Professional Documents

Culture Documents

Job - ID190222 - Tag Reports PDF

Uploaded by

Daniel DuongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job - ID190222 - Tag Reports PDF

Uploaded by

Daniel DuongCopyright:

Available Formats

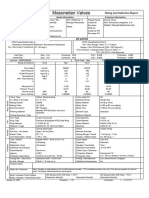

Tag ID190222: ASCDA-PSV-570001 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASCDA-PSV-570001 WHP01-PMC1-ASDCA-05-2700 0

Selected

Drawing Index Inlet Line Outlet Line

Plant # Issue For Service Revised By

# # # #

DIESEL SUPPLY HEADER System

FRO Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII - Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 93 °C Min. Design T. 5 °C

Operating Operating Constant Back

Pressure

5 Bar G Temp. 50 °C P. 0.2 Bar G

Set Pressure 10 Bar G Relief Temp. 93 °C Variable Back P. 0 Bar G

Operating to Set

%

50 % Percent Over P. 10 % Over Pressure 1 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 12.013 Bar Abs P. 9.8 Bar G

Non-Compressible State

Fluid Type DIESEL OIL, FUEL Specific Gravity 0.84 sp gr Viscosity Type Absolute

Req. Flow Cap. 47.8 kg/hr Viscosity 0.98 Centipoise

Calculated Area 0.51325 mm² Reynolds # 1554.8

Resolved ASME Area: 0.51325 mm² (Resolved by Maximum) Resolved API Area: 0.46193 mm²

Model Selection

Manufacturer Farris API Letter D Inlet Size 1.0 in Outlet Size 2.0 in

Model Number 26DA10L-120/LCN/SP API Area 71 mm² In. Rating 150 # Out. Rating 150 #

Valve Design Conventional ASME Area 97 mm² In. Facing RF Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 2 NACE Yes

Name Plate Capacity (Water): 10.675 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASCDA-PSV-570001 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Case A Liquid Unknown 47.8 kg/hr 9033.8 kg/hr 93 °C -N - - 0.51325 mm²

Scenario: Case A / Liquid Mass

Required Flow Capacity Vliquid 0.056987 m³/hr

Specific Gravity Gliquid 0.84 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 10.8 Bar G

Liquid Viscosity Factor Ku 0.93277

Liquid Flow Factor Kw -

DIESEL OIL,

Fluid Type Req'd Flow Capacity Qliquid 47.8 kg/hr

FUEL

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.98 Centipoise Relief Temperature Trelief 93 °C

Reynolds # R 1554.8 ASME Area (Actual) 0.51325 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASCDA-PSV-570001 Data Sheet

2019-05-03 12:06 Page 2

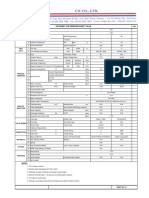

Tag ID190222: ASDCA-PSV-275104 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-275104 0

Selected

Drawing Index Inlet Line

Plant # Issue For Service Outlet Line # Revised By

# # #

TORE SCRUB System

Bidding

OUTLET Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Blocked Discharge Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 93 °C Min. Design T. -10 °C

Operating Operating Constant Back

Pressure

11 Bar G Temp. 25 °C P. 0.26 Bar G

Set Pressure 25 Bar G Relief Temp. 52.65 °C Variable Back P. 0 Bar G

Operating to Set

%

44 % Percent Over P. 10 % Over Pressure 2.5 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 28.513 Bar Abs P. 24.74 Bar G

Non-Compressible State

Fluid Type Sea Water Specific Gravity 0.988 sp gr Viscosity Type Absolute

Req. Flow Cap. 59180 kg/hr Viscosity 0.52 Centipoise

Calculated Area 344.13 mm² Reynolds # 1879265

Resolved ASME Area: 344.13 mm² (Resolved by Maximum) Resolved API Area: 309.71 mm²

Model Selection

Manufacturer Farris API Letter G Inlet Size 1.5 in Outlet Size 3.0 in

Model Number 26GA12B-120/M4N/SP API Area 325 mm² In. Rating 300 # Out. Rating 150 #

Valve Design Conventional ASME Area 361 mm² In. Facing RF Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Water): 62.459 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-275104 - Data Sheet

Model Materials

Body Monel (SA-494 Gr. M35-1) Bonnet Monel (SA-494 Gr. M35-1)

Nozzle Monel Disc Monel

Guide Monel Spring Inconel X750

Bellows N/A Custom Boltings A276 S32760-S / S32760-A (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Blocked

Case A Liquid 59180 kg/hr 62082 kg/hr 52.65 °C - lbs - - 344.13 mm²

Discharge

Scenario: Case A / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 59.986 m³/hr

Specific Gravity Gliquid 0.988 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 27.24 Bar G

Liquid Viscosity Factor Ku 1

Liquid Flow Factor Kw -

Fluid Type Sea Water Req'd Flow Capacity Qliquid 59180 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.52 Centipoise Relief Temperature Trelief 52.65 °C

Reynolds # R 1879265 ASME Area (Actual) 344.13 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-275104 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-290127 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-290127 0

Selected

Drawing Index Inlet Line

Plant # Issue For Service Outlet Line # Revised By

# # #

LIFT GAS HEATER System

Bidding

OUTLET Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Block In/Heat On Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

120 Bar G Temp. 26 °C P. 2.7 Bar G

Set Pressure 139.5 Bar G Relief Temp. 62.56 °C Variable Back P. 0 Bar G

Operating to Set

%

86.022 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 136.8 Bar G

Compressible State

Fluid Process Gas, Sour Molecular Weight 20.82 Mol Wt Gas Flow Const. 331.7

Req. Flow Cap. 3762.2 kg/hr Specific Gravity 0.71867 sp gr Compressibility 0.92

Calculated Specific Heat

Area

43.384 mm² Ratio 1.147

Resolved ASME Area: 43.384 mm² (Resolved by Maximum) Resolved API Area: 39.046 mm²

Model Selection

Manufacturer Farris API Letter D Inlet Size 1.5 in Outlet Size 2.0 in

Model Number 26DA15-920/LCN/SP API Area 71 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 97 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 8516.3 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-290127 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Block

Case A Vapor 3762.2 kg/hr 8411.7 kg/hr 62.56 °C 212.26 lbs 109.58 82.187 43.384 mm²

In/Heat On

Scenario: Case A / Vapor Mass -- Block In/Heat On

Required Flow Capacity Wvapor 3762.2 kg/hr

Relief Temperature Trelief 62.56 °C

Compressibility Z 0.92

Gas Flow Constant C 331.7

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Process Gas,

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined)

