Professional Documents

Culture Documents

2.329 - OSH Performance.

Uploaded by

kirandevi1981Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.329 - OSH Performance.

Uploaded by

kirandevi1981Copyright:

Available Formats

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

Title 2.329

TITLE - Procedure measurement and monitoring

2.329.1 Introduction

for

Health

and

Safety

performance

An essential element of any improvement program is the measurement of existing and future performance. Therefore, to continuously improve upon safety performance, In EPCL site Plant/ ept. level !"E#$ Performance rating is done %ased on %est prevailing safety practices, latest regulations # standards. 2.329.2 Scope

It applies to all plants and services &ithin the EPCL complex. To eliminate or minimi'e the ris( to employees including contractors. To implement, maintain and continually improve the safety system. To calculate the !"E#$ performance for internal and external a&ard purpose.

2.329.3

Responsibility

The responsi%ility of implementing this procedure lies &ith the !) "afety 2.329.4 Procedure

The "afety epartment along &ith Plant safety Am%assador shall do the Audit of the Plant and facility covering all the elements of the audit chec(list given in the Annexure I and calculate the rating of each plant and facility. Plant/ ept. level !"E#$ Performance &ill %e decided on six monthly %asis The Plant safety Am%assador shall do the compliance of the audit findings and send the compliance report to the safety department in format given in the annexure I. The !"E#$ audit and rating shall %e revie&ed in the !) .!)$ !"E#$ meeting one in three months.

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

" , o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32 EPCL+ !"E#$+,.-31

EPCL+ !"E#$+,.-31

$ormat *o. EPCL+!"E$+,.-./, 0ev 11, ate2 1./1,/31..

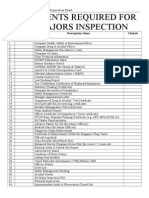

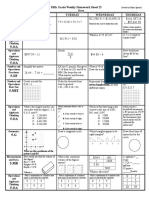

S !ety " n #e$ent Syste$s Audit-EP%L Pl nt "ont&s -

"r

Element and it4s Criteria

)%servations

5ar(s

1. S !ety %o$$it$ent A 'SE Policy A( reness )3* " r+s, Interact for &ith $ive EPCL employees to assess the a&areness.

Safety Committee Meeting (20 Marks) 5eeting on scheduled Availa%le Committee mem%ers list availa%le 5inimum 61 7 participants from nominated committee mem%ers. Action points are not pending.

Minimum Mandatory PPE (100 Marks) "afety shoes, helmet, hand gloves, goggles, respiratory protection etc. )%servation on use of re8uired PPE for the 9o% and it4s 8uality.

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

" 2 o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

"r D

Element and it4s Criteria

)%servations

5ar(s

Housekeeping (50 Marks) Poor house(eeping after 9o% completion, "catter nuts # %olts, Algae formation due to accumulation of condensate / li8uid dripping. )verflo&ing gar%age %in. "pillage of polymer resin . "pillage of oil near pump %ay / compressor house. :nhygienic condition at toilet %loc(. 5aterial stac(ing at non+ designated place, :p (eeping of safety signage. 5issing vehicle movement mar(ing on floor. ;rass and vegetation. amaged &ooden pallet.

2. Syste$ Audit !or -per tion l .iscipline A /or+ Per$it )01 " r+s, )%servations on Permit preparation, !a'ards identification and execution of The <o% Accident 2 Incident In3esti# tion )1* " r+s, Lea(age, $ire incident and in9ury incident and non compliance to investigation recommendations &ill attract mar( deduction.

Compliance report of previous au it (20 Marks) Compliance report to %e sent %y concerned plant / dept "afety Am%assador to "afety dept.

Scaffol ing (!0 Marks) )%servation of safety petrol officer certification and doing &or( execution.

during

"

" inten nce o! S !ety S&o(er )1* " r+s, rain cho(ed, dirt in eye sponge, no &ater, missing / damaged atomi'er, missing sign mar(ing, identification num%er etc.

