Professional Documents

Culture Documents

Bagasse Pellet Plant PG Assembagoes Rotary Dryer Calculation Sizing

Uploaded by

Akhmad Audi HarvanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bagasse Pellet Plant PG Assembagoes Rotary Dryer Calculation Sizing

Uploaded by

Akhmad Audi HarvanCopyright:

Available Formats

DOC NO : TBA

CON. DOC. NO : TBA

REVISION :A

BAGASSE PELLET PLANT DATE : 10/10/2018

PG ASSEMBAGOES STATUS : IFR

ROTARY DRYER CALCULATION SIZING

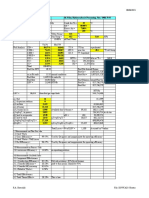

1. Data

Mass Flowrate of wet powder = 8.10 ton/hr

Wet powder = 51% MC

Dry Powder = 5% MC

Mass Flowrate of Dry Powder = 4.18 ton/hr

MC weight to take = 3.92 ton/hr

Tin powder = 30.00 degC

T_out powder = 100.00 degC

T_in air = 250.00 degC

T_out air = 100.00 degC

2. Ambient Condition

Avg. Dry Bulb temp. = 40.00 degC = 104 degF

RH = 95%

Avg. Wet bulb temp. = 38.89 degC = 102 degF

Y1 = 0.0048 lb water/lb dry air

= 0.0048 kg water/kg dry air

3. Calculation of air needed

Cs = 1.014024 kJ/kg/K 1.005 1.88

Panas latent 579.3 kcal/kg

Cp = 1 kcal/kg/C ∆

Q = 2,546,622.95 kcal/hr

= 10,662,200.96 kJ/hr

Air mass need = 150,210.60 kg/hr

Y2 = 0.03 kg water/kg dry air

4. Calculate RH of air outlet

A = 29.8605 B

B = -3152.2 logPHs 2O = A + + C log T + DT + ET 2 , P [=] mmHg; T [=] K

T

C = -7.3037

D = 2.4247E-09

E = 0.000001809

T = 100 degC

= 373 K

log P = 2.88

P0 = 755.54 mmHg

= 100730.31 Pa

P_H2O = 4776 Pa

RH outlet air = 4.74% OK

Design Margin = 10.00%

Air mass needs = 165,232 kg/hr

5. Calculate of Inside Diameter & Length

Allowable range of mass velocity of air = 2000 - 25000 kg/hr/m2 (Mc. Cabe, Harriot & Smith, 1993)

Allowable range of Dryer = 1-3 m (Mc. Cabe, Harriot & Smith, 1993)

Selected mass velocity of air = 25000 kg/hr/m2

Area of pipe = 6.61 m2

Calculated Diameter of Drum = 2.90 m

Selected Diameter = 3 m

Selected Area of Drum = 7.07 m2

G slected = 23,375.50 kg/hr/m2

Use empirical calculation to calculate the overall heat transfer coeef

Use, index n = 0.67 (Mc. Commick, 1962)

Typical k range = 3.75 <= k <= 5.25

Selected k = 3.5

U_a = 1,031.73 kJ/hr/m3/K

DOC NO : TBA

CON. DOC. NO : TBA

REVISION :A

BAGASSE PELLET PLANT DATE : 10/10/2018

PG ASSEMBAGOES STATUS : IFR

ROTARY DRYER CALCULATION SIZING

6. Calculation of wet bulb temperature

Range values of Nt = 1.5 < Nt < 2.5

Selected Nt value = 2.2 ln

Tw = 81.31 degC

∆T lmtd = 68.18 K

7. Calculate the length of dryer ∆

Q = 10,662,200.96 kJ/hr

U_a = 1,031.73 kJ/hr/m3/K

A = 7.07 m2

∆T lmtd = 68.18 K

L = 21.44 m

L/D Range = 4 - 10

Calculated L/D = 7.15

8. Calculate of RPM

Range of speed = 0.1 - 0.5 m/s (van't Land, 2012)

Range of RPM = 2-5 RPM

Selected Speed = 0.20 m/s

RPM = 4.00 RPM

9. Calculation of Flight Design 3

D = 9.84 ft

No of Flight = 29.53

Selected no of Flight = 30.00

Flight Depth = 0.38 m

8

.

10. Calculation of Resident Time 5

Range of Resident time = 5 - 90 min

dp = 60,000.00 um

B = 0.02

S = 0.49

Teta (sudut kemiringan) = 26.00 0.23 2

N = 4.00 1/min .

