Professional Documents

Culture Documents

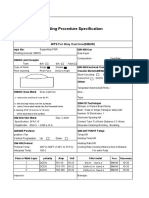

Welding Procedure Specification: WPS For SS Material 316 (GTAW)

Uploaded by

Lipika Gayen0 ratings0% found this document useful (0 votes)

179 views1 pageThis welding procedure specification outlines the parameters for gas tungsten arc welding (GTAW) of stainless steel material 316. The document specifies:

1) The welding process as GTAW using argon gas with a flow rate of 6-12 liters per minute.

2) The base metal as types 316, F 316, WP316, and TYPE 316 stainless steel in all diameters and thicknesses.

3) The filler metal as ER-316 stainless steel classification in diameters less than 6mm.

4) The welding positions as all groove positions and all fillet welds.

Original Description:

Decided

Original Title

4_6021560431213020207

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis welding procedure specification outlines the parameters for gas tungsten arc welding (GTAW) of stainless steel material 316. The document specifies:

1) The welding process as GTAW using argon gas with a flow rate of 6-12 liters per minute.

2) The base metal as types 316, F 316, WP316, and TYPE 316 stainless steel in all diameters and thicknesses.

3) The filler metal as ER-316 stainless steel classification in diameters less than 6mm.

4) The welding positions as all groove positions and all fillet welds.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

179 views1 pageWelding Procedure Specification: WPS For SS Material 316 (GTAW)

Uploaded by

Lipika GayenThis welding procedure specification outlines the parameters for gas tungsten arc welding (GTAW) of stainless steel material 316. The document specifies:

1) The welding process as GTAW using argon gas with a flow rate of 6-12 liters per minute.

2) The base metal as types 316, F 316, WP316, and TYPE 316 stainless steel in all diameters and thicknesses.

3) The filler metal as ER-316 stainless steel classification in diameters less than 6mm.

4) The welding positions as all groove positions and all fillet welds.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

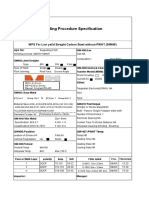

Welding Procedure Specification

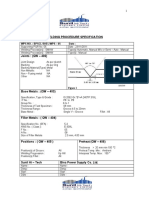

WPS For SS Material 316(GTAW)

wps No: Supporting PQR: QW-408:Gas

Welding process: GTAW Gas:Argon

Composition:99.95 Flow Rate:6-12Lit/min

QW402:Joint Desighn

Type: BW SW Fillet

Type of Weld: Single Double QW-409:Electrical Characterist

Root Opening: Root Face: Groove Angle Transfer Mode(GMAW):

Short-Circuiting Glubular Spray

Current:AC DCEN DCEP

Other:

Tangestan Electrode(GTAW): SFA5.12

QW403: Base Metal Size:1.6mm

[P,S] no:8 Group No:1 To [P,S] no:8 Group No1 Type:ETWH

Material Spec:TP 316 , F 316 , WP316 , TYPE 316 QW410:Technique

Stringer or Weave Bead:Both

Multi - Pass or Single Pass(per side) both

Diametere For pipe: All Thickness:THK:All Number Of Electrodes: 1

QW-404:Filler Metal Dia< 6mm Electrode Spacing:NA

Specification: SFA5.9 A NO 8+8 Contact Tube To Worke Distance:12-14mm

Classificatin:ER316 F NO:6+8 Interpass Cleaning:Grinding , Brushing

QW405:Position QW-407:PWHT Temp:

position of Groove:All Fillet:All Temp:NR

Vertical Progression: Up Down Holding Time:NR

QW-406:Preheat Heating Rate:NR

Preheat Temp: Min:NA Cooling Rate:NR

Interpass Temp: Min: Max:200 C

Pass or Weld Layer polarity Amp Volt Filler metal Proc. TV(cm/min)

1 DCEN 70-110 18-22 ER-316 Dia =2.2mm GTAW 10-20

2 DCEN 110-170 18-22 ER-316 Dia =3.2mm GTAW 10-20

n DCEN 150-200 18-22 ER-316 Dia =3.2mm GTAW 10-20

Welding Engineer: Manager:

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Wps - Eni-Ci - Enife-ci-A (Gray Cast Iron)Document1 pageWps - Eni-Ci - Enife-ci-A (Gray Cast Iron)AminNo ratings yet

- All Metal Hose, Medium Pressure, FJ Sereis (MS-02-322-E) R2Document6 pagesAll Metal Hose, Medium Pressure, FJ Sereis (MS-02-322-E) R2herysyam1980No ratings yet