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

" 3 o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

"r #

Element and it4s Criteria

)%servations

5ar(s

$lant Buil ings% Drains & #loor 'ratings (20 Marks) Loose covers on drain, overflo& of se&er pit, unsupported gratings, %ro(en stair steps etc.

'

"obile E4uip$ents 2 3e&icles )5or+ li!t6 7u$bo truc+6 'ydr 6 %r ne6 ro d t n+er6 trolley6 tr iler6 bicycle6 tr c+s6 !our (&eeler 3 n etc. )3* " r+s, efective vehicle, =ithout muffler, *on use of seat %elt, $or( at elevated position during for( lift driving / par(ing, >ra(e not &or(ing, !orn not &or(ing, *on+use of helmet %y for(lift driver, Exhaust duct of for(lift not insulated, river not holding license, Par(ing at ha'ardous place, *on compliance of mechanical material handling procedure, riving at over speed, 5aterial loaded on for( %loc(ing vision of driver, etc. /or+ t &ei#&t 8 use o! port ble l dder )3* " r+s, )e-ecti.e r2n%s, *se o- ma3e shi-t ladder, &issin% anti s3ids, Pads, +on 2se o- sa-ety !elt, $mproper tyin% o- sa-ety !elt etc.

5ire 5i#&tin# Syste$ )3* " r+s, $nspection pendin%, +on a.aila!ility o- Fire E4tin%2isher at the desi%nated place, *sed -or hot 5or3 preparation etc. &issin% l2%s, 6ammin% o.al.e, 7ater drippin%, (!str2ction, etc.

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

" 8 o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

"r )

Element and it4s Criteria 5ire Protection Syste$ )2* " r+s, ?"mo(e / heat detector, 5CP, Emergency Exits, $ixed LEL / PP5 detection systems, $ire / gas detection panel@ 9loc3a%e, &issin% si%n mar3, Loose ca!le, *prooted 0 han%in%, Acc2m2lation o- -ilth 0 dirt 0 co!5e!s, +o 0 mismatchin% identi-ication, )isplayin% o- -a2lty alarm etc.

)%servations

5ar(s

Port ble 9 s .etectors )2* " r+s, Inspection and healthiness of )3 LEL # PP5 instruments.

3. Process S !ety nd "ec& nic l Inte#rity A

+isk Assessment A,areness (50 Marks) 0is( assessment training status/ List of manual 9o%s availa%le and ris( assessment is made. Employees are a&are regarding the ris( assessment of the 9o%. :pd tin# "S.S )3* " r+s, 5" " of all chemicals used in plant/ department availa%le. Chemical list and prporitry chemical 5" " given for centrali'ed 5" " data %an( Employees are a&are regarding chemicals they use. "-% 2 PSSR );* " r+s, 5)C list updated approved 5)Cs in file !AA)P study done on recommended 5)Cs P""0 done of implemented 5)Cs and record of all availa%le &ith compliance report.

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

" : o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

"r

Element and it4s Criteria

)%servations

5ar(s

(nsulation - Cla ing (20 Marks) Loose cladding, "oa(ed insulation, 5issing strapping strips, *o insulation etc. e

.$D - H$/-"n 0lin s (10 Marks) 5issing plugging # %linding, Less / short %olting etc.

"lectrical (nstallation (50 Marks) 5issing gland, Loose / missing %olt for flameproof type elect. $ittings, amaged soc(et, Inserting %are &ire, Extension %oard &ithout -1 mA ELC> / not &or(ing, *on metallic, 5issing / less (no% on 9unction %ox, 5issing identification on LC" and feeder, efective electrical hand tools, <ointed ca%le, angling ca%le, Earthing, :se of non flame proof fittings at classified 'one, amaged lighting fixture, *on availa%ility of manual resuscitator, Emergency light etc.