Sour

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.71867 sp gr

Molecular Weight Mvapor 20.82 Mol Wt Ratio of Specific Heats k 1.147

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 43.384 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-290127 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-291127 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-291127 0

Selected

Drawing Index Inlet Line

Plant # Issue For Service Outlet Line # Revised By

# # #

LIFT GAS HEATER System

Bidding

OUTLET Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Block In/Heat On Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

120 Bar G Temp. 26 °C P. 2.7 Bar G

Set Pressure 139.5 Bar G Relief Temp. 62.56 °C Variable Back P. 0 Bar G

Operating to Set

%

86.022 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 136.8 Bar G

Compressible State

Fluid Process Gas, Sour Molecular Weight 20.82 Mol Wt Gas Flow Const. 331.7

Req. Flow Cap. 3762.2 kg/hr Specific Gravity 0.71867 sp gr Compressibility 0.92

Calculated Specific Heat

Area

43.384 mm² Ratio 1.147

Resolved ASME Area: 43.384 mm² (Resolved by Maximum) Resolved API Area: 39.046 mm²

Model Selection

Manufacturer Farris API Letter D Inlet Size 1.5 in Outlet Size 2.0 in

Model Number 26DA15-920/LCN/SP API Area 71 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 97 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 8516.3 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-291127 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Block

Case A Vapor 3762.2 kg/hr 8411.7 kg/hr 62.56 °C 212.26 lbs 109.58 82.187 43.384 mm²

In/Heat On

Scenario: Case A / Vapor Mass -- Block In/Heat On

Required Flow Capacity Wvapor 3762.2 kg/hr

Relief Temperature Trelief 62.56 °C

Compressibility Z 0.92

Gas Flow Constant C 331.7

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Process Gas,

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined)

Sour

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.71867 sp gr

Molecular Weight Mvapor 20.82 Mol Wt Ratio of Specific Heats k 1.147

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 43.384 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-291127 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-330019 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-330019 0

Selected

Drawing Index Inlet Line

Plant # Issue For Service Outlet Line # Revised By

# # #

PROD. MANIFOLD System

Bidding

WEST Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Subsurface Fracture/Gas Release Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

7 Bar G Temp. 53 °C P. 2.7 Bar G

Set Pressure 139.5 Bar G Relief Temp. 53 °C Variable Back P. 0 Bar G

Operating to Set

%

5.0179 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 136.8 Bar G

Compressible State

Fluid Hydrocarbon Molecular Weight 22.05 Mol Wt Gas Flow Const. 330.1

Req. Flow Cap. 27510 kg/hr Specific Gravity 0.76113 sp gr Compressibility 0.7222

Calculated Specific Heat

Area

270.5 mm² Ratio 1.131

Resolved ASME Area: 270.5 mm² (Resolved by Maximum) Resolved API Area: 243.45 mm²

Model Selection

Manufacturer Farris API Letter G Inlet Size 2.0 in Outlet Size 3.0 in

Model Number 26GA15-920/LCN/SP API Area 325 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 361 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 31693 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-330019 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Subsurface

Case A Vapor 27510 kg/hr 36713 kg/hr 53 °C 899.72 lbs 115.55 86.66 270.5 mm²

Fracture/Gas Release

Subsurface

Case B Vapor 26400 kg/hr 35342 kg/hr 53 °C 887.76 lbs 115.59 86.689 269.66 mm²

Fracture/Gas Release

Scenario: Case A / Vapor Mass -- Subsurface Fracture/Gas Release

Required Flow Capacity Wvapor 27510 kg/hr

Relief Temperature Trelief 53 °C

Compressibility Z 0.7222

Gas Flow Constant C 330.1

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.76113 sp gr

Molecular Weight Mvapor 22.05 Mol Wt Ratio of Specific Heats k 1.131

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 270.5 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-330019 - Data Sheet

Scenario: Case B / Vapor Mass -- Subsurface Fracture/Gas Release

Required Flow Capacity Wvapor 26400 kg/hr

Relief Temperature Trelief 53 °C

Compressibility Z 0.7514

Gas Flow Constant C 330.8

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.73076 sp gr

Molecular Weight Mvapor 21.17 Mol Wt Ratio of Specific Heats k 1.138

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 269.66 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-330019 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-330020 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-330020 0

Selected

Drawing Index Inlet Line

Plant # Issue For Service Outlet Line # Revised By

# # #

PROD. MANIFOLD System

Bidding

WEST Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Subsurface Fracture/Gas Release Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

7 Bar G Temp. 53 °C P. 2.7 Bar G

Set Pressure 139.5 Bar G Relief Temp. 53 °C Variable Back P. 0 Bar G

Operating to Set

%

5.0179 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 136.8 Bar G

Compressible State

Fluid Hydrocarbon Molecular Weight 22.05 Mol Wt Gas Flow Const. 330.1

Req. Flow Cap. 27510 kg/hr Specific Gravity 0.76113 sp gr Compressibility 0.7222

Calculated Specific Heat

Area

270.5 mm² Ratio 1.131

Resolved ASME Area: 270.5 mm² (Resolved by Maximum) Resolved API Area: 243.45 mm²

Model Selection

Manufacturer Farris API Letter G Inlet Size 2.0 in Outlet Size 3.0 in

Model Number 26GA15-920/LCN/SP API Area 325 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 361 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 31693 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-330020 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Subsurface

Case A Vapor 27510 kg/hr 36713 kg/hr 53 °C 899.72 lbs 115.55 86.66 270.5 mm²

Fracture/Gas Release

Subsurface

Case B Vapor 26400 kg/hr 35342 kg/hr 53 °C 887.76 lbs 115.59 86.689 269.66 mm²

Fracture/Gas Release

Scenario: Case A / Vapor Mass -- Subsurface Fracture/Gas Release

Required Flow Capacity Wvapor 27510 kg/hr

Relief Temperature Trelief 53 °C

Compressibility Z 0.7222

Gas Flow Constant C 330.1

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.76113 sp gr

Molecular Weight Mvapor 22.05 Mol Wt Ratio of Specific Heats k 1.131

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 270.5 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-330020 - Data Sheet

Scenario: Case B / Vapor Mass -- Subsurface Fracture/Gas Release

Required Flow Capacity Wvapor 26400 kg/hr

Relief Temperature Trelief 53 °C

Compressibility Z 0.7514

Gas Flow Constant C 330.8

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.73076 sp gr

Molecular Weight Mvapor 21.17 Mol Wt Ratio of Specific Heats k 1.138

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 269.66 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-330020 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-340112 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Tag # Tag Description Tag Status P / ID Discharge To Revision #

