Professional Documents

Culture Documents

Saic Q 1012

Uploaded by

Naushad AlamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic Q 1012

Uploaded by

Naushad AlamCopyright:

Available Formats

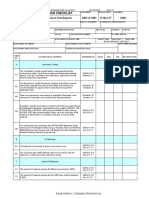

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.

00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Cast-In-Place Concrete Formwork Inspection SAIC-Q-1012 15-Nov-17 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Structural engineering design calculations are prepared and

approved by a degreed structural engineer for all elevated formwork. SAES-Q-001

A1

Approved formwork drawings and plans are available at the job site. Sec. 7.19.1

(Construction Safety Manual 2011, Vol. II, Sec. 6.4.3 & 6.4.4)

Formwork are erected in full compliance with the approved drawings SAES-Q-001

A2

and plans. (Construction Safety Manual 2011, Vol. II, Sec. 6.4.3) Sec. 7.19.1

Scaffolds, working platforms, and guardrails are incorporated into SAES-Q-001

A3

formwork design and all formwork drawings. (ACI 347-04, Sec. 3.1) Sec. 7.19

Forms shall be substantial and sufficiently tight to prevent leakage of SAES-Q-001

A4

mortar from the concrete. (ACI 347-04, Sec. 3.2.1.6) Sec. 7.19

Studs, wales, or shores are properly spliced. (ACI 347-04, Sec. SAES-Q-001

A5

3.2.1.1) Sec. 7.19

Joints or splices in sheathing, plywood panels, and bracing are SAES-Q-001

A6

staggered. (ACI 347-04, Sec. 3.2.1.2) Sec. 7.19

Forms shall result in a final structure that conforms to shapes, lines,

SAES-Q-001

A7 and dimensions of the members as required by the IFC drawings.

Sec. 3.2

(ACI 318M-2011, Sec. 6.1.1)

Forms are properly braced or tied together to maintain position and SAES-Q-001

A8

shape. (ACI 318-2011, Sec. 6.1.3) Sec. 3.2

Forms and their supports shall be designed so as not to damage SAES-Q-001

A9

previously placed structure(s). (ACI 318M-2011, Sec. 6.1.4) Sec. 3.2

Proper formwork foundations are provided on ground, such as

mudsills, spread footings, or pile footings. If soil under mudsills is or

SAES-Q-001

A10 may become incapable of supporting superimposed loads, it should

Sec. 7.19

be stabilized or other means of support should be provided. (ACI

347-04, Sec. 2.7)

Formwork shall be anchored to the shores below so that movement

SAES-Q-001

A11 of any part of the formwork system will be prevented during

Sec. 7.19

concreting. (ACI 347-04, Sec. 3.6.1.3)

Safety signs and barricades are erected to keep unauthorized

SAES-Q-001

A12 personnel clear of areas in which erection, concrete placing, or

Sec. 7.19

formwork stripping is under way. (ACI 347-04, Sec. 3.1)

Anchorage of alternative fall protection devices, such as personal fall

SAES-Q-001

A13 arrest systems, safety net systems, and positioning device systems

Sec. 7.19

are provided. (ACI 347-04, Sec. 3.1)

Saudi Aramco: Company General Use

Reused forms are not damaged, distorted, disassembled, or SAES-Q-001

A14

otherwise unable to perform as designed. (ACI 347-04, Sect. 5.5.1) Sec. 3.2

Saudi Aramco: Company General Use

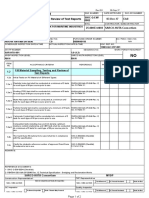

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Cast-In-Place Concrete Formwork Inspection SAIC-Q-1012 15-Nov-17 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Damaged or defective materials are not used for formwork and are

SAES-Q-001

A15 immediately removed from the site. (Construction Safety Manual

Sec. 7.19

2011, Vol. II, Sec. 6.4.12)

Blockouts, inserts, sleeves, anchors, waterstops and other

SAES-Q-001

A16 embedded items are properly identified, positioned and secured.

