Professional Documents

Culture Documents

Saic W 2018

Saic W 2018

Uploaded by

munnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic W 2018

Saic W 2018

Uploaded by

munnaCopyright:

Available Formats

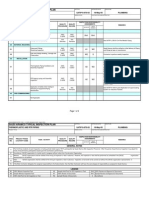

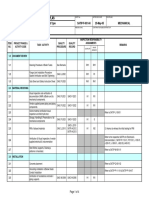

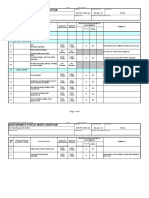

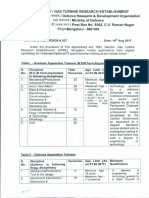

SAUDI ARAMCO ID/PIEU - 14- May 2018 - REV. 2018.03.00 (Standards Cutoff -March 31, 2018) Rev. 2018.03.

Rev. 2018.03.00 31-Mar-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Supplemental Procedure - Method Statements

SAIC-W-2018 14-May-18 MECH-

related to Overlay Welding, Cladding Restoration, Repair

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements

Welding procedures for corrosion resistant weld overlay have been

prepared & qualified in accordance with ASME SECTION IX & SAES- SAES-W-014,

A1

W-014 and CSD has approved the Welding Package. (Refer SAIC- Para. 5.1

W-2017)

All corrosion-resistant weld overlays, including clad restoration, shall

conform with ASME SEC VIII reqts (Div. 1 or Div. 2) & W-014. SAES-W-014,

A2

Commentary Note: Refer to ASME SEC VIII D1, Part UCL and ASME Para. 4.1

SEC VIII D2, Article F-5 for specific requirements.

Repairs to integrally clad material shall not be done without the

SAES-W-014,

A3 specific approval of CSD. Any weld repairs to the cladding shall meet

Para. 4.7

the requirements for weld overlays.

The minimum deposit thickness shall be specified in the engineering

SAES-W-014,

A4 design but shall not be less than 3.2 mm for corrosion-resistant

Para. 4.2

overlays.

Single layer overlays require prior approval by CSD. Additional

SAES-W-014,

A5 qualification and production tests may be required, as determined by

Para. 4.9

CSD.

Weld deposit chemistry shall be specified in engineering design.

Where a nominal alloy designation for overlay or cladding is listed SAES-W-014,

A6

(e.g., 316L), then overlay deposit shall meet equivalent filler metal Para. 4.4

composition reqmts unless otherwise specified or exempted.

The direction of overlay deposition shall be circumferential unless

otherwise approved by CSD. (Some components and geometries, SAES-W-014

A7

such as small diameter nozzles, or special applications may not Para. 4.3

permit welding in a circumferential direction.)

The WPS shall indicate the minimum deposit thickness qualified and

the minimum number of layers required. The number of layers used

SAES-W-014,

A9 for the Procedure Qualification Record (PQR) shall be recorded and

Para. 5.2

shall be the minimum number of layers specified on the WPS and

used in production.

Method of Weld Overlay identification (to be supplemented by the SAES-W-010,

A10

weld map - see SAES-W-010, Para. 7.1.2). MARKING METHODS! Para. 15.1/15.2

Saudi Aramco: Company General Use

You might also like

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- G.R. No. 173188 - Sps Cadaveda Vs Atty. Lacaya - Case DigestDocument2 pagesG.R. No. 173188 - Sps Cadaveda Vs Atty. Lacaya - Case DigestSarah jade LayugNo ratings yet

- Pre Welding ChecklistDocument2 pagesPre Welding Checklistmunna100% (3)

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- SACIC-T-5702 OSP Ductbank-Manhole & Handhole Hardware - Storage, Handling, and Preservation (RTS)Document2 pagesSACIC-T-5702 OSP Ductbank-Manhole & Handhole Hardware - Storage, Handling, and Preservation (RTS)Arshad ImamNo ratings yet

- Saic-P-3455 RevDocument7 pagesSaic-P-3455 RevDipuNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test ReportzhangNo ratings yet

- SAIC-P-3602 Rev 3Document3 pagesSAIC-P-3602 Rev 3DipuNo ratings yet

- Satr J 6104Document5 pagesSatr J 6104Shahzad HussainNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- SATIP S 070 03 ThermoplasticDocument2 pagesSATIP S 070 03 ThermoplasticMuhammad Farukh Manzoor100% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Saic P 3424Document3 pagesSaic P 3424spravin231No ratings yet

- Saudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911Document10 pagesSaudi Aramco Test Report: Power Transformer Tank - Jobsite Acceptance Test 3-Jul-18 Elect SATR-P-3911karthi51289No ratings yet

