Professional Documents

Culture Documents

Formula Collection 02

Uploaded by

eihdqdlmOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formula Collection 02

Uploaded by

eihdqdlmCopyright:

Available Formats

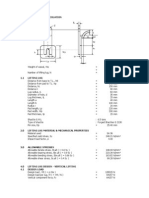

Design of Axles: Bending Bending Stress: b ,max =

M b ,max u ,b Wb

Required Axle Diameter:

d3

32 M b ,max u ,b

Design of Axles: Surface Pressure Surface Pressure: Pr :

Nm cm 2 s

metallic steel / synthetic

p=

F pu l1 d

Approximate Value:

insufficient = 0 .1 ...0 .3 3 ...1 0 1 ...5

pu

Pr v

Pr = relative bearing power v = running speed

Lubrication mating of material

low = 0 .1 ...0 .3 2 0 ...8 0 1 0 ...4 0

efficient = 0 .1 ...0 .3 8 0 ...2 0 0

Design of Shafts: Torsion

shaft diameter ds over 6 till 8 over 8 till 10 over 10 till 12 over 12 till 17 over 17 till 22 over 22 till 30 over 30 till 38 over 38 till 44 over 44 till 50 over 50 till 58 over 58 till 65 over 65 till 75 over 75 till 95 over 95 till 100 over 110 till 130 depth of groove for feather key hK 1,2 1,8 2,5 3,0 3,5 4,0 5,0 5,0 5,5 6,0 7,0 7,5 9,0 10,0 11,0 d ds hk

Torsional Stress:

t =

Mt u ,t Wt

16 M t u ,t

Required Shaft Diameter:

d3

Realised diameter of a groove shaft:

ds d + h k

Design of Shafts: Bending + Torsion

Effective Stress (DET):

v = 2 b + 3( 0 t ) u ,b

2

Strain Relationship:

0 =

u ,b 1.73 u ,t

Required Shaft Diameter:

d3

32 M v u ,b

Effective Moment:

2 Mv = Mb + 0.75( 0 Mt )2

Elastic Deformation of Shafts Angel of Twist: rad =

Mt l 180 M t l resp. deg = It G It G

d

4

180 32 M

Required Shaft Diameter:

G u l

u/l = 0.25...0.5/m

Deflection:

fu

1 l fu = safe deflection standard value 3000

Determination of the lowest natural frequency Centrifugal Force: Restoring Force:

Fc = m r 2

Fr = c y

c y = m r 2

Equilibrium of Forces: With r = y + e:

m e 2 = (c m r 2 ) y

m: mass of shaft r: excursion of mass : radian frequency c: flexural strength y: excursion of shaft e: eccentricity of gravity centre

At natural radian frequency: c/m-2=0 The Critical Speed: With c = Fw/fw and Fw = mg:

nb ,c

nb , c =

e 1 = 2 2

c m

1 = 2

Fw 1 = f w m 2 E Ib m l3

g fw

The deflection fw is known:

nb ,c =

e: natural radian frequency nb,c: critical speed g: gravitation Fw: weight fw: deflection due to weight E: modulus of elasticity Ib: polar moment of inertia l: length of shaft

Designing Fitting Keys Surface Pressure:

p=

2 Mt Fr p = (h t 1 ) l z d (h t 1 ) l z u

Experimental Values Of The Hub:

torque material 65 115 cast iron steel length L 1.8d ... 2.0d 1.6d ... 1.8d outside diameter D 1.8d ... 2.0d 1.6d ... 1.8d constant

Ulimate Surface Pressure (pu):

material shaft S275JR, E295 E295, hard steel hub S,E,GG S,E,GS 45 75 impulsive

You might also like

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Connection Weld Bolt (06!06!2016)Document21 pagesConnection Weld Bolt (06!06!2016)raymond100% (1)

- Mathcad - PIN PLATE CONNECTION Al WAHA PDFDocument9 pagesMathcad - PIN PLATE CONNECTION Al WAHA PDFMonotobo X MakinaNo ratings yet

- Embodyment Design: Sambungan (Pengelasan)Document7 pagesEmbodyment Design: Sambungan (Pengelasan)naschuy2No ratings yet

