Professional Documents

Culture Documents

CH 2 Toxicology

Uploaded by

Mohammad YounesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH 2 Toxicology

Uploaded by

Mohammad YounesCopyright:

Available Formats

Toxicology

Chapter 2

1 Apr 6, 2020 Chemical process safety

Toxicology

Definitions

Toxicological studies

Dose-response correlations

Threshold limit values

Examples

2 Chemical process safety Apr 6, 2020

Definitions

Toxicology is the quantitative and qualitative study of

the adverse effects of toxicants on biological organisms

Toxicant is a chemical or physical agent that produces

adverse effects on biological organisms including

dusts, fibers, noise and radiation

Toxicity is a property of the agent describing its effect

on biological organisms.

3 Chemical process safety Apr 6, 2020

Three Types of Toxic Hazardous

Materials

Chemical Agents (poisons)

Physical Agents (dusts, fibers, heat, noise,

corrosive)

Biological Agents (pathogens)

4 Chemical process safety Apr 6, 2020

Toxicology

Paracelsus, an early investigator of toxicology during the

1500s stated that “all substances are poisons; there is none

which is not a poison. The right dose differentiate a poison and

a remedy. ” Harmless substances such as water, can become

fatal if delivered to the biological organism in large amounts.

There are no harmless substances , only harmless ways of

using substances

5 Chemical process safety Apr 6, 2020

Environmental Health Paradigm

Exposure Assessment

Emission Sources Environmental

Concentrations

Effects Assessment

Internal Dose Human Exposure

Health Effects

6 Chemical process safety Apr 6, 2020

Hazardous

Industrial Hazards

– Toxicity

– Explosivity

– Ignitability

– Reactivity

7 Chemical process safety Apr 6, 2020

Toxic Substance

Capacity of a substance to produce injury or

illness

Acute( ( فوريEffects

– Short term, appear shortly after exposure. Can be

from single exposure

Chronic ن

( مزم (Effects

– There is a latency, long period of time before you

see effect

8 Chemical process safety Apr 6, 2020

So Toxicology is the study of:

How toxicants enter the organism

How toxicants effect the organism

How toxicants are eliminated from the organism

Remember that , all substances are toxic if taken in the

wrong quantities

9 Chemical process safety Apr 6, 2020

2.1 How toxicants enter organism

Inhalation (mouth or nose to lungs) then into

blood(+*)

Ingestion (mouth to stomach) then into

blood(+)

Injection (cuts, punctures in skin) into blood

Dermal absorption (through skin) into blood(+*)

+ Involve membrane transport

* Greatest threats in industry

10 Chemical process safety Apr 6, 2020

2.3 Effects of Toxicants

Irreversible Effects

Carcinogen - causes cancer

Mutagen - causes chromosome damage

Reproductive hazard - damage to reproductive

system

Teratogen - causes birth defects

11 Chemical process safety Apr 6, 2020

Effects of Toxicants

May or may not be reversible

Dermatotoxic – affects skin

Hemotoxic – affects blood

Hepatotoxic – affects liver

Nephrotoxic – affects kidneys

Neurotoxic – affects nervous system

Pulmonotoxic – affects lungs

12 Chemical process safety Apr 6, 2020

Definitions

Pharmacokinetics – the absorption, distribution,

metabolism and excretion of chemicals through the

(human) system.

Bioaccumulation – things such as lead, mercury,

PCBs (polychlorinated biphenyl) , carbon

tetrachloride that build up in organs and have low

excretion rate. Low exposure over a long time leads

to response

13 Chemical process safety Apr 6, 2020

2.2 Elimination of toxins

Excretion through kidneys, liver and lungs

Detoxification (liver) is the biotransformation of

chemicals into something less harmful.

Storage in fatty tissue

14 Chemical process safety Apr 6, 2020

2.4 Toxicological Studies

A major objective of toxicological study is to

quantify the effect of toxicants on specified

physical state.

For most toxicological studies

animals are used.

15 Chemical process safety Apr 6, 2020

Difficulties in Toxicological studies

Response not necessarily numerical.

