Professional Documents

Culture Documents

BBS 10 W8 DS 001 C Glycol Contactor DS

Uploaded by

Adianto RahmanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BBS 10 W8 DS 001 C Glycol Contactor DS

Uploaded by

Adianto RahmanCopyright:

Available Formats

Glycol Contactor [Structured Packing] - 1/4

BBS-C-001 / Glycol Contactor Data Sheet (StructuredPacking Data Sheet)

Engineered by:

Document No. BBS-10-W8-DS-001

Project No. 90814

Project Name/Location Pengadaan & Pemasangan Dehydration Unit (DHU) Rev C Prepared P.W

Package Fasilitas Produksi LapanganBambu Besar Date 16-May-19 Checked H.I

End User PT. Pertamina EP BBS & ABS Dev Project Approved M.G

Customer PT Promatcon Tepat Guna

Equipment Tag No. BBS-C-001 Onshore/Offshore Onshore

Equipment Name Glycol Contactor Sour Service No NACE Region NA

Service Wet Natural Gas + Lean TEG Quantity 1 .

DESIGN CONDITION

Packing Type Structured [MellapakPlus 252.Y] Feed Gas Composition

Column Section Imperial Top Bottom [mole fraction]

Vapour Phase Dry Gas-DG1 Feed Gas-WG1 WG1

Op. Pressure [psig] 385.00 390.00 [TEGlycol] 0.000000 0.000000

Op. Temp [F] 120 113 [H2O] 0.003799 0.003799

Molecular Weight 20.73 20.733 [Nitrogen] 0.009400 0.009400

Mass Density [lb/ft3] 1.44 1.485 [CO2] 0.036200 0.036200

Viscosity [cP] 0.01 0.013 [H2S] 0.000000 0.000000

Glycol Mass Flow-Rate [lb/h] 0.09 0.00 [Methane] 0.821801 0.821801

Water Mass Flow-Rate [lb/h] 2.23 * 57.96 [Ethane] 0.055300 0.055300

Hydrocarbon Mass-Flowrate [lb/h] 17,490.27 17,503.53 [Propane] 0.040100 0.040100

Total Mass-Flowrate [lb/h] 17,492.6 * 17,561.50 [Note 4] [i-Butane] 0.010600 0.010600

[n-Butane] 0.010300 0.010300

Liquid Phase Lean TEG-LG1 Rich TEG-RG1 [i-Pentane] 0.004300 0.004300

Op. Pressure [psig] 426.25 390.00 [n-Pentane] 0.002800 0.002800

Op. Temp [F] 126 118 [C6+] 0.005400 0.005400

Molecular Weight 147.06 107.26

Mass Density [lb/ft3] 68.81 68.16 Ʃ Total 1.000000

Viscosity [cP] 12.19 10.73

Surface Tension [dyne/cm] 42.71 43.27

Glycol Mass Flow-Rate [lb/h] 1,078.17 1,078.08

Water Mass Flow-Rate [lb/h] 2.99 58.73 *

Hydrocarbon Mass-Flowrate [lb/h] 0.25 13.51

Total Mass-Flowrate [lb/h] 1,081.41 1,150.32 *

Condensate-DR1

Op. Pressure [psig] 390.00

Op. Temp [F] 113.00

Molecular Weight 18.04

Mass Density [lb/ft3] 54.89

Viscosity [cP] 0.58

Surface Tension [dyne/cm] 68.31

Glycol Mass Flow-Rate [lb/h] 0.00 NOTE :

Water Mass Flow-Rate [lb/h] 0.00 * Total mass flowrate for DG1 and RG1 may be slightly different with flowrate indicated in

Hydrocarbon Mass-Flowrate [lb/h] 0.00 in the HMB and Contactor Datasheet. It is because flowrate indicated in packing data

Total Mass-Flowrate [lb/h] 0.00 sheet is used to describe max. allowable water content as per guarantee figure.

