RPTESDC Developed by: Page 47 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

HOW THE STARTER SWITCH WORKS

a. Initial current causes electrical arc between

electrodes, which ionizes gas.

b. Heat from the light bends bimetallic strip,

closing the switch, which turns off the starter light

c. The bimetallic strip cools and returns to its original

position. Current flows through the ionized gas in the tube.

3. The Ballast

In common with all gaseous discharge lamps, the fluorescent must be provided with some

device for limiting the current drawn by the discharge. Without a limiting device, the current

would rise to avalue that would destroy the lamp. This requirement can be met by a device or

auxiliary called ballast.

Induction Type Ballast Electronic Type Ballast

Install wiring devices of floor and wall

RPTESDC Developed by: Page 48 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

PRE HEAT START FLUORESCENT LAMP

The tube filaments, starter (glow switch), and ballast are all connected in series, which

constitute a complete circuit once the switch, is closed. As a current flows through, the gas

(inert) inside the starter glows and the electrodes are heated. Since one of the electrodes is a

bi-metal, it bends and makes contact with the other. At this instant, the circuit is metallically

complete. The filaments of the fluorescent tube are then heated and partial ionization takes

place. The bi-metals in the starter cools and the contacts open. The magnetic field in the

ballast collapses rapidly producing an inductive kick, which establishes a current between the

filaments and fires the tube into operation.

Schematic Diagram of Pre -

Heat Fluorescent Lamp

Frame –is the metal housing of the whole Lamp holder and starter socket – are

fixture. the point of connection of the

fluorescent and starter

Install wiring devices of floor and wall

RPTESDC Developed by: Page 49 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

RAPID START FLUORESCENT LAMP

Most fluorescent fixtures with two or more lamps are known as "rapid start". In this system,

there is no starter. Instead, the ballast keeps a low flow of current running through the

filaments at all times or during the start-up period, and uses a capacitor or other techniques

to start the lamp by ionizing the gas, which is another way to reduce the initial resistance of

gas to a flow of electrical current.

TWO (2) FLUORESCENT LAMP

ONE (1) FLUORESCENT

Install wiring devices of floor and wall

RPTESDC Developed by: Page 50 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Trouble and Repair of a Fluorescent Lamp

SYMPTOM CAUSES REMEDY

1. Flashing ON and - End of life (if old) - Replace lamp

OFF

- Possible fault of lamp - Check lamp holder if

and holder blinking continuously

investigate further

- Faulty starter - Replace starter

- Low ballast rating - Check voltage and

correct it possible

- Loose contacts - See that the lamp are

surely fitted and

holders surely

mounted

2. No starting effort

or low starting - End of life - Replace lamp

- Defective starter in - Replace starter

correct wiring check wiring and

make proper

connection check

voltage and correct it

possible.

- Air leak in lamp - Replace lamp

- Low ballast rating - Check ballast

- Replace lamp

- Open electrode circuit - Test lamp in another

- Possible open circuit circuit

3. Ends of lamp - fault starter - replace starter

remain lighted - incorrect wiring - make proper

connection

- low ballast starting - replace ballast

4. Flicker/ swirl/flutter - New lamp may flicker - Usually clears after

when first place in short operation turn

service ON and OFF a few

times.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 51 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

COMPACT FLUORESCENT LAMP (CFL)

A compact fluorescent lamp (CFL), also called compact fluorescent light, energy-

saving light, and compact fluorescent tube, is a fluorescent lamp designed to replace

an incandescent light bulb; some types fit into light fixtures designed for incandescent

bulbs. The lamps use a tube which is curved or folded to fit into the space of an

incandescent bulb, and a compact electronic ballast in the base of the lamp.

Compared to general-service incandescent lamps giving the same amount of visible

light, CFLs use one-fifth to one-third the electric power, and last eight to fifteen times

longer. A CFL has a higher purchase price than an incandescent lamp, but can save

over five times its purchase price in electricity costs over the lamp's lifetime. [1]Like all

fluorescent lamps, CFLs contain toxic mercury[2] which complicates their disposal. In

many countries, governments have banned the disposal of CFLs together with

regular garbage. These countries have established special collection systems for

CFLs and other hazardous waste.

