Professional Documents

Culture Documents

R7220303 Thermal Engineering-I

Uploaded by

sivabharathamurthyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R7220303 Thermal Engineering-I

Uploaded by

sivabharathamurthyCopyright:

Available Formats

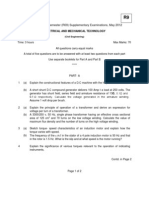

Code: R7220303

R07

THERMAL ENGINEERING-I

(Mechanical Engineering)

B.Tech II Year II Semester (R07) Supplementary Examinations, April/May 2013

Time: 3 hours

Answer any FIVE questions All questions carry equal marks *****

1. (a) (b) 2. (a) (b) (a) (b) (a) (b)

Max. Marks: 80

Define volumetric efficiency and discuss the effect of various factors affecting the volumetric efficiency. Why do designer go for multi cylinder engine for heavy loads and name some multi cylinder types? Describe the phenomenon of pre-ignition in S.I. engines and discuss its effect on the performance. What are the various types of combustion chambers used in S.I. engines? Explain them briefly. Explain with figure various types of combustion chambers used in C.I. engine. Bring out clearly the process of combustion in C.I. engine. Also explain various stages of combustion. Describe the phenomenon of pre-ignition in S.I. engines and discuss its effect on the performance. Explain with a neat sketch the battery ignition system. The following data refer to an oil engine working on Otto 4-stroke cycle. Brake power = 14.7 KW, Suction press = 0.9 bar, Mechanical efficiency = 80%, Index of compression curve = 1.35, Index of expansion curve = 1.3, Maximum explosion pressure = 24 bar, Engine speed = 1000 rpm. Ratio of stroke : bore = 1.5 Find the diameter of the piston.

3.

4.

5.

6.

(a) (b)

Explain the effect of inter cooling in a multi stage reciprocating compressor. Determine the size of the cylinder for a double acting air compressor of 40 KW indicated power, in which 1.2 air is drawn at 1 bar and 15 and compressed according to the law PV = constant to 6 bar the compressor runs at 100 rpm with average piston speed of 152.5 m/min. Neglect clearance. Compare centrifugal and axial flow compressors. 3 A root blower compresses 0.06 m of air from 1.0 bar to 1.45 bar per revolution. Calculate compressor efficiency. What do you mean by surging & choking? An axial flow compressor with an overall isentropic efficiency of 85% draws air at 20 and compresses it in the pressure ratio of 4:1. The mean blade speed and flow velocity are constant throughout the compressor. Assuming 50% reaction blading and taking blade velocity as 180 m/s and work input factor as 0.82 calculate: (i) flow velocity and (ii) the number of stages. Take

7.

(a) (b)

8.

(a) (b)

*****

You might also like

- 9A03402 Thermal Engineering - IDocument4 pages9A03402 Thermal Engineering - IsivabharathamurthyNo ratings yet

- Unit I: Gas Power CyclesDocument78 pagesUnit I: Gas Power CyclesBalaji DsNo ratings yet

- ETD - III 2nd AssignmentDocument7 pagesETD - III 2nd Assignmentmallesh mendaNo ratings yet

- Thermal Engineering - I Jntua Question PapersDocument15 pagesThermal Engineering - I Jntua Question PapersHimadhar SaduNo ratings yet

- Me2301 QBDocument7 pagesMe2301 QBbalajigandhirajanNo ratings yet

- Atd PaperDocument7 pagesAtd PaperWestNo ratings yet

- Question Bank: AE1254 - PROPULSION IDocument8 pagesQuestion Bank: AE1254 - PROPULSION ISêlvâkûmâr JayabalaNo ratings yet

- Chapter 7 - Work Study (Time and Motion Study)Document8 pagesChapter 7 - Work Study (Time and Motion Study)Pankaj KanatheNo ratings yet

- 09a52104 - Aerospace Propulsion-IDocument4 pages09a52104 - Aerospace Propulsion-IMoin KhanNo ratings yet

- Part A and B QB PropulsionDocument3 pagesPart A and B QB Propulsionsrinithims78No ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISRINIVASA RAO GANTANo ratings yet

- 9A21505 Aerospace Propulsion-IDocument4 pages9A21505 Aerospace Propulsion-IsivabharathamurthyNo ratings yet

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyNo ratings yet

- ME6404 Thermal EngineeringDocument21 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- Propulsion !Document3 pagesPropulsion !dickandballsNo ratings yet