- Perencanaan Beton Dimensi Balok Sudah Diketahui, Hitung M.max Yang Mampu Dipikul Balok Tersebut .??????? HitunganDocument23 pagesPerencanaan Beton Dimensi Balok Sudah Diketahui, Hitung M.max Yang Mampu Dipikul Balok Tersebut .??????? HitunganArif Setya AwanNo ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Mathcad - BASEPLATE DESIGN - 10 PDFDocument6 pagesMathcad - BASEPLATE DESIGN - 10 PDFMonotobo X MakinaNo ratings yet

- Column Base Plate DesignDocument5 pagesColumn Base Plate Design_jessecaNo ratings yet

- Design of a mechanical bottle jack with bevel gearsDocument9 pagesDesign of a mechanical bottle jack with bevel gearsdagem100% (1)

- Bolted Cover Plate Splice Connection B1Document4 pagesBolted Cover Plate Splice Connection B1ikanyu79No ratings yet

- Mechanische WellenDocument62 pagesMechanische WellenScribdTranslationsNo ratings yet

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Compressed air tank design and calculationsDocument6 pagesCompressed air tank design and calculationsDanijel DjordjicNo ratings yet

- PDF SF BMD and Spindle DesignDocument65 pagesPDF SF BMD and Spindle DesignPRAVEEN ENo ratings yet

- Mathcad - Baseplate Design - 8Document6 pagesMathcad - Baseplate Design - 8Monotobo X MakinaNo ratings yet

- Indrumator Metal - EGDocument37 pagesIndrumator Metal - EGhooky1100% (1)

- Stair DesignDocument6 pagesStair DesignBathrudeen IshakNo ratings yet

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Fixed Base Anchor Bolt DesignDocument3 pagesFixed Base Anchor Bolt Designkhan84mind50% (2)

- Composite Bridge Design CalculatorDocument20 pagesComposite Bridge Design CalculatoriGp2013No ratings yet

- Hoist Design Procedure For EOT CraneDocument14 pagesHoist Design Procedure For EOT CraneKeerthi KumarNo ratings yet

- Design of Beam To Beam Connection Using Web CleatDocument2 pagesDesign of Beam To Beam Connection Using Web CleatAnonymous UUAriPf8KqNo ratings yet

- Practical Lesson 4Document11 pagesPractical Lesson 4marjory.dezNo ratings yet

- 2 ProracunDocument6 pages2 ProracunStjepan RadosavljevicNo ratings yet

- Pipeline Design Parameters and Stability AnalysisDocument19 pagesPipeline Design Parameters and Stability AnalysisFaridah ZahraNo ratings yet

- Machine Design Formula ListDocument7 pagesMachine Design Formula ListHarpreet Randhawa100% (3)

- RC Stair Design 25Document6 pagesRC Stair Design 25Abel MulugetaNo ratings yet

- Chapter11 Prob01Document13 pagesChapter11 Prob01imranakhtarNo ratings yet

- Column Footing 1Document5 pagesColumn Footing 1Ayreesh Mey SpntNo ratings yet

- Design of Solid ShaftsDocument8 pagesDesign of Solid ShaftsQa LabNo ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- Reference:: Design of Axially Loaded Tied ColumnsDocument4 pagesReference:: Design of Axially Loaded Tied ColumnsjezNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Directional Drilling CalcuationsDocument43 pagesDirectional Drilling CalcuationsNourden Al100% (1)

- PC Viga AceroDocument5 pagesPC Viga AcerocristhianNo ratings yet

- Design of Elastomeric BearingsDocument6 pagesDesign of Elastomeric BearingsHarshitha GaneshNo ratings yet

- Upgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectDocument14 pagesUpgradation and Relocation of Karakorum Highway For Basha Diamer Dam ProjectkuttakhaoNo ratings yet

- Base Plate - MammutDocument8 pagesBase Plate - MammutAwais Hameed100% (1)

- Design of flywheel componentsDocument2 pagesDesign of flywheel componentsrip111176No ratings yet

- Lecture 2 Sample Problems WordDocument9 pagesLecture 2 Sample Problems Wordjake luis matthewNo ratings yet

- Block Shear ExampleDocument2 pagesBlock Shear ExampleDubu DubuNo ratings yet

- F C BW D 1400,07 KNDocument10 pagesF C BW D 1400,07 KN[GRH] H2ONo ratings yet

- Jasper PDFDocument72 pagesJasper PDFLimuel Milo Lebios100% (1)

- Connection No.: 66: Load Ver. Brace L120X120X10 AxialDocument5 pagesConnection No.: 66: Load Ver. Brace L120X120X10 Axialrts123No ratings yet