- Ebook Membranes 2013Document577 pagesEbook Membranes 2013sergiogonzalez371375% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Impact TestDocument6 pagesImpact TestSoumadipta SenNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- API 650 Datasheet 1Document16 pagesAPI 650 Datasheet 1alwacsNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Tank Shell DesignDocument4 pagesTank Shell Designgon972001No ratings yet

- Tank Shell DesignDocument4 pagesTank Shell Designgon972001No ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- ANSI B16.5 FlangesDocument24 pagesANSI B16.5 Flangesgateauxboy100% (2)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- Plastic Industry of PakistanDocument65 pagesPlastic Industry of Pakistanhelperforeu72% (18)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Inspection Test & Plan: Pondasi Bangunan NOMOR: I-QAC-027/100.19Document21 pagesInspection Test & Plan: Pondasi Bangunan NOMOR: I-QAC-027/100.19pahrizan100% (2)

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Acoustic Emission - Standards and Technology UpdateDocument257 pagesAcoustic Emission - Standards and Technology Updatetobby65100% (1)

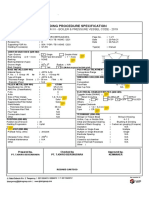

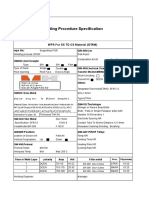

- Welding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Document1 pageWelding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Lipika GayenNo ratings yet

- Mole Concept PDFDocument43 pagesMole Concept PDFPratyushNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- API 650 Tank Shell Evaluation Rev 3Document31 pagesAPI 650 Tank Shell Evaluation Rev 3alokbdasNo ratings yet

- S.No. Hospital Code Hospital NameDocument20 pagesS.No. Hospital Code Hospital NameLipika GayenNo ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

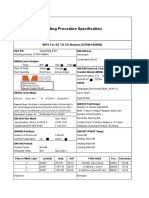

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- CyanideDocument52 pagesCyanideWilliamEliezerClNo ratings yet

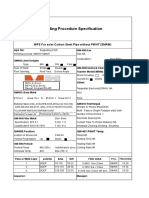

- Welding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Exist Carbon Steel Pipe Without PWHT (SMAW)Lipika Gayen100% (1)

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

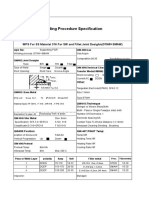

- Welding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 304 (GTAW+SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Document1 pageWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel Without PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel Without PWHT (SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenNo ratings yet

- Welding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Document1 pageWelding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Lipika GayenNo ratings yet

- Welding Procedure Specification: Wps NoDocument1 pageWelding Procedure Specification: Wps NoLipika Gayen100% (1)

- Welding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Document1 pageWelding Procedure Specification: WPS For Repair of Corrod Area (SMAW)Lipika GayenNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 01 DateAmjad PathanNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocument2 pagesQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNo ratings yet

- Table T-233.1 For RTDocument1 pageTable T-233.1 For RTLipika GayenNo ratings yet

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenNo ratings yet

- Table T-233.1 For RTDocument1 pageTable T-233.1 For RTLipika GayenNo ratings yet

- T-721 For MPTDocument1 pageT-721 For MPTLipika GayenNo ratings yet

- Acceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Document4 pagesAcceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Lipika Gayen100% (1)

- Quality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VDocument1 pageQuality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VLipika Gayen100% (1)

- Ductile Pipe MFG ProcessDocument1 pageDuctile Pipe MFG ProcessLipika GayenNo ratings yet

- CompressorDocument6 pagesCompressorLipika GayenNo ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Tee JointsDocument1 pageTee JointsLipika GayenNo ratings yet

- Third Party Inspection For Reciprocating Compressor - ProcedureDocument12 pagesThird Party Inspection For Reciprocating Compressor - ProcedureLipika GayenNo ratings yet

- Wa0000Document9 pagesWa0000Lipika GayenNo ratings yet

- Tank No: Bottom Sketch: Attached Sheet According Api 650 Note 5.3.3 Vacuum Pressure Glass Window Dimentions: Acceptance Creteria:No Leakage LocationDocument1 pageTank No: Bottom Sketch: Attached Sheet According Api 650 Note 5.3.3 Vacuum Pressure Glass Window Dimentions: Acceptance Creteria:No Leakage LocationLipika GayenNo ratings yet