The principle of operation remains the same as in other fluorescent lighting: electrons

that are bound to mercury atoms are excited to states where they will radiate

ultraviolet light as they return to a lower energy level; this emitted ultraviolet light is

converted into visible light as it strikes the fluorescent coating (as well as into heat

when absorbed by other materials such as glass).

COMPACT FLUORESCENT LAMPS

Install wiring devices of floor and wall

RPTESDC Developed by: Page 52 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

SELF CHECK: 3.1-8

Fluorescent Lamp

I.

1. What is the role of the ballast in a fluorescent lighting fixture?

a. current regulator b. voltage regulator

c. resistance regulator d. pressure regulator

2. It is used to initiate operation of pre heat fluorescent lamps.

a. ballast b. electrode

c. starter d. argon gas

3. There is no starter in this fluorescent lamp system.

a. One (1) lamp pre heat start fluorescent lamp

b. rapid start fluorescent lamp

c. two (2) lamp pre heat start fluorescent lamp

d. single lamp pre heat fluorescent lamp

4. The pre heat fluorescent lamp starter is .

a. normally open b. normally close

c. permanent open d. permanent close

5. A lamp which is a electrode type consisting of a sealed glass tube containing a mixture of

inert gas and mercury vapor.

a. incandescent lamp b. L.E.D. lamp

c. pilot lamp d. fluorescent lamp

II.

1. Explain the difference between a rapid start and pre-heat start fluorescent lamp.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 53 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Answer Key.3.1-8

Fluorescent Lamp

I.

1. a.

2. c.

3. b.

4. a.

5. d.

II.

1. A pre heat start makes use of a bi-metallic starter while rapid start does not require a

starter.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 54 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

LEARNING OUTCOME NO. 2 Install wiring devices

CONTENTS:

• Wiring devices

• PEC provisions on wiring devices

• Procedures in installing wiring devices

• Safety procedures in wiring devices

• GFCI protected outlets.

ASSESSMENT CRITERIA

1. Wiring devices are installed according to the latest edition of Philippine

Electrical Code and National Electrical Code.

2. Wiring devices are installed according to the job requirements

3. Tools/equipment and materials needed for the installation are prepared in line

with job requirements.

4. Safety procedures in installing Wiring devices are strictly observed according

OHS guidelines and procedures.

CONDITIONS:

Equipment Supplies and Materials

o Simulated work place or actual

work place o Wiring devices

o ladder

Learning Materials

Tools

o Linesman’s pliers o Learning elements

o Long nose pliers o Drawing plan

o Diagonal cutting pliers o Books, manuals, and

o Bar level catalogs

o Screw drivers, o Philippine Electrical

o Set of screw drivers Code

o Chisel

ASSESSMENT METHOD

Demonstration

Direct observation and questioning

Install wiring devices of floor and wall

RPTESDC Developed by: Page 55 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Learning Experience

INSTALL WIRING DEVICES

Learning Activities Special Instructions

1. Perform Task Sheet 3.2-1 In this learning outcome you shall prepare

Installing Plug In Type Circuit Breaker tools and materials needed to install wiring

Refer to performance criteria devices.

checklist 3.2-1

2. Read Information Sheet No. 3.2-1 Study the Information Sheet and answer

Power Circuit self-checks to ensure the knowledge of

Answer Self- Check No. 3.2-1 learning outcome are acquired.

Compare answers with answer key 3.2-1

Perform the task sheet, operation sheet and

3. Perform Task Sheet 3.2-2 job sheet in order to meet the needed skills

Installing Convenience Outlet required.

Refer to performance criteria If you have questions you could ask your

checklist 3.2-2

facilitator/trainer.

4. Perform Task Sheet 3.2-3

GFCI Receptacle

Refer to performance criteria

checklist 3.2-3

5. Perform Task Sheet 3.2-4

Installing A.C.U. outlet

Refer to performance criteria

checklist 3.2-4

Install wiring devices of floor and wall

RPTESDC Developed by: Page 56 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Installing Wiring Devices

A. Install electrical wiring devices in accordance with the installation instructions and

listing for each device. Install wiring devices in strict accordance with approved

shop drawings and with equipment manufacturer's recommendations.

B. Verify that wiring devices are compatible with wiring methods, loads served,

construction materials, fire ratings, type of occupancy, and installed environment.

Ensure that wiring devices are rated for the nominal operating voltage and current

of the branch circuit.