Max. Allowable Press. Drop [psi] 5.0

Section Height [ft] -

Material of Construction 316L

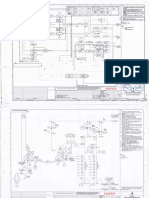

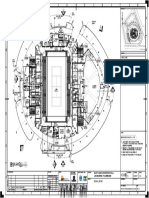

DESIGN CONDITION COLUMN SKECTH

Column ID [ft] 1.48

Packing Height [ft] 13.46 DG1

DG1

Flooding [%] 60-85

System Factor 1.0 LG1 LG1

Pressure Drop [psi/in] 0.0006

Total packing pressure drop [psi] 0.0988

Turndown of Normal Gas Flow [%] 10 (Gas) ; 50 (Liquid-TEG)

Opt. Load for Normal Gas Flow [%] 10-110 WG2 RG1

Required NTU WG1

NOTE

1. Lean TEG Concentration: 99.7 %wt RG1

2. Water content in dry gas specification: <7 lbH2O/MMSCF DR2

3. Max. glycol loss 0.07 USGal TEG/MMSCF

4. Flowrate inclusive of 10% margin. Without Scrubber W/Integral Scrubber

5. Inlet Baffle design shall be provided by column internal vendor OTHERS COLUMN INTERNAL

Type

Inlet Gas Distributor Baffle

Bottom Demister

Chimney Tray Design only

Packing Support Grid

Inlet Liquid Distributor

Top Demister

Cyclonic demister

Glycol Contactor - 2/4

BBS-C-001 / Glycol Contactor Data Sheet

Engineered by:

Document No. BBS-10-W8-DS-001

Project No. 90814

Project Name/Location Pengadaan & Pemasangan Dehydration Unit (DHU) Rev C Prepared P.W

Package Fasilitas Produksi LapanganBambu Besar Date 16-May-19 Checked H.I

End User PT. Pertamina EP BBS & ABS Dev Project Approved M.G

Customer PT Promatcon Tepat Guna

Equipment Tag No. BBS-C-001 Onshore/Offshore Onshore

Equipment Name Glycol Contactor Sour Service No NACE Region NA

Service Wet Natural Gas + Lean TEG Quantity 1

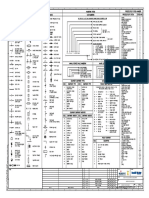

DESIGN BASIS

Feed Gas-WG1 Rich TEG-RG1 Dry Gas-DG1 Lean TEG-LG1 Condensate-

Operating condition Imperial DR1 Design condition

Temperature [F] 113.00 117.89 120.42 126.00 113.00 Temperature [F] 165

Pressure [psig] 390.00 390.00 385.00 426.25 390.00 MDMT [F] -20

Flowrate [lb/h] 17,561.50 1,150.90 17,492.01 1,081.41 0.00 Pressure [psig] 500

[MMSCFD] 7.70 7.67 Inlet H2O Content

[ft3/min] 197.16 0.28 202.34 0.26 0.00 [lbH2O/MMSCF] 180.7

[ft/s] 1.92 [KgH2O/MMSCM] 2890.8

Outlet H2O Content, Less than

Density [lb/ft3] 1.48 68.16 1.44 68.81 54.89 [lbH2O/MMSCF] 7.0

Viscosity [cp] 0.01 10.73 0.01 12.19 0.58 [ppm.v]

Surface tension [dyne/cm] - 43.27 - 42.71 68.31 Max. glycol loss in

Molecular weight [kg/kgmol] 20.73 107.26 20.73 147.06 18.04 [US Gal/MMSCF] 0.07

p CO2 [psia] 14.65

p H2S [psia] 0.000

COLUMN DIAMETER CALCULATION

Demister Type Top 1st N/A Packing type Structured

Top 2nd Hor-Wiremesh [MellapakPlus 252.Y]

Bottom Hor-Wiremesh Design std. gas flowrate [MMSCFD] 7.70

Derrated K factor [ft/s] 0.32 Design act. gas flowrate [ft3/s] 3.29

Maximum allow. gas velocity [ft/s] 2.15 Design gas load factor, λmax [ft/s] 0.46

Gas volumetric flowrate [ft3/s] 3.29 Design gas superficial velocity [ft/s] 1.92

Min. required area for demister [ft2] 1.53 Volumetric load factor, Q* [ft3/s] 0.49

