Professional Documents

Culture Documents

Construction Check Sheet Piping Cleanliness PC-0024A

Uploaded by

hrimklimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Check Sheet Piping Cleanliness PC-0024A

Uploaded by

hrimklimCopyright:

Available Formats

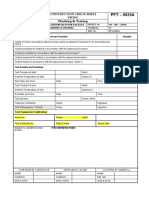

CONSTRUCTION CHECK SHEET PC-0024A

PIPING

Piping Cleanliness

PROJECT

DESCRIPTION

n-BUTYL LITHIUM DILUTION FACILITY PROJECT No. 44 – NC – 2900

SYSTEM

DESCRIPTION

PIPING CLEANLINESS SYSTEM No. 18

SERVICE

TEST No. PC-0024

DESCRIPTION

This Sheet is to allow the cleaning of certain sections of line which are identified as needing extra attention to

cleanliness, typically suction lines to Rotating equipment downstream of the commissioning strainers or Hot Oil

Circulation systems as a whole.

The method to be employed will be the bursting disc method. The open end of the line will be covered with

polythene sheet, air will be introduced at the other end to a maximum pressure of 7 barg. until the polythene

membranes break. This has the effect of forming a Vacuum & will draw dirt out. It is much more efficient than

valve opening.

Item Description of check Result

01 * Limits of Line blow to be Verified by the commissioning Engineer

02 * Remove the line, initially check & remove any welding spatter etc by hand prior to

blowing

03 Prepare for blow, the amount of Polythene sheets can be varied to suit

04 Ensure that safety signs are erected

05 To check the amount of debris removed it is best to have a sheet of white material

opposite where the disc breaks to see the amount of debris removed

06 At least 2 blows will be required

07 * For the final blow Commissioning must attend & sign off this sheet

08 Reinstate pipe ready for service

09 If required carry out a gross air reinstatement test, then fill in P-002B2

REMARKS / OBSERVATIONS: * COMMISSIONING WITNESS POINT

COMPLETED BY CONTRACTOR APPROVED BY JACOBS ACCEPTED BY CHEMETALL

NAME NAME NAME

COMPANY COMPANY REF. IND.

SIGN & DATE SIGN & DATE SIGN & DATE

You might also like

- Construction Check Sheet Piping Cleanliness PC-0024ADocument1 pageConstruction Check Sheet Piping Cleanliness PC-0024AKailash PandeyNo ratings yet

- Construction Check Sheet Insulation of Piping PIN-0023ADocument1 pageConstruction Check Sheet Insulation of Piping PIN-0023AhrimklimNo ratings yet

- Construction Check Sheet P-0008A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0008A: Mechanical Installation of PumphrimklimNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumpKailash PandeyNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumphrimklimNo ratings yet

- Construction Check Sheet Tank B-0005A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0005A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet: PipingDocument1 pageConstruction Check Sheet: PipingKailash PandeyNo ratings yet

- Construction Check Sheet: PipingDocument1 pageConstruction Check Sheet: PipinghrimklimNo ratings yet

- Construction Check Sheet Tank B-0002A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0002A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Heat Exchanger W-0002A: MechanicalDocument1 pageConstruction Check Sheet Heat Exchanger W-0002A: MechanicalKailash PandeyNo ratings yet

- Construction Check Sheet Tank B-0004A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0004A: MechanicalhrimklimNo ratings yet

- Drying & Cleanning SpecificationDocument5 pagesDrying & Cleanning SpecificationAnant Rubade100% (1)

- Construction Check Sheet Vessel B-0003A: MechanicalDocument1 pageConstruction Check Sheet Vessel B-0003A: MechanicalhrimklimNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalKailash PandeyNo ratings yet

- Construction Check Sheet Piping Installation For Test PI-0021ADocument1 pageConstruction Check Sheet Piping Installation For Test PI-0021AhrimklimNo ratings yet

- Construction Check Sheet Fire Fighting Equipment Installation E-0017ADocument2 pagesConstruction Check Sheet Fire Fighting Equipment Installation E-0017AhrimklimNo ratings yet

- Construction Check Sheet Fire Fighting Equipment Installation E-0017ADocument2 pagesConstruction Check Sheet Fire Fighting Equipment Installation E-0017AKailash PandeyNo ratings yet

- Field Quality Control PlanDocument59 pagesField Quality Control Plan1339979100% (2)

- Vendor document review cover sheetDocument9 pagesVendor document review cover sheetvelmurug_balaNo ratings yet

- Construction Check Sheet Tank B-0015A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0015A: MechanicalhrimklimNo ratings yet

- Field Joint CoatingDocument7 pagesField Joint Coatingkrishna3794No ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- Construction Check Sheet P-0010A-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010A-A: Mechanical Installation of PumphrimklimNo ratings yet

- Method Statement For Welding RepairDocument7 pagesMethod Statement For Welding RepairHarun AkkayaNo ratings yet

- Form No. Sheet: Acid Gas Incinerator Installation Process SheetDocument1 pageForm No. Sheet: Acid Gas Incinerator Installation Process SheetMathias OnosemuodeNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BDocument6 pagesHFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BMohamed FarisNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- SAIC-E-2009 Intrnal Cleanliness Insp of HEDocument2 pagesSAIC-E-2009 Intrnal Cleanliness Insp of HEAnonymous S9qBDVkyNo ratings yet

- 11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureDocument8 pages11-KU-TWK-50-QA-PRO-2173 - 0 - Wrapping ProcedureAvak NishanNo ratings yet

- Adobe Scan 25-Oct-2022Document6 pagesAdobe Scan 25-Oct-2022himanshu koleyNo ratings yet

- MS For Heat ExchangersDocument6 pagesMS For Heat ExchangersravikumarNo ratings yet

- Construction Check of Neutral Earth ResistorDocument2 pagesