Professional Documents

Culture Documents

Ab 036029 001 - 05312022

Ab 036029 001 - 05312022

Uploaded by

JAWAHAR TCopyright:

Available Formats

You might also like

- Module 5 Compressive and Flexural Strength of Wood NewDocument31 pagesModule 5 Compressive and Flexural Strength of Wood NewEUREKA JANAH MENDOZANo ratings yet

- Tub Mill Fist Piece & Inprocess Inspection ReportDocument1 pageTub Mill Fist Piece & Inprocess Inspection ReportZeeshan PathanNo ratings yet

- Principles of Geotechnical Engineering-149-151Document3 pagesPrinciples of Geotechnical Engineering-149-151Andrea Arroba0% (1)

- Notes:: Fit-UpDocument1 pageNotes:: Fit-UpMuhammad Fahmi MahmudNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Ramp SectionDocument1 pageRamp SectionBhavya PatelNo ratings yet

- Typ 2Document1 pageTyp 2aedlk.cpwdNo ratings yet

- Wall Elevation - C - Kitchen - Second Floor: RevisionsDocument1 pageWall Elevation - C - Kitchen - Second Floor: RevisionsAnishma AyyappanNo ratings yet

- ACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Document1 pageACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Aecom IndiaNo ratings yet

- Structural Notes: Typ. CHB Partition On Suspended Slab 7Document1 pageStructural Notes: Typ. CHB Partition On Suspended Slab 7Joshua VacaroNo ratings yet

- PLN001 Sh3of4Document1 pagePLN001 Sh3of4Rodney ZephaniaNo ratings yet

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- Ac 036437 001 - 05312022Document1 pageAc 036437 001 - 05312022JAWAHAR TNo ratings yet

- General Notes:: Typical Section of R.C.C. Storm Water DrainDocument2 pagesGeneral Notes:: Typical Section of R.C.C. Storm Water Drainbijnor officeNo ratings yet

- RCC Drawing of Open Drain 11-10-2022Document16 pagesRCC Drawing of Open Drain 11-10-2022AKB CONSULTANTSNo ratings yet

- Al Nakhli Tunnel On Dubai-Hatta Road-Op3Document1 pageAl Nakhli Tunnel On Dubai-Hatta Road-Op3salma.alshamsi80No ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesnauman faiziNo ratings yet

- A 616 Typical DetailsDocument1 pageA 616 Typical DetailsEmmanuel InfanteNo ratings yet

- Acm TSC VS MF DWG ST 2001Document1 pageAcm TSC VS MF DWG ST 2001Aecom IndiaNo ratings yet

- Ab 036262 003 - 05312022Document1 pageAb 036262 003 - 05312022JAWAHAR TNo ratings yet

- Position of Services in Road Reserves: Typical Standard DetailsDocument1 pagePosition of Services in Road Reserves: Typical Standard DetailsRenier JoubertNo ratings yet

- Concept Plan-R1Document1 pageConcept Plan-R1akhil krisNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- General Notes: Ugt Tank (15000x10200x2000) Total Capacity: 3,12,000 L Pump RoomDocument1 pageGeneral Notes: Ugt Tank (15000x10200x2000) Total Capacity: 3,12,000 L Pump RoomDary ConstanceNo ratings yet

- Structural Drawings Extension LondonDocument1 pageStructural Drawings Extension LondonVlad CiupituNo ratings yet

- General: Shoring of ExcavationDocument7 pagesGeneral: Shoring of ExcavationshanihakkNo ratings yet

- Section 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byDocument1 pageSection 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byPaschal MazikuNo ratings yet

- Typ 1Document1 pageTyp 1aedlk.cpwdNo ratings yet

- Dpw-1 Retaining Wall 1028' RFTDocument1 pageDpw-1 Retaining Wall 1028' RFTM JAVEDNo ratings yet

- Saudi Arabian Oil Company: Co2 Fire Suppression System Piping LayoutDocument1 pageSaudi Arabian Oil Company: Co2 Fire Suppression System Piping Layoutsaleem shahidNo ratings yet

- Standard NZ Footbridge With Horizontal Wires Rev A March 2017 Full SetDocument7 pagesStandard NZ Footbridge With Horizontal Wires Rev A March 2017 Full SetbetsegaNo ratings yet

- DRG 1Document1 pageDRG 1Palak BhatiaNo ratings yet

- 1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)Document1 page1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)rohanZorbaNo ratings yet

- CondenserDocument1 pageCondenserKrizza Joyce AblolaNo ratings yet

- Viva School of Arch.: ElevationDocument17 pagesViva School of Arch.: ElevationNeha DasNo ratings yet

- Structural Notes: GeneralDocument1 pageStructural Notes: GeneralKris King Domingo JacobNo ratings yet

- 27 Sheet Standard DetailsDocument1 page27 Sheet Standard DetailsFun TonNo ratings yet

- 4525 S HSK Ew 010 SeriesDocument10 pages4525 S HSK Ew 010 SeriesBartosz ZaforemskiNo ratings yet

- JERSD J 0071 Instrument StandpipesDocument1 pageJERSD J 0071 Instrument StandpipescesarvalenciaperdomoNo ratings yet

- 12.stairs 3 PDFDocument1 page12.stairs 3 PDFJohnny cusoNo ratings yet

- 010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000Document1 page010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000Harsha nrNo ratings yet

- Base Plate 200 X 200: For ApprovalDocument1 pageBase Plate 200 X 200: For ApprovalManthan AgrawalNo ratings yet

- 132kV Isolator WESDocument1 page132kV Isolator WESManthan AgrawalNo ratings yet

- G FootingsDocument9 pagesG FootingsRiham Massoud SobhyNo ratings yet

- APD STR GendaranDocument12 pagesAPD STR GendaranBp SodokNo ratings yet

- 23 - Sheet-ELEVATIONS 1&2Document1 page23 - Sheet-ELEVATIONS 1&2Fun TonNo ratings yet

- L 0.3L 0.3L 0.20L 0.3L: Future Floor 3Document1 pageL 0.3L 0.3L 0.20L 0.3L: Future Floor 3Anonymous cclKewWGVNo ratings yet

- Elevation A - Montreal City Hall-FurnDocument1 pageElevation A - Montreal City Hall-FurnMukhlis AbroriNo ratings yet

- Toureen Group: Stage3 - Piling + UnderpinningDocument1 pageToureen Group: Stage3 - Piling + UnderpinningAnonymous qEPNPwANo ratings yet

- RCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendDocument1 pageRCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendSafi Zabihullah SafiNo ratings yet

- 02 - 08 - 2022 - ISULAN Shop Drawings-Layout6Document1 page02 - 08 - 2022 - ISULAN Shop Drawings-Layout6Troy ValeriaNo ratings yet

- KerbsDocument1 pageKerbsMubashar Islam JadoonNo ratings yet

- Section B-B: C C 1a 1aDocument1 pageSection B-B: C C 1a 1aAli KayaNo ratings yet

- Preliminary: Lineshop LineshopDocument1 pagePreliminary: Lineshop LineshopDarren LaiNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- SC-348 - Carbonic Solution Injector - R2Document1 pageSC-348 - Carbonic Solution Injector - R2sajanNo ratings yet

- Shear Wall Notes:: SCALE: 3/4" 1'-0"Document1 pageShear Wall Notes:: SCALE: 3/4" 1'-0"IamJace C.No ratings yet

- Notes:-: Structural ConsultantsDocument1 pageNotes:-: Structural ConsultantsHarbhajan SinghNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesWaqarNo ratings yet

- QP10-U-703 Rev0 Typical Line MarkerDocument1 pageQP10-U-703 Rev0 Typical Line MarkernawajhaNo ratings yet

- BPS-UTI-501-R.C.C.Road DetailDocument1 pageBPS-UTI-501-R.C.C.Road Detailsri projectssNo ratings yet

- Parallel and Series CircuitDocument13 pagesParallel and Series CircuitsafaNo ratings yet

- GenChem 1 Q1 M2Document36 pagesGenChem 1 Q1 M2Jabeguero Marvelyn JessicaNo ratings yet

- Chemical EquilibriumDocument29 pagesChemical EquilibriumAjay ChoudharyNo ratings yet

- 4.determination of Stefan Boltzmann ConstantDocument3 pages4.determination of Stefan Boltzmann ConstantSuraj RoyNo ratings yet

- Padhle 10th - Electricity Lecture SlidesDocument31 pagesPadhle 10th - Electricity Lecture Slidespriyanjalnautiyal328No ratings yet

- JJ205 Engineering Mechanic Chapter 4 Jj205Document9 pagesJJ205 Engineering Mechanic Chapter 4 Jj205Ah TiangNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant Test ProcedurDocument4 pagesPerformance and Efficiency Test of A Refrigeration Plant Test ProcedurEJ TolentinoNo ratings yet

- HDRDocument34 pagesHDRMoh LisajidinNo ratings yet

- Impact Test PDFDocument3 pagesImpact Test PDFالشهاب ناروتوNo ratings yet

- Finite Element Analysis of Natural Fibers Composites: A ReviewDocument23 pagesFinite Element Analysis of Natural Fibers Composites: A ReviewDiptoNo ratings yet

- 2nd PPT Torsional IrregulartitiesDocument20 pages2nd PPT Torsional IrregulartitiesAnkit DalviNo ratings yet

- Material Sci by Vishal SirDocument53 pagesMaterial Sci by Vishal SirMsraoNo ratings yet

- Airex C70: Universal Structural FoamDocument3 pagesAirex C70: Universal Structural FoamBaris senelNo ratings yet

- Assignment 1Document2 pagesAssignment 1Calvin LabialNo ratings yet

- Prospekt Bazenove Jednotky enDocument4 pagesProspekt Bazenove Jednotky envvukmirovic_2No ratings yet

- Flywheel For HNDDocument115 pagesFlywheel For HNDUchenna ClaudioNo ratings yet

- Earthquakes: What Is An Earthquake? Click Here To Find OutDocument43 pagesEarthquakes: What Is An Earthquake? Click Here To Find Outemo mHAYNo ratings yet

- Thermal Analysis of An Aluminum Heat SinkDocument7 pagesThermal Analysis of An Aluminum Heat Sinkapi-247715646No ratings yet

- Al Ut fm1 U4 TestDocument2 pagesAl Ut fm1 U4 TestEliNo ratings yet

- Fluid Mechanics ProbsetDocument2 pagesFluid Mechanics ProbsetJanine ArtigoNo ratings yet

- Circular Motion and GravitationDocument21 pagesCircular Motion and GravitationKhawaja EshaNo ratings yet

- Carbon Nanotubes:: Figure 1: Schematic of Carbon Nanotube Made From Rolled Graphene SheetDocument3 pagesCarbon Nanotubes:: Figure 1: Schematic of Carbon Nanotube Made From Rolled Graphene SheetShreyashis SealNo ratings yet

- Monel Alloy 400 PropertiesDocument16 pagesMonel Alloy 400 PropertiesVelibor StokicNo ratings yet

- PCB Layout Thermal Design Guide An-EDocument18 pagesPCB Layout Thermal Design Guide An-EpkNo ratings yet

- Practice Test I (Basic Science) - SolvedDocument18 pagesPractice Test I (Basic Science) - SolvedUmesh PatilNo ratings yet

- Spe 29363 MSDocument11 pagesSpe 29363 MSswaala4realNo ratings yet

Ab 036029 001 - 05312022

Ab 036029 001 - 05312022

Uploaded by

JAWAHAR TOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ab 036029 001 - 05312022

Ab 036029 001 - 05312022

Uploaded by

JAWAHAR TCopyright:

Available Formats

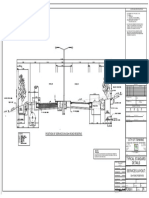

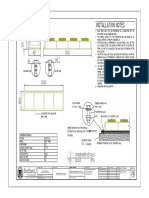

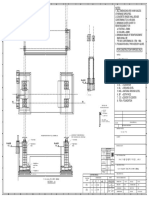

NOTES:

NOTES:

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

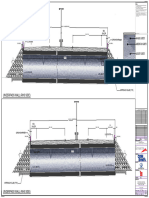

1. NON-PRESSURE CONTAINING SLEEVES

SHALL BE FABRICATED OR

SLEEVE HALVES

MANUFACTURED FROM STEEL MEETING

THE MATERIAL SPECIFICATIONS OF THE CONSTRUCTION

SEE DETAIL-2

CODE. ALL SLEEVES SHOULD BE INSTALLED

IN ACCORDANCE WITH THIS STD. DRAWING.

3000 (+

- 100 ) 2. THESE SLEEVES MAY BE USED FOR:

STANDARD LENGTH (SEE NOTE-4) - REINFORCING MINIMUM WALL THICKNESS

VIOLATIONS DUE TO EXTERNAL CORROSION

OR EXCESSIVE GRINDING.

BOTH SIDES - REINFORCING DENTS WITHOUT GOUGES.

SEE NOTE-6 tb - CORROSION BARRIERS.

3. THESE SLEEVES SHALL NOT BE USED FOR :

- REPAIRING LEAKS.

BUTT STRAP

- REPAIRING MINIMUM WALL THICKNESS

PIPE VIOLATIONS DUE TO INTERNAL CORROSION.

C

- COUPLING SECTIONS OF PIPE TOGETHER.

4. DO NOT MODIFY THESE SLEEVES IN ANY

MANNER WITHOUT THE APPROVAL OF CSD.

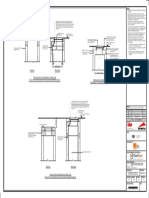

SHOP WELD

(TYP. BOTH SIDES) 5. REPAIR SLEEVE FIT-UP SHOULD BE AS TIGHT

AS POSSIBLE. IN ANY CASE, THE MAXIMUM

GAP BETWEEN THE SLEEVE AND PIPE

SHOP WELDS SURFACE AT THE ENDS OF THE SLEEVE

(BOTH SIDES) SHALL NOT EXCEED 3.2mm (⅛" ). TO

FIELD BEVEL SLEEVE 37° PROVIDE THE BEST STRESS SHARING

PRIOR TO FIT-UP AND INSTALLATION CAPABILITY OF THIS SLEEVE, IT IS

OF PRE-FORMED FILLER PIECES RECOMMENDED TO FILL THE ANNULAR

SEE DETAIL-1 (TYP. ALL SIDES) SPACE BETWEEN THE SLEEVE AND PIPE

SEE DETAIL-3 WALL WITH A HARDENABLE EPOXY MATERIAL.

IF NECESSARY, USE CHAINS AND HYDRAULIC

BOTH

JACKS DURING THE FIT-UP. DO NOT

SIDES tb REMOVE THESE RESTRAINTS UNTIL THE

t

SEE NOTE-6 s WELDERS HAVE DEPOSITED AT LEAST

t

b 9.6mm (⅜" ) OR 25% OF THE REQUIRED

FIT-UP

20° BEVEL LONGITUDINAL FILLET WELD SIZE ON BOTH

+ 5° FILLER PIECES SIDES.

-

CUT TO FIT

6. WELDERS AND WELDING PROCEDURES SHALL

(TYP.)

BE QUALIFIED TO EITHER API 1104 OR

ASME SECTION IX. ALL WELDS SHALL BE

MADE WITH LOW HYDROGEN ELECTRODES.

THE WELDING SEQUENCE FOR A STANDARD

3,000 mm (10 ft.) SLEEVE IS :

- WELD BOTH LONGITUDINAL FILLET WELDS.

SHOP WELDS

- FIT-UP AND WELD ALL THE FILLER PIECES.

SLEEVE ts (TYP.)

- WELD BOTH CIRCUMFERENTIAL FILLET

GIRTH WELDS ONE AT A TIME OR

SIMULTANEOUSLY. NOTE: IF APPROVAL HAS

PIPE t BEEN GIVEN BY CSD TO SHORTEN

THE SLEEVE LENGTH TO LESS THAN

1500mm (5 ft.) , WELD ONE END OF THE

SLEEVE AT A TIME, ALLOWING IT TO

DETAIL-1 COOL TO AMBIENT TEMPERATURE BEFORE

STARTING THE OTHER WELD.

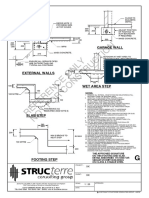

SEE NOTE-5

7. ALL FIELD WELDS, INCLUDING THE SHOP

DETAIL-3

WELDS SHALL HAVE A FINAL MAGNETIC

PARTICLE OR LIQUID PENETRANT (MT OR PT)

DETAIL-2

EXAMINATION.

SEE NOTE-5

8. REFER TO SAEP-310 FOR ADDITIONAL

BOTH SIDES INFORMATION.

BOTH SIDES & ENDS

SEE NOTE-6 tb (TYP.)

SEE NOTE-6

SCALE:

SCALE:

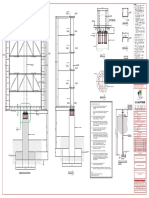

REVISION VALIDATION

REVISION VALIDATION

BOTH ENDS

THIS REVISION NO.

THIS REVISION NO. 07 ISCOVERED,

IS COVERED,FOR

FORALL

ALLAPPROVAL

APPROVAL AND

AND CERTIFICATION

CERTIFICATION

(TYP.) REQUIREMENTS, PER SAEP-334,

REQUIREMENTS, PER SAEP-334,UNDER

UNDERDRAWING

DRAWING COMPLETION

COMPLETION CERTIFICATE

CERTIFICATE NO:

NO:

ts

SEE NOTE-6 30027516-0522-013

DESIGN CERTIFICATION

DESIGN CERTIFICATION REVIEW FOR

REVIEW KEY DRAWINGS

FOR KEY DRAWINGS OTHER

OTHER

(DESIGN AGENCY)

(DESIGN AGENCY) REQUIRED

REQUIRED (SAUDI ARAMCO)

(SAUDI ARAMCO)

| ENGG./DATE

ENGG./DATE CERTIFIED BY/DATE

CERTIFIED BY/DATE CONST. AGENCY/DATE OPERATIONS/DATE

CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

BY/DATE

MSK KMM MSK KMM

05/24/22 05/24/22 05/24/22 05/24/22

REV.NO. DATE

REV.NO. DATE REVISION DESCRIPTION

REVISION DESCRIPTION

07 05/22/22 REVISION UPDATE

JOB ORDER/EWO NO.

JOB ORDER/EWO NO.

THIS REVISION

THIS REVISION IS

IS NOT

NOT TO

TO BE

BE USED

USED FOR

FOR

30027516 CONSTRUCTION UNTIL CERTIFIED

CONSTRUCTION UNTIL CERTIFIED AND

AND DATED

DATED

SAUDI ARABIAN OIL

SAUDI ARABIAN OIL COMPANY

COMPANY

DRAWING TYPE

DRAWING TYPE

INSTALLATION OF PIPELINE STD

REPAIR SLEEVES

(NON-PRESSURE CONTAINIG)

STD.DWG. SAUDI ARABIA

SAUDI ARABIA

PLANT NO.

PLANT NO. INDEX

INDEX DRAWING NUMBER

DRAWING NUMBER SHT. NO.

SHT. NO. REV. NO.

REV. NO.

990 L AB-036029 001 07

Saudi Aramco 2634 ENG. (05/05)

RESTRICTED VECTOR CADD-05

You might also like

- Module 5 Compressive and Flexural Strength of Wood NewDocument31 pagesModule 5 Compressive and Flexural Strength of Wood NewEUREKA JANAH MENDOZANo ratings yet

- Tub Mill Fist Piece & Inprocess Inspection ReportDocument1 pageTub Mill Fist Piece & Inprocess Inspection ReportZeeshan PathanNo ratings yet

- Principles of Geotechnical Engineering-149-151Document3 pagesPrinciples of Geotechnical Engineering-149-151Andrea Arroba0% (1)

- Notes:: Fit-UpDocument1 pageNotes:: Fit-UpMuhammad Fahmi MahmudNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Ramp SectionDocument1 pageRamp SectionBhavya PatelNo ratings yet

- Typ 2Document1 pageTyp 2aedlk.cpwdNo ratings yet

- Wall Elevation - C - Kitchen - Second Floor: RevisionsDocument1 pageWall Elevation - C - Kitchen - Second Floor: RevisionsAnishma AyyappanNo ratings yet

- ACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Document1 pageACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Aecom IndiaNo ratings yet

- Structural Notes: Typ. CHB Partition On Suspended Slab 7Document1 pageStructural Notes: Typ. CHB Partition On Suspended Slab 7Joshua VacaroNo ratings yet

- PLN001 Sh3of4Document1 pagePLN001 Sh3of4Rodney ZephaniaNo ratings yet

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- Ac 036437 001 - 05312022Document1 pageAc 036437 001 - 05312022JAWAHAR TNo ratings yet

- General Notes:: Typical Section of R.C.C. Storm Water DrainDocument2 pagesGeneral Notes:: Typical Section of R.C.C. Storm Water Drainbijnor officeNo ratings yet

- RCC Drawing of Open Drain 11-10-2022Document16 pagesRCC Drawing of Open Drain 11-10-2022AKB CONSULTANTSNo ratings yet

- Al Nakhli Tunnel On Dubai-Hatta Road-Op3Document1 pageAl Nakhli Tunnel On Dubai-Hatta Road-Op3salma.alshamsi80No ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract Pagesnauman faiziNo ratings yet

- A 616 Typical DetailsDocument1 pageA 616 Typical DetailsEmmanuel InfanteNo ratings yet

- Acm TSC VS MF DWG ST 2001Document1 pageAcm TSC VS MF DWG ST 2001Aecom IndiaNo ratings yet

- Ab 036262 003 - 05312022Document1 pageAb 036262 003 - 05312022JAWAHAR TNo ratings yet

- Position of Services in Road Reserves: Typical Standard DetailsDocument1 pagePosition of Services in Road Reserves: Typical Standard DetailsRenier JoubertNo ratings yet

- Concept Plan-R1Document1 pageConcept Plan-R1akhil krisNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- General Notes: Ugt Tank (15000x10200x2000) Total Capacity: 3,12,000 L Pump RoomDocument1 pageGeneral Notes: Ugt Tank (15000x10200x2000) Total Capacity: 3,12,000 L Pump RoomDary ConstanceNo ratings yet

- Structural Drawings Extension LondonDocument1 pageStructural Drawings Extension LondonVlad CiupituNo ratings yet

- General: Shoring of ExcavationDocument7 pagesGeneral: Shoring of ExcavationshanihakkNo ratings yet

- Section 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byDocument1 pageSection 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byPaschal MazikuNo ratings yet

- Typ 1Document1 pageTyp 1aedlk.cpwdNo ratings yet

- Dpw-1 Retaining Wall 1028' RFTDocument1 pageDpw-1 Retaining Wall 1028' RFTM JAVEDNo ratings yet

- Saudi Arabian Oil Company: Co2 Fire Suppression System Piping LayoutDocument1 pageSaudi Arabian Oil Company: Co2 Fire Suppression System Piping Layoutsaleem shahidNo ratings yet