Required column I.D [ft] 1.39 [ft] 1.16

[m] 0.43 [m] 0.35

Selected column I.D [ft] 1.48 ------> Column cross section area [ft2] 1.71

[m] 0.45 [√lb/ft-s] 2.34

PACKING HEIGHT CALCULATION

Estimation of the Packing Height Required

Lean TEG circulation rate [lb TEG/lb H2O] 19.4

Margin of inlet water content [%] 0

Effective fraction of dehydration, η(with inlet water content inlet margin) 0.96

NTU 4.2

Specific area of a packing [m2/m3] 250

HTU [m] 0.73 [ft] 2.41

Required Packing Height [m] 3.59 [ft] 11.77

Selected Packing Height [m] 4.104 [ft] 13.46

CHIMNEY TRAY DESIGN CALCULATION

Liquid hold on the packing [%] 5.50

Column design With Integral Scrubber Volume liquid hold up on the packing [ft3] 1.27

Chimney-shell area ratio [0.15-0.2] 0.15

Chimney, nom. pipe size [inch] 4

Chimney, nom. pipe schedule STD Levels from btm tray Liq. Vol. Ret. Time

ID of chimney [inch] 4.03 [mm] [inch] [ft3] [min]

[mm] 102.26 Chimney top 900 35.4 4.27 5.06

OD of chimney [inch] 4.50 HHLL 600 23.6 2.85 1.69

[mm] 114.30 HLL 500 19.7 2.37 1.69

NLL 400 15.7 1.90 1.69

Total chimney required cross sectional area [ft2] 0.26 LLL 300 11.8 1.42 1.69

Required number of chimney 2.90 LLLL 200 7.9 0.95 3.37

Selected number of chimney 3 Btm of tray 0 0.00 0.00 0.00

Gas velocity at chimney [ft/s] 12.39

Pressure drop across chimney tray, [psi] 0.06

Actual cross sectional area of chimney [ft2] 0.09

Actual sectional area of total chimneys [ft2] 0.27

Actual chimneys-shell area ratio 0.15

Glycol Contactor - 3/4

BBS-C-001 / Glycol Contactor Data Sheet

Engineered by:

Document No. BBS-10-W8-DS-001

Project No. 90814

Project Name/Location Pengadaan & Pemasangan Dehydration Unit (DHU) Rev C Prepared P.W

Package Fasilitas Produksi LapanganBambu Besar Date 16-May-19 Checked H.I

End User PT. Pertamina EP BBS & ABS Dev Project Approved M.G

Customer PT Promatcon Tepat Guna

Equipment Tag No. BBS-C-001 Onshore/Offshore Onshore

Equipment Name Glycol Contactor Sour Service No NACE Region NA

Service Wet Natural Gas + Lean TEG Quantity 1

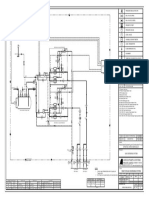

HC CONDENSATE - BOTTOM LIQUID LEVEL ARRANGEMENT/NOT APPLICABLE

Liquid levels from btm T/L [mm] [inch] [ft3]

Top of Weir 700 27.56 3.93

LSHH 0.00 0.00

LAH 600 23.62 3.37

NLL 0.00 0.00

LAL 400 15.75 2.25

LSLL 0.00 0.00

Bottom of Skimming Bucket 250 9.84 2.00

BW; Bucket Width 300 11.81

Note: Normally no flow is expected in the outlet line of HC skimming bucket.

[mm] 900 Chimney tray btm

BOTTOM LIQUID LEVEL ARRANGEMENT

Total Vol. Delta Vol. Ret. Time

Liquid Levels from Btm Head [mm] [inch] [ft3] [ft3] [min] Residence time between levels

HHLL 600 23.62 3.37 0.56 NNF LSHH-LAH NNF

HLL 500 19.69 2.81 0.56 NNF LAH-NLL NNF

NLL 400 15.75 2.25 0.56 NNF

LLL 300 11.81 1.68 0.56 NNF NLL-LAL NNF

LLLL 200 7.87 1.12 1.12 NNF

Bottom T/L 0 0.00 0.00 0.00 NNF LAL-LSLL NNF

Btm Head Volume [ft3] 0.42 [Elliptical 2:1]