ASDCA-PSV-340112 Valve Selected 0

Plant # Drawing # Index # Issue For Service Inlet Line # Outlet Line # Revised By

Bidding INLET SEPARATOR System Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Blocked Outlet Two-Phase Flow No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

7.062 Bar G Temp. 48.28 °C P. 2.7 Bar G

Set Pressure 13.8 Bar G Relief Temp. 50.85 °C Variable Back P. 0 Bar G

Operating to Set

%

51.174 % Percent Over P. 16 % Over Pressure 2.208 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 17.021 Bar Abs P. 13.8 Bar G

Two-Phase Flow State

2 Phase Sat

Scenario Noncond or Highly Equation Equation D.3 Vap. Gas Mass Frac. -

Subcooled

Mass Flow 671700 kg/hr

Calculated Area 32688 mm² Fluid Type User Defined Fluid Name Hydrocarbon

Resolved ASME Area: 32688 mm² (Resolved by Maximum) Resolved API Area: 29419 mm²

Model Selection (Multiple Valves)

Manufacturer Farris In. Rating 300 # Out. Rating 150 # Test Gag No

Model Number H26TB12L-120/LCN/SP+T In. Facing RF Out. Facing RF Quantity 2

Valve Design Bellows Cap Constrn Screwed Cap NACE Yes

Tag # ASDCA-PSV-340113 Model Number H26TB12L-120/LCN API Letter T

API Area 16775 mm² ASME Area 18671 mm² Inlet Size 8.0 in Outlet Size 10.0 in

Set Pressure 14.49 Bar G Over Pressure 1.518 Bar G CDTP 14.49 Bar G

Max. Cap. 383665 kg/hr React. F. 21609 N Noise -

Name Plate Capacity:

Water 2189.5 m³/hr Air 171843 Nm³/hr Steam 136232 kg/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-340112 - Data Sheet

Tag # ASDCA-PSV-340112 Model Number H26TB12L-120/LCN API Letter T

API Area 16775 mm² ASME Area 18671 mm² Inlet Size 8.0 in Outlet Size 10.0 in

Set Pressure 13.8 Bar G Over Pressure 2.208 Bar G CDTP 13.8 Bar G

Max. Cap. 383665 kg/hr React. F. 21609 N Noise -

Name Plate Capacity:

Water 2189.5 m³/hr Air 171843 Nm³/hr Steam 136232 kg/hr

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750 (SP)

Bellows Inconel Composite Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Two Blocked

Omega A 671700 kg/hr 767333 kg/hr 50.85 °C -N - - 32688 mm²

Phase Outlet

Two Blocked

Omega B 629600 kg/hr 1117188 kg/hr 53.65 °C -N - - 21044 mm²

Phase Outlet

Scenario: Omega A / Two Phase -- Blocked Outlet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-340112 - Data Sheet

Fluid Type (User Defined) Hydrocarbon

Omega by Equ'n D3 0.9558

2 Phase Sat

Two-Phase Scenario Noncond or

Flow Type Critical Flow

Highly Subcooled

Scenario Equation Equation D.3

Set Pressure Pset 13.8 Bar G

Two-Phase Mass Flux G 7461.4 kg/sec m²

Const BP Pbackconst 2.7 Bar G

Mass Flow Rate W2phase 671700 kg/hr

Var BP Pbackvar 0 Bar G

Max. BP (abs) Pbackmax 3.7133 Bar Abs

Relief Pressure Prelief 17.021 Bar Abs

Over

16 %

Pressure Pover%-actual

Relieving

50.85 °C

Temperature Trelief

Thermodynamic

-

Temp Tcritical

Thermodynamic

-

Pres Pcritical

Thermo. Crit. Point -

Critical Pressure Pc 10.224 Bar Abs

K d Selection API

Critical Pressure Ratio

Combined Two-Phase Discharge

(from API 520 Figure 0.60064 0.765

Coefficient Kd 2phase

D.1) c

Vapor Density over -

At Inlet Conditions

Gas KGas

Discharge Coefficient 0.8577

Vapor Mass Fraction xo -

Liquid Discharge Coefficient Kliquid 0.6516

Specific Vol of System vo 0.0115479 m³/kg

Rupture Disc Coefficient KCCF 1

Specific Vol at

0.0127743 m³/kg Constant Flow Factor Kb -

90% Inlet Pressure v9

Variable Flow Factor Kv 1

ASME Area (Actual) 32688 mm²

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-340112 - Data Sheet

Scenario: Omega B / Two Phase -- Blocked Outlet

Fluid Type (User Defined) Hydrocarbon

Omega by Equ'n D3 0.84124

2 Phase Sat

Two-Phase Scenario Noncond or

Flow Type Critical Flow

Highly Subcooled

Scenario Equation Equation D.3

Set Pressure Pset 13.8 Bar G

Two-Phase Mass Flux G 10863 kg/sec m²

Const BP Pbackconst 2.7 Bar G

Mass Flow Rate W2phase 629600 kg/hr

Var BP Pbackvar 0 Bar G

Max. BP (abs) Pbackmax 3.7133 Bar Abs

Relief Pressure Prelief 17.021 Bar Abs

Over

16 %

Pressure Pover%-actual

Relieving

53.65 °C

Temperature Trelief

Thermodynamic

-

Temp Tcritical

Thermodynamic

-

Pres Pcritical

Thermo. Crit. Point -

Critical Pressure Pc 9.9403 Bar Abs

K d Selection API

Critical Pressure Ratio

Combined Two-Phase Discharge

(from API 520 Figure 0.58399 0.765

Coefficient Kd 2phase

D.1) c

Vapor Density over -

At Inlet Conditions

Gas Discharge Coefficient KGas 0.8577

Vapor Mass Fraction xo -

Liquid Discharge Coefficient Kliquid 0.6516

Specific Vol of System vo 0.00585135 m³/kg

Rupture KCCF

Disc Coefficient 1

Specific Vol at

0.00639828 m³/kg Constant Flow Factor Kb -

90% Inlet Pressure v9

Variable Flow Factor Kv 1

ASME Area (Actual) 21044 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-340112 Data Sheet

2019-05-03 12:06 Page 4

Tag ID190222: ASDCA-PSV-340207 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Tag # Tag Description Tag Status P / ID Discharge To Revision #

ASDCA-PSV-340207 Valve Selected WHP01-PMC1-ASDCA-04-2700 0

Plant # Drawing # Index # Issue For Service Inlet Line # Outlet Line # Revised By

Bidding TEST SEPARATOR System Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Blocked Outlet Two-Phase Flow No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

6.769 Bar G Temp. 51.82 °C P. 0.4 Bar G

Set Pressure 13.8 Bar G Relief Temp. 52.55 °C Variable Back P. 0 Bar G

Operating to Set

%

49.051 % Percent Over P. 10 % Over Pressure 1.38 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 16.193 Bar Abs P. 13.4 Bar G

Two-Phase Flow State

2 Phase Sat

Scenario Noncond or Highly Equation Equation D.3 Vap. Gas Mass Frac. -

Subcooled

Mass Flow 150100 kg/hr

Calculated Area 6374.2 mm² Fluid Type User Defined Fluid Name Hydrocarbon

Resolved ASME Area: 6374.2 mm² (Resolved by Maximum) Resolved API Area: 5736.7 mm²

Model Selection

Manufacturer Farris API Letter Q Inlet Size 6.0 in Outlet Size 8.0 in

Model Number 26QA12L-120/LCN/SP API Area 7130 mm² In. Rating 300 # Out. Rating 150 #

Valve Design Conventional ASME Area 7917 mm² In. Facing RF Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 2 NACE Yes

Name Plate Capacity:

Water 1010.5 m³/hr Air 72866 Nm³/hr Steam 57766 kg/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-340207 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Two Blocked

Omega A 145400 kg/hr 189982 kg/hr 48.04 °C 384.54 lbs - - 6059.1 mm²

Phase Outlet

Two Blocked

Omega B 150100 kg/hr 186431 kg/hr 52.55 °C 396.61 lbs - - 6374.2 mm²

Phase Outlet

Scenario: Omega A / Two Phase -- Blocked Outlet

Fluid Type (User Defined) Hydrocarbon

Omega by Equ'n D3 0.92146

2 Phase Sat

Two-Phase Scenario Noncond or

Flow Type Critical Flow

Highly Subcooled

Scenario Equation Equation D.3

Set Pressure Pset 13.8 Bar G

Two-Phase Mass Flux G 8713.4 kg/sec m²

Const BP Pbackconst 0.4 Bar G

Mass Flow Rate W2phase 145400 kg/hr

Var BP Pbackvar 0 Bar G

Max. BP (abs) Pbackmax 1.4133 Bar Abs

Relief Pressure Prelief 16.193 Bar Abs

Over

10 %

Pressure Pover%-actual

Relieving

48.04 °C

Temperature Trelief

Thermodynamic

-

Temp Tcritical

Thermodynamic

-

Pres Pcritical

Thermo. Crit. Point -

Critical Pressure Pc 9.6491 Bar Abs

K d Selection API

Critical Pressure Ratio

Combined Two-Phase Discharge

(from API 520 Figure 0.59587 0.765

Coefficient Kd 2phase

D.1) c

Vapor Density over -

At Inlet Conditions

Gas Discharge Coefficient KGas 0.8577

Vapor Mass Fraction xo -

Liquid Discharge Coefficient Kliquid 0.6516

Specific Vol of System vo 0.0082239 m³/kg

Rupture Disc Coefficient KCCF 1

Specific Vol at

0.0090659 m³/kg Constant Flow Factor Kb 1

90% Inlet Pressure v9

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-340207 - Data Sheet

90% Inlet Pressure v9

Variable Flow Factor Kv -

ASME Area (Actual) 6059.1 mm²

Scenario: Omega B / Two Phase -- Blocked Outlet

Fluid Type (User Defined) Hydrocarbon

Omega by Equ'n D3 0.88803

2 Phase Sat

Two-Phase Scenario Noncond or

Flow Type Critical Flow

Highly Subcooled

Scenario Equation Equation D.3

Set Pressure Pset 13.8 Bar G

Two-Phase Mass Flux G 8550.5 kg/sec m²

Const BP Pbackconst 0.4 Bar G

Mass Flow Rate W2phase 150100 kg/hr

Var BP Pbackvar 0 Bar G

Max. BP (abs) Pbackmax 1.4133 Bar Abs

Relief Pressure Prelief 16.193 Bar Abs

Over

10 %

Pressure Pover%-actual

Relieving

52.55 °C

Temperature Trelief

Thermodynamic

-

Temp Tcritical

Thermodynamic

-

Pres Pcritical

Thermo. Crit. Point -

Critical Pressure Pc 9.571 Bar Abs

K d Selection API

Critical Pressure Ratio

Combined Two-Phase Discharge

(from API 520 Figure 0.59105 0.765

Coefficient Kd 2phase

D.1) c

Vapor Density over -

At Inlet Conditions

Gas Discharge Coefficient KGas 0.8577

Vapor Mass Fraction xo -

Liquid Discharge Coefficient Kliquid 0.6516

Specific Vol of System vo 0.008719 m³/kg

Rupture KCCF

Disc Coefficient 1

Specific Vol at

0.0095793 m³/kg Constant Flow Factor Kb 1

90% Inlet Pressure v9

Variable Flow Factor Kv -

ASME Area (Actual) 6374.2 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-340207 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-350001 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-350001 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

WATER INJECTION System

Bidding

SUPPLY Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Thermal Exp. Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

120 Bar G Temp. 35 °C P. 0 Bar G

Set Pressure 139.5 Bar G Relief Temp. 100 °C Variable Back P. 0 Bar G

Operating to Set

%

86.022 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 139.5 Bar G

Non-Compressible State

Fluid Type Injection Water Specific Gravity 1 sp gr Viscosity Type Absolute

Req. Flow Cap. 96.2 kg/hr Viscosity 0.775 Centipoise

Calculated Area 0.24379 mm² Reynolds # 3956.9

Resolved ASME Area: 0.24379 mm² (Resolved by Maximum) Resolved API Area: 0.21941 mm²

Model Selection

Manufacturer Farris API Letter D Inlet Size 1.5 in Outlet Size 2.0 in

Model Number 26DA15L-920/LCN/SP API Area 71 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 97 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 2 NACE Yes

Name Plate Capacity (Water): 39.974 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-350001 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Thermal

Case A Liquid 96.2 kg/hr 38277 kg/hr 100 °C - lbs - - 0.24379 mm²

Exp.

Scenario: Case A / Liquid Mass -- Thermal Exp.

Required Flow Capacity Vliquid 0.096339 m³/hr

Specific Gravity Gliquid 1 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 153.45 Bar G

Liquid Viscosity Factor Ku 0.96096

Liquid Flow Factor Kw -

Fluid Type Injection Water Req'd Flow Capacity Qliquid 96.2 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.775 Centipoise Relief Temperature Trelief 100 °C

Reynolds # R 3956.9 ASME Area (Actual) 0.24379 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-350001 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-350003 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-350003 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

WATER INJECTION System

Bidding

MANIFOLD Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Check Valve Leak Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

120 Bar G Temp. 35 °C P. 3.5 Bar G

Set Pressure 139.5 Bar G Relief Temp. 50 °C Variable Back P. 0 Bar G

Operating to Set

%

86.022 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 136 Bar G

Compressible State

Fluid Hydrocarbon Molecular Weight 20.82 Mol Wt Gas Flow Const. 331.1

Req. Flow Cap. 51950 kg/hr Specific Gravity 0.71867 sp gr Compressibility 0.7508

Calculated Specific Heat

Area

531.92 mm² Ratio 1.141

Resolved ASME Area: 531.92 mm² (Resolved by Maximum) Resolved API Area: 478.73 mm²

Model Selection

Manufacturer Farris API Letter H Inlet Size 2.0 in Outlet Size 3.0 in

Model Number 26HA15-920/LCN/SP API Area 507 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 564 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 49514 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-350003 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Check

Case A Vapor 51950 kg/hr 55083 kg/hr 50 °C 1566.3 lbs 117.56 88.167 531.92 mm²

Valve Leak

Scenario: Case A / Vapor Mass -- Check Valve Leak

Required Flow Capacity Wvapor 51950 kg/hr

Relief Temperature Trelief 50 °C

Compressibility Z 0.7508

Gas Flow Constant C 331.1

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.71867 sp gr

Molecular Weight Mvapor 20.82 Mol Wt Ratio of Specific Heats k 1.141

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 531.92 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-350003 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-350004 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-350004 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

WATER INJECTION System

Bidding

MANIFOLD Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Check Valve Leak Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

120 Bar G Temp. 35 °C P. 3.5 Bar G

Set Pressure 139.5 Bar G Relief Temp. 50 °C Variable Back P. 0 Bar G

Operating to Set

%

86.022 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 136 Bar G

Compressible State

Fluid Hydrocarbon Molecular Weight 20.82 Mol Wt Gas Flow Const. 331.1

Req. Flow Cap. 51950 kg/hr Specific Gravity 0.71867 sp gr Compressibility 0.7508

Calculated Specific Heat

Area

531.92 mm² Ratio 1.141

Resolved ASME Area: 531.92 mm² (Resolved by Maximum) Resolved API Area: 478.73 mm²

Model Selection

Manufacturer Farris API Letter H Inlet Size 2.0 in Outlet Size 3.0 in

Model Number 26HA15-920/LCN/SP API Area 507 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 564 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 49514 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-350004 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Check

Case A Vapor 51950 kg/hr 55083 kg/hr 50 °C 1566.3 lbs 117.56 88.167 531.92 mm²

Valve Leak

Scenario: Case A / Vapor Mass -- Check Valve Leak

Required Flow Capacity Wvapor 51950 kg/hr

Relief Temperature Trelief 50 °C

Compressibility Z 0.7508

Gas Flow Constant C 331.1

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.71867 sp gr

Molecular Weight Mvapor 20.82 Mol Wt Ratio of Specific Heats k 1.141

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 531.92 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-350004 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-350010 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-350010 WHP01-PMC1-ASDCA-04-2700 0

Selected

Drawing Index Inlet Line Outlet Line

Plant # Issue For Service Revised By

# # # #

WATER INJECTION System

MANIFOLD Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

120 Bar G Temp. 20 °C P. 0.2 Bar G

Set Pressure 228 Bar G Relief Temp. 100 °C Variable Back P. 0 Bar G

Operating to Set

%

52.632 % Percent Over P. 10 % Over Pressure 22.8 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 251.81 Bar Abs P. 227.8 Bar G

Non-Compressible State

INJECTION

Fluid Type

WATER

Specific Gravity 1.007 sp gr Viscosity Type Absolute

Req. Flow Cap. 21.69 kg/hr Viscosity 0.715 Centipoise

Calculated Area 0.045203 mm² Reynolds # 967.01

Resolved ASME Area: 0.045203 mm² (Resolved by Maximum) Resolved API Area: 0.040682 mm²

Model Selection

Manufacturer Farris API Letter D Inlet Size 1.5 in Outlet Size 2.0 in

Model Number 26DA15L-920/LCN/SP API Area 71 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 97 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 2 NACE Yes

Name Plate Capacity (Water): 50.876 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-350010 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Case A Liquid - 21.69 kg/hr 46544 kg/hr 100 °C -N - - 0.045203 mm²

Scenario: Case A / Liquid Mass --

Required Flow Capacity Vliquid 0.02157 m³/hr

Specific Gravity Gliquid 1.007 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 250.6 Bar G

Liquid Viscosity Factor Ku 0.9112

Liquid Flow Factor Kw -

INJECTION

Fluid Type WATER

Req'd Flow Capacity Qliquid 21.69 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.715 Centipoise Relief Temperature Trelief 100 °C

Reynolds # R 967.01 ASME Area (Actual) 0.045203 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-350010 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-360005 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-360005 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

DC PF CRUDE EXPORT System

Bidding

HEADE Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Blocked Discharge Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

38 Bar G Temp. 55 °C P. 5.75 Bar G

Set Pressure 46.6 Bar G Relief Temp. 55 °C Variable Back P. 0 Bar G

Operating to Set

%

81.545 % Percent Over P. 10 % Over Pressure 4.66 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 52.273 Bar Abs P. 46.6 Bar G

Non-Compressible State

Fluid Type Hydrocarbon Specific Gravity 0.9818 sp gr Viscosity Type Absolute

Req. Flow Cap. 584466 kg/hr Viscosity 0.5741 Centipoise

Calculated Area 2637.7 mm² Reynolds # 5723742

Resolved ASME Area: 2637.7 mm² (Resolved by Maximum) Resolved API Area: 2373.9 mm²

Model Selection

Manufacturer Farris API Letter N Inlet Size 4.0 in Outlet Size 6.0 in

Model Number 26NB13L-920/LCN/SP API Area 2800 mm² In. Rating 600 # Out. Rating 150 #

Valve Design Bellows ASME Area 3111 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Water): 696.59 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-360005 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750 (SP)

Bellows Inconel Composite Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Blocked

Case A Liquid 551815 kg/hr 670267 kg/hr 55 °C - lbs - - 2561.2 mm²

Discharge

Blocked

Case B Liquid 584466 kg/hr 689348 kg/hr 55 °C - lbs - - 2637.7 mm²

Discharge

Scenario: Case A / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 595.36 m³/hr

Specific Gravity Gliquid 0.9282 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 45.51 Bar G

Liquid Viscosity Factor Ku 1

Liquid Flow Factor Kw 1

Fluid Type Hydrocarbon Req'd Flow Capacity Qliquid 551815 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 27.46 Centipoise Relief Temperature Trelief 55 °C

