Professional Documents

Culture Documents

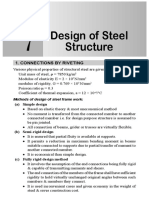

Calculation Method: For The Case Where M Is Zero

Calculation Method: For The Case Where M Is Zero

Uploaded by

Vasanth KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation Method: For The Case Where M Is Zero

Calculation Method: For The Case Where M Is Zero

Uploaded by

Vasanth KumarCopyright:

Available Formats

Calculation Method For the case where M* is zero – Minimum cross sectional area of stud

The design of Shearfix follows the Vuo = ud(fcv + 0.3σ cp ) reinforcement -

specifications set out in the Clause 9.2 of AS 0.35bs

Clause 9.2.3a, AS 3600: 2009 Avs ≥

3600: 2009, but the major part of the design is fvy

based on the research presented by F K Lim Where –

0.35as

and B V Rangan from the School of Vuo = shear capacity of the slab Avt ≥

fvy

Engineering at Curtin University of Technology σ cp = average pre-stress in concrete

in Perth. Fcv = concrete shear strength, where – Clause 8.2.8, AS 3600: 2009

The design calculations check the shear fcv = 0.17(1 + 2 βh ) f' c ≤0.34 f' c When using the Shearfix Design Program, the

stresses imposed on the critical shear βh is the ratio of the effective loaded program automatically determines the

perimeter surrounding the column, with area = X/Y (X≥Y) diameter, spacing and number of studs

Shearfix stud reinforcement provided as required.

required. For the case where M* is not zero –

Alternatively the user can specify the diameter,

Vuo

Design Actions Vu = spacing and number of studs and check

When checking the shear capacity of the slab, 1+( v* 8V* ad )

uM

against the shear capacity of the slab.

the design shear force V* and design transfer Clause 9.2.4, AS 3600: 2009

Detailing

moment from the slab into the support Mv* Where “a” is the dimension of the critical shear When using the Shearfix Design Program, the

must be taken into account. perimeter parallel in the direction of Mv* program automatically arranges the stud rails

In the Shearfix Design Program, these values If V* > φVu or φVuo, then Shearfix studs are around the column.

must be calculated and inputted into the required. When arranging Shearfix studs around columns,

program.

To determine the shear capacity of the slab the following limits should be implemented –

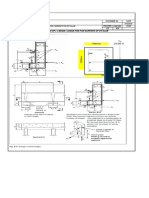

Critical Shear Perimeter

The critical shear perimeter “u” is the boundary

with Shearfix studs for the slab strip, the • The position of the first stud from the

following equation from Lim and Rangan is column face is 0.5d (d = effective depth of

of the effective area of a support or used – slab)

concentrated loads located at a distance of

d/2, (d = effective depth of the slab). Vu = Vuo(1 + kt ) • The maximum stud spacing is 500mm or

OR 0.75D or 0.7(D – Top Cover – Bottom Cover

For rectangular columns –

Vuo – 5mm), whichever is less (D – overall depth

u = 2(x + d/2 + d/2) + 2(y + d/2 + d/2) Vu = of slab)

1 + uMv*

Critical shear perimeter ks 8V* ad • The minimum spacing for 12mm studs is

(the lesser result of the two equations) 45mm, and 55mm for 16mm studs

d/

where – • The height of stud (hs ) is calculated as –

2 y ks = 1 Avs fvy d u hs = D – Top cover - Bottom cover - 5mm

Vuo sb

d/ Avs = cross sectional area of a row of studs in For 24mm Studs, the minimum stud height

2

the slab strip is 360mm

x

Fvy = Yield strength of the stud (500 MPa)

Where there are critical openings within 2.5 b0 s = spacing of the studs

• The cross sectional area for the headed

ends on each stud needs to be at least 10

from the critical perimeter, the projected width b = width of the critical shear perimeter times the cross sectional area of the stud

of the opening will be ineffective and will perpendicular to the direction Mv* diameter. (Clause 13.1.4, AS 3600: 2009).

reduce the length of the critical perimeter.

For the torsion strip, the following equations This ensures the stud is fully anchored to

b0 are used – provide full transfer of forces through the

Ineffective portion

of critical shear stud.