Specificity of individual response

– Allergy or immunity () المناعة والحساسية

– Statistical study required

– Organism specific response, not applicable to humans

– Dosage response

– Response time, latency, acute versus chronic

– Difficulty in measuring intended variable (lead in liver

measured by lead in blood)

16 Chemical process safety Apr 6, 2020

Difficulties in Toxicological Studies

Major Problem

– No ethical way to get human volunteers, hence

need to use “model” systems of rats, cats, dogs,

rabbits, etc.

Hinders production of a new chemical, almost

as stringent as a new drug.

17 Chemical process safety Apr 6, 2020

2.5 Dose versus Response

Run test on “large”

population

Given same dose

(usually in dose/body

mass)

Determine the number

or fraction of individuals

that have a response

Low High

* Read example 2-1 response response

Figure 2-5 Percentage of individuals affected based on response.

18 Chemical process safety Apr 6, 2020

Dose versus Response (cont)

Repeat tests using

different doses

Find average response

to each dose

Plot Response versus

logarithm of dose

Forms Sigmoid shaped

curve

19 Chemical process safety Apr 6, 2020

Dose Limit Values; Dose curves

EDf – (minor) Effective dose

for f percent of population.

Reversible response

TDf – Toxic dose for f percent

of population. Undesirable

response that is irreversible

LDf or LC – Lethal dose for f

percent of population.

20 Chemical process safety Apr 6, 2020

Dose/Response Models

Use Probits to Linearize Dose-Response Curve

Use Table 2.4

Some calculators calculate the erfc

(complimentary error function)

erfc = 1 – erf(x)

21 Chemical process safety Apr 6, 2020

Probit Correlations

22 Chemical process safety Apr 6, 2020

Probit Correlations

Table 2-5 gives values of a linear interpolation

of Dose/Response data that has been

linearized using Probits.

Y = k1 + k2*Ln(V)

Y – Probit

V – Causative variable

23 Chemical process safety Apr 6, 2020

24 Chemical process safety Apr 6, 2020

Chemical Vapors

When dealing with exposures of a chemical

vapor (toxic cloud) then the probit constants

are correlated by:

– Y = a + b ln Cnt

– a, b and n are experimentally determined constants

– C is concentration in ppm

– t is the exposure time in minutes

25 Chemical process safety Apr 6, 2020

Chemical Vapors

When the exposed subjects receive different doses

as a function of time

t2

C t C dt C ti

n n

i

n

t1 i

26 Chemical process safety Apr 6, 2020

2.7 Relative Toxicity Classification

Classification Lethal Dose for a 70 KG person

Dangerously Toxic A taste ,

Highly Toxic a teaspoon

Moderately Toxic 1 oz = ~ 28.3 g

Slightly Toxic 1 pint = ~ 473 g

Practically nontoxic 1 qt = ~ 946 g

Relatively harmless > 1 qt

27 Chemical process safety Apr 6, 2020

2.8 Threshold Limit Values

Lowest value on the response versus dose curve is

called the threshold dose.

American Conference of Governmental Industrial

Hygienists (ACGIH) has established “Threshold Limit

Values” (TLV)

United States Occupational Safety and Health

Administration (OSHA) has established “Permissible

Exposure Limits” (PEL)

Table 2-8 gives the TLVs and PELs for many

substances

For some toxicants (particularly carcinogens) exposures at any level are not permitted.

These toxicants have zero thresholds.

28 Chemical process safety Apr 6, 2020

Threshold Limit Values

TLVTWA Time weighted average for a normal 8

hour workday or 40 hour workweek.

TLVSTEL Short-term exposure limit. The

maximum concentration can be exposed to for

up to 15 minutes. Four excursions per day with

at least 60 minutes between.