Reynolds # R 124047 ASME Area (Actual) 2561.2 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-360005 - Data Sheet

Scenario: Case B / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 596.16 m³/hr

Specific Gravity Gliquid 0.9818 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 45.51 Bar G

Liquid Viscosity Factor Ku 1

Liquid Flow Factor Kw 1

Fluid Type Hydrocarbon Req'd Flow Capacity Qliquid 584466 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.5741 Centipoise Relief Temperature Trelief 55 °C

Reynolds # R 5723742 ASME Area (Actual) 2637.7 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-360005 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-360007 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-360007 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

DC PF CRUDE EXPORT System

Bidding

HEADE Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Blocked Discharge Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

38 Bar G Temp. 55 °C P. 5.75 Bar G

Set Pressure 46.6 Bar G Relief Temp. 55 °C Variable Back P. 0 Bar G

Operating to Set

%

81.545 % Percent Over P. 10 % Over Pressure 4.66 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 52.273 Bar Abs P. 46.6 Bar G

Non-Compressible State

Fluid Type Hydrocarbon Specific Gravity 0.9818 sp gr Viscosity Type Absolute

Req. Flow Cap. 584466 kg/hr Viscosity 0.5741 Centipoise

Calculated Area 2637.7 mm² Reynolds # 5723742

Resolved ASME Area: 2637.7 mm² (Resolved by Maximum) Resolved API Area: 2373.9 mm²

Model Selection

Manufacturer Farris API Letter N Inlet Size 4.0 in Outlet Size 6.0 in

Model Number 26NB13L-920/LCN/SP API Area 2800 mm² In. Rating 600 # Out. Rating 150 #

Valve Design Bellows ASME Area 3111 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Water): 696.59 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-360007 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750 (SP)

Bellows Inconel Composite Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Blocked

Case A Liquid 551815 kg/hr 670267 kg/hr 55 °C - lbs - - 2561.2 mm²

Discharge

Blocked

Case B Liquid 584466 kg/hr 689348 kg/hr 55 °C - lbs - - 2637.7 mm²

Discharge

Scenario: Case A / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 595.36 m³/hr

Specific Gravity Gliquid 0.9282 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 45.51 Bar G

Liquid Viscosity Factor Ku 1

Liquid Flow Factor Kw 1

Fluid Type Hydrocarbon Req'd Flow Capacity Qliquid 551815 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 27.46 Centipoise Relief Temperature Trelief 55 °C

Reynolds # R 124047 ASME Area (Actual) 2561.2 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-360007 - Data Sheet

Scenario: Case B / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 596.16 m³/hr

Specific Gravity Gliquid 0.9818 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 45.51 Bar G

Liquid Viscosity Factor Ku 1

Liquid Flow Factor Kw 1

Fluid Type Hydrocarbon Req'd Flow Capacity Qliquid 584466 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.5741 Centipoise Relief Temperature Trelief 55 °C

Reynolds # R 5723742 ASME Area (Actual) 2637.7 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-360007 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-501108 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-501108 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

CLOSED DRAIN DISCH. System

Bidding

LINE Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Blocked Discharge Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

13.9 Bar G Temp. 46.12 °C P. 0 Bar G

Set Pressure 17.7 Bar G Relief Temp. 46.12 °C Variable Back P. 0 Bar G

Operating to Set

%

78.531 % Percent Over P. 10 % Over Pressure 1.77 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 20.483 Bar Abs P. 17.7 Bar G

Non-Compressible State

Fluid Type Closed Drain Specific Gravity 0.9824 sp gr Viscosity Type Absolute

Req. Flow Cap. 29432 kg/hr Viscosity 0.5786 Centipoise

Calculated Area 203.01 mm² Reynolds # 1031043

Resolved ASME Area: 203.01 mm² (Resolved by Maximum) Resolved API Area: 182.71 mm²

Model Selection

Manufacturer Farris API Letter F Inlet Size 1.5 in Outlet Size 2.0 in

Model Number 26FA10L-120/D8N/SP API Area 199 mm² In. Rating 150 # Out. Rating 150 #

Valve Design Conventional ASME Area 240 mm² In. Facing RF Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Water): 35.204 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-501108 - Data Sheet

Model Materials

Body SA 995, Gr. 6A / UNS J93380 Bonnet SA 995, Gr. 6A / UNS J93380

Nozzle Super Duplex Disc Super Duplex

Guide Super Duplex Spring Inconel X750

Bellows N/A Custom Boltings A276 S32760-S /A276 S32760-A (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Blocked

Case A Liquid 28000 kg/hr 33400 kg/hr 46.12 °C - lbs - - 201.2 mm²

Discharge

Blocked

Case B Liquid 29432 kg/hr 34795 kg/hr 46.12 °C - lbs - - 203.01 mm²

Discharge

Scenario: Case A / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 29.983 m³/hr

Specific Gravity Gliquid 0.9352 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 19.47 Bar G

Liquid Viscosity Factor Ku 0.98384

Liquid Flow Factor Kw -

Fluid Type Closed Drain Req'd Flow Capacity Qliquid 28000 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 35.47 Centipoise Relief Temperature Trelief 46.12 °C

Reynolds # R 16000 ASME Area (Actual) 201.2 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-501108 - Data Sheet

Scenario: Case B / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 30.003 m³/hr

Specific Gravity Gliquid 0.9824 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 19.47 Bar G

Liquid Viscosity Factor Ku 1

Liquid Flow Factor Kw -

Fluid Type Closed Drain Req'd Flow Capacity Qliquid 29432 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.5786 Centipoise Relief Temperature Trelief 46.12 °C

Reynolds # R 1031043 ASME Area (Actual) 203.01 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-501108 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-502108 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-502108 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

CLOSED DRAIN DISCH. System

Bidding

LINE Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Blocked Discharge Liquid (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

13.9 Bar G Temp. 46.12 °C P. 0 Bar G

Set Pressure 17.7 Bar G Relief Temp. 46.12 °C Variable Back P. 0 Bar G

Operating to Set

%

78.531 % Percent Over P. 10 % Over Pressure 1.77 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 20.483 Bar Abs P. 17.7 Bar G

Non-Compressible State

Fluid Type Closed Drain Specific Gravity 0.9815 sp gr Viscosity Type Absolute

Req. Flow Cap. 29432 kg/hr Viscosity 0.5786 Centipoise

Calculated Area 203.1 mm² Reynolds # 1031043

Resolved ASME Area: 203.1 mm² (Resolved by Maximum) Resolved API Area: 182.79 mm²