C. Install wiring devices in boxes or assemblies that are designed for the purpose and

that are securely fastened in place. Install wiring devices only in boxes that are

clean and free from excess building materials, dirt, and debris.

D. Tighten electrical connectors and terminals according to manufacturers published

torque tightening values.

E. Install wiring devices and cover plates after all raceways, boxes and conductors

are installed, and after all wall preparation, painting and finish work is complete.

F. Verify that box gaps and setbacks comply with Code requirements:

Ensure that openings or gaps around device boxes or plaster rings are effectively

closed with no more than 1/8-inch gap between the opening and the surface

finish.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 57 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Task Sheet 3.2-1

Installing Plug In Type Circuit Breaker

Performance Objective: Given the needed tools and materials, you should be able

to install convenience outlet.

Supplies/Materials: Plug In type Circuit Breaker, Screw drivers, Wire stripper,

Electrician pliers

Steps/Procedures:

1. Test the circuit breakers.

2. Check the rating of the circuit breakers.

4. Mount the circuit breaker with a correct rating to the panel board by referring to

load schedule.

3. Strip the outer insulation from the wires. ( L1 and L2, estimated 1 cm).

4. Terminate wires to plug in type circuit breakers.

5. Inspect your work, when it passes the criteria, let your instructor

check it for you.

6. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 58 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3 .2-1

Power Circuit

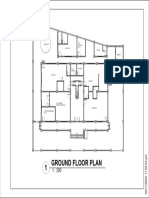

Branch Circuit Layout for Power

Residences typically include several types of receptacle symbols on the electrical

plan. Special receptacles such as ranges and clothes dryers may also be marked

with their amperage requirements.

A basic branch circuit requires two wires or conductors to provide a continuous path

for the flow of electric current, plus a third wire for equipment grounding

Large appliances such as electric ranges, clothes

dryers, and water heaters operate on 240V and

are each fed by their own circuit connected to a

two-pole breaker in the panel board.

The conductor size and overcurrent protection

for 240V loads must be calculated per the NEC

Install wiring devices of floor and wall

RPTESDC Developed by: Page 59 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Locating Receptacles

Install wiring devices of floor and wall

RPTESDC Developed by: Page 60 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Task Sheet 3.2-2

Installing Convenience Outlet

Performance Objective: Given the needed tools and materials, you should be able

to install convenience outlet.

Supplies/Materials: Convenience outlets, Screw drivers, Wire stripper, Electrician

pliers

Steps/Procedures:

1. Mount the convenience outlet to its plate and cover.

2. Make a jumper for duplex and triplex convenience outlet.

3. Strip the outer insulation from the wires. ( L1 and L2, estimated 1 cm).

4. Terminate wires to convenience outlet by referring to electrical plan

5. Connect the power circuit to circuit breaker with a proper rating, by referring to load

schedule.

6. Inspect your work, when it passes the criteria, let your instructor

check it for you.

7. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 61 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Task Sheet 3.2-3

Installing GFCI Receptacle type

Performance Objective: Given the needed tools and materials, you should be able

to install GFCI Receptacle type.

Supplies/Materials: GFCI receptacle type, Screw drivers, Wire stripper, Electrician

pliers

Steps/Procedures:

1. Strip the outer insulation from the wires. ( L1 and L2, estimated 1 cm).

2. Terminate wires to gfci receptacle type as per electrical plan

3. Connect the power circuit to circuit breaker with a proper rating, by referring to load

schedule.

4. Inspect your work, when it passes the criteria, let your instructor

check it for you.

5. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 62 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Task Sheet 3.2-4

Installing A.C.U. Outlet

Performance Objective: Given the needed tools and materials, you should be able

to install A.C.U. Outlet

Supplies/Materials: A.C.U. Outlet, Screw drivers, Wire stripper, Electrician pliers

Steps/Procedures:

1. Strip the outer insulation from the wires. ( L1 and L2, estimated 1 cm).

2. Terminate wires to A.C.U. outlet as per electrical plan

3. Connect the A.C.U. outlet by referring to load schedule.

4. Inspect your work, when it passes the criteria, let your instructor

check it for you.

5. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 63 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

LEARNING OUTCOME NO. 3 Install wiring fixtures/switches

CONTENTS:

• PEC provisions on installing lighting fixtures

• Procedures in installing lighting fixtures

• Safety procedures in installing lighting fixtures

• Floodlights/Spotlights

• Fluorescent Lamps

• CFL

• LED Lamps

• Perimeter Lighting

ASSESSMENT CRITERIA

1. Lighting fixtures are installed according to the latest edition of Philippine

Electrical Code and National Electrical Code.

2. Lighting fixtures are installed according to the job requirements

3. Tools/equipment and materials needed for the installation are prepared in

line with job requirements.

4. Safety procedures in installing lighting fixtures are strictly observed

according OHS guidelines and procedures.

CONDITIONS:

Equipments

Tools and Equipment

o Lineman’s pliers o Wiring booth/Simulated

o Long nose pliers workplace/wiring booth

o Diagonal cutting pliers o PPE

o Set of screw driver

o Claw hammer Learning Materials

o Hacksaw o Learning elements

o Measuring tools o Manuals

o reamer o Books and

o Ladder o Philippine Electrical

Code/National

Electrical Code,

Latest Edition

ASSESSMENT METHOD

Demonstration

Direct observation and questioning

Install wiring devices of floor and wall

RPTESDC Developed by: Page 64 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Learning Experience

Install Wiring Fixtures/Switches

Learning Activities Special Instructions

1. Job Sheet 3.3-1 In this learning outcome you shall

Two (2) lamps controlled by duplex switch. prepare tools and materials needed to

2. Job Sheet 3.3-2 install wiring fixtures/switches.

One (1) lamp controlled from three

locations. Study the Information Sheet and

3. Job Sheet 3.3-3 answer self-checks to ensure the

Assembling 20 Watts Pre Heat Fluorescent knowledge of learning outcome are

Lamp Fixture acquired.

4. Job Sheet 3.3-4

Wiring of Fluorescent Lamp Fixture. Perform the task sheet, operation

5. Read Information Sheet No. 3.3-1 sheet and job sheet in order to meet

Installing Closed Circuit Television (CCTV) the needed skills required.

Answer Self- Check No. 3.3-1

Compare answers with answer key 3.3-1 If you have questions you could ask

your facilitator/trainer.

6. Perform Task Sheet 3.3-1.

Crimping BNC Connector to RG 59 cable.

7. Perform Task Sheet 3.3-2

Installing Hard Disk Drive to the DVR.

8. Perform Job Sheet 3.3-5

Installing CCTV

9. Read Information Sheet No. 3.3-2

Fire Detection and Alarm System (FDAS)

Answer Self- Check No. 3.3-2

Compare answers with answer key 3.3-2

10. Perform Task Sheet 3.3-3.

Testing of Fire Alarm Bell (Sounders)

11. Job Sheet 3.3-6

Installing Fire Detection and Alarm

System (FDAS)

Install wiring devices of floor and wall

RPTESDC Developed by: Page 65 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Installing Lighting Fixtures/Switches

A. Install lighting fixtures and switches in accordance with the installation instructions

and requirements. Install lighting fixtures and switches in strict accordance with

approved shop drawings and with equipment manufacturer's recommendations.

B. Verify that lighting fixtures are compatible with wiring methods, loads served,

construction materials, fire ratings, type of occupancy, and installed environment.

Ensure that lamps and switches are rated for the nominal operating voltage of the

branch circuit.

C. Install lighting fixtures and switches in boxes or assemblies that are designed for

the purpose and that are securely fastened in place. Install lighting fixtures and

switches only in boxes that are clean and free from excess building materials,

dirt, and debris.

D. Install switches and cover plates after all raceways, boxes and conductors

are installed, and after all wall preparation, painting and finish work is complete.

E. Verify that box gaps and setbacks comply with Code requirements:

Ensure that openings or gaps around device boxes or plaster rings are effectively

closed with no more than 1/8-inch gap between the opening and the surface

finish.

F. In residential occupancies, wall switches should normally be located at the latch

side of doors Wall switches are normally mounted at a 1.5 m. height

Verify mounting heights when installing switches. The mounting height of wall-

mounted switches is generally measured from the finished floor surface to the

center line of the box.

G. Minimum size of wire to be used shall be 2.0 mm² TW rated for 600V AC.

Light control switches shall be rated 10A, 230V AC.

Install wiring devices of floor and wall

RPTESDC Developed by: Page 66 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Job Sheet 3.3-1

Two (2) Lamps Controlled by Duplex Switch

Performance Objective: Given the needed tools and materials, you should be able

to install two lamps controlled by duplex switch

Supplies/Materials: Incandescent lamps, duplex switch, Screw drivers, Wire

stripper, Electrician pliers

Steps/Procedures:

1. Prepare a single line diagram based on the lay out plan, indicate the number of

wire per line..

2. Prepare a block diagram based on the lay out plan

3. Cable pulling based on the single line diagram.

4. Connect lighting fixture and switches by referring on the block diagram.

5. Check/Test the lighting circuit with the use of ohmmeter.

6. Let your instructor check it again for you.

7. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 67 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Job Sheet 3.3-2

One (1) Lamp Controlled from three locations

Performance Objective: Given the needed tools and materials, you should be able

to install two lamps controlled by duplex switch

Supplies/Materials: Incandescent lamp,(2) three way switch, (1) four way switch,

Screw drivers, Wire stripper, Electrician pliers

Steps/Procedures:

1. Prepare a single line diagram based on the lay out plan, indicate the number of

wire per line..

2. Prepare a block diagram based on the lay out plan

3. Cable pulling based on the single line diagram.

4. Connect lighting fixture and switches by referring on the block diagram.

5. Check/Test the lighting circuit with the use of ohmmeter.

6. Let your instructor check it again for you.

7. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 68 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Job Sheet 3.3-3

Assembling 20 Watts Pre Heat Fluorescent Lamp Fixture

Performance Objective: Given the needed tools and materials, you should be able

to assemble 20 watts pre heat fluorescent lamp fixture.

Supplies/Materials: Fluorescent lamp (w/ complete accessories), Single pole switch

Screw drivers, Wire stripper, Electrician pliers

Steps/Procedures:

1. Prepare the components and parts of 40 watts pre heat fluorescent lamp fixture.

2. Mount the following: to the frame of lamp fixture.

a. ballast

b. starter socket

c. lamp holders

3. Check the mounting of the above components, refer to manufacturer’s torque

specifications.

4. Let your instructor check it again for you.

5. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 69 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

Job Sheet 3.3-4

Wiring of Pre Heat Fluorescent Lamp

Performance Objective: Given the needed tools and materials, you should be able

to connect the wirings pre heat fluorescent lamp.

Supplies/Materials: Fluorescent lamp (w/ complete accessories), Single pole switch

Screw drivers, Wire stripper, Electrician pliers

Steps/Procedures:

1. Prepare a schematic diagram of pre heat fluorescent lamp.

2. Connect the wiring of pre heat fluorescent lamp, by referring on the schematic

diagram.

3. Check the loose connections.

4. Loop check the wiring connection.

5. Let your instructor check it again for you.

6. Perform house keeping

Assessment Method:

• Direct observation

• Interview

Install wiring devices of floor and wall

RPTESDC Developed by: Page 70 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105

and auxiliary outlets

INFORMATION SHEET NO. 3.3-1

INSTALL CLOSED CIRCUIT TELEVISION (CCTV)

LEARNINGOBJECTIVE:

After reading this Information Sheet you should able to:

1. Identify the components tools and materials needed in installing closed

circuit television.

2. Apply the provision and specification in installing closed circuit television

3. Install closed circuit television.

4. Value the importance of using closed circuit television.

CLOSED CIRCUIT TELEVISION SYSTEM

CCTV (CLOSED CIRCUIT TELEVISION) Closed-circuit television (CCTV) is the use

of video cameras to transmit a signal to a specific place, on a limited set of monitors.

It differs from broadcast television in that the signal is not openly transmitted, though

it may employ point to point (P2P), point to multipoint, or mesh wireless links.

Reasons of using CCTV

Crime prevention and investigation tool

Statistics point to major reductions in the amount of crime being committed

where there are cameras installed. An article in 'New Scientist' magazine

showed that simply installing a system can reduce crime, in the areas covered,

by over 95%.

Generally, once a Camera system is installed, it will only be fools who attempt

to perpetrate offences within its field of view. These are often caught but for

Install wiring devices of floor and wall

RPTESDC Developed by: Page 71 of

mounted outlets, lighting fixtures/switches, JESSIE D. RECTO

-Cainta 105