Professional Documents

Culture Documents

Saic D 2017

Saic D 2017

Uploaded by

jerinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic D 2017

Saic D 2017

Uploaded by

jerinCopyright:

Available Formats

A B C D E F G H I J K L M N O P Q R S T U VWX Y ZAAABACADAEAFAG

AHAIAJAKALAM

ANAOAPAQ

ARASATAUAV

AWAX AY AZ

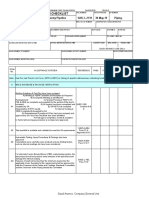

1 SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

2 SAUDI ARAMCO INSPECTION CHECKLIST

3 Inspection of FRP Tank installation SAIC-D-2017 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

4

5 EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

7

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

9

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

11

12 SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

13

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

15

18 ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

19 No. DATE

20 A Underground FRP Tank (UL 1316)

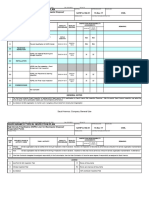

A tank shall be provided with one or more lugs for lifting that are

21 A1

attached to the tank or can be attached to a fitting on the tank.

UL Para. 3.1

A fitting for pipe connection shall be a standard threaded pipe

coupling (ANSI/ASME B36.10), a threaded flange, a standard half

22 A2

pipe nipple, or a bolted and gasketed flanged connection. The

UL Para. 4.1

connection shall be bonded directly to the tank.

All openings in a tank shall be located in the top. They shall be

located on the longitudinal centerline of the top when the tank is

cylindrical. When the tank is spherical, the openings shall be located

on the vertical centerline of the tank. Exception:

23 A3 When the application of a tank is such that openings in the top for pipe connection are UL Para. 4.2

required to be gruoped, the openings shall be located not more than 12 inches (305)

from the longitudinal centerline of the top of a cylindrical tank or the vertical centerline

of a spherical tank. This exception applies when the upper end of each pipe coupling

or other fitting for pipe connection terminates above the top of the shell.

24 B Aboveground FRP Tank (API SPEC 12P)

Vertical flat bottom tanks should be installed on a base providing

continuous support for both the tank bottom and knuckle radius, and API Spec 12P

25 B1

having sufficient strength to support the weight of the tank full of Annex A.1

liquid with negligible deflection.

The following materials are recommended for tank grades: sand or

API Spec 12P

26 B2 material of less than 1/8 inch diameter, smooth surfaced concrete, or

Annex A.1

a concrete grout.

Retaining rings are highly recommended for tank pads to help

API Spec 12P

27 B3 prevent wind and water erosion around the base of the tank.

Annex A.1

(API spec 12P Para A.1)

Use of rock riprap, large diameter gravel or other coarse material

API Spec 12P

28 B4 around the base of the tank after installation will prevent tank grade

Annex A.1

erosion. (API spec 12P Para A.1)

Once the tank is installed on the grade, a final inspection is done to

API Spec 12P

29 B5 ensure no fractures in the base, knuckle, side wall or connections,

Annex A.2

either in the interior or exterior of the tank.

FRP tanks should be remotely located from any obvious ignition

source and or so located that any spill resulting from the failure of API Spec 12P

30 B6

these materials could not unduly expose persons, buildings, or Annex A.3

structures.

31

Saudi Aramco: Company General Use

A B C D E F G H I J K L M N O P Q R S T U VWX Y ZAAABACADAEAFAG

AHAIAJAKALAM

ANAOAPAQ

ARASATAUAV

AWAX AY AZ

REMARKS:

This checklist is for UL 1316 and API SPEC 12P Tanks. The current revision of 32-SAMSS-030 (13 December

2011) specifically refers to metallic tanks only. Tank UL 1316 refers to FRP tanks intended for underground

storage and API Spec 12P refers to FRP tanks intended for above ground and atmosperic pressure service.

32 Thus, the title should be Inspection of FRP Tank Installation. The inspection parameters were then taken

directly from the Specifications for UL 1316 and API Spec 12P.

34

NOTES:

36

REFERENCE DOCUMENTS:

37 1. UL 1316, FRP Tanks, 12 May 2006

38 2. API 12P Fiberglass Reinforced Plastic Tanks, THIRD EDITION, OCTOBER 2008

40 Contractor / Third-Party Saudi Aramco

41 Construction Representative* PMT Representative

42 Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

43

44 QC Inspector PID Representative

45 Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

46

47 QC Supervisor Proponent and Others

48 Quality Record Approved:

Name, Organization,

T&I Witnessed QC Record Reviewed Work Verified

Name, Sign and Date:

49 Initials and Date:

50 *Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Keynote Intermediate Test 1Document5 pagesKeynote Intermediate Test 1peienglish33% (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Ledge Wall ConstructionDocument3 pagesLedge Wall ConstructionGabriel Gabe100% (1)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Seminar Report: Rajasthan Technical UniversityDocument28 pagesSeminar Report: Rajasthan Technical UniversityLakshya SinghNo ratings yet