Mec2anical (nstallation (50 Marks) !and tools, Inade8uate / vulnera%le piping support, 5issing / defective guard, "hort / less %olting on flange 9oint, 5issing guard on porta%le grinder, "agging of pipeline, efective &elding machine, efective hand carts, Porta%le platform, 5issing loc(ing arrangement on &heel mounted porta%le platform etc.

'as cylin ers - Mo0ile pressure vessels (10 Marks) Corrosion, :nsupported / unchained, Pending inspection, =ithout valve cap, efective P;, Loose tu%ing / unclamped, efective tu%e, "egregation of cylinders etc.

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

" ; o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

"r i

Element and it4s Criteria Li!tin# Tools 8 T c+les )3* " r+s, Inspection # use of Chain Pulley >loc(s, "lings, =e% "lings, Lifts # !oists.

)%servations

5ar(s

4- <e& 3ior b sed s !ety a Intr pl nt s !ety Tr inin# =) 1* " r+, Tr ined e$ployees $ +in# nd recodin# ST-P obser3 tions

"ummary Tot l " r+s> 091 " r+s obt ined> ? -bt ined>

@-TE>- "ac2 o0servation ,ill attract e uction of 5 marks3

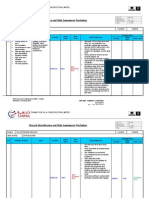

SAFE MA!A"EME!# S S#EM A$%&# '(MP)&A!'E *EP(*# Prepared !y" #PP Pa%e " < o$nte%rated &ana%ement System HSEF Appro.ed !y" *#C 'e.. +o " // P'(CE)*'E &A+*AL 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

Sr. no

Sr. no o! Audit report

-bser3 tion

" r+s deducted

'ompliance st at us

Re$ r+ i! re4uired

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

" 1 o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

SAFETY

Eleme Petrochemicals Company Ltd, PHC

EPCL-HSEF-2.32

2.329.1

Re!erences

>ritish safety council ;uidelines on !ealth # "afety 5anagement system )!"A" .611. 2.329.A Record Plant "afety Am%assador shall (eep the record of the filled chec(list for t&o years.

Prepared !y" #PP Appro.ed !y" *#C

$nte%rated &ana%ement System HSEF P'(CE)*'E &A+*AL

Pa%e

"

o-

'e.. +o " // 'e.. )ate " 2,0/102/,,

You might also like

- Storage Tanks Inspection ReportDocument15 pagesStorage Tanks Inspection ReportAreo Tolulope A80% (5)

- Civil Aircraft Electrical Power System Safety Assessment: Issues and PracticesFrom EverandCivil Aircraft Electrical Power System Safety Assessment: Issues and PracticesRating: 5 out of 5 stars5/5 (1)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Gap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101Document13 pagesGap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101kirandevi1981No ratings yet

- SMAN52730 - Wiring Diagram B11RaDocument58 pagesSMAN52730 - Wiring Diagram B11RaJonathan Nuñez100% (1)

- Performance Guarantee Test ProcedureDocument112 pagesPerformance Guarantee Test Procedurevinay1999No ratings yet

- Safe Work Procedure (Air Compressor)Document2 pagesSafe Work Procedure (Air Compressor)SURJIT SINGH100% (1)

- Routine Maintenance Safe Work Permit-GeneralDocument3 pagesRoutine Maintenance Safe Work Permit-GeneralVel MuruganNo ratings yet

- CSIR NET December 2019 Admit CardDocument1 pageCSIR NET December 2019 Admit CardDevendra Singh RanaNo ratings yet

- COE10205, Other Corrosion Monitoring TechniquesDocument62 pagesCOE10205, Other Corrosion Monitoring Techniquesامين100% (1)

- GST Licence PDFDocument3 pagesGST Licence PDFkirandevi1981No ratings yet

- 3.402-Sop For Vacuum TruckDocument2 pages3.402-Sop For Vacuum Truckkirandevi1981No ratings yet