Vu = Vuo(1 + kt )

perimeter

<2.5 b0 d/

2 OR • The maximum spacing between rails is

Vuo 600mm or D, whichever is less

Vu1 =

d/ 1 + uMv*

2

1+kt 8V* ad

• The minimum spacing is 100mm

(the lesser result of the two equations) • The position of the last stud is located 2.5d

where – from the column face

kt = 1 Avt fvy d u

Vuo sa

• The minimum slab thicknesses for each stud

size with 20mm cover is as follows –

<2.5 b0 Avt = cross sectional area of a row of studs in

Stud Size Min Slab Thickness

the torsion strip

12mm 140mm

a = width of the critical shear perimeter parallel

b0 16mm 140mm

to the direction Mv* (the width of the torsion 20mm 180mm

Calculation of Shear Stress strip) 24mm 410mm

b

The shear capacity of the slab is determined in

accordance to Clause 9.2.3 for the case where For rectangular columns the areas of maximum

there are no transfer moments (M* is zero), or stress will be at the corners of the column,

Clause 9.2.4 for the case where there are Direction of Torsion because of this it is best to try and place rails at

transfer moments (M* is not zero). Bending Strip a the end of the column sides.

You might also like

- Car StealingDocument4 pagesCar StealingRoberto Quiroz0% (1)

- RC Beam Design Using ACIDocument1 pageRC Beam Design Using ACIdantevariasNo ratings yet

- Overview of Building CodeDocument17 pagesOverview of Building CodeVasanth KumarNo ratings yet

- 4JVP44 We 0111Document238 pages4JVP44 We 0111Elkin Martínez SilvaNo ratings yet

- Design of One Way SlabDocument31 pagesDesign of One Way SlabRam Ingalkar90% (10)

- 009 - Steel Column - Without Top Row FinalDocument4 pages009 - Steel Column - Without Top Row FinalVAIBHAVNo ratings yet

- Some Basics of LasersDocument102 pagesSome Basics of LasersVinisha Vipin SharmaNo ratings yet

- Ribbed SlabsDocument10 pagesRibbed SlabsAlemayehu DargeNo ratings yet

- Calculation PoF and CoFDocument10 pagesCalculation PoF and CoFHamidNo ratings yet

- Part 6 Analysis and Design of PurlinsDocument18 pagesPart 6 Analysis and Design of PurlinsPaul P.No ratings yet

- BS8110 RC Beam DesignDocument2 pagesBS8110 RC Beam DesignDicky DjayadiNo ratings yet

- Torsion 9Document13 pagesTorsion 9Vasanth KumarNo ratings yet

- Shear DesignDocument5 pagesShear DesigntrixiaNo ratings yet

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- User Manual TMS 300 Rayos X PortatilDocument37 pagesUser Manual TMS 300 Rayos X Portatilpablo50% (2)

- ستيل ستركشرDocument73 pagesستيل ستركشرAws SamaNo ratings yet

- HVAC CalculationDocument1 pageHVAC CalculationbradalbiNo ratings yet

- 0 1 Reinforced Concrete EC2 Definitions and Details p1-5Document6 pages0 1 Reinforced Concrete EC2 Definitions and Details p1-5VijayNo ratings yet

- "Financial Management Is The Area of BusinessDocument12 pages"Financial Management Is The Area of BusinessVasanth Kumar100% (1)

- MDSO831D Petro Retailing Business PDFDocument264 pagesMDSO831D Petro Retailing Business PDFVasanth KumarNo ratings yet

- Manual: Engineering Calculation TemplateDocument8 pagesManual: Engineering Calculation TemplateHamiNo ratings yet

- Solved Computer MCQs For UDC/LDC MS OFFICEDocument40 pagesSolved Computer MCQs For UDC/LDC MS OFFICErashid33% (3)

- RDSODocument8 pagesRDSOVikasNo ratings yet

- Useful Data From IS456 & Is-13920Document29 pagesUseful Data From IS456 & Is-13920MayurNo ratings yet

- EAPP Budget of WorkDocument4 pagesEAPP Budget of WorkAriane del Rosario100% (3)

- Column Base Plate DesignDocument1 pageColumn Base Plate DesignBunkun15No ratings yet

- CerartsantoDocument6 pagesCerartsantoLucia Sueli Taguchi100% (1)

- Plate Girder BridgeDocument14 pagesPlate Girder BridgeDHANALAKSHMI G TeachingNo ratings yet

- Reinforced Concrete Design Module 7 Subject: CE 74A-Reinforced Concrete DesignDocument25 pagesReinforced Concrete Design Module 7 Subject: CE 74A-Reinforced Concrete DesignJemson VictorioNo ratings yet

- Punching Shear and One Way Shear Check.Document2 pagesPunching Shear and One Way Shear Check.ElancheliyanNo ratings yet

- Chapter 5 - 2 Super Structure Design Example (Compatibility Mode)Document42 pagesChapter 5 - 2 Super Structure Design Example (Compatibility Mode)Asfaw BelayNo ratings yet

- BeamsDocument27 pagesBeamsHarpreetNo ratings yet

- Review Module (Steel Design 2)Document4 pagesReview Module (Steel Design 2)Lenielle AmatosaNo ratings yet