- Standard NZ Footbridge With Horizontal Wires Rev A March 2017 Full SetDocument7 pagesStandard NZ Footbridge With Horizontal Wires Rev A March 2017 Full SetbetsegaNo ratings yet

- DRG 1Document1 pageDRG 1Palak BhatiaNo ratings yet

- 1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)Document1 page1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)rohanZorbaNo ratings yet

- CondenserDocument1 pageCondenserKrizza Joyce AblolaNo ratings yet

- Viva School of Arch.: ElevationDocument17 pagesViva School of Arch.: ElevationNeha DasNo ratings yet

- Structural Notes: GeneralDocument1 pageStructural Notes: GeneralKris King Domingo JacobNo ratings yet

- 27 Sheet Standard DetailsDocument1 page27 Sheet Standard DetailsFun TonNo ratings yet

- 4525 S HSK Ew 010 SeriesDocument10 pages4525 S HSK Ew 010 SeriesBartosz ZaforemskiNo ratings yet

- JERSD J 0071 Instrument StandpipesDocument1 pageJERSD J 0071 Instrument StandpipescesarvalenciaperdomoNo ratings yet

- 12.stairs 3 PDFDocument1 page12.stairs 3 PDFJohnny cusoNo ratings yet

- 010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000Document1 page010-029 Precast Sewer Maintenance Holes Sewers Less or Equal To DN 300 Depth Less or Equal To 1200 and 1200-6000Harsha nrNo ratings yet

- Base Plate 200 X 200: For ApprovalDocument1 pageBase Plate 200 X 200: For ApprovalManthan AgrawalNo ratings yet

- 132kV Isolator WESDocument1 page132kV Isolator WESManthan AgrawalNo ratings yet

- G FootingsDocument9 pagesG FootingsRiham Massoud SobhyNo ratings yet

- APD STR GendaranDocument12 pagesAPD STR GendaranBp SodokNo ratings yet

- 23 - Sheet-ELEVATIONS 1&2Document1 page23 - Sheet-ELEVATIONS 1&2Fun TonNo ratings yet

- L 0.3L 0.3L 0.20L 0.3L: Future Floor 3Document1 pageL 0.3L 0.3L 0.20L 0.3L: Future Floor 3Anonymous cclKewWGVNo ratings yet

- Elevation A - Montreal City Hall-FurnDocument1 pageElevation A - Montreal City Hall-FurnMukhlis AbroriNo ratings yet

- Toureen Group: Stage3 - Piling + UnderpinningDocument1 pageToureen Group: Stage3 - Piling + UnderpinningAnonymous qEPNPwANo ratings yet

- RCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendDocument1 pageRCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendSafi Zabihullah SafiNo ratings yet

- 02 - 08 - 2022 - ISULAN Shop Drawings-Layout6Document1 page02 - 08 - 2022 - ISULAN Shop Drawings-Layout6Troy ValeriaNo ratings yet

- KerbsDocument1 pageKerbsMubashar Islam JadoonNo ratings yet

- Section B-B: C C 1a 1aDocument1 pageSection B-B: C C 1a 1aAli KayaNo ratings yet

- Preliminary: Lineshop LineshopDocument1 pagePreliminary: Lineshop LineshopDarren LaiNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- SC-348 - Carbonic Solution Injector - R2Document1 pageSC-348 - Carbonic Solution Injector - R2sajanNo ratings yet

- Shear Wall Notes:: SCALE: 3/4" 1'-0"Document1 pageShear Wall Notes:: SCALE: 3/4" 1'-0"IamJace C.No ratings yet

- Notes:-: Structural ConsultantsDocument1 pageNotes:-: Structural ConsultantsHarbhajan SinghNo ratings yet

- Saudi Arabian Oil Company: NotesDocument1 pageSaudi Arabian Oil Company: NotesWaqarNo ratings yet