- SAIC-H-1002 Rev 7 (Final)Document2 pagesSAIC-H-1002 Rev 7 (Final)ryann mananquilNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistshahzadaNo ratings yet

- Saudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbDocument1 pageSaudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbUzair AhmadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalik100% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- SAIC-P-3456 RevDocument7 pagesSAIC-P-3456 RevDipuNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saic P 3859Document6 pagesSaic P 3859Niel TanedoNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- SATIP S 060 04 Plumbing FixturesDocument2 pagesSATIP S 060 04 Plumbing FixturesMuhammad Farukh ManzoorNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistOmer aliNo ratings yet

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Document4 pages1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- SATIP-K-001-08 - Air Filtration Devices and Grease FilterDocument2 pagesSATIP-K-001-08 - Air Filtration Devices and Grease Filterimrankhan22No ratings yet

- SG6427-SY-CK0P-MTD-736-005 - Method Statement of Local Panel & Enclosure Installattion - Rev.BDocument12 pagesSG6427-SY-CK0P-MTD-736-005 - Method Statement of Local Panel & Enclosure Installattion - Rev.Bbrian sanchezNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001usmanNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- SACIC-T-5603 Comms Facilities - Cable Rack - Material ReceivingDocument4 pagesSACIC-T-5603 Comms Facilities - Cable Rack - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Saic P 3426Document8 pagesSaic P 3426spravin231No ratings yet

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- SATIP S 070 02 Irrigation PipingDocument2 pagesSATIP S 070 02 Irrigation PipingMuhammad Farukh ManzoorNo ratings yet

- SACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingDocument2 pagesSACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- SAIC-K-4031 Rev 7 TTW & Window Mounted Air ConditionerDocument2 pagesSAIC-K-4031 Rev 7 TTW & Window Mounted Air ConditionershahzadaNo ratings yet

- SACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingDocument1 pageSACIC-T-5602 Comms Facilities - Guyed Steel Communication Tower - Material ReceivingArshad ImamNo ratings yet

- SAIC-W-2043 Rev 0Document3 pagesSAIC-W-2043 Rev 0philipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- SAIC-X-3001 Rev 2Document2 pagesSAIC-X-3001 Rev 2josephjohn2No ratings yet

- SATIP-K-001-02 Rev 6 Air-Handling Unit (AHU)Document4 pagesSATIP-K-001-02 Rev 6 Air-Handling Unit (AHU)imrankhan22No ratings yet

- SACIC-T-5707 OSP Ductbank-Plastic Innerducts and Accessories - Material ReceivingDocument2 pagesSACIC-T-5707 OSP Ductbank-Plastic Innerducts and Accessories - Material ReceivingArshad ImamNo ratings yet

- SAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionDocument2 pagesSAIC-H-1002 - Coatings and Repair Materials Receiving, InspectionzuknesedriNo ratings yet

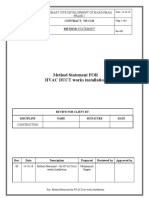

- Saudi Aircon Method StatementDocument12 pagesSaudi Aircon Method StatementSavad AlwyeNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Satip X 400 01Document11 pagesSatip X 400 01munnaNo ratings yet

- Satr P 3206Document6 pagesSatr P 3206munnaNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Satip M 100 09Document10 pagesSatip M 100 09munnaNo ratings yet

- Satip M 100 10Document10 pagesSatip M 100 10munnaNo ratings yet

- Satip M 100 07Document10 pagesSatip M 100 07munnaNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Schedule FDocument5 pagesSchedule FmunnaNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Saic W 2090Document2 pagesSaic W 2090munnaNo ratings yet

- Satip Q 001 03Document10 pagesSatip Q 001 03munnaNo ratings yet

- Satip Q 006 03Document10 pagesSatip Q 006 03munnaNo ratings yet

- Schedule I Company Attachment IDocument1 pageSchedule I Company Attachment ImunnaNo ratings yet

- Saep 42Document11 pagesSaep 42munnaNo ratings yet

- Schedule B - Attachment IDocument27 pagesSchedule B - Attachment Imunna100% (2)

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- Schedule C - Attachment 01Document50 pagesSchedule C - Attachment 01munnaNo ratings yet

- Saep 74Document29 pagesSaep 74munna100% (2)

- 01-SAMSS-333-HF Welded Line Pipe PDFDocument35 pages01-SAMSS-333-HF Welded Line Pipe PDFmunnaNo ratings yet

- Saep 750Document19 pagesSaep 750munnaNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- Saep 342Document5 pagesSaep 342munnaNo ratings yet