- Design of Singly ReinforcedDocument26 pagesDesign of Singly ReinforcedPronab Kumar DasNo ratings yet

- Design of Singly Reinforced.Document26 pagesDesign of Singly Reinforced.anuj3936No ratings yet

- Design For Shear and Torsion - Design of TiesDocument2 pagesDesign For Shear and Torsion - Design of TiesJohn Philip NuñezNo ratings yet

- Design of Singly Reinforced.Document25 pagesDesign of Singly Reinforced.Gaurav SharmaNo ratings yet

- Allowable Shearing StressDocument11 pagesAllowable Shearing StressSofia GaliciaNo ratings yet

- 1.3 Design Data - SD 672 New Final - PDF 02-04-2018Document19 pages1.3 Design Data - SD 672 New Final - PDF 02-04-2018simon maaaklaNo ratings yet

- 7.7.1.4 Trusses SpecificationsDocument3 pages7.7.1.4 Trusses Specificationsishaan choudharyNo ratings yet

- Chiranjit Manna Roll-25701321071 Ce (PC) 501Document26 pagesChiranjit Manna Roll-25701321071 Ce (PC) 501Chiranjit MannaNo ratings yet

- Design of Singly Reinforced.Document33 pagesDesign of Singly Reinforced.Abarajitha AmudhanNo ratings yet

- Lecture 6-Design For ShearDocument14 pagesLecture 6-Design For ShearMarkos DanielNo ratings yet

- Session 8 FootingsDocument13 pagesSession 8 FootingsAyaNo ratings yet

- DesignofpilecapDocument14 pagesDesignofpilecapkjkjNo ratings yet

- Crack Width For Walls and Raft 2711231021183044Document5 pagesCrack Width For Walls and Raft 2711231021183044Eman FaroukNo ratings yet

- Pump Room Slab Crack WidthDocument3 pagesPump Room Slab Crack WidthWai HonNo ratings yet

- Notching On BeamsDocument5 pagesNotching On BeamsRRussel CastroNo ratings yet

- LAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side LengthsDocument20 pagesLAB Design Procedure: 1. Decide The Type of Slab According To Aspect Ratio of Long and Short Side Lengthsmollikamin100% (1)

- IS 456: 2000 32.8 Design of RCC Isolated Footings For Columns (Square and Rectangle) - Working Stress Method: 32.8.1 Design Considerations:Minimum Reinforcement: (As Per IS456:2000, ClauseDocument8 pagesIS 456: 2000 32.8 Design of RCC Isolated Footings For Columns (Square and Rectangle) - Working Stress Method: 32.8.1 Design Considerations:Minimum Reinforcement: (As Per IS456:2000, ClauseMonika VechalapuNo ratings yet

- PCI N03 KP LedgeDocument4 pagesPCI N03 KP Ledgekifayathulla003No ratings yet

- RCD Lecture Note 4 - USD of Non-Rectangular Beams PDFDocument2 pagesRCD Lecture Note 4 - USD of Non-Rectangular Beams PDFAugosto FraceNo ratings yet

- Cl.40, p-72, IS:456-2000: Limit State of Collapse in Shear - Design For ShearDocument6 pagesCl.40, p-72, IS:456-2000: Limit State of Collapse in Shear - Design For ShearNitish KumarNo ratings yet

- Development Length & Splices of ReinforcementDocument19 pagesDevelopment Length & Splices of ReinforcementAshraf ZayedNo ratings yet

- Solved Example - DSSDocument8 pagesSolved Example - DSSsaratNo ratings yet

- Punching ShearDocument2 pagesPunching ShearJulianNo ratings yet

- Chapter 7 PDFDocument8 pagesChapter 7 PDFWendimu TolessaNo ratings yet

- Project: Client: Engineer: Remarks:: SteelmanDocument5 pagesProject: Client: Engineer: Remarks:: SteelmanDaniel RabascallNo ratings yet

- Design Check of Seismic Arrestor (Station)Document3 pagesDesign Check of Seismic Arrestor (Station)sesadimadennisNo ratings yet

- Structural Design I: Course Code: CIVL312Document66 pagesStructural Design I: Course Code: CIVL312layaljamal2No ratings yet

- Plate Girders: Sequence of Fabrication of Plate GirderDocument16 pagesPlate Girders: Sequence of Fabrication of Plate Girderraunak upadhyayaNo ratings yet

- ENGG 135 Design of Reinforced Concrete Structures: Shear in RC Beams Required Reading: Wight Chapter 6Document31 pagesENGG 135 Design of Reinforced Concrete Structures: Shear in RC Beams Required Reading: Wight Chapter 6Manuel MirandaNo ratings yet