[m3] 0.01

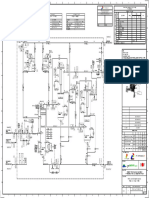

COLUMN HEIGHT CALCULATION

Inlet gas distributor design Outlet NOV Std

Selected nozzle nominal size [inch] 6 18 Top Demister-Top Cover Flange W.L [mm] 50

Nozzle schedule HOLD XXS 80.00 Cyclone Height [mm] N/A

Nozzle ID [inch] 4.90 16.11 Top Demister - Inlet Cyclone [mm] N/A

[mm] 124.40 409.24 Top Demister [mm] 200

Nozzle OD [inch] 6.63 Liquid Distributor - Top Demister [mm] 300

[mm] 168.30 Liquid Distributor [mm] 200

Feed gas mass flowrate, gas phase [lb/h] 17561.50 17492.01 Structured Packing Height [mm] 4,104

[kg/s] 2.21 2.20 Chimney Tray to Btm of Packing [mm] 400

Feed gas mass flowrate, liq. phase [lb/h] 0.00 0.00 Chimney Tray Section [mm] 900

[kg/s] 0.00 0.00 Bottom Demister-Chimney Tray [mm] 450

Feed gas vol. flowrate, gas phase [ft3/s] 3.29 3.37 Bottom Demister [mm] 200

[m3/s] 0.09 0.10 Feed Nozzle Center-Bottom Demister [mm] 262

Feed gas vol. flowrate, liq. phase [ft3/s] 0.0000 0.0000 LAHH-Feed Nozzle Center [mm] 634

[m3/s] 0.00 0.00 Bottom T/L - LAHH [mm] 600

Feed gas density mixture [lb/ft3] 1.48 1.44

[kg/m3] 23.78 23.08 Total Height T/L - T/L [mm] 8,300

Feed mixture velocity at inlet [ft/s] 25.12 2.38 27.23 [ft] 27-2.8"

[m/s] 7.66 0.73 Column I.D [mm] 450

Inlet momentum [Pa] 1393.74 12.16 [ft] 1-5.7"

Inlet feed gas device type Inlet Baffle

Pressure Drop Vessel volume [ft3] 47

Inlet device [mbar] 6.97 [m3] 1.34

Bottom demister [mbar] TBA TEG Volume [ft3] 3.17

Chimney Tray [mbar] 4.41 [m3] 0.09

Structured packing [mbar]

Top 1st Demister [mbar] TBA With Integral Scrubber

Top 2nd Demister [mbar] TBA

Outlet Nozzle [mbar] 0.03

Total [mbar] TBA

Glycol Contactor - 4/4

BBS-C-001 / Glycol Contactor Data Sheet

Engineered by:

Document No. BBS-10-W8-DS-001

Project No. 90814

Project Name/Location Pengadaan & Pemasangan Dehydration Unit (DHU) Rev C Prepared P.W

Package Fasilitas Produksi LapanganBambu Besar Date 16-May-19 Checked H.I

End User PT. Pertamina EP BBS & ABS Dev Project Approved M.G

Customer PT Promatcon Tepat Guna

Equipment Tag No. BBS-C-001 Onshore/Offshore Onshore

Equipment Name Glycol Contactor Sour Service No NACE Region NA

Service Wet Natural Gas + Lean TEG Quantity 1

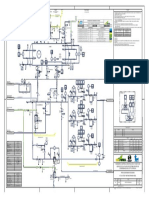

DESIGN SUMMARY

Design Code ASME SEC.VIII DIV.1

U-Stamp / MIGAS No / Yes

Type Vertical

Fluid name Wet Natural Gas + Lean TEG

Lethal service No

Special service No

Operating temperature [F] 113.0-120.4

Design temperature [F] 165 MDMT -20

Operating pressure [psig] 390

Design pressure [psig] 500 FV Yes

Corrosion allowance [inch] 1/8 For C.S part only

Insulation No [inch] -

Fire proofing [inch] No

Blast load [psig] -

Material of Construction [Note-1]

Shell Top CS

Bottom CS + 316L SS Cladding [Note 1]

Head Cover Flange Top CS

[Elliptical 2:1] Bottom CS + 316L SS Cladding [Note 1]