- Effects of Student Engagement With Social Media On Student Learning: A Review of LiteratureDocument13 pagesEffects of Student Engagement With Social Media On Student Learning: A Review of LiteratureGeorge DimitriadisNo ratings yet

- Electric Start HandbookDocument179 pagesElectric Start HandbookGeronimo JaimeNo ratings yet

- Northern Elevator Engineering LLC, Dubai, U.A.E Method Statement For Elevator InstallationDocument8 pagesNorthern Elevator Engineering LLC, Dubai, U.A.E Method Statement For Elevator InstallationjonesNo ratings yet

- Geometric Stiffness and P-Delta EffectsDocument14 pagesGeometric Stiffness and P-Delta EffectsRaul Vilcherrez MendietaNo ratings yet

- Cuối kỳ QTHDocument21 pagesCuối kỳ QTHKún BaleNo ratings yet

- (English) How To Achieve Your Most Ambitious Goals - Stephen Duneier - TEDxTucson (DownSub - Com)Document18 pages(English) How To Achieve Your Most Ambitious Goals - Stephen Duneier - TEDxTucson (DownSub - Com)Maulana Yazid Al AnnuriNo ratings yet

- Nid Case StudyDocument32 pagesNid Case StudyAbhishek AcharyaNo ratings yet

- IT, Pharma Depts Ask For Top-Up Funds in PLI Push: Asset Quality Set To Worsen: FSRDocument20 pagesIT, Pharma Depts Ask For Top-Up Funds in PLI Push: Asset Quality Set To Worsen: FSRSubhay kumarNo ratings yet

- Board PAper 2021 Term1Document15 pagesBoard PAper 2021 Term1zaharaaebrahim06No ratings yet

- Are We All Producers NowDocument16 pagesAre We All Producers NowAAliNo ratings yet

- Fabm1 Grade-11 Qtr4 Module5 Week-5Document6 pagesFabm1 Grade-11 Qtr4 Module5 Week-5Crestina Chu BagsitNo ratings yet

- The Impact of Burnout On Medical StudentsDocument3 pagesThe Impact of Burnout On Medical StudentsJulie Ann BagamaspadNo ratings yet

- App GtreDocument8 pagesApp GtreprankysayuNo ratings yet

- R A Scheme FORMS PDFDocument3 pagesR A Scheme FORMS PDFJnyanendra Kumar PradhanNo ratings yet

- Concrete Technology Lab Experiments: by A1 BatchDocument15 pagesConcrete Technology Lab Experiments: by A1 BatchsugunaNo ratings yet

- 51-Article Text (Mandatory) - 578-2-10-20220927Document9 pages51-Article Text (Mandatory) - 578-2-10-20220927Alemayehu ZostietNo ratings yet

- Recently Announced A Slew of Reforms: Other ImpactsDocument27 pagesRecently Announced A Slew of Reforms: Other ImpactsPriya VermaNo ratings yet

- WOMEN EMPOWERMENT MCQs UNIT - IIDocument13 pagesWOMEN EMPOWERMENT MCQs UNIT - IIRohit Choudhary 2100% (12)

- Familiarization With The Basics of Python Programming: Chapter-2Document37 pagesFamiliarization With The Basics of Python Programming: Chapter-2Santosh ShresthaNo ratings yet

- Mining Engines: Slope StabilityDocument9 pagesMining Engines: Slope StabilityISAAC TAWIAHNo ratings yet

- 6.1 Monthly Report - March 2023 - Perway Emergency Slope StabilityDocument22 pages6.1 Monthly Report - March 2023 - Perway Emergency Slope StabilityJeanri RustNo ratings yet

- Web-Based Student Result Management System: October 2018Document21 pagesWeb-Based Student Result Management System: October 2018Ranjay PratapNo ratings yet

- Octagon Studio's Augmented World Expo 2016 SubmissionDocument26 pagesOctagon Studio's Augmented World Expo 2016 SubmissionGrawas SugihartoNo ratings yet

- Unit 4 Activity Worksheet Revenue and Collection Cycle IDocument2 pagesUnit 4 Activity Worksheet Revenue and Collection Cycle IFinneth AchasNo ratings yet

- Diploma Mathematics NotesDocument82 pagesDiploma Mathematics NotesmogirejudNo ratings yet

- A Project On CRM in StarbucksDocument40 pagesA Project On CRM in StarbucksLibasti Bhaskaran68% (22)

- Solder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFDocument83 pagesSolder Joint Reliability - A Unified Thermo-Mechanical Model Approach PDFQUALITY LABORATORYNo ratings yet

- Geography Sba GuideDocument3 pagesGeography Sba GuideKareem WignallNo ratings yet

- APtransco PlanningcodeDocument55 pagesAPtransco PlanningcoderajfabNo ratings yet