- Saic Gi 2102Document3 pagesSaic Gi 2102jerin100% (3)

- Basic Personality InventoryDocument8 pagesBasic Personality InventoryElisa Mae Oranza Gura100% (2)

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- SAIC-A-2017 Rev 2Document3 pagesSAIC-A-2017 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Saic G 2023Document2 pagesSaic G 2023Noor Mohamed AzeezNo ratings yet

- Saic L 1001Document2 pagesSaic L 1001noor mohamedazeezNo ratings yet

- Saic D 2016Document2 pagesSaic D 2016razzak.me.enggNo ratings yet

- Saic L 1004Document3 pagesSaic L 1004noor mohamedazeezNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 30-Apr-13 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic L 2114 SfnyDocument3 pagesSaic L 2114 Sfnykhansalman51thNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Pipeline Right of Way (ROW) Inspection SAIC-L-1001 30-Oct-17 CivilAhmad BassemNo ratings yet

- Piper - 1379 BulletinDocument5 pagesPiper - 1379 BulletinFRRNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- SL 1297 - Rudder Tube Assembly Inspection 2021-10-22Document4 pagesSL 1297 - Rudder Tube Assembly Inspection 2021-10-22Alexander GraytrousesNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- SATIP-A-104-01 High Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation PondsDocument10 pagesSATIP-A-104-01 High Density Polyethylene (HDPE) Liner For Wastewater Disposal Evaporation Pondsjohn ajitNo ratings yet

- SAIC-A-2006 Rev 7Document5 pagesSAIC-A-2006 Rev 7Shyam Sundar GayenNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 22-Jan-18 MechaneeshNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007Shahzad HussainNo ratings yet

- SAIC-L-2106 Rev 7Document8 pagesSAIC-L-2106 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechDocument3 pagesSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 15-Dec-09 MechEagle SpiritNo ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- SAIC-A-2026 Rev 2Document5 pagesSAIC-A-2026 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanJagdishNo ratings yet

- Punch List - Substation 2 - HVACDocument1 pagePunch List - Substation 2 - HVACxu tao daiNo ratings yet

- SACIC-CV-0003 Rev.04 Electronic Friction Cone and Piezocone Penetration TestDocument3 pagesSACIC-CV-0003 Rev.04 Electronic Friction Cone and Piezocone Penetration TestEr Nizamuddin AliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- SAIC-K-4020 Rev 08 - Chilled Water Piping Lay-OutDocument4 pagesSAIC-K-4020 Rev 08 - Chilled Water Piping Lay-Outranausman1987No ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saic B 2014Document4 pagesSaic B 2014usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingDocument5 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 31-Dec-14 PipingpravinNo ratings yet

- Sab Ic P 0101Document3 pagesSab Ic P 0101sajid latifNo ratings yet

- SAIC-L-2135 Rev 0Document9 pagesSAIC-L-2135 Rev 0philipyapNo ratings yet

- Ds-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Document3 pagesDs-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Panisa BanimaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanNo ratings yet

- SAIC-A-2006 Rev 6Document16 pagesSAIC-A-2006 Rev 6biplabpal2009No ratings yet

- SAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsDocument2 pagesSAIC-A-2016 Pneumatic Test of Reinf Pad, Weld+EndsAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 24-Jul-18 MechnadeemNo ratings yet

- SAIC-D-2005 Rev 8Document6 pagesSAIC-D-2005 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Gf-4172-Qc-ei-fm-0003, Rev. 1 Cable Tray Ladder TrunkingDocument10 pagesGf-4172-Qc-ei-fm-0003, Rev. 1 Cable Tray Ladder TrunkingsureshNo ratings yet

- Pi Ups 1007Document30 pagesPi Ups 1007JOEL ARNAO CORTEGANANo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- SAIC-D-2002 Rev 8Document5 pagesSAIC-D-2002 Rev 8Syed ImranNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- 3 CWater PlansDocument5 pages3 CWater Plans许爱文No ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- Saic LPT 2001Document22 pagesSaic LPT 2001jerinNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saic LPT 2004Document13 pagesSaic LPT 2004jerinNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saic B 1002Document3 pagesSaic B 1002jerinNo ratings yet

- Saic M 1004Document2 pagesSaic M 1004jerinNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- Saic A 2013Document6 pagesSaic A 2013jerinNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Saic H 2033Document6 pagesSaic H 2033jerinNo ratings yet

- Saic A 2011Document8 pagesSaic A 2011jerinNo ratings yet

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Satip N 110 01Document11 pagesSatip N 110 01jerinNo ratings yet