- Self-Assessment ScoringDocument28 pagesSelf-Assessment Scoringkirandevi1981No ratings yet

- 2012-02-06 Blank HSE Verification Clarification Checklist FinalDocument12 pages2012-02-06 Blank HSE Verification Clarification Checklist FinalrwerwerwNo ratings yet

- Protocol for Performance Qualification of Purified Water Generation, Storage and Distribution SystemDocument46 pagesProtocol for Performance Qualification of Purified Water Generation, Storage and Distribution Systemasit_mNo ratings yet

- Nanowires - Fundamental ResearchDocument564 pagesNanowires - Fundamental ResearchJosé Ramírez100% (1)

- Code General Design GuideDocument12 pagesCode General Design Guidec_nghiaNo ratings yet

- 2.331 - Employee Participation & Consultantion.Document4 pages2.331 - Employee Participation & Consultantion.kirandevi1981No ratings yet

- OISD. PESO Gap AnalysisDocument18 pagesOISD. PESO Gap Analysiskirandevi1981100% (1)

- INSPECTION Checklist: Page 1 of 2 Control Valve FIC 30/01Document2 pagesINSPECTION Checklist: Page 1 of 2 Control Valve FIC 30/01Aldeline SungahidNo ratings yet

- Reliability Centered Maintenance (RCM)Document6 pagesReliability Centered Maintenance (RCM)Hoang Thanh VanNo ratings yet

- Ferrite Content Measurement ProcedureDocument5 pagesFerrite Content Measurement ProcedureSenthil Periyasamy0% (1)

- The Control of Hazardous Energy (Lockout/Tagou T)Document27 pagesThe Control of Hazardous Energy (Lockout/Tagou T)talhabctianNo ratings yet

- Cairn Energy India Pty Limited Mangala Process Terminal Piping Fabrication ProcedureDocument16 pagesCairn Energy India Pty Limited Mangala Process Terminal Piping Fabrication Procedurevpsimbu86No ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- U-00034-PR-CRT-0001 - Rev.ADocument46 pagesU-00034-PR-CRT-0001 - Rev.AthinhviproNo ratings yet

- Documents Required For Oil Majors Inspection: No. Responsible Rank Description Items Cheked MasterDocument6 pagesDocuments Required For Oil Majors Inspection: No. Responsible Rank Description Items Cheked MasterBernard MamoraNo ratings yet

- 2.330 Prestart Up Review Procedure.Document6 pages2.330 Prestart Up Review Procedure.kirandevi1981No ratings yet

- Level I - PPP - Area8Document8 pagesLevel I - PPP - Area8Elizalde HusbandNo ratings yet

- 2.325-Risk Assessment Procedure FinalDocument8 pages2.325-Risk Assessment Procedure Finalkirandevi1981No ratings yet

- Supply EMOC Form - Fixed Monitor - TejgaonDocument5 pagesSupply EMOC Form - Fixed Monitor - Tejgaontejcd1234No ratings yet

- Scheme of Instruction and Evaluation for M. Pharmacy (PharmaceuticsDocument19 pagesScheme of Instruction and Evaluation for M. Pharmacy (PharmaceuticsNaveen LankadasariNo ratings yet

- Oisd RP 233 DraftDocument66 pagesOisd RP 233 DraftVenkatesh NatlaNo ratings yet

- 2.326-Excavation and Cordnoing1Document13 pages2.326-Excavation and Cordnoing1kirandevi1981No ratings yet

- Erau Mgmt-419 SyllabusDocument8 pagesErau Mgmt-419 SyllabusAbed Almajeed AlowioiNo ratings yet

- Standard ChecklistscorrectedDocument51 pagesStandard Checklistscorrectedmohan_krishna372No ratings yet

- 2.308 - Vehicle Entry Permit ProcedureDocument5 pages2.308 - Vehicle Entry Permit Procedurekirandevi1981No ratings yet