- RC 3Document11 pagesRC 3AyaNo ratings yet

- Crack Width Calculation BS 8100 BS 8007Document1 pageCrack Width Calculation BS 8100 BS 8007asdNo ratings yet

- Chapter 3 Shear ExamplesDocument30 pagesChapter 3 Shear ExamplesRefisa JiruNo ratings yet

- Crack Width Calculations To BS8110: 1997/ BS8007:1987: RC 12-Nov-2021 33 CHG - R68Document3 pagesCrack Width Calculations To BS8110: 1997/ BS8007:1987: RC 12-Nov-2021 33 CHG - R68Benedict OgbaghaNo ratings yet

- Greenwich Peninsula: Ground Slab - Building B SK 04-Jan-2022 KK - 4464Document4 pagesGreenwich Peninsula: Ground Slab - Building B SK 04-Jan-2022 KK - 4464christi SNo ratings yet

- Corbel DesignDocument13 pagesCorbel DesignAshraf ZayedNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- California Kadhali PDFDocument43 pagesCalifornia Kadhali PDFVasanth KumarNo ratings yet

- Pad Eye Design Guidelines PDFDocument4 pagesPad Eye Design Guidelines PDFVasanth KumarNo ratings yet

- Reviewofbasicsinstructuralanalysis PDFDocument157 pagesReviewofbasicsinstructuralanalysis PDFOSCARDELTANo ratings yet

- Civil Works ManualDocument32 pagesCivil Works ManualVasanth KumarNo ratings yet

- Time Value of MoneyDocument38 pagesTime Value of MoneyVasanth Kumar100% (1)

- Safety Moment - Plastic BagsDocument24 pagesSafety Moment - Plastic BagsVasanth KumarNo ratings yet

- User Manual - Omega.x 1.3Document24 pagesUser Manual - Omega.x 1.3SebNo ratings yet

- Object Detection and Shadow Removal From Video StreamDocument10 pagesObject Detection and Shadow Removal From Video StreamPaolo PinoNo ratings yet

- Appendix 5.1. BIE Prospectus 2021Document73 pagesAppendix 5.1. BIE Prospectus 2021Tosan DanuNo ratings yet

- COMP3900 Cheat SheetDocument2 pagesCOMP3900 Cheat SheetIanMonica100% (1)

- Emision StandardsDocument4 pagesEmision StandardsAshish RoongtaNo ratings yet

- El Poder de Los Padres Que Oran Libro de Oracion DownloadDocument2 pagesEl Poder de Los Padres Que Oran Libro de Oracion DownloadVictoria Eugenia Chica RamirezNo ratings yet

- Recovery Boiler: Esa VakkilainenDocument20 pagesRecovery Boiler: Esa Vakkilainenmarcus vinicius silva de souzaNo ratings yet

- A Des ExampleDocument15 pagesA Des Examplenagaraj100% (1)

- Embedded System Ch1 - PDFDocument25 pagesEmbedded System Ch1 - PDFImad AlbadawiNo ratings yet

- H1A2Document421 pagesH1A2Juan Pablo Sanchez MelgarejoNo ratings yet

- DFC1023 Test1Document4 pagesDFC1023 Test1faris_39No ratings yet

- Writing 4. Writing Task 2 (1) - UEB 2BDocument3 pagesWriting 4. Writing Task 2 (1) - UEB 2BMai Nguyễn PhươngNo ratings yet

- Bedplate PDFDocument4 pagesBedplate PDFDean DsouzaNo ratings yet

- Sendai Motorsales Inc - CROSBYDocument8 pagesSendai Motorsales Inc - CROSBYJeff D. AgustinNo ratings yet

- Mobile Shop Management System DocumentationDocument98 pagesMobile Shop Management System DocumentationAdnanNo ratings yet

- Mid Continent CatalogDocument40 pagesMid Continent Catalogcatseekit 캣시킷No ratings yet

- Cma 1325Document70 pagesCma 1325brandonnsayavonggNo ratings yet

- Absorbance Coeff FormulaDocument6 pagesAbsorbance Coeff FormulaoktavNo ratings yet

- D116 Gypsum Board Suspended Ceiling System D116 Gypsum Board Suspended Ceiling SystemDocument2 pagesD116 Gypsum Board Suspended Ceiling System D116 Gypsum Board Suspended Ceiling Systemanon_158565729No ratings yet

- Recover From A Bad Flash - ...Document12 pagesRecover From A Bad Flash - ...ali_shaikh81No ratings yet

- A133 2240 1023 MR 0Document178 pagesA133 2240 1023 MR 0kalaiNo ratings yet