- Saic N 2026Document3 pagesSaic N 2026jerinNo ratings yet

- Satr M 1063Document3 pagesSatr M 1063jerin100% (1)

- BRC7F634F DatasheetDocument23 pagesBRC7F634F DatasheetSicologo CimeNo ratings yet

- Dar 05292018Document5 pagesDar 05292018Fauquier NowNo ratings yet

- 2022materialcanvassform 1215710892601434Document8 pages2022materialcanvassform 1215710892601434Diana ValienteNo ratings yet

- Answers For MPF QuestionsDocument6 pagesAnswers For MPF QuestionsJack bandannaNo ratings yet

- Name: Mr. M AGE: 62 Years Old SEX: Male CC: Persistent Cough Admitting/Working Diagnosis: PnuemoniaDocument3 pagesName: Mr. M AGE: 62 Years Old SEX: Male CC: Persistent Cough Admitting/Working Diagnosis: PnuemoniaMae Therese B. MAGNONo ratings yet

- Chapter 31: Fungi Study GuideDocument2 pagesChapter 31: Fungi Study GuideMadeline JensenNo ratings yet

- Mutoh Rock Hopper 3-65-90Document319 pagesMutoh Rock Hopper 3-65-90Koki SmokiNo ratings yet

- Comparative Hydrolysis and Fermentation of Sugarcane and Agave BagasseDocument8 pagesComparative Hydrolysis and Fermentation of Sugarcane and Agave BagasseAnonymous Wcj4C3jNo ratings yet

- GOC Neet Key NotesDocument40 pagesGOC Neet Key Notesiampriyatiwarii890No ratings yet

- Final Budgetfor WebsitDocument445 pagesFinal Budgetfor Websitsally elderaaNo ratings yet

- Eng 11 Unit 8 Become IndependentDocument9 pagesEng 11 Unit 8 Become IndependentLương Quang HiệuNo ratings yet

- Tarea 4Document6 pagesTarea 4Bladimir SánchezNo ratings yet

- Item Analysis With Least Learned Competencies Lica 3rdDocument9 pagesItem Analysis With Least Learned Competencies Lica 3rdLa LayNo ratings yet

- SamsoniteDocument17 pagesSamsoniteDeepak Nayak100% (1)

- Final SynopsisDocument14 pagesFinal SynopsisAlex100% (1)

- In Vitro Determination of Sun Protection Factor On Clays Used For Cosmetic Purposes in KenyaDocument7 pagesIn Vitro Determination of Sun Protection Factor On Clays Used For Cosmetic Purposes in KenyaRafaella ResendeNo ratings yet

- World's Fair: PublicationsDocument365 pagesWorld's Fair: PublicationsJohnWilliams86No ratings yet

- Dicom Cs v3 5 r1Document79 pagesDicom Cs v3 5 r1Basheer AlmetwakelNo ratings yet

- Design Aid 6.15.3 Minimum Length of Weld To Develop Full Strength of Bar. Weld Parallel To Bar LengthDocument1 pageDesign Aid 6.15.3 Minimum Length of Weld To Develop Full Strength of Bar. Weld Parallel To Bar LengthbrettNo ratings yet

- Control of HVDC Transmission System Based On MMC With Three-Level Flying Capacitor SubmoduleDocument22 pagesControl of HVDC Transmission System Based On MMC With Three-Level Flying Capacitor SubmoduleAnand Parakkat Parambil100% (1)

- Water HomeostasisDocument9 pagesWater HomeostasisRini MagfirahNo ratings yet

- How To Perform Criticality Analysis To Prioritize Asset MaintenanceDocument22 pagesHow To Perform Criticality Analysis To Prioritize Asset MaintenanceSreekanthMylavarapuNo ratings yet

- Single Display PID Temperature Controllers: TC SeriesDocument6 pagesSingle Display PID Temperature Controllers: TC SeriesDinho AcioliNo ratings yet

- DLD Lab 1Document6 pagesDLD Lab 1waqasNo ratings yet

- Light Independent Reaction - BiologyDocument3 pagesLight Independent Reaction - BiologyHidayah SakinahNo ratings yet

- Rapid Diagnostic Testing in Microbiology: Adeleke Olaide.A. 17/1078Document18 pagesRapid Diagnostic Testing in Microbiology: Adeleke Olaide.A. 17/1078Ay GlassesNo ratings yet

- Farming The Amur Strugeon (Acipenser Shrenckii) and The Mississippi Paddlefish (Polyodon Spathula) in MalaysiaDocument9 pagesFarming The Amur Strugeon (Acipenser Shrenckii) and The Mississippi Paddlefish (Polyodon Spathula) in MalaysiaWagen Low Yi KhangNo ratings yet

- Physiology of PleuraDocument16 pagesPhysiology of PleuraMohamedSalah100% (2)