- ACCIDENT REPORTING AND INVESTIGATION PROCEDUREDocument23 pagesACCIDENT REPORTING AND INVESTIGATION PROCEDUREkirandevi1981No ratings yet

- Bridon Service Procedures SP - 45Document5 pagesBridon Service Procedures SP - 45Khawaja Arslan AhmedNo ratings yet

- Protection SettingsDocument33 pagesProtection SettingsmagdyibraheemNo ratings yet

- Electrical Lock Out PermitDocument14 pagesElectrical Lock Out Permitkirandevi1981No ratings yet

- Reference Books: Notre Dame, ISBN-10: 0136081681, ISBN-13: 9780136081685, Publisher: PrenticeDocument5 pagesReference Books: Notre Dame, ISBN-10: 0136081681, ISBN-13: 9780136081685, Publisher: PrenticeShubham KaushııkNo ratings yet

- Sample CV1Document11 pagesSample CV1palosotNo ratings yet

- 2.332 Scaffold TaggingDocument4 pages2.332 Scaffold Taggingkirandevi1981No ratings yet

- Ernest Allen's CVDocument6 pagesErnest Allen's CVernestrallenNo ratings yet

- 02 66 00 - Gas Venting System GeotextileDocument7 pages02 66 00 - Gas Venting System GeotextiletachmidNo ratings yet

- Hazard & Effect Register for ContractsDocument2 pagesHazard & Effect Register for ContractsWisnu KertaningnagoroNo ratings yet

- Sibin K MathewDocument3 pagesSibin K MathewsibinmathewNo ratings yet

- CV Instrumentation EngineerDocument4 pagesCV Instrumentation EngineerisukuruNo ratings yet

- Prefunctional Test ChecklistDocument4 pagesPrefunctional Test ChecklistthembamusNo ratings yet

- Clients ProjectsDocument8 pagesClients Projectsajay0ajayNo ratings yet

- MMSL LIFTING EQUIPMENT EXAMINATION AND TESTINGDocument3 pagesMMSL LIFTING EQUIPMENT EXAMINATION AND TESTINGAhmed ButtNo ratings yet

- Compressor Use Risks Sess MentDocument3 pagesCompressor Use Risks Sess MentvigneshNo ratings yet

- RISK ASSESSMENT FOR GRIT BLASTINGDocument5 pagesRISK ASSESSMENT FOR GRIT BLASTINGengmgsNo ratings yet

- Shripad Dattatray Vaishampayan Engineer - ProcessDocument3 pagesShripad Dattatray Vaishampayan Engineer - ProcessavaisharmaNo ratings yet

- ELECTRICAL SYSTEMS COMMISSIONINGDocument6 pagesELECTRICAL SYSTEMS COMMISSIONINGtidjani86No ratings yet

- Service Procedures Examination and Test Procedures: MMSL-003Document12 pagesService Procedures Examination and Test Procedures: MMSL-003Ahmed ButtNo ratings yet

- J. Kammarajan: Seeking Challenging Assignments As PRODUCTION OperatorDocument4 pagesJ. Kammarajan: Seeking Challenging Assignments As PRODUCTION OperatorRama NathanNo ratings yet

- Sample of UT InstructionDocument4 pagesSample of UT Instructionmusaismail8863No ratings yet

- Annex A To Report of The ECDIS Stakeholder Meeting UK Meeting On ECDIS IssuesDocument10 pagesAnnex A To Report of The ECDIS Stakeholder Meeting UK Meeting On ECDIS IssuesVarunNairNairNo ratings yet

- Applicable Parts of Pnri Regulations: Safety in The Use of Nuclear Equipment and DevicesDocument64 pagesApplicable Parts of Pnri Regulations: Safety in The Use of Nuclear Equipment and DevicesAlvin Garcia PalancaNo ratings yet

- O&M Manual For FCUDocument30 pagesO&M Manual For FCUBeatrice Li50% (2)

- NASA Manual Arc Welder Qualification TitleDocument50 pagesNASA Manual Arc Welder Qualification TitleTanpreet SinghNo ratings yet