TLVC Ceiling limit. This concentration should

not be exceeded

29 Chemical process safety Apr 6, 2020

Converting from mg/m3 to ppm(v/v)

22.4 T 1

C ppm

3

(mg / m )

M 273 P

M is molecular weight

T is temperature in Kelvin

P is pressure in atm

30 Chemical process safety Apr 6, 2020

Threshold Limit Values

31 Chemical process safety Apr 6, 2020

32 Chemical process safety Apr 6, 2020

33 Chemical process safety Apr 6, 2020

34 Chemical process safety Apr 6, 2020

You might also like

- How to Empower Children in the World: Earth Leaders for Environmental MonitoringFrom EverandHow to Empower Children in the World: Earth Leaders for Environmental MonitoringNo ratings yet

- Kinetics of Substrate Utilization, Product Formation and Biomass Production in Cell CulturesDocument5 pagesKinetics of Substrate Utilization, Product Formation and Biomass Production in Cell CulturesfayeNo ratings yet

- SCI 11 Module 2Document5 pagesSCI 11 Module 2Sebastian SmytheNo ratings yet

- Hazardous WasteDocument110 pagesHazardous WastekailasasundaramNo ratings yet

- Three Types of Paints and CoatingsDocument6 pagesThree Types of Paints and CoatingsberchardNo ratings yet

- Fluidization 180402101141Document13 pagesFluidization 180402101141suraj nakumNo ratings yet

- Problem Set Instructions for Chemistry AnalysisDocument2 pagesProblem Set Instructions for Chemistry AnalysisJohn Kristoffer RoblezaNo ratings yet

- OJTReportDocument28 pagesOJTReportFranz Loui RosarioNo ratings yet

- ChE - Project Design RubricDocument5 pagesChE - Project Design RubricMadel IsidroNo ratings yet

- CHE 46: Biochemical EngineeringDocument30 pagesCHE 46: Biochemical EngineeringJunn Edgar LibotNo ratings yet

- Comparative Decolorization of Dyes in Textile Wastewater Using Biological and Chemical TreatmentDocument5 pagesComparative Decolorization of Dyes in Textile Wastewater Using Biological and Chemical TreatmentsnowhuliNo ratings yet

- Grain Dryer and Mill EvaluationDocument9 pagesGrain Dryer and Mill EvaluationGreatle Mae D. BasbañoNo ratings yet

- Waste CharacterizationDocument35 pagesWaste CharacterizationNurzan M. JefryNo ratings yet

- Greenhouse Effect and Global Warming: Topic 5Document55 pagesGreenhouse Effect and Global Warming: Topic 5Nurl AinaNo ratings yet

- Lec 1Document15 pagesLec 1umarNo ratings yet

- Quiz On Enzyme KineticsDocument3 pagesQuiz On Enzyme KineticsHens Christian FuentesNo ratings yet

- The Effect of Copper Loading On The Selective Nox Reduction of Gypsum-Reinforced Zeolite CompositeDocument38 pagesThe Effect of Copper Loading On The Selective Nox Reduction of Gypsum-Reinforced Zeolite CompositeFrances Kaye MagaoayNo ratings yet

- Factor Influenching Solar Drying Red AlgaeDocument9 pagesFactor Influenching Solar Drying Red AlgaeEko Putra BayuNo ratings yet

- Waste Analysis and Characterization Study (WACS)Document24 pagesWaste Analysis and Characterization Study (WACS)Marie AlejoNo ratings yet

- ChE - Laws and EthicsDocument5 pagesChE - Laws and EthicsChosel LawagonNo ratings yet

- Assessing the Risk of Methane Explosions in Underground Coal MinesDocument2 pagesAssessing the Risk of Methane Explosions in Underground Coal MinesJef Michael L. DahuylaNo ratings yet

- Topic 1 - Introduction Mechanical OperationsDocument82 pagesTopic 1 - Introduction Mechanical OperationsAmeen HussainNo ratings yet

- Metro ClarkDocument21 pagesMetro ClarkRowelito Talawan67% (6)

- Sadp Mango Report - 111109Document43 pagesSadp Mango Report - 111109Ulysses J. Lustria Jr.No ratings yet

- Lec 1 Properties and Handling of Particulate SolidsDocument95 pagesLec 1 Properties and Handling of Particulate SolidsAli HasSsanNo ratings yet

- Carlos Sierra - Mine Ventilation - A Concise Guide For Students-Springer International Publishing - Springer (2020)Document372 pagesCarlos Sierra - Mine Ventilation - A Concise Guide For Students-Springer International Publishing - Springer (2020)George GomezNo ratings yet

- CHEMICAL ENGINEERING THERMODYNAMICSDocument5 pagesCHEMICAL ENGINEERING THERMODYNAMICSarslanjameelmalikNo ratings yet

- Laboratory Experiment No. 1Document9 pagesLaboratory Experiment No. 1JAMIR ARIOLANo ratings yet

- FT Laboratory Report 4 by Marian CalingDocument5 pagesFT Laboratory Report 4 by Marian CalingMarian CalingNo ratings yet

- The Philippine Environmental Impact Assessment System PDFDocument47 pagesThe Philippine Environmental Impact Assessment System PDFNoreen T� ClaroNo ratings yet

- Size Reduction Methods and Equipment for Particle Size ReductionDocument2 pagesSize Reduction Methods and Equipment for Particle Size Reductionnhalieza1067No ratings yet

- Action 1 10-Year Plan - 01 PDFDocument160 pagesAction 1 10-Year Plan - 01 PDFAaron Trev Paghasian TajerosNo ratings yet

- Characterizing Solid ParticlesDocument34 pagesCharacterizing Solid ParticlesAmeen HussainNo ratings yet

- R.A. 9297 New ChE LawDocument10 pagesR.A. 9297 New ChE LawRexel ReedusNo ratings yet

- Acidity Lab Report Rev1Document5 pagesAcidity Lab Report Rev1api-311220565No ratings yet

- Density and Specific Gravity MethodsDocument3 pagesDensity and Specific Gravity MethodsAGENT M.DNo ratings yet

- Lab Report Exp 4 (Siti Nuraziemah Binti Azmy - 2021373309)Document7 pagesLab Report Exp 4 (Siti Nuraziemah Binti Azmy - 2021373309)SITI NURAZIEMAH AZMYNo ratings yet

- Answers To Questions Expt3Document5 pagesAnswers To Questions Expt3Ana Lorraine DalilisNo ratings yet

- Market Study For The Philippines Plastics Circularity Opportunities and BarriersDocument106 pagesMarket Study For The Philippines Plastics Circularity Opportunities and BarriersEmerson EnriquizNo ratings yet

- 04 Oxygen DemandDocument19 pages04 Oxygen DemandCharisma SubaNo ratings yet

- 1983 Properties of Gamma Irradiated Sugarcane BagasseDocument5 pages1983 Properties of Gamma Irradiated Sugarcane BagassexsystemNo ratings yet

- Factors Affecting Particle Settling and Sedimentation RatesDocument2 pagesFactors Affecting Particle Settling and Sedimentation RatesLara Melissa50% (2)

- Lecture 1-Fluid Statics 2003Document6 pagesLecture 1-Fluid Statics 2003Leonardo LibresNo ratings yet

- Solid Waste PollutionDocument11 pagesSolid Waste Pollutionankitkh83% (6)

- Plastic Pollution in PakistanDocument3 pagesPlastic Pollution in PakistanEngr Iftikhar Chandio100% (1)

- 2a Theory PDFDocument41 pages2a Theory PDF5ChEA DriveNo ratings yet

- All About LeachingDocument3 pagesAll About Leachinganon_850753764No ratings yet

- 3 - Vegetable Oil and BiofuelsDocument15 pages3 - Vegetable Oil and BiofuelsVenus Abigail GutierrezNo ratings yet

- Film mass-transfer theory explained in 40 chars or lessDocument6 pagesFilm mass-transfer theory explained in 40 chars or lessNyamukNo ratings yet

- Experiment No.1 (Difussion) FINALDocument7 pagesExperiment No.1 (Difussion) FINALSharmaine RoseNo ratings yet

- EUT 444: Pengurusan Kejuruteraan / Engineering Management: Cost Concepts and Design EconomicsDocument53 pagesEUT 444: Pengurusan Kejuruteraan / Engineering Management: Cost Concepts and Design EconomicsJerry KhuzairiNo ratings yet