D = 3.00 m

L = 21.44 m

G = 23,375.50 kg/hr/m2

Dry Product = 4,177.89 kg/hr

A = 7.07 m2

F = 591.05 kg/hr/m2

P = 0.97

Q = 34.62

Resident Time = 35.59 min

11. Calculate the working stress

Su = 380.00 Mpa (ASME SA285 Gr. C)

Fm = 0.92 (Material Factor for Grade C)

Fa = 1.00 (Radiographing factor. 1 = not employed radiographing)

Fr = 1.00 (Stress relieving factor, 1 = not employed)

Fs = 0.25 (Safety factor for temperature less than 315.56 degC)

Sw = 87.40 Mpa

e = 0.70 Joint efficiency 2

Design Pressue = 50.00 psig (hesse & Rushton, 1975)

= 446,090.80 N/m2 Abs

CA = 6.35 mm

D = 3.00 m

= 3,000.00 mm

DOC NO : TBA

CON. DOC. NO : TBA

REVISION :A

BAGASSE PELLET PLANT DATE : 10/10/2018

PG ASSEMBAGOES STATUS : IFR

ROTARY DRYER CALCULATION SIZING

ts = 17.33 mm

Selected Thickness = 20.00 mm

Outer Diameter of Drum = 3.040 m

12. Calculation of insulation thickness 2 1

Q = 10,662,200.956 kJ/hr 2 3

= 2,961,722.511 W ln ln

L = 21.44 m

T2 = 523.00 K

T1 = 313.00 K

kA = 51.92 W/m/K (thermal cond of steel)

kB = 0.72 W/m/K (thermal cond of insulation)

t_insulation = 0.000 m

= 0.00 mm

r1 = 1.50 m

r2 = 1.52 m

r3 = 1.52 m

C1 = 28,292.96

C2 = 0.00025510

C3 = 0.00000000

Q = 110,909,942 W

delta = 107,948,219.33

Dryer total diameter = 3.040 m

13. Calculate the live load & rotating load

V_Shell Material = 16.28 m3

W_Shell Material = 127,760.25 kg

V_Insulation = 0.00 m3

W_Insulation = 0.00 kg

W_material load = 4,804.51 kg

W total loaded = 132,564.76 kg

14. Calculation blower power, motive power & driver power

Power motive = 45.47 kW

Q inlet air = 248,151.74 m3/hr

Power blower = 134.99 kW

Power driver = 21.15 BHP

= 15.77 kW

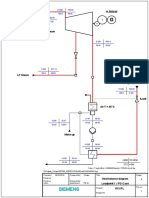

GENERAL ARRANGEMENT

D in

Flight No

Around the

D out

D in = 3 m L= 21.44 m

D out = 3.040 m

Flight Depth

Flight No = 30.00 ea

Flight Depth = 0.38 m

You might also like

- Calculating flow and heat transfer in a cement plant cyclone preheaterDocument5 pagesCalculating flow and heat transfer in a cement plant cyclone preheaterhmaza shakeelNo ratings yet

- Powder transfer rate and vacuum system sizingDocument3 pagesPowder transfer rate and vacuum system sizingm_nassifNo ratings yet

- Atfd Design Calculation: Data Energy Balance Agitator Shell DesignDocument1 pageAtfd Design Calculation: Data Energy Balance Agitator Shell DesignManoj BNo ratings yet

- IPA PreheaterDocument9 pagesIPA PreheaterNitin KurupNo ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationGLENDA CASINONo ratings yet

- BẢNG TÍNH TOÁN THÀNH PHẦN XI MĂNGDocument1 pageBẢNG TÍNH TOÁN THÀNH PHẦN XI MĂNGVo Anh HaoNo ratings yet

- Unit conversion program for engineering processesDocument9 pagesUnit conversion program for engineering processesAnubhav KhandelwalNo ratings yet

- COAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISDocument5 pagesCOAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISDenny ThomasNo ratings yet

- U Cal For ReactorDocument5 pagesU Cal For ReactorwestewrNo ratings yet

- XCELDocument2 pagesXCELridanormaNo ratings yet

- Belt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldDocument1 pageBelt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldManoj ThakurNo ratings yet