- QP10-U-703 Rev0 Typical Line MarkerDocument1 pageQP10-U-703 Rev0 Typical Line MarkernawajhaNo ratings yet

- BPS-UTI-501-R.C.C.Road DetailDocument1 pageBPS-UTI-501-R.C.C.Road Detailsri projectssNo ratings yet

- Parallel and Series CircuitDocument13 pagesParallel and Series CircuitsafaNo ratings yet

- GenChem 1 Q1 M2Document36 pagesGenChem 1 Q1 M2Jabeguero Marvelyn JessicaNo ratings yet

- Chemical EquilibriumDocument29 pagesChemical EquilibriumAjay ChoudharyNo ratings yet

- 4.determination of Stefan Boltzmann ConstantDocument3 pages4.determination of Stefan Boltzmann ConstantSuraj RoyNo ratings yet

- Padhle 10th - Electricity Lecture SlidesDocument31 pagesPadhle 10th - Electricity Lecture Slidespriyanjalnautiyal328No ratings yet

- JJ205 Engineering Mechanic Chapter 4 Jj205Document9 pagesJJ205 Engineering Mechanic Chapter 4 Jj205Ah TiangNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant Test ProcedurDocument4 pagesPerformance and Efficiency Test of A Refrigeration Plant Test ProcedurEJ TolentinoNo ratings yet

- HDRDocument34 pagesHDRMoh LisajidinNo ratings yet

- Impact Test PDFDocument3 pagesImpact Test PDFالشهاب ناروتوNo ratings yet

- Finite Element Analysis of Natural Fibers Composites: A ReviewDocument23 pagesFinite Element Analysis of Natural Fibers Composites: A ReviewDiptoNo ratings yet

- 2nd PPT Torsional IrregulartitiesDocument20 pages2nd PPT Torsional IrregulartitiesAnkit DalviNo ratings yet

- Material Sci by Vishal SirDocument53 pagesMaterial Sci by Vishal SirMsraoNo ratings yet

- Airex C70: Universal Structural FoamDocument3 pagesAirex C70: Universal Structural FoamBaris senelNo ratings yet

- Assignment 1Document2 pagesAssignment 1Calvin LabialNo ratings yet

- Prospekt Bazenove Jednotky enDocument4 pagesProspekt Bazenove Jednotky envvukmirovic_2No ratings yet

- Flywheel For HNDDocument115 pagesFlywheel For HNDUchenna ClaudioNo ratings yet

- Earthquakes: What Is An Earthquake? Click Here To Find OutDocument43 pagesEarthquakes: What Is An Earthquake? Click Here To Find Outemo mHAYNo ratings yet

- Thermal Analysis of An Aluminum Heat SinkDocument7 pagesThermal Analysis of An Aluminum Heat Sinkapi-247715646No ratings yet

- Al Ut fm1 U4 TestDocument2 pagesAl Ut fm1 U4 TestEliNo ratings yet

- Fluid Mechanics ProbsetDocument2 pagesFluid Mechanics ProbsetJanine ArtigoNo ratings yet

- Circular Motion and GravitationDocument21 pagesCircular Motion and GravitationKhawaja EshaNo ratings yet

- Carbon Nanotubes:: Figure 1: Schematic of Carbon Nanotube Made From Rolled Graphene SheetDocument3 pagesCarbon Nanotubes:: Figure 1: Schematic of Carbon Nanotube Made From Rolled Graphene SheetShreyashis SealNo ratings yet

- Monel Alloy 400 PropertiesDocument16 pagesMonel Alloy 400 PropertiesVelibor StokicNo ratings yet

- PCB Layout Thermal Design Guide An-EDocument18 pagesPCB Layout Thermal Design Guide An-EpkNo ratings yet

- Practice Test I (Basic Science) - SolvedDocument18 pagesPractice Test I (Basic Science) - SolvedUmesh PatilNo ratings yet

- Spe 29363 MSDocument11 pagesSpe 29363 MSswaala4realNo ratings yet