- Bar and Liquid Soap: Department of Chemical EngineeringDocument8 pagesBar and Liquid Soap: Department of Chemical EngineeringErnie Mark Patosa MaratasNo ratings yet

- Iloilo Province Watershed Score Card For Ulian River, Jalaur RiverDocument71 pagesIloilo Province Watershed Score Card For Ulian River, Jalaur RiverEscantillaMariaLea50% (2)

- Act 1Document6 pagesAct 1Rejie Boy CortesNo ratings yet

- Thermodynamics Lab - Boyle's LawDocument5 pagesThermodynamics Lab - Boyle's Lawfaezahjalal100% (2)

- Lecture 1 Particle Technology (Introduction)Document20 pagesLecture 1 Particle Technology (Introduction)Muhammad kashifNo ratings yet

- Review Questions: LeachingDocument1 pageReview Questions: LeachingJohn P. BandoquilloNo ratings yet

- Solid Waste Management Practices in Selected Food Service Establishments in Talisay City, Negros Island Region, PhilippinesDocument5 pagesSolid Waste Management Practices in Selected Food Service Establishments in Talisay City, Negros Island Region, PhilippinesesatjournalsNo ratings yet

- Risk AssessmentDocument62 pagesRisk Assessmentpia_shupaNo ratings yet

- 01 Lurman The Toxicological Evaluation of PesticidesDocument42 pages01 Lurman The Toxicological Evaluation of PesticidesImed MAATOUKNo ratings yet

- CH 2 ToxicologyDocument34 pagesCH 2 ToxicologyMohammad YounesNo ratings yet

- CH 2 ToxicologyDocument34 pagesCH 2 ToxicologyMohammad YounesNo ratings yet

- CH 10 Process IdentificationDocument31 pagesCH 10 Process IdentificationMohammad YounesNo ratings yet

- Heat TransferDocument13 pagesHeat TransferAhmed EĻ-dawodyNo ratings yet

- Matlab Guide BookDocument26 pagesMatlab Guide BookKingchemNo ratings yet

- Matlab Guide BookDocument26 pagesMatlab Guide BookKingchemNo ratings yet

- Matlab Guide BookDocument26 pagesMatlab Guide BookKingchemNo ratings yet

- Jaw Crusher PDFDocument6 pagesJaw Crusher PDFMohammad YounesNo ratings yet

- Material BalanceDocument42 pagesMaterial Balancealireza_e_20% (1)

- Chemical Resistance Chart GlovesDocument8 pagesChemical Resistance Chart Glovesjitendertalwar1603No ratings yet

- Thermo LectureDocument16 pagesThermo LectureSedfrey Dela CruzNo ratings yet

- Service Manual 38cvur13!16!42cvur13 16Document104 pagesService Manual 38cvur13!16!42cvur13 16Leo De ocampoNo ratings yet

- SDS - Barrier 90 - Comp. A - Marine - Protective - English (Uk) - Australia - 2528 - 30.10.2012Document8 pagesSDS - Barrier 90 - Comp. A - Marine - Protective - English (Uk) - Australia - 2528 - 30.10.2012DonNo ratings yet

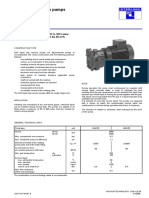

- Liquid ring vacuum pumps in compact designDocument7 pagesLiquid ring vacuum pumps in compact designDarwin Barra TorresNo ratings yet

- Nanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009Document9 pagesNanomechanical Testing of Gum Metal: # Society For Experimental Mechanics 2009yerly ramirezNo ratings yet

- Pre-Qualification Docs ListDocument11 pagesPre-Qualification Docs ListNikhil RajuNo ratings yet

- Tuning, Calibration, and Optimization Guide: Part Number: 1018437 A May 2005Document88 pagesTuning, Calibration, and Optimization Guide: Part Number: 1018437 A May 2005Harishq PothuriNo ratings yet

- MAT. VOLATIL ASTM E872-82 (Reapproved 2013)Document3 pagesMAT. VOLATIL ASTM E872-82 (Reapproved 2013)Andrea Urbano NilaNo ratings yet