Sec. 7.19

(ACI 347-04, Sec. 3.2.4.2)

Shores shall be installed plumb and with adequate bearing and SAES-Q-001

A17

bracing. (ACI 347-04, Sec. 3.2.1.3) Sec. 7.19

The size of form ties and clamps shall be as specified in the IFC SAES-Q-001

A18

drawings. (ACI 347-04, Sec. 3.2.1.4) Sec. 7.19

All form ties or clamps are installed and properly tightened as SAES-Q-001

A19

specified. (ACI 347-04, Sec. 3.2.1.5) Sec. 7.19

Irregularities in formwork surfaces measured with a 1.5m

straightedge shall not exceed: 3mm for Class A surfaces exposed to

public view; 6mm for Class B areas to be plastered; 13mm for Class SAES-Q-001

A20

C where appearance does not matter; 25mm for Class D Sec. 7.19

permanently hidden concrete surfaces. (ACI 347-04, Sec. 3.4, Table

3.1)

Formwork surfaces and embedded materials are cleaned of mortar,

SAES-Q-001

A21 grout, and foreign materials before concrete placement. (ACI 301-

Sec. 3.2

2010, Sec. 2.3.1.14)

Building materials, including concrete, shall not be dropped or piled

SAES-Q-001

A22 on the formwork in such a manner as to damage or overload it.

Sec. 8.0

(ACI 347-04, Sec. 3.2.6.1)

Runways for moving equipment and support runways are provided

SAES-Q-001

A23 directly on formwork or structural member without resting on

Sec. 3.2

reinforcement. (ACI 301-2010, Sec. 2.3.1.11)

Commercially manufactured formwork release agent that reduces

formwork moisture absorption, prevents bond with concrete, and SAES-Q-001

A24

does not stain exposed concrete surfaces are used on the formwork. Sec. 2.2.1.3

(ACI 301-2010, Sec. 2.2.1.3)

Formwork release agents shall not puddle on forms. Formwork

SAES-Q-001

A25 release agent to contact reinforcement or hardened concrete against

Sec. 3.2

which fresh concrete is to be placed. (ACI 301-2010, Sec. 2.3.1.15)

Formwork release agent shall not be in contact with reinforcement or

SAES-Q-001

A26 hardened concrete against which fresh concrete is to be placed. (ACI

Sec. 3.2

301-2010, Sec. 2.3.1.15)

Chamfer strips (minimum of 20mm) are placed in corners of

formwork to produce beveled edges on permanently exposed

SAES-Q-001

A27 surfaces. Unless otherwise specified, reentrant corners or edges of

Sec. 3.2

formed joints of concrete are not beveled. (ACI 301-2010, Sec.

2.3.1.2)

Saudi Aramco: Company General Use

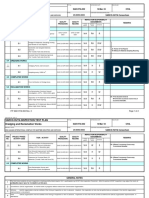

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Cast-In-Place Concrete Formwork Inspection SAIC-Q-1012 15-Nov-17 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A plasticized sheet vapor barrier shall be placed beneath and around

SAES-Q-001

A28 the sides of concrete that is placed where bitumen or coal tar epoxy

Sec. 7.20.3

cannot be applied.

A plasticized sheet vapor barrier, minimum 0.15mm thick, shall be SAES-Q-001

A29

placed beneath slabs on grade except for exterior sidewalks. Sec. 7.20.1

Joints not specified on the design drawings shall be in accordance

SAES-Q-001

A30 with ACI 301, Chapter 2, Section 2.2.2.5 and Chapter 5, Sections

Sec. 7.20

5.1.2.3a, 5.2.2.1 and 5.3.2.6.

Unless otherwise specified, construction joints are located within

middle third of spans of slabs, beams, and girders. When a beam

SAES-Q-001

A31 intersects a girder within this region, offset joint in girder a distance

Sec. 3.2

equal to or greater than twice width of beam. (ACI 301-2010, Sec.

2.2.2.5.a)

Unless otherwise specified, construction joints in walls and columns

SAES-Q-001

A32 are located at the underside of slabs, beams, or girders and at tops

Sec. 3.2

of footings or slabs. (ACI 301-2010, Sec. 2.2.2.5.a)

Construction joints are made perpendicular to main reinforcement. SAES-Q-001

A33

(ACI 301-2010, Sec. 2.2.2.5.a) Sec. 3.2

Paving or slab construction joints not specified on the drawings, shall SAES-Q-001

A34

be located at column centerlines and at intermediate intervals. Sec. 7.20.7

Waterstops shall be provided in joints where watertight construction

is required in accordance with ACI 350.4R. Waterstops shall be SAES-Q-001

A35

specified and shown on the drawings and shall satisfy the function Sec. 7.20.8

and operation of the structure..