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocument9 pagesEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- Fluid Properties Correlation for NeonDocument68 pagesFluid Properties Correlation for NeonSiddiqui Muhammad AshfaqueNo ratings yet

- CALCULATION OF GAS POLLUTANT RATE PER YEARDocument2 pagesCALCULATION OF GAS POLLUTANT RATE PER YEARtouhidNo ratings yet

- Cost estimation of 6T rotary tilting dryerDocument4 pagesCost estimation of 6T rotary tilting dryerAlok NayakNo ratings yet

- Pressur Drop Calculation For DS Unit Vessels With F ProductsDocument9 pagesPressur Drop Calculation For DS Unit Vessels With F ProductsMaryam vafaee.nNo ratings yet

- Boiler CalculationDocument4 pagesBoiler Calculationmohsin husen BargirNo ratings yet

- Coal Calculation 2Document2 pagesCoal Calculation 2Hanuman TripathiNo ratings yet

- HBDs 01Document4 pagesHBDs 01deepdaman18891No ratings yet

- Furnace EfficiencyDocument1 pageFurnace EfficiencySteve WanNo ratings yet

- HEAT EXCHANGER PERFORMANCE ANALYSISDocument6 pagesHEAT EXCHANGER PERFORMANCE ANALYSISJM Flores De SilvaNo ratings yet

- 3 - Heating - Calculation - Tool - EmptyDocument7 pages3 - Heating - Calculation - Tool - EmptyThaigroup CementNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Upl HBDSDocument32 pagesUpl HBDSSuparna BhoseNo ratings yet

- MODEL: PFTA 1500-4: Ratings & Performance DataDocument4 pagesMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcNo ratings yet

- Design of Condenser: 1) Heat Balance 2) Temeprature DifferenceDocument1 pageDesign of Condenser: 1) Heat Balance 2) Temeprature DifferenceBhawani Pratap Singh PanwarNo ratings yet

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerDocument6 pagesDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzNo ratings yet

- Modified Vyas formula for S.D.P. treatment of organic and aqueous wasteDocument11 pagesModified Vyas formula for S.D.P. treatment of organic and aqueous wasteNITIN P SHAHNo ratings yet

- DRYER CALCULATIONSDocument4 pagesDRYER CALCULATIONSOmprakaash MokideNo ratings yet

- Evaporation Principles and Black Liquor Properties: David T. Clay, PH.DDocument6 pagesEvaporation Principles and Black Liquor Properties: David T. Clay, PH.DJKKNo ratings yet

- CycloneDocument10 pagesCyclonepradeep4545No ratings yet

- CentrifugalCompressorPower SI UnitsDocument4 pagesCentrifugalCompressorPower SI UnitsReza GhanavatiNo ratings yet

- Piping CalculationsDocument3 pagesPiping CalculationsAkhilesh Dhar DiwediNo ratings yet

- LPPJFF RL - Envi - 2013 04 04Document10 pagesLPPJFF RL - Envi - 2013 04 04Petros IosifidisNo ratings yet

- Triplex BoilerDocument53 pagesTriplex Boilershahroze mustafaNo ratings yet

- HPGRSim Openpractica1Document83 pagesHPGRSim Openpractica1Aldo PabloNo ratings yet

- Typical Cement Mill Bag Filter Capital Cost CamparisonDocument1 pageTypical Cement Mill Bag Filter Capital Cost CamparisonKenny RuizNo ratings yet

- Boil Up RateDocument1 pageBoil Up RateNitin KurupNo ratings yet

- Sjae ParameterDocument296 pagesSjae Parameterrizka nur failaNo ratings yet

- Design: of Shell & Tube Heat ExchangerDocument27 pagesDesign: of Shell & Tube Heat ExchangerBalamurugan SakthivelNo ratings yet

- Bag Filter CalculationDocument3 pagesBag Filter CalculationJag KhadseNo ratings yet

- MicrofilterDocument17 pagesMicrofilterArrianne Jaye MataNo ratings yet

- Ta 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorDocument8 pagesTa 0 °C Pa 0.98 Bar Xa 9260 % Ha 2435 KJ/KG: EvaporatorShella Theresya PandianganNo ratings yet

- AHUs Calculations Air Side Friction & Dynamic Losses.F.1 01.17PMDocument73 pagesAHUs Calculations Air Side Friction & Dynamic Losses.F.1 01.17PMAdnan AttishNo ratings yet