- Inspection Test Plan On Welding Quality ControlDocument12 pagesInspection Test Plan On Welding Quality Controlnike_y2kNo ratings yet

- Maintain Safety When Working With Biosafety CabinetsDocument15 pagesMaintain Safety When Working With Biosafety CabinetsReni LenggogeniNo ratings yet

- Krakatau Posco job openingsDocument8 pagesKrakatau Posco job openingsHenny Komala Sari SibaraniNo ratings yet

- Rajiv Gandhi Aviation Academy Semester-I Unit Test Series D'Document7 pagesRajiv Gandhi Aviation Academy Semester-I Unit Test Series D'Aamir Imam KhanNo ratings yet

- DNV OS-F101 - 2013-10 Submarine Pipeline SystemsDocument372 pagesDNV OS-F101 - 2013-10 Submarine Pipeline Systemsseantbt100% (1)

- Electronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesFrom EverandElectronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesNo ratings yet

- Summary of Code ChangesDocument4 pagesSummary of Code ChangesAlfredo MedinaNo ratings yet

- Court Date PDFDocument4 pagesCourt Date PDFkirandevi1981No ratings yet

- Jogi JobDocument1 pageJogi Jobkirandevi1981No ratings yet

- Court Date PDFDocument4 pagesCourt Date PDFkirandevi1981No ratings yet

- Preamble: Description of GuidelinesDocument2 pagesPreamble: Description of Guidelineskirandevi1981No ratings yet

- Kailash Pandey OISD 117Document29 pagesKailash Pandey OISD 117kirandevi1981No ratings yet

- MSDS Mapei Mortar For Tile PDFDocument6 pagesMSDS Mapei Mortar For Tile PDFkirandevi1981No ratings yet

- Asme V Si UnitsDocument3 pagesAsme V Si UnitsvidhisukhadiyaNo ratings yet

- Asme7 PersonnelDocument10 pagesAsme7 Personnelkirandevi1981No ratings yet

- Statement of PolicyDocument2 pagesStatement of Policyapi-26723112No ratings yet

- Appendix I - Mandatory Preparation of Technical Inquiries To TheDocument1 pageAppendix I - Mandatory Preparation of Technical Inquiries To TheJason501No ratings yet

- Woodwaste CollectionDocument4 pagesWoodwaste Collectionkirandevi1981No ratings yet

- Guideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel CodeDocument2 pagesGuideline On The Approval of New Materials Under The Asme Boiler and Pressure Vessel Codekirandevi1981No ratings yet

- Asme2b MaterialsDocument6 pagesAsme2b Materialskuchku123No ratings yet

- Asme2b NumericDocument4 pagesAsme2b Numerickkskasdkk12No ratings yet

- As Me 1 PreambleDocument1 pageAs Me 1 Preamblekirandevi1981No ratings yet

- Statement of PolicyDocument2 pagesStatement of Policyapi-26723112No ratings yet

- Part PR Requirements For Boilers Fabricated by RivetingDocument1 pagePart PR Requirements For Boilers Fabricated by Rivetingkirandevi1981No ratings yet

- Asme1pfh PDFDocument1 pageAsme1pfh PDFkirandevi1981No ratings yet

- Asme 1 PMBDocument4 pagesAsme 1 PMBPopescu AlinNo ratings yet

- OISD Compliance Vopak Kailash.Document7 pagesOISD Compliance Vopak Kailash.kirandevi1981No ratings yet

- Std1090-07 Chapter17 ReferencesDocument2 pagesStd1090-07 Chapter17 Referenceskirandevi1981No ratings yet

- Maintenance Redce Human ErrorDocument12 pagesMaintenance Redce Human ErrorradzeeryNo ratings yet

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocument4 pagesWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashNo ratings yet

- ERA News Mar 23 - Final - 0Document10 pagesERA News Mar 23 - Final - 0Băltoiu Son AlisaNo ratings yet

- RADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintDocument392 pagesRADEMAKER) Sophrosyne and The Rhetoric of Self-RestraintLafayers100% (2)

- Proportional, Solenoid Actuated Flow Control Valves Type SE and SEHDocument16 pagesProportional, Solenoid Actuated Flow Control Valves Type SE and SEHwords2zhigang_612545No ratings yet

- EPFO Declaration FormDocument4 pagesEPFO Declaration FormSiddharth PednekarNo ratings yet

- Sleep Hygiene Sleep QualityandDocument8 pagesSleep Hygiene Sleep QualityandVriddhi AgrawalNo ratings yet

- RallinAneil 2019 CHAPTER2TamingQueer DreadsAndOpenMouthsLiDocument10 pagesRallinAneil 2019 CHAPTER2TamingQueer DreadsAndOpenMouthsLiyulianseguraNo ratings yet

- Solve Equations and InequalitiesDocument13 pagesSolve Equations and InequalitiesFons Roxas-ChuaNo ratings yet

- Memo-on-Orientation and Submission of PNPKIDocument5 pagesMemo-on-Orientation and Submission of PNPKICoronia Mermaly LamsenNo ratings yet

- Writing Visual Basic ProjectsDocument1 pageWriting Visual Basic ProjectsAmmuKuttyNo ratings yet

- In2it: A System For Measurement of B-Haemoglobin A1c Manufactured by BIO-RADDocument63 pagesIn2it: A System For Measurement of B-Haemoglobin A1c Manufactured by BIO-RADiq_dianaNo ratings yet

- Logix5000 Control Systems: Connect Kinetix 350 Drives Over An Ethernet/Ip NetworkDocument50 pagesLogix5000 Control Systems: Connect Kinetix 350 Drives Over An Ethernet/Ip NetworkAlan Ruiz CortezNo ratings yet

- Final Portfolio Cover LetterDocument2 pagesFinal Portfolio Cover Letterapi-321017157No ratings yet

- Electric Machine Design 01 Electric Machine DesignDocument10 pagesElectric Machine Design 01 Electric Machine Designkhodabandelou100% (1)

- Cover Letter and Resume for Electrical Engineer PositionDocument4 pagesCover Letter and Resume for Electrical Engineer Positiongrabani77No ratings yet

- Switches Demystified Assembly PDFDocument1 pageSwitches Demystified Assembly PDFkocekoNo ratings yet

- Achmad Nurdianto, S.PD: About MeDocument2 pagesAchmad Nurdianto, S.PD: About Medidon knowrezNo ratings yet

- E-Ship Assignment 2 Utkarsh Surjey MBA-FT-EDocument3 pagesE-Ship Assignment 2 Utkarsh Surjey MBA-FT-Eutkarsh surjeyNo ratings yet

- Sa Sem Iv Assignment 1Document2 pagesSa Sem Iv Assignment 1pravin rathodNo ratings yet

- Enlightened DespotismDocument19 pagesEnlightened Despotismmeghna mNo ratings yet

- The University, Bhopal: National Law InstituteDocument19 pagesThe University, Bhopal: National Law InstituteOk OkNo ratings yet

- Vidya Mandir Public School Class 11 Computer Science String Assignment SolutionsDocument5 pagesVidya Mandir Public School Class 11 Computer Science String Assignment SolutionsArun SharmaNo ratings yet

- The Reading Process PDFDocument1 pageThe Reading Process PDFAdy OliveiraNo ratings yet

- 3 6 17weekly Homework Sheet Week 23 - 5th Grade - CcssDocument3 pages3 6 17weekly Homework Sheet Week 23 - 5th Grade - Ccssapi-328344919No ratings yet

- Work Readiness Integrated Competence Model Conceptualisation and ScaleDocument23 pagesWork Readiness Integrated Competence Model Conceptualisation and ScaleMelly NadiaNo ratings yet