Model Selection

Manufacturer Farris API Letter F Inlet Size 1.5 in Outlet Size 2.0 in

Model Number 26FA10L-120/D8N/SP API Area 199 mm² In. Rating 150 # Out. Rating 150 #

Valve Design Conventional ASME Area 240 mm² In. Facing RF Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Water): 35.204 m3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-502108 - Data Sheet

Model Materials

Body SA 995, Gr. 6A / UNS J93380 Bonnet SA 995, Gr. 6A / UNS J93380

Nozzle Super Duplex Disc Super Duplex

Guide Super Duplex Spring Inconel X750

Bellows N/A Custom Boltings A276 S32760-S /A276 S32760-A (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Blocked

Case A Liquid 29432 kg/hr 34779 kg/hr 46.12 °C - lbs - - 203.1 mm²

Discharge

Blocked

Case B Liquid 28000 kg/hr 33386 kg/hr 46.12 °C - lbs - - 201.28 mm²

Discharge

Scenario: Case A / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 30.03 m³/hr

Specific Gravity Gliquid 0.9815 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 19.47 Bar G

Liquid Viscosity Factor Ku 1

Liquid Flow Factor Kw -

Fluid Type Closed Drain Req'd Flow Capacity Qliquid 29432 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 0.5786 Centipoise Relief Temperature Trelief 46.12 °C

Reynolds # R 1031043 ASME Area (Actual) 203.1 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-502108 - Data Sheet

Scenario: Case B / Liquid Mass -- Blocked Discharge

Required Flow Capacity Vliquid 30.009 m³/hr

Specific Gravity Gliquid 0.9344 sp gr

Discharge Coeff. (0.9 x Kd) Kliquid 0.6516

Rupture Disk Coefficient KCCF 1

Pset + Pover - Pback P 19.47 Bar G

Liquid Viscosity Factor Ku 0.98384

Liquid Flow Factor Kw -

Fluid Type Closed Drain Req'd Flow Capacity Qliquid 28000 kg/hr

Viscosity Type Absolute Discharge Coefficient Kd 0.724

Viscosity 35.47 Centipoise Relief Temperature Trelief 46.12 °C

Reynolds # R 16000 ASME Area (Actual) 201.28 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-502108 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASDCA-PSV-570202 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-570202 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

DIESEL FILTER System

Bidding

COALESCER Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Fire Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 93 °C Min. Design T. 5 °C

Operating Operating Constant Back

Pressure

5 Bar G Temp. 50 °C P. 0.2 Bar G

Set Pressure 10 Bar G Relief Temp. 331.6 °C Variable Back P. 0 Bar G

Operating to Set

%

50 % Percent Over P. 21 % Over Pressure 2.1 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 13.113 Bar Abs P. 9.8 Bar G

Compressible State

Fluid Diesel Oi, Fuel Molecular Weight 200 Mol Wt Gas Flow Const. 317.4

Req. Flow Cap. 2331.3 kg/hr Specific Gravity 6.9037 sp gr Compressibility 0.69

Calculated Specific Heat

Area

124.11 mm² Ratio 1.016

Resolved ASME Area: 124.11 mm² (Resolved by Maximum) Resolved API Area: 111.7 mm²

Model Selection

Manufacturer Farris API Letter E Inlet Size 1.0 in Outlet Size 2.0 in

Model Number 26EA10-120/LCN/SP API Area 127 mm² In. Rating 150 # Out. Rating 150 #

Valve Design Conventional ASME Area 146 mm² In. Facing RF Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 2 NACE Yes

Name Plate Capacity (Air): 996.62 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-570202 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Fire Vapor

Vapor Fire 2331.3 kg/hr 2742.5 kg/hr 331.6 °C 32.37 lbs 96.919 72.689 124.11 mm²

Generation

Scenario: Fire Vapor Generation / Vapor Mass -- Fire

Required Flow Capacity Wvapor 2331.3 kg/hr

Relief Temperature Trelief 331.6 °C

Compressibility Z 0.69

Gas Flow Constant C 317.4

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Diesel Oi, Fuel

Relief Pressure Prelief 13.113 Bar Abs Specific Gravity Ggas 6.9037 sp gr

Molecular Weight Mvapor 200 Mol Wt Ratio of Specific Heats k 1.016

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 124.11 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-570202 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASDCA-PSV-570304 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASDCA-PSV-570304 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

WET GAS INLET TO System

Bidding

COALESE Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Fire Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

5 Bar G Temp. 52 °C P. 2.7 Bar G

Set Pressure 13.8 Bar G Relief Temp. 593 °C Variable Back P. 0 Bar G

Operating to Set

%

36.232 % Percent Over P. 21 % Over Pressure 2.898 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 17.711 Bar Abs P. 13.8 Bar G

Compressible State

Fluid - Molecular Weight 21 Mol Wt Gas Flow Const. 327.3

Req. Flow Cap. 30.52 kg/hr Specific Gravity 0.72489 sp gr Compressibility 1

Calculated Specific Heat

Area

5.1868 mm² Ratio 1.103

Resolved ASME Area: 5.1868 mm² (Resolved by Maximum) Resolved API Area: 4.6681 mm²

Model Selection

Manufacturer Farris API Letter D Inlet Size 1.0 in Outlet Size 2.0 in

Model Number 26DB12-120/LCN/SP API Area 71 mm² In. Rating 300 # Out. Rating 150 #

Valve Design Bellows ASME Area 97 mm² In. Facing RF Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 892.14 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASDCA-PSV-570304 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Chrome Alloy

Bellows Inconel Composite Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Fire Vapor

Vapor Fire 30.52 kg/hr 570.77 kg/hr 593 °C 124.17 lbs 100.11 75.086 5.1868 mm²

Generation

Scenario: Fire Vapor Generation / Vapor Mass -- Fire

Required Flow Capacity Wvapor 30.52 kg/hr

Relief Temperature Trelief 593 °C

Compressibility Z 1

Gas Flow Constant C 327.3

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) -

Relief Pressure Prelief 17.711 Bar Abs Specific Gravity Ggas 0.72489 sp gr

Molecular Weight Mvapor 21 Mol Wt Ratio of Specific Heats k 1.103

Vapor Flow Factor Kb - Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv 1 ASME Area (Actual) 5.1868 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASDCA-PSV-570304 Data Sheet

2019-05-03 12:06 Page 2

Tag ID190222: ASEGA-PSV-330019 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASEGA-PSV-330019 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

PRODUCTION MANIFOLD System

Bidding

WEST Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Subsurface Fracture/Gas Release Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