Joint filler strips for expansion joints shall conform to ASTM D1751 SAES-Q-001

A36

OR ASTM D1752. Type shall be as noted in the design drawings. Sec. 6.3.1

Joint sealers shall be elastomeric, single or multi-component, non-

SAES-Q-001

A37 sag, paintable and have good resistance to occasional hydrocarbon

Sec. 6.3.2

and lubricating oil spills. (09-SAMMS-075)

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-Q-001 -- Criteria for Design and Construction of Concrete Structures, 07 January 2016

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 15-Nov-2017 - REV. 2016.06.00 (Standards Cutoff -June 30, 2016) Rev. 2016.06.00 30-Jun-16

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Cast-In-Place Concrete Formwork Inspection SAIC-Q-1012 15-Nov-17 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNo ratings yet

- Vessel Pedestal Crane Student ManualDocument19 pagesVessel Pedestal Crane Student Manualfafejaya1350% (2)

- Streamlined Beauty - A History of Automotive DesignDocument9 pagesStreamlined Beauty - A History of Automotive DesignRajanikantJadhav100% (2)

- UrbanClap: India's Largest At-Home Services MarketplaceDocument37 pagesUrbanClap: India's Largest At-Home Services Marketplacenaksh arora60% (25)

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Material Master List Model 2016 UPDATED 1Document482 pagesMaterial Master List Model 2016 UPDATED 1mohamed hamedNo ratings yet

- Saudi Aramco Precast Concrete Installation PlanDocument10 pagesSaudi Aramco Precast Concrete Installation PlanNaushad AlamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul Hannan100% (1)

- Saudi Aramco Tank Inspection ChecklistDocument12 pagesSaudi Aramco Tank Inspection ChecklistMd ShariqueNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Visualforce Cheat SheetDocument2 pagesVisualforce Cheat SheetMahendraKumarNo ratings yet

- Inspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechDocument2 pagesInspection of Support Foundation Prior To Structural or Equipment Installation SAIC-M-2006 03-Apr-22 MechsankuNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilDocument8 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilAbdul HannanNo ratings yet

- SAUDI ARAMCO GEOTECHNICAL INSPECTION CHECKLISTDocument4 pagesSAUDI ARAMCO GEOTECHNICAL INSPECTION CHECKLISTkarthi51289No ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saic M 1025Document4 pagesSaic M 1025Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist 6232Document19 pagesSaudi Aramco Inspection Checklist 6232Munir Choudary100% (1)

- PSD SiemensDocument45 pagesPSD Siemensbrijendra2185% (13)

- SAIC-K-4012 Rev 08 - Metal Duct Hangers and Support InstallationDocument3 pagesSAIC-K-4012 Rev 08 - Metal Duct Hangers and Support Installationranausman1987No ratings yet

- SAIC-Q-1013 Rev 7 (Final)Document7 pagesSAIC-Q-1013 Rev 7 (Final)Prince JoseNo ratings yet

- Paint Slip Coefficient PDFDocument28 pagesPaint Slip Coefficient PDFRk Sabarinathan100% (1)

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Reinstatement Procedure ChecklistDocument5 pagesSaudi Aramco Reinstatement Procedure ChecklistpravinNo ratings yet

- Saic Q 1012Document2 pagesSaic Q 1012Hussain Nasser Al- Nowiesser100% (2)

- Saic M 1069Document2 pagesSaic M 1069Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saic M 1032Document3 pagesSaic M 1032Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- Zone 13 PDFDocument54 pagesZone 13 PDFSobiya100% (1)

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Saic Q 1014Document2 pagesSaic Q 1014Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1013Document5 pagesSaic Q 1013Hussain Nasser Al- NowiesserNo ratings yet

- ACX5 Brochure enDocument44 pagesACX5 Brochure enrnkmip100% (3)

- SAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTDocument5 pagesSAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTNaushad AlamNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CDocument4 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Saic Q 1015Document2 pagesSaic Q 1015Hussain Nasser Al- Nowiesser100% (1)

- Saudi Aramco Inspection Checklist: Structural Steel - Erection Inspection SAIC-M-1025 1-Nov-09 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Structural Steel - Erection Inspection SAIC-M-1025 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAIC-B-2001 Revw Proprietary Fireproofing MaterialsDocument2 pagesSAIC-B-2001 Revw Proprietary Fireproofing MaterialsAnonymous S9qBDVkyNo ratings yet

- SACIC-CV-0001 Rev.04 Survey and CoordinatesDocument3 pagesSACIC-CV-0001 Rev.04 Survey and CoordinatesEr Nizamuddin AliNo ratings yet

- Saic Q 1026Document2 pagesSaic Q 1026Qays YousefNo ratings yet

- Saic A 1013Document2 pagesSaic A 1013karthi51289No ratings yet

- Saic M 1030Document3 pagesSaic M 1030Hussain Nasser Al- NowiesserNo ratings yet

- Concrete Grade Inspection ChecklistDocument2 pagesConcrete Grade Inspection ChecklistShazab NawazNo ratings yet

- Surface Preparation ChecklistDocument2 pagesSurface Preparation ChecklistWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- Saudi Aramco Weld Repair Procedure ReviewDocument9 pagesSaudi Aramco Weld Repair Procedure ReviewIrshad IqbalNo ratings yet

- SAIC-D-2002 Rev 8Document5 pagesSAIC-D-2002 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection ChecklistDocument14 pagesSaudi Aramco Inspection Checklistpookkoya thangalNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilAhmad BassemNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Receiving, Handling, Storage and Preservation Inspection ChecklistDocument8 pagesReceiving, Handling, Storage and Preservation Inspection ChecklistKirubhakarPooranamNo ratings yet

- Saic L 1001Document2 pagesSaic L 1001noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 MechDocument2 pagesSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic M 1034Document3 pagesSaic M 1034Hussain Nasser Al- NowiesserNo ratings yet

- SAIC-W-2086 In-Process Welding Inspection PDFDocument5 pagesSAIC-W-2086 In-Process Welding Inspection PDFkarioke mohaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Structural Steel Materials Receiving Inspection SAIC-M-1021 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Structural Steel Materials Receiving Inspection SAIC-M-1021 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008Naushad AlamNo ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilMD SHARIQUENo ratings yet

- Saic-A-2006 Rev 62Document5 pagesSaic-A-2006 Rev 62pradeepthalava97No ratings yet

- Saudi Aramco Post-Test Reinstatement ChecklistDocument15 pagesSaudi Aramco Post-Test Reinstatement Checklistpookkoya thangalNo ratings yet

- Performance-Based Road Maintenance Contracts in the CAREC RegionFrom EverandPerformance-Based Road Maintenance Contracts in the CAREC RegionNo ratings yet

- SAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWDocument27 pagesSAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWNaushad AlamNo ratings yet

- Saudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 15-Nov-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 15-Nov-17 CivilNaushad AlamNo ratings yet

- Non Shrink GroutingDocument13 pagesNon Shrink GroutingNaushad AlamNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportNaushad AlamNo ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- Installation of Utility Piping Systems StandardsDocument2 pagesInstallation of Utility Piping Systems StandardsNaushad AlamNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Naushad AlamNo ratings yet

- Astm C 94Document15 pagesAstm C 94Naushad AlamNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005Naushad AlamNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- Geotechnical Standards for Excavation and BackfillDocument1 pageGeotechnical Standards for Excavation and BackfillNaushad AlamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistNaushad AlamNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- Shic Q Ew 0006Document1 pageShic Q Ew 0006Naushad AlamNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- Geotextile Material Inspection ReportDocument2 pagesGeotextile Material Inspection ReportNaushad AlamNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilNaushad AlamNo ratings yet

- Shic Q Ew 0007Document1 pageShic Q Ew 0007Naushad AlamNo ratings yet

- Shic Q Ew 0002Document2 pagesShic Q Ew 0002Naushad AlamNo ratings yet

- Shic Q Ew 0008Document1 pageShic Q Ew 0008Naushad AlamNo ratings yet

- Saudi Aramco Vibro Replacement ChecklistDocument4 pagesSaudi Aramco Vibro Replacement ChecklistNaushad AlamNo ratings yet