Internal 316L SS

Flange

Nozzle ID Qty Description

Size (in) Rating Face

N1 1 6 300# RF Gas inlet

N2 1 4 300# RF Gas outlet

N3 1 1 300# RF Lean Glycol inlet

N4 1 1 1/2 300# RF Rich Glycol outlet

N5 1 1 1/2 300# RF Condensate outlet

UC 1 1 300# RF Utility Connection

N6 1 2 300# RF Vent

N7 1 2 (HOLD) 300# RF PSV Inlet

K1A/B 2 1 300# RF Bottom LT/LIC (LLL, HLL)

K2A/B 2 2 300# RF Bottom LT (LLLL/HHLL)

K3A/B 2 1 300# RF Rich Glycol LT/LIC (LLL, HLL)

K4A/B 2 2 300# RF Rich Glycol LT (LLLL/HHLL)

K5A/B 2 3/4 300# RF PDT

K6 1 3/4 300# RF PZT

H1 1 6 300# RF Inspection Hole (Chimney)

H2 1 6 300# RF Inspection Hole (Bottom)

* SkirtHeight (HOLD) [mm] 800

[ft] 2-7.5"

* Total Height T/L - T/L [mm] 8,300

[ft] 27-2.8"

* Column I.D [mm] 450

[ft] 1-5.7"

NOTE(S)

1. CS + 316L Cladd to be applied from bottom head up to 1/3

of structural packing height.

2. All Column removable internals will be supplied by NOV

You might also like

- BBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFDocument2 pagesBBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFAdianto RahmanNo ratings yet

- Amine PKGDocument18 pagesAmine PKGRathinavel PerumalNo ratings yet

- P&ID 068 - Comment Marking - 220606Document61 pagesP&ID 068 - Comment Marking - 220606Azhar BudimanNo ratings yet

- PP Aaa PP1 123Document20 pagesPP Aaa PP1 123Rabah AmidiNo ratings yet

- Comparative Study of DEA and MDEADocument4 pagesComparative Study of DEA and MDEAsaleh4060No ratings yet

- AICHE S01 02 FCC Debutanizer Revamp For Flexibility and AddiDocument16 pagesAICHE S01 02 FCC Debutanizer Revamp For Flexibility and AddiSrbislav GenicNo ratings yet

- 541-PC-1002 Utility Consumption Summary1Document3 pages541-PC-1002 Utility Consumption Summary1svnaik14No ratings yet

- BBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFDocument1 pageBBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFAdianto RahmanNo ratings yet

- Indra: SonatrachDocument9 pagesIndra: SonatrachhichamNo ratings yet

- Structured Packings GasDocument20 pagesStructured Packings GasBowo Edhi WibowoNo ratings yet

- 9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)Document7 pages9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)engr anharNo ratings yet

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlDocument77 pagesAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- MATIX Effluent Summary-Rev0Document1 pageMATIX Effluent Summary-Rev0Sanju ChauhanNo ratings yet

- Hydrocarbon Eng Feb 2017Document24 pagesHydrocarbon Eng Feb 2017jcarbajal2013No ratings yet

- MTG ProcessDocument59 pagesMTG ProcessShehzad Afzal MaharNo ratings yet

- q226030 Gdu PidDocument17 pagesq226030 Gdu PidAnonymous bHh1L1No ratings yet

- DJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADocument3 pagesDJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADIANTORONo ratings yet

- PSV Report BlockedDocument5 pagesPSV Report BlockedElias EliasNo ratings yet

- 510 C 013 (Absorber II)Document2 pages510 C 013 (Absorber II)idilfitriNo ratings yet

- Om-Tk-5.4.4-16-1 P&idDocument1 pageOm-Tk-5.4.4-16-1 P&idLu CianusNo ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- P&ID For Inst Scope ReferenceDocument1 pageP&ID For Inst Scope Referenceprabudass pNo ratings yet

- Specification For Diesel Fuel Conditioning PackageDocument17 pagesSpecification For Diesel Fuel Conditioning PackagesudjonoNo ratings yet

- Pp12-00-Pgb-mdd-bgs-001 Rev 0 P&id Closed Cooling Water System For GTDocument2 pagesPp12-00-Pgb-mdd-bgs-001 Rev 0 P&id Closed Cooling Water System For GTfaiyazirfanNo ratings yet