- Question PapersDocument11 pagesQuestion Papersbharath devasothNo ratings yet

- WWW - Jdrr5.co - CC: Model Question PaperDocument3 pagesWWW - Jdrr5.co - CC: Model Question PaperPavan KishoreNo ratings yet

- Thermal Univ PDFDocument8 pagesThermal Univ PDFNithin Mathew EyyalilNo ratings yet

- 07a4ec05-Thermal Engineering - IDocument7 pages07a4ec05-Thermal Engineering - ISRINIVASA RAO GANTANo ratings yet

- Ic Engine Sug..Document5 pagesIc Engine Sug..dipzbarma5No ratings yet

- Air Standard Cycles and Engine SystemsDocument5 pagesAir Standard Cycles and Engine SystemsGerlan Madrid MingoNo ratings yet

- QP 2010Document25 pagesQP 2010samy_175No ratings yet

- AE1304 Propulsion IDocument8 pagesAE1304 Propulsion ISriram100% (1)

- GT & JP QuestionsDocument7 pagesGT & JP QuestionsNaveen gupiNo ratings yet

- Thermal Univ QBDocument15 pagesThermal Univ QBrajapratyNo ratings yet

- ICE Assignment 30072016 043902AM PDFDocument6 pagesICE Assignment 30072016 043902AM PDFJayPatelNo ratings yet

- Thermal Engg Qbank 2017 FinalDocument10 pagesThermal Engg Qbank 2017 FinalBalaji DsNo ratings yet

- Ii Mech ThermalDocument8 pagesIi Mech ThermalRameez FaroukNo ratings yet

- Internal-II Question Paper TE - SET-IIDocument2 pagesInternal-II Question Paper TE - SET-IItagoreboopathyNo ratings yet

- Summer Carryover Exam of IC EnginesDocument3 pagesSummer Carryover Exam of IC EnginessrishashankNo ratings yet

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering IandhracollegesNo ratings yet

- ME6404 Thermal EngineeringDocument12 pagesME6404 Thermal EngineeringprasanthprpNo ratings yet

- Ae2255 Propulsion-1 Question Bank UNIT-1Document5 pagesAe2255 Propulsion-1 Question Bank UNIT-1kanscse100% (1)

- Ic 1 STDocument1 pageIc 1 STMitesh KumarNo ratings yet

- May-June 2015 Proplusion-1Document3 pagesMay-June 2015 Proplusion-1srinithims78No ratings yet

- Maximizing Efficiency in IC Engines and Gas TurbinesDocument15 pagesMaximizing Efficiency in IC Engines and Gas TurbinesVishnu DasNo ratings yet

- ME8493 Important Questions PDFDocument6 pagesME8493 Important Questions PDFNihal AshikNo ratings yet

- Propulsion I CIA I examDocument2 pagesPropulsion I CIA I examNatesan MahendranNo ratings yet

- ATD - I B.techDocument4 pagesATD - I B.techKarthiKeyanNo ratings yet

- Ic Engines (2) Question PaperDocument2 pagesIc Engines (2) Question Paperstalinrajesh143No ratings yet

- 6.thermal EngineeringDocument7 pages6.thermal EngineeringprasanthprpNo ratings yet

- Question Paper Code: 77006Document3 pagesQuestion Paper Code: 77006Vishnu Kumar G CNo ratings yet

- RR220306 Thermal Engineering - IDocument1 pageRR220306 Thermal Engineering - IsivabharathamurthyNo ratings yet

- Assignment Unit IIIDocument2 pagesAssignment Unit IIIRASHMINo ratings yet

- Te QbwaDocument50 pagesTe Qbwasrinithims78No ratings yet

- ICGT Question Bank 13ME301 InternalDocument13 pagesICGT Question Bank 13ME301 Internalవిష్ణువర్ధన్రెడ్డిNo ratings yet

- Coaching - I TEDocument2 pagesCoaching - I TEtagoreboopathyNo ratings yet

- 2018 Dec. ME204-D - Ktu QbankDocument3 pages2018 Dec. ME204-D - Ktu QbankamaljyothyrajNo ratings yet

- 9A 02303 Electrical & Mechanical TechnologyDocument2 pages9A 02303 Electrical & Mechanical TechnologysivabharathamurthyNo ratings yet

- r5220306 Thermal Engineering IDocument1 pager5220306 Thermal Engineering ISaitheja SharmaNo ratings yet

- 5TH UnitDocument2 pages5TH UnitHarsha Vardhan GuptaNo ratings yet

- Thermal Engineering Exam QuestionsDocument4 pagesThermal Engineering Exam QuestionsDhanabal Palanisamy PNo ratings yet