- 1.5 NPS RecuperatorDocument7 pages1.5 NPS RecuperatorAnonymous pVoSWn8yh0No ratings yet

- Result: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationDocument2 pagesResult: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationjagjitNo ratings yet

- Gas Flow Rate Mass Flow Mol Flow Gas Volume FlowDocument9 pagesGas Flow Rate Mass Flow Mol Flow Gas Volume FlownivethithaNo ratings yet

- Rotary LockDocument224 pagesRotary LockTahirMutluNo ratings yet

- FAD CALCULATION FOR AIR DELIVERYDocument4 pagesFAD CALCULATION FOR AIR DELIVERYAnonymous JZK84WzfKNo ratings yet

- Conveyor Design Summary ReportDocument1 pageConveyor Design Summary ReportAlejandro Castro0% (1)

- Heat Exchanger Shell Id CalculationsDocument7 pagesHeat Exchanger Shell Id CalculationsmanojNo ratings yet

- Heat Exchanger Design and HT Coefficent Calculation From RC-6 BookDocument20 pagesHeat Exchanger Design and HT Coefficent Calculation From RC-6 BookJag KhadseNo ratings yet

- Vapor Line Sizing-Mpp6Document10 pagesVapor Line Sizing-Mpp6Nitin KurupNo ratings yet

- Steam Drum (Single) : Drum Thickness Calculation - Sa 516 Gr. 70 (As Per Ibr)Document3 pagesSteam Drum (Single) : Drum Thickness Calculation - Sa 516 Gr. 70 (As Per Ibr)neelNo ratings yet

- Stack Gas Specification: Project Name Client Location GeneralDocument6 pagesStack Gas Specification: Project Name Client Location Generalbudi utomoNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Determination and correlation of heat transfer coefficients in a falling film evaporatorDocument7 pagesDetermination and correlation of heat transfer coefficients in a falling film evaporatorGonzaloNo ratings yet

- Lampiran 1: Perhitungan Nilai RD Dan Pressure Drop DesainDocument21 pagesLampiran 1: Perhitungan Nilai RD Dan Pressure Drop DesainAdiyat AdiNo ratings yet

- Psychrometric Chart NotesDocument50 pagesPsychrometric Chart NotesMohammed MudassirNo ratings yet

- CyclonesDocument11 pagesCyclonesMisdi HabibiNo ratings yet

- CyclonesDocument11 pagesCyclonesMisdi HabibiNo ratings yet

- Amadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-012 HAZ Dossier - Pine Creek MS - August 2015Document288 pagesAmadeus Gas Pipeline - Project Justifications - Item 8 - 18756-5-HAD-012 HAZ Dossier - Pine Creek MS - August 2015Akhmad Audi HarvanNo ratings yet

- Assembly Water Treatment PackageDocument1 pageAssembly Water Treatment PackageAkhmad Audi HarvanNo ratings yet

- CyclonesDocument11 pagesCyclonesMisdi HabibiNo ratings yet

- Asma CapitalDocument10 pagesAsma CapitalAkhmad Audi HarvanNo ratings yet

- Evaporator Cooler MediaDocument2 pagesEvaporator Cooler MediaAkhmad Audi HarvanNo ratings yet

- Dry Capacity ChartDocument2 pagesDry Capacity CharttowiwaNo ratings yet

- FoggingDocument4 pagesFoggingAkhmad Audi HarvanNo ratings yet

- Batch Mixing of Chemicals - Ed-1001Document1 pageBatch Mixing of Chemicals - Ed-1001osto72No ratings yet

- Column SizingDocument16 pagesColumn SizingSyed Muzamil Ahmed100% (9)

- Column SizingDocument16 pagesColumn SizingSyed Muzamil Ahmed100% (9)

- Transmital ProsympacDocument2 pagesTransmital ProsympacAkhmad Audi HarvanNo ratings yet

- Nickel Pig Iron Long Term SolutionsDocument18 pagesNickel Pig Iron Long Term SolutionsAkhmad Audi HarvanNo ratings yet

- Vibrating Screen Data SheetDocument1 pageVibrating Screen Data SheetAkhmad Audi HarvanNo ratings yet

- Molten Salt Engineering Database - 4502650Document70 pagesMolten Salt Engineering Database - 4502650Mauricio Cesar DalzochioNo ratings yet

- Draft M.O.M ProSympacDocument1 pageDraft M.O.M ProSympacAkhmad Audi HarvanNo ratings yet