- Design of Square FootingDocument4 pagesDesign of Square FootingThirdie LerajeNo ratings yet

- Design of Composite Steel Girder BridgeDocument10 pagesDesign of Composite Steel Girder BridgesorowareNo ratings yet

- Final Plate Design of Roof Truss Ce 153-Timber DesignDocument37 pagesFinal Plate Design of Roof Truss Ce 153-Timber DesignJohn Lloyd JuanoNo ratings yet

- Rezanje FORMULEDocument13 pagesRezanje FORMULEАлександар ВујаковићNo ratings yet

- Conductor Cone Guide Design CalculationsDocument3 pagesConductor Cone Guide Design CalculationsThomas StephenNo ratings yet

- Material Properties, Dimensions, Service LoadsDocument10 pagesMaterial Properties, Dimensions, Service LoadsAmira RamleeNo ratings yet

- Design of base plate for pipe column supportsDocument4 pagesDesign of base plate for pipe column supportsRAMSNo ratings yet

- Design of FootingDocument15 pagesDesign of FootingRickyNo ratings yet

- Vessel support system: weight of the shell=π r r pgDocument3 pagesVessel support system: weight of the shell=π r r pgPorkkodi SugumaranNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Introduction To Sociology 2e OpDocument535 pagesIntroduction To Sociology 2e Opeihdqdlm0% (1)

- ON QUATERNIONS, OR ON A NEW SYSTEM OF IMAGINARIES IN ALGEBRA by William Rowan Hamilton (Philosophical Magazine, (1844-1850) )Document92 pagesON QUATERNIONS, OR ON A NEW SYSTEM OF IMAGINARIES IN ALGEBRA by William Rowan Hamilton (Philosophical Magazine, (1844-1850) )markrichardmuradNo ratings yet

- ON QUATERNIONS, OR ON A NEW SYSTEM OF IMAGINARIES IN ALGEBRA by William Rowan Hamilton (Philosophical Magazine, (1844-1850) )Document92 pagesON QUATERNIONS, OR ON A NEW SYSTEM OF IMAGINARIES IN ALGEBRA by William Rowan Hamilton (Philosophical Magazine, (1844-1850) )markrichardmuradNo ratings yet

- Laurent Series & Partial Fractions XXXDocument3 pagesLaurent Series & Partial Fractions XXXeihdqdlmNo ratings yet

- Atomic & Molecular StructureDocument233 pagesAtomic & Molecular StructureeihdqdlmNo ratings yet

- Euler L. A Solution To A Problem of Fermat, On Two Numbers of Which The Sum Is A Square and The Sum of Their Squares I (... ) Range (1780) (En) (3s)Document3 pagesEuler L. A Solution To A Problem of Fermat, On Two Numbers of Which The Sum Is A Square and The Sum of Their Squares I (... ) Range (1780) (En) (3s)eihdqdlmNo ratings yet

- Euler L. A Most Easy Method For Finding Many Very Large Prime Numbers (1778) (En) (10s)Document10 pagesEuler L. A Most Easy Method For Finding Many Very Large Prime Numbers (1778) (En) (10s)eihdqdlmNo ratings yet

- Euler L. A Commentary On The Continued Fraction by Which The Illustrious La Grange Has Expressed The Binomial Powers (1780) (En) (7s)Document7 pagesEuler L. A Commentary On The Continued Fraction by Which The Illustrious La Grange Has Expressed The Binomial Powers (1780) (En) (7s)eihdqdlmNo ratings yet

- A Theorem of Arithmetic and Its Proof EulerDocument8 pagesA Theorem of Arithmetic and Its Proof EulereihdqdlmNo ratings yet

- Mobile 1 MJ SMES System for On-Site Power System Stability EstimationDocument7 pagesMobile 1 MJ SMES System for On-Site Power System Stability EstimationSUNOBHAINo ratings yet

- Supermix PC550 PDFDocument2 pagesSupermix PC550 PDFmanavNo ratings yet

- Optical Study of Titanium Dioxide Thin Films Prepared by Vacuum Evaporation TechniqueDocument9 pagesOptical Study of Titanium Dioxide Thin Films Prepared by Vacuum Evaporation TechniqueFarid ElsehrawyNo ratings yet

- A Complete Theory ofDocument13 pagesA Complete Theory ofLaura Natalia SalcedoNo ratings yet