4 Bar G Temp. 54.4 °C P. 5.6 Bar G

Set Pressure 139.5 Bar G Relief Temp. 48.55 °C Variable Back P. 0 Bar G

Operating to Set

%

2.8674 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 133.9 Bar G

Compressible State

Fluid Hydrocarbon Molecular Weight 22.81 Mol Wt Gas Flow Const. 339.1

Req. Flow Cap. 27860 kg/hr Specific Gravity 0.78737 sp gr Compressibility 0.697

Calculated Specific Heat

Area

255.82 mm² Ratio 1.221

Resolved ASME Area: 255.82 mm² (Resolved by Maximum) Resolved API Area: 230.24 mm²

Model Selection

Manufacturer Farris API Letter G Inlet Size 2.0 in Outlet Size 3.0 in

Model Number 26GA15-920/LCN/SP API Area 325 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 361 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 31693 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASEGA-PSV-330019 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Subsurface

Case A Vapor 27860 kg/hr 39315 kg/hr 48.55 °C 5342.5 N 115.97 86.977 255.82 mm²

Fracture/Gas Release

Subsurface

Case B Vapor 25810 kg/hr 36578 kg/hr 54.84 °C 5260.3 N 116.08 87.058 254.72 mm²

Fracture/Gas Release

Scenario: Case A / Vapor Mass -- Subsurface Fracture/Gas Release

Required Flow Capacity Wvapor 27860 kg/hr

Relief Temperature Trelief 48.55 °C

Compressibility Z 0.697

Gas Flow Constant C 339.1

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.78737 sp gr

Molecular Weight Mvapor 22.81 Mol Wt Ratio of Specific Heats k 1.221

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 255.82 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASEGA-PSV-330019 - Data Sheet

Scenario: Case B / Vapor Mass -- Subsurface Fracture/Gas Release

Required Flow Capacity Wvapor 25810 kg/hr

Relief Temperature Trelief 54.84 °C

Compressibility Z 0.74

Gas Flow Constant C 340

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.73386 sp gr

Molecular Weight Mvapor 21.26 Mol Wt Ratio of Specific Heats k 1.23

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 254.72 mm²

SizeMaster 4.3.3.9, DB: D:\Farris Database (Nga) End of ASEGA-PSV-330019 Data Sheet

2019-05-03 12:06 Page 3

Tag ID190222: ASEGA-PSV-330020 - Data Sheet

Pressure Relief Valve Data Sheet Date Prepared: 2019-05-03 12:06

General Job Data

Customer Requisition # Job # Job Description

PTSC M&C I10- PSV for Gallaf Proj ID190222 AL SHAHEEN FIELD Development

Prepared By Checked By Approved By Job Status Revision #

Ngan Nga Brian Nguyen Sizing/Selecting 0

PSV Identification

Discharge

Tag # Tag Description Tag Status P / ID Revision #

To

Valve

ASEGA-PSV-330020 0

Selected

Drawing Index Inlet Outlet Line

Plant # Issue For Service Revised By

# # Line # #

PRODUCTION MANIFOLD System

Bidding

WEST Admin

Sizing Basis

ASME Code Cause of Over Pressure Fluid State Rupture Disk Coeff. NACE

ASME Sec. VIII Subsurface Fracture/Gas Release Vapor (Mass) No Rupture Disk, 1 Yes

Process Parameters

MAWP - Bar G Max. Design T. 100 °C Min. Design T. -46 °C

Operating Operating Constant Back

Pressure

4 Bar G Temp. 54.4 °C P. 5.6 Bar G

Set Pressure 139.5 Bar G Relief Temp. 48.55 °C Variable Back P. 0 Bar G

Operating to Set

%

2.8674 % Percent Over P. 10 % Over Pressure 13.95 Bar G

Cold Diff. Test

Atm Pressure 1.0133 Bar Abs Relief Pressure 154.46 Bar Abs P. 133.9 Bar G

Compressible State

Fluid Hydrocarbon Molecular Weight 22.81 Mol Wt Gas Flow Const. 339.1

Req. Flow Cap. 27860 kg/hr Specific Gravity 0.78737 sp gr Compressibility 0.697

Calculated Specific Heat

Area

255.82 mm² Ratio 1.221

Resolved ASME Area: 255.82 mm² (Resolved by Maximum) Resolved API Area: 230.24 mm²

Model Selection

Manufacturer Farris API Letter G Inlet Size 2.0 in Outlet Size 3.0 in

Model Number 26GA15-920/LCN/SP API Area 325 mm² In. Rating 1500 # Out. Rating 300 #

Valve Design Conventional ASME Area 361 mm² In. Facing RJ Out. Facing RF

Cap Constrn Screwed Cap Test Gag No Quantity 1 NACE Yes

Name Plate Capacity (Air): 31693 Nm3/hr

2019-05-03 12:06 Page 1

Tag ID190222: ASEGA-PSV-330020 - Data Sheet

Model Materials

Body LCC (SA-352 Gr. LCC) Bonnet LCC (SA-352 Gr. LCC)

Nozzle 316 SS Disc 316 SS

Guide 316 SS Spring Inconel X750

Bellows N/A Custom Boltings A320 GR L7 / A194 GR 7L (SP)

Sizing Scenarios

Fluid Cause of Relief Load Noise Noise Required

Scenario Max Rel Cap Relief T. React. Force

State Over P. Capacity Atm (dBa) Flare (dBa) Area

Subsurface

Case A Vapor 27860 kg/hr 39315 kg/hr 48.55 °C 5342.5 N 115.97 86.977 255.82 mm²

Fracture/Gas Release

Subsurface

Case B Vapor 25810 kg/hr 36578 kg/hr 54.84 °C 5260.3 N 116.08 87.058 254.72 mm²

Fracture/Gas Release

Scenario: Case A / Vapor Mass -- Subsurface Fracture/Gas Release

Required Flow Capacity Wvapor 27860 kg/hr

Relief Temperature Trelief 48.55 °C

Compressibility Z 0.697

Gas Flow Constant C 339.1

Discharge Coeff. (0.9 x Kd) KGas 0.8577

Flow Flow Critical

Rupture Disk Coefficient KCCF 1 Fluid Type (User Defined) Hydrocarbon

Relief Pressure Prelief 154.46 Bar Abs Specific Gravity Ggas 0.78737 sp gr

Molecular Weight Mvapor 22.81 Mol Wt Ratio of Specific Heats k 1.221

Vapor Flow Factor Kb 1 Discharge Coefficient Kd 0.953

Vapor Flow Factor Kv - ASME Area (Actual) 255.82 mm²

2019-05-03 12:06 Page 2

Tag ID190222: ASEGA-PSV-330020 - Data Sheet