- Group Codes and Rates for Agricultural ProductsDocument260 pagesGroup Codes and Rates for Agricultural ProductsSK Business groupNo ratings yet

- Drawings - 37163, 37164Document23 pagesDrawings - 37163, 37164intecNo ratings yet

- Welcome To Car Tuning TipsDocument60 pagesWelcome To Car Tuning TipsVeer HondaNo ratings yet

- C3 Rock Seal acrylic cement waterproof coatingDocument2 pagesC3 Rock Seal acrylic cement waterproof coatingimran jamalNo ratings yet

- Commercial Desalination Products Powered by Renewable EnergyDocument28 pagesCommercial Desalination Products Powered by Renewable EnergyCognosferaNo ratings yet

- Guia 1Document62 pagesGuia 1Jorge Luis Rafaele CondeNo ratings yet

- "KEI" Three Core Aluminium & Copper Conductor, XLPE Insulated, Armoured Cable Conforming To IS 7098 Part-2/1985Document7 pages"KEI" Three Core Aluminium & Copper Conductor, XLPE Insulated, Armoured Cable Conforming To IS 7098 Part-2/1985rakeshamechNo ratings yet

- Section 14 (Water Distribution Systems)Document88 pagesSection 14 (Water Distribution Systems)badrul79No ratings yet

- Thin FilmDocument42 pagesThin FilmBhagyashree PaniNo ratings yet

- Cooling Tower TDS CalculationsDocument3 pagesCooling Tower TDS CalculationsBharat MahajanNo ratings yet

- Sikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDocument7 pagesSikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDarwin SagiNo ratings yet

- METAL CASTING GUIDEDocument18 pagesMETAL CASTING GUIDEvelavansuNo ratings yet

- Non-Asbestos Gasket: Catalogue No. Zy03Document24 pagesNon-Asbestos Gasket: Catalogue No. Zy03Wh NgNo ratings yet

- The Vlasov Foundation Model: Summary-AnDocument7 pagesThe Vlasov Foundation Model: Summary-AnPartho MukherjeeNo ratings yet

- Housekeeping ScheduleDocument3 pagesHousekeeping ScheduleJohn Dominic AcuñaNo ratings yet

- Duct Base Fdbz492 SeriesDocument4 pagesDuct Base Fdbz492 SeriesWERMERMNo ratings yet

- Structural Joint FailuresDocument4 pagesStructural Joint FailuresManoj ManoharanNo ratings yet

- Mil PRF 87937DDocument23 pagesMil PRF 87937DmurphygtNo ratings yet

- Ge Converteam mv3000 Ferrite InstallDocument4 pagesGe Converteam mv3000 Ferrite InstallDiego MontanezNo ratings yet

- Peracetic Acid SDSDocument3 pagesPeracetic Acid SDSEsteban MurilloNo ratings yet

- N 50B 4KG1 PDFDocument2 pagesN 50B 4KG1 PDFdocrafiNo ratings yet

- Proposed Perimeter Fence Project SpecsDocument3 pagesProposed Perimeter Fence Project Specsmaria cristina santosNo ratings yet

- Tension and shear anchorage systems for limestone structuresDocument32 pagesTension and shear anchorage systems for limestone structuresHussein K. AliNo ratings yet

- Propaver: An Innovative Design, Built To The Highest Standards To Meet and Exceed The Customer'S DemandsDocument4 pagesPropaver: An Innovative Design, Built To The Highest Standards To Meet and Exceed The Customer'S Demandswalk002No ratings yet

- Product Data: Hexply 916Document2 pagesProduct Data: Hexply 916McLemiNo ratings yet

- Lec2 CIVE1144 2013Document36 pagesLec2 CIVE1144 2013Joe TangNo ratings yet

- Pro Forma Invoice For HOWO Spare Parts (FOB7.8)Document4 pagesPro Forma Invoice For HOWO Spare Parts (FOB7.8)FAOUZINo ratings yet

- An Overview of Photocells and Photoreactors For Photoelectrochemical Water SplittingDocument12 pagesAn Overview of Photocells and Photoreactors For Photoelectrochemical Water SplittingjmcorreahoyNo ratings yet

- MR Aviation Turbine Fuel (Def Stan 91 91 Issue 6)Document4 pagesMR Aviation Turbine Fuel (Def Stan 91 91 Issue 6)Karthik BalajiNo ratings yet