- LaserDocument54 pagesLasermrkishan395No ratings yet

- Mass Properties Measurement HandbookDocument13 pagesMass Properties Measurement Handbookkilo kiloNo ratings yet

- Advantest R6561 R6871 BrochureDocument16 pagesAdvantest R6561 R6871 Brochurebudi0251No ratings yet

- Design 2Document6 pagesDesign 2bmyertekinNo ratings yet

- Sample LET Math QuestionsDocument5 pagesSample LET Math QuestionsAljon Tupas TevesNo ratings yet

- 5 Displacement and Force in Two Dimensions: 2 FrictionDocument5 pages5 Displacement and Force in Two Dimensions: 2 Frictionalex murker100% (1)

- Practice Paper For XII BDocument6 pagesPractice Paper For XII BvartikaagrawalaNo ratings yet

- Bs 1377 5pdfDocument40 pagesBs 1377 5pdfToihir ben abdou salimNo ratings yet

- Ncert Exemplar Jan2021 Solutions Class 12 Maths Chapter 5Document33 pagesNcert Exemplar Jan2021 Solutions Class 12 Maths Chapter 5ishman singh bediNo ratings yet

- Cambridge Physics PhD Tutor solves differential equationsDocument3 pagesCambridge Physics PhD Tutor solves differential equationsHin Wa Leung100% (1)

- Bahir Dar Institute of Technology Faculty o Mechanical and Industrial EngineeringDocument74 pagesBahir Dar Institute of Technology Faculty o Mechanical and Industrial EngineeringEphrem AbabiyaNo ratings yet

- BRE IP06 Assessing The Affects of Thermal Bridging Atjunctions and Around OpeningsDocument7 pagesBRE IP06 Assessing The Affects of Thermal Bridging Atjunctions and Around OpeningsNiamh IrishNo ratings yet

- 1-Principles and Practice of Ground Improvement-Wiley (2015) - 11Document1 page1-Principles and Practice of Ground Improvement-Wiley (2015) - 11Ahmed KhedrNo ratings yet

- 3-Laws of Chemical Thermodynamics-08!03!2022Document78 pages3-Laws of Chemical Thermodynamics-08!03!2022krishna sanapala2003100% (1)

- A Generalization of Gelfand-Mazur TheoremDocument3 pagesA Generalization of Gelfand-Mazur TheoremJorge_JorgitoNo ratings yet

- Earth Science Activity on Heat Transfer TypesTITLEPlate Tectonics Activity Classifying Boundary DescriptionsDocument3 pagesEarth Science Activity on Heat Transfer TypesTITLEPlate Tectonics Activity Classifying Boundary DescriptionsCharity AmboyNo ratings yet

- 2 Out 2 PDFDocument426 pages2 Out 2 PDFSwapnil MaladkarNo ratings yet

- Experiment 2: Determination of Viscosity of Food Products Using ViscometerDocument20 pagesExperiment 2: Determination of Viscosity of Food Products Using ViscometerSyusyu HyNo ratings yet

- AIATS JEE (A) 2023 Test-2A P-1 (Code-A) 30-01-2022 Sol.Document24 pagesAIATS JEE (A) 2023 Test-2A P-1 (Code-A) 30-01-2022 Sol.KESSAVAN.M ECE20No ratings yet

- EET 411 Control ExampleDocument6 pagesEET 411 Control ExampleBpp Ikm Kuching100% (1)

- Regional Subsidence Effects in Tunnel-Soil-Structure Seismic InteracionDocument7 pagesRegional Subsidence Effects in Tunnel-Soil-Structure Seismic Interacionmauricio perez diazNo ratings yet

- RD Sharma Inverse Trig Solutions Class 12 Ch 4Document165 pagesRD Sharma Inverse Trig Solutions Class 12 Ch 4YashicaNo ratings yet

- Introduction To Power ScrewsDocument14 pagesIntroduction To Power Screwsاوبنتو العراقيNo ratings yet

- Restriction Orifice Calculation SheetDocument2 pagesRestriction Orifice Calculation Sheetparykoochak50% (2)

- Lab Services Materials CharacterizationDocument8 pagesLab Services Materials CharacterizationOwais MalikNo ratings yet

- 1 Intro To Differential EquationsDocument16 pages1 Intro To Differential EquationsJanina Christelle OrmitaNo ratings yet