- HS523217 51 PR PID 0018 0001rev1Document1 pageHS523217 51 PR PID 0018 0001rev1Nasim MammadovNo ratings yet

- Hydroprocessing for Clean Energy: Design, Operation, and OptimizationFrom EverandHydroprocessing for Clean Energy: Design, Operation, and OptimizationNo ratings yet

- Vessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Document13 pagesVessel Sizing Calculation Data Sheets: Customer Name: Project Title: Cpe Job #: Document #Michael HaiseNo ratings yet

- Ge312-1121 Columns - DrumDocument20 pagesGe312-1121 Columns - DrumDiarista Thoma SaputraNo ratings yet

- Z-19 Glycol Regeneration UnitsDocument24 pagesZ-19 Glycol Regeneration Unitssfar yassineNo ratings yet

- ECUMED Sizing Report For The First Phase Rev - 0 MCH (Réparé)Document63 pagesECUMED Sizing Report For The First Phase Rev - 0 MCH (Réparé)mamspapsNo ratings yet

- Df-25054-Rep-03-001 (Proceso H2)Document110 pagesDf-25054-Rep-03-001 (Proceso H2)María Macharé GutierrezNo ratings yet

- Forced Evaporation Ponds DesignDocument10 pagesForced Evaporation Ponds Designfotikos100% (1)

- Cpe 12016 Ped 1903Document97 pagesCpe 12016 Ped 1903ImmanuelNo ratings yet

- Specification For Air Compressors and Air Dryer PackagesDocument21 pagesSpecification For Air Compressors and Air Dryer PackagesSudjono BroNo ratings yet

- SARB Documentation Training Dossier 2 (A4)Document116 pagesSARB Documentation Training Dossier 2 (A4)gfsdgNo ratings yet

- PP Aaa PP1 122Document19 pagesPP Aaa PP1 122Rabah AmidiNo ratings yet

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDNo ratings yet

- SCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFDocument3 pagesSCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFSEGUNNo ratings yet

- IPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsDocument22 pagesIPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsAbdi RahimianNo ratings yet

- Process Description Part 1 of 2 32618-196-06-DB-001Document13 pagesProcess Description Part 1 of 2 32618-196-06-DB-001waheedNo ratings yet

- Jihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191Document2 pagesJihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191HarryBouterNo ratings yet

- 04454H45-14-DB-0001 Rev0Document9 pages04454H45-14-DB-0001 Rev0garciahoNo ratings yet

- Design Basis Process Design Basis FOR UNIT 13,14,15Document42 pagesDesign Basis Process Design Basis FOR UNIT 13,14,15dhiaa mohammedNo ratings yet

- SFCCL Reformer DCI R1Document38 pagesSFCCL Reformer DCI R1maheshNo ratings yet

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Document23 pagesGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongNo ratings yet

- Varicon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDocument1 pageVaricon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDeva NaiduNo ratings yet

- M07 PDFDocument48 pagesM07 PDFAdrian GuzmanNo ratings yet

- PP Aaa PP1 164Document57 pagesPP Aaa PP1 164Rabah AmidiNo ratings yet

- API STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingDocument2 pagesAPI STD 2000-2009, Calculation For Max. Flow Rates For Normal InbreathingFendy ShirahNo ratings yet

- 140706DPRB14303 Exde03 79 PDFDocument80 pages140706DPRB14303 Exde03 79 PDFBassem BalghouthiNo ratings yet

- 7 - V-0801 P-0801 ABC HOT OIL SYSTEM PUMPS - Rev 0Cx PDFDocument1 page7 - V-0801 P-0801 ABC HOT OIL SYSTEM PUMPS - Rev 0Cx PDFMariaNo ratings yet

- Isolation PhilosophyDocument13 pagesIsolation PhilosophySamir BhongadeNo ratings yet

- Data Sheet Ejector PDFDocument2 pagesData Sheet Ejector PDFSuryaprakashNo ratings yet

- Appendix A - DATASHEET - BilectricDocument11 pagesAppendix A - DATASHEET - BilectricChakravarthy BharathNo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Process Design Basis: LPG Train-4 Project at MAA RefineryDocument42 pagesProcess Design Basis: LPG Train-4 Project at MAA RefineryVenkat RanganNo ratings yet