- SAR-KIS-T-0300-ITP Earthworks Up To Formation Level Rev 4Document18 pagesSAR-KIS-T-0300-ITP Earthworks Up To Formation Level Rev 4Naushad AlamNo ratings yet

- SAR-HTA-002 Rev. 3Document2 pagesSAR-HTA-002 Rev. 3Naushad AlamNo ratings yet

- Saic A 1003Document4 pagesSaic A 1003Naushad AlamNo ratings yet

- Saic A 1008Document4 pagesSaic A 1008Naushad AlamNo ratings yet

- Orion Conveyorized Twin Station Stretch Wrappers CTS Mechanical DrawingsDocument43 pagesOrion Conveyorized Twin Station Stretch Wrappers CTS Mechanical DrawingsTony BravoNo ratings yet

- Electromagnetic Radiation Applications in Food ProcessingDocument34 pagesElectromagnetic Radiation Applications in Food ProcessingMichaela ZacharovovaNo ratings yet

- Unix by PratapDocument280 pagesUnix by Pratapanon_78505863No ratings yet

- Social WeeblyDocument4 pagesSocial Weeblyapi-401560883No ratings yet

- Modified Flashing LED ALGORITHMDocument24 pagesModified Flashing LED ALGORITHMDinesh Loitongbam100% (1)

- Quectel M10 AT Commands Manual V4.0 PDFDocument248 pagesQuectel M10 AT Commands Manual V4.0 PDFNarendra NarenNo ratings yet

- Rockwell Automation TechED 2018 - PR26 - Endress+HauserDocument33 pagesRockwell Automation TechED 2018 - PR26 - Endress+HauserAlex Rivas100% (1)

- 813820112016-Mini ProjectDocument5 pages813820112016-Mini ProjectYokes WaranNo ratings yet

- KONSTRUKSI KAPAL PPTDocument13 pagesKONSTRUKSI KAPAL PPTHarboyot YpNo ratings yet

- A New Approach For Measuring Water and Heavy Hydrocarbon Dew Points of Natural GasesDocument17 pagesA New Approach For Measuring Water and Heavy Hydrocarbon Dew Points of Natural Gasesmajid maheriNo ratings yet

- BT 2 Elec Plumbing Struc CedarsideDocument14 pagesBT 2 Elec Plumbing Struc CedarsideK4 Printing ServicesNo ratings yet

- Thong So Ky Thuat Cua ScheuerleDocument6 pagesThong So Ky Thuat Cua ScheuerleCuong DinhNo ratings yet

- RICS Associate - Quick Reference GuideDocument5 pagesRICS Associate - Quick Reference GuideHoang Vien DuNo ratings yet

- Audit Harley DavidsonDocument2 pagesAudit Harley DavidsonAbdul Hafizh100% (1)

- Wilson Tool - Press Brake Specials - Scule Speciale Pentru Abkant - SM TECH SRLDocument25 pagesWilson Tool - Press Brake Specials - Scule Speciale Pentru Abkant - SM TECH SRLSM TECH SRLNo ratings yet

- Fluke 27 II and 28 II:: Rugged IP 67 Industrial MultimetersDocument2 pagesFluke 27 II and 28 II:: Rugged IP 67 Industrial MultimetersSuleyman KapucuNo ratings yet

- Delta SigmaDocument12 pagesDelta Sigmaelad-lachmi-4064No ratings yet

- Amahan Namo - F. PaleroDocument16 pagesAmahan Namo - F. PaleroJaybie SabadoNo ratings yet

- 3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws ArmouredDocument2 pages3c Cu Xlpe PVC 12.7 (22) KV Heavy Duty Cws Armouredgari_monsantoNo ratings yet

- Sangoma Vega Sbct-smb-020 For SMB - 20 Simultaneous Calls l1Document3 pagesSangoma Vega Sbct-smb-020 For SMB - 20 Simultaneous Calls l1lykorianNo ratings yet

- DD DDDD DDDD DDDDDocument1,692 pagesDD DDDD DDDD DDDDgebreNo ratings yet