- How Does A Steam Boiler Work?Document11 pagesHow Does A Steam Boiler Work?Lipika GayenNo ratings yet

- Axial Flow For Industry 1Document9 pagesAxial Flow For Industry 1Lipika GayenNo ratings yet

- Test ConditionDocument1 pageTest ConditionLipika GayenNo ratings yet

- Test ConditionDocument1 pageTest ConditionLipika GayenNo ratings yet

- Activity:: Work Permit No.: Date: Mechanical Chemical I&C Electrical CivilDocument1 pageActivity:: Work Permit No.: Date: Mechanical Chemical I&C Electrical CivilLipika GayenNo ratings yet

- Joint No: Backing: Yes No Backing Mat: N/ADocument1 pageJoint No: Backing: Yes No Backing Mat: N/ALipika GayenNo ratings yet

- 4 6048613395123405697Document64 pages4 6048613395123405697Lipika GayenNo ratings yet

- CB 523-Method I - DR Elsayed - LectDocument31 pagesCB 523-Method I - DR Elsayed - LectEslam SamirNo ratings yet

- Forging Applications: Uddeholm Tool Steels ForDocument24 pagesForging Applications: Uddeholm Tool Steels ForMin HanNo ratings yet

- SRM - A318/A319/A320/A321 REV DATE: Nov 01/2022 Tail Number - MSN - FSN: ALLDocument3 pagesSRM - A318/A319/A320/A321 REV DATE: Nov 01/2022 Tail Number - MSN - FSN: ALLingeniero aeroestructurasNo ratings yet

- Staying Ahead of The CurveDocument8 pagesStaying Ahead of The CurvehimanshuNo ratings yet

- CeramicproductsmarketDocument132 pagesCeramicproductsmarketDavid Budi SaputraNo ratings yet

- MicroDocument3 pagesMicroPrince MoniNo ratings yet

- 11 Repair KitsDocument2 pages11 Repair KitsbuddhansamratNo ratings yet

- Technical Info Librel RMX 26Document4 pagesTechnical Info Librel RMX 26Rijalul AuthonNo ratings yet

- KMMLDocument35 pagesKMMLAJITH SNo ratings yet

- Fermi Surface: Notes By: Shahzaib ShahidDocument7 pagesFermi Surface: Notes By: Shahzaib ShahidShazaib MirzaNo ratings yet

- Reverse OsmosisDocument4 pagesReverse OsmosisKiran ShresthaNo ratings yet

- 2.4 Transition Metals Formation of Coloured Ions QsDocument27 pages2.4 Transition Metals Formation of Coloured Ions QsJesulayomi BolajiNo ratings yet

- Lead, Zinc and Strontium Distribution in The Oxidation ZoneDocument11 pagesLead, Zinc and Strontium Distribution in The Oxidation ZoneAnonymous Lrw61wNo ratings yet

- Loss of Prestressed Due To ANCHORAGEDocument38 pagesLoss of Prestressed Due To ANCHORAGEKimberly Shawn Nicole SantosNo ratings yet

- CAPE Chemistry Mock Exams U2 2015Document19 pagesCAPE Chemistry Mock Exams U2 2015Nicholas CharlesNo ratings yet

- G40 Ready Mix Data Sheet: PropertiesDocument4 pagesG40 Ready Mix Data Sheet: Propertieswadi ajanaNo ratings yet

- Sustainable Materialization of Responsive ArchitectureDocument20 pagesSustainable Materialization of Responsive ArchitectureAlexander TeohNo ratings yet

- Bom of Studs & Nuts For Balance SystemDocument4 pagesBom of Studs & Nuts For Balance SystemmishtinilNo ratings yet

- CIV-MS-010-07-Rapid Chloride PermeabilityDocument7 pagesCIV-MS-010-07-Rapid Chloride PermeabilityAdil faridNo ratings yet

- Chemistry Investigatory Project: Topic: Preparation of Rayon ThreadDocument14 pagesChemistry Investigatory Project: Topic: Preparation of Rayon Threadkhushi chelaniNo ratings yet

- Report On Treatment of Waste WaterDocument7 pagesReport On Treatment of Waste WaterSaptarshi GiriNo ratings yet

- Inorganic Chemistry 2-1Document48 pagesInorganic Chemistry 2-1Oliver JumaNo ratings yet

- Midland Gear Pumps Phase 1Document5 pagesMidland Gear Pumps Phase 1Рома БлошенкоNo ratings yet