- Eme 15062009Document2 pagesEme 15062009Bhavesh PipaliyaNo ratings yet

- Propulsion 1 Unit-V Question Bank (Compressors)Document4 pagesPropulsion 1 Unit-V Question Bank (Compressors)kevintsubasa0% (2)

- r05220304 Thermal Engineering IDocument8 pagesr05220304 Thermal Engineering ISrinivasa Rao G100% (2)

- Assignment 2023Document3 pagesAssignment 2023Ali SeidNo ratings yet

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- 9A13701 Robotics and AutomationDocument4 pages9A13701 Robotics and AutomationsivabharathamurthyNo ratings yet

- SSC Telugu (FL) (AP)Document232 pagesSSC Telugu (FL) (AP)sivabharathamurthyNo ratings yet

- SSC Social Textbook (AP)Document100 pagesSSC Social Textbook (AP)sivabharathamurthyNo ratings yet

- Control Systems (CS) Notes As Per JntuaDocument203 pagesControl Systems (CS) Notes As Per Jntuasivabharathamurthy100% (3)

- 07A4EC01 Environmental StudiesDocument1 page07A4EC01 Environmental StudiessivabharathamurthyNo ratings yet

- 9A05707 Software Project ManagementDocument4 pages9A05707 Software Project ManagementsivabharathamurthyNo ratings yet

- R5410201 Neural Networks & Fuzzy LogicDocument1 pageR5410201 Neural Networks & Fuzzy LogicsivabharathamurthyNo ratings yet

- R7410506 Mobile ComputingDocument1 pageR7410506 Mobile ComputingsivabharathamurthyNo ratings yet

- R7410407 Operating SystemsDocument1 pageR7410407 Operating SystemssivabharathamurthyNo ratings yet

- R7310306 Heat TransferDocument1 pageR7310306 Heat Transfersivabharathamurthy100% (1)

- R7312301 Transport Phenomena in BioprocessesDocument1 pageR7312301 Transport Phenomena in BioprocessessivabharathamurthyNo ratings yet

- R7311506 Operating SystemsDocument1 pageR7311506 Operating SystemssivabharathamurthyNo ratings yet

- Code: R7311306: (Electronics & Control Engineering)Document1 pageCode: R7311306: (Electronics & Control Engineering)sivabharathamurthyNo ratings yet

- R7311205 Distributed DatabasesDocument1 pageR7311205 Distributed DatabasessivabharathamurthyNo ratings yet

- R7310506 Design & Analysis of AlgorithmsDocument1 pageR7310506 Design & Analysis of AlgorithmssivabharathamurthyNo ratings yet

- R7311006 Process Control InstrumentationDocument1 pageR7311006 Process Control InstrumentationsivabharathamurthyNo ratings yet

- R7310406 Digital CommunicationsDocument1 pageR7310406 Digital CommunicationssivabharathamurthyNo ratings yet

- 9A10505 Principles of CommunicationsDocument4 pages9A10505 Principles of CommunicationssivabharathamurthyNo ratings yet

- R7310206 Linear Systems AnalysisDocument1 pageR7310206 Linear Systems AnalysissivabharathamurthyNo ratings yet

- R5310204 Power ElectronicsDocument1 pageR5310204 Power ElectronicssivabharathamurthyNo ratings yet

- R5310406 Digital CommunicationsDocument1 pageR5310406 Digital CommunicationssivabharathamurthyNo ratings yet

- R7310106 Engineering GeologyDocument1 pageR7310106 Engineering GeologysivabharathamurthyNo ratings yet

- 9A15502 Digital System DesignDocument4 pages9A15502 Digital System Designsivabharathamurthy100% (1)

- 9A23501 Heat Transfer in BioprocessesDocument4 pages9A23501 Heat Transfer in BioprocessessivabharathamurthyNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- 9A05505 Operating SystemsDocument4 pages9A05505 Operating SystemssivabharathamurthyNo ratings yet

- 9A21506 Mechanisms & Mechanical DesignDocument8 pages9A21506 Mechanisms & Mechanical DesignsivabharathamurthyNo ratings yet

- 9A04504 Digital IC ApplicationsDocument4 pages9A04504 Digital IC ApplicationssivabharathamurthyNo ratings yet

- 9A02505 Electrical Machines-IIIDocument4 pages9A02505 Electrical Machines-IIIsivabharathamurthyNo ratings yet

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyNo ratings yet