- Chapter 10 Respiration - WorksheetDocument4 pagesChapter 10 Respiration - Worksheetapi-3728508100% (4)

- Preparation and Properties of Compounds-03 - Assignments (New)Document12 pagesPreparation and Properties of Compounds-03 - Assignments (New)Raju SinghNo ratings yet

- Fike Webinar Dust Hazard Analysis 4th MayDocument26 pagesFike Webinar Dust Hazard Analysis 4th MayAda-MNo ratings yet

- STS PPT EditedDocument13 pagesSTS PPT EditedRayne Andreana YuNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Chemical and of The SupplierDocument8 pagesSafety Data Sheet: Section 1: Identification of The Chemical and of The SupplierFikriey AbdullahNo ratings yet

- Life Cycle Assessment of Soap and DetergentsDocument14 pagesLife Cycle Assessment of Soap and Detergentstewegeb5100% (3)

- Ayurvedic Dosage FormsDocument9 pagesAyurvedic Dosage FormsDeepak BasyalNo ratings yet

- 1 - Description of The Hydrologic Cycle-1Document4 pages1 - Description of The Hydrologic Cycle-1Sheraz gillNo ratings yet

- Test Methodology FORD TM 00.00 L 467 2 PDFDocument5 pagesTest Methodology FORD TM 00.00 L 467 2 PDFFadi MagdyNo ratings yet

- Saturation Pressure Is The Pressure For A Corresponding Saturation Temperature at Which A LiquidDocument2 pagesSaturation Pressure Is The Pressure For A Corresponding Saturation Temperature at Which A LiquidMark Angelo UyNo ratings yet

- Masterseal TC 257 D GREY Part ADocument10 pagesMasterseal TC 257 D GREY Part ADhiwagar MJNo ratings yet

- Disinfection and SterilisationDocument36 pagesDisinfection and SterilisationvaidyamNo ratings yet

- Triple Q WatersDocument4 pagesTriple Q Watersendalehadgu2866No ratings yet

- Sika PDS - E - SikaGrout - 212 GP PDFDocument2 pagesSika PDS - E - SikaGrout - 212 GP PDFlwin_oo2435No ratings yet

- Lakshya JEE 2.0 (2024) : SolutionDocument5 pagesLakshya JEE 2.0 (2024) : SolutionAyush KumarNo ratings yet

- Engineering Stress-Strain and True Stress-Strain Analysis in Uniaxial Tension TestingDocument33 pagesEngineering Stress-Strain and True Stress-Strain Analysis in Uniaxial Tension TestingZANTHERNo ratings yet

- ASTM D974 14 (For Acid and Base Number by Color-Indicator Titration)Document7 pagesASTM D974 14 (For Acid and Base Number by Color-Indicator Titration)Fabian Ricardo100% (1)

- 25-12-19 - Sri Chaitanya SR - Icon All - GTM-2 - Question Paper - No PasswordDocument22 pages25-12-19 - Sri Chaitanya SR - Icon All - GTM-2 - Question Paper - No PasswordZomatoswiggyNo ratings yet

- 2 Toxicokinetics & ToxicodynamicsDocument32 pages2 Toxicokinetics & ToxicodynamicsLaura RodriguezNo ratings yet

- DS HLTP 60 Rev12 1107Document2 pagesDS HLTP 60 Rev12 1107Luisito Aguilar RojasNo ratings yet

- AHS &MRIT III-SEMESTER Organic Chemistry SyllabusDocument11 pagesAHS &MRIT III-SEMESTER Organic Chemistry SyllabusNandhuNo ratings yet

- Van Meerbeek (2001) Adhesives and Cements To Promote Preservation DenitistryDocument26 pagesVan Meerbeek (2001) Adhesives and Cements To Promote Preservation DenitistryAnderson Chamblas100% (1)

- Gilbert - Kaufman - Relational Analysis - Guidelines For Estimating The High - and Low-Temperature Properties of MetalsDocument20 pagesGilbert - Kaufman - Relational Analysis - Guidelines For Estimating The High - and Low-Temperature Properties of MetalsCristian Saftescu-JescuNo ratings yet