- Yemen LNG Upstream Facilities Project: Phase 1 Process Design Basis ManualDocument23 pagesYemen LNG Upstream Facilities Project: Phase 1 Process Design Basis Manualabdoamer.2553No ratings yet

- 720-C-003 (LP Methanol Column)Document7 pages720-C-003 (LP Methanol Column)idilfitriNo ratings yet

- BBS-10-W8-DS-003 - C - TEG Reflux Condenser DS PDFDocument1 pageBBS-10-W8-DS-003 - C - TEG Reflux Condenser DS PDFAdianto RahmanNo ratings yet

- NOZZLEDocument16 pagesNOZZLEAdianto RahmanNo ratings yet

- BBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFDocument1 pageBBS-10-W8-DS-006 - C - Glycol Charcoal Filter DS PDFAdianto RahmanNo ratings yet

- Deliverable JCH ArchitectureDocument4 pagesDeliverable JCH ArchitectureAdianto Rahman100% (1)

- Bbs 10 w8 Ds 007 - C - Rich Lean Glycol He DsDocument1 pageBbs 10 w8 Ds 007 - C - Rich Lean Glycol He DsAdianto RahmanNo ratings yet

- TC20200716 2253 5207122866 01Document1 pageTC20200716 2253 5207122866 01Adianto RahmanNo ratings yet

- S CurveDocument2 pagesS CurveAdianto Rahman100% (1)

- BBS-10-W8-DS-003 - C - TEG Reflux Condenser DS PDFDocument1 pageBBS-10-W8-DS-003 - C - TEG Reflux Condenser DS PDFAdianto RahmanNo ratings yet

- MDR (MK) - Bukit Asam Convention Hall JakabaringDocument6 pagesMDR (MK) - Bukit Asam Convention Hall JakabaringAdianto Rahman100% (3)

- SUTDI DENAH-Layout1Document1 pageSUTDI DENAH-Layout1Adianto RahmanNo ratings yet

- MDR - Convention Hall Rev3Document6 pagesMDR - Convention Hall Rev3Adianto Rahman100% (1)

- Microsoft Volume Licensing Reference Guide PDFDocument55 pagesMicrosoft Volume Licensing Reference Guide PDFAdianto RahmanNo ratings yet

- MDR - Bukit Asam Convention Hall Rev.1Document6 pagesMDR - Bukit Asam Convention Hall Rev.1Adianto Rahman100% (1)

- Contoh Proposal Bisnis PlanDocument31 pagesContoh Proposal Bisnis PlanHadianto Nugroho100% (4)

- BBS 10 P1 PID 0045 ModelDocument1 pageBBS 10 P1 PID 0045 ModelAdianto RahmanNo ratings yet

- Intro PDFDocument26 pagesIntro PDFAdianto RahmanNo ratings yet

- 1922A624OO-11-PE-PID-002 Sand Trap SBR-V-003 R-B1 IFRDocument1 page1922A624OO-11-PE-PID-002 Sand Trap SBR-V-003 R-B1 IFRAdianto RahmanNo ratings yet

- Ahub1-103 Iq Report - R2Document47 pagesAhub1-103 Iq Report - R2Adianto RahmanNo ratings yet

- Able of Contents:: Folder No. 1 Design & EngineeringDocument36 pagesAble of Contents:: Folder No. 1 Design & EngineeringAdianto RahmanNo ratings yet

- 1922A624OO-11-PE-PID-002 Sand Trap SBR-V-003 R-B1 IFR PDFDocument1 page1922A624OO-11-PE-PID-002 Sand Trap SBR-V-003 R-B1 IFR PDFAdianto RahmanNo ratings yet

- DatasheetDocument7 pagesDatasheetAdianto RahmanNo ratings yet

- List Doc Hot Water & ChillerDocument47 pagesList Doc Hot Water & ChillerAdianto RahmanNo ratings yet

- Distillation DesignDocument1 pageDistillation DesignvicopipNo ratings yet

- Principles of Semiconductor DevicesDocument658 pagesPrinciples of Semiconductor DeviceskrechbaNo ratings yet

- Wood StructuresDocument390 pagesWood Structuresvladimir071No ratings yet

- Science 10 4th Quarter ExamDocument4 pagesScience 10 4th Quarter Examzayd87% (39)

- Heat Pump Hoval Everest (37-108) v3Document14 pagesHeat Pump Hoval Everest (37-108) v3DONGTA123100% (1)

- MDSP SET O3Document26 pagesMDSP SET O3BrilliantJohnMalandacRubiaNo ratings yet

- Freshwater Acidification - WikipediaDocument4 pagesFreshwater Acidification - Wikipediatsvmpm1765No ratings yet

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Shielding Commissioning Factors in Nuclear Medicine FacilitiesDocument14 pagesShielding Commissioning Factors in Nuclear Medicine FacilitiesGoffredo PrincigalliNo ratings yet

- MS Basics - Herbert JAIRDocument473 pagesMS Basics - Herbert JAIRrubensfisicoNo ratings yet

- Metallography Is Defined As The Study of Metal and Its AlloysDocument6 pagesMetallography Is Defined As The Study of Metal and Its AlloysbazilNo ratings yet

- Dayananda Sagar University School of EngineeringDocument9 pagesDayananda Sagar University School of EngineeringMohd AbbasNo ratings yet

- Argon Recovery From Silicon Crystal FurnaceDocument7 pagesArgon Recovery From Silicon Crystal FurnaceasdfqwerNo ratings yet

- Transport Properties of Fluids Their Correlation Prediction and EstimationDocument497 pagesTransport Properties of Fluids Their Correlation Prediction and Estimationvamsi_m100% (1)

- Clark Kent Manzano - Science MicroscopeDocument3 pagesClark Kent Manzano - Science MicroscopeMaria Christina ManzanoNo ratings yet

- Eota TR 061 Design Method Fasteners Fatigue Loading 2018-06-11Document19 pagesEota TR 061 Design Method Fasteners Fatigue Loading 2018-06-11coolkaisyNo ratings yet

- Ochsner 2008 Carbon Dioxide Heat Pipe in ConjuncDocument6 pagesOchsner 2008 Carbon Dioxide Heat Pipe in ConjuncHugo PeresNo ratings yet

- PVT PropertiesDocument20 pagesPVT PropertiesJoseph YepezNo ratings yet

- (De Gruyter Textbook) Tadros, Tharwat F. - Polymeric Surfactants Dispersion Stability and Industrial Applications (2017) - Libgen - LiDocument288 pages(De Gruyter Textbook) Tadros, Tharwat F. - Polymeric Surfactants Dispersion Stability and Industrial Applications (2017) - Libgen - LishaziaNo ratings yet

- Measurement of Horizontal Distances 3Document11 pagesMeasurement of Horizontal Distances 3Joshua50% (2)

- Cast Iron: History and Application: AbstractDocument12 pagesCast Iron: History and Application: Abstract13311A0341 S SHIVA SAI KIRANNo ratings yet

- Heat Input in Welding: PT - Bakrie ConstructionDocument6 pagesHeat Input in Welding: PT - Bakrie ConstructionAlifNo ratings yet

- IAL - Chemistry - SB2 - Mark Scheme - T18Document2 pagesIAL - Chemistry - SB2 - Mark Scheme - T18salmaNo ratings yet

- TZ 21 PDFDocument16 pagesTZ 21 PDFAlmir MachadoNo ratings yet

- Vegard 1916Document17 pagesVegard 1916Preda ManuelaNo ratings yet

- Chapter 4 AllDocument30 pagesChapter 4 AllRobel Metiku100% (2)

- CX31 Maintenance ManualDocument25 pagesCX31 Maintenance ManualRodrigo RiveraNo ratings yet

- Ground Improvement by Heating and Freezing MethodDocument7 pagesGround Improvement by Heating and Freezing MethodHamadNo ratings yet

- Steam Turbine ModelDocument19 pagesSteam Turbine ModelRoberto ZuñigaNo ratings yet

- CES CBT Test Questions and Answers About Vessel Structure ConditionDocument27 pagesCES CBT Test Questions and Answers About Vessel Structure ConditionMyo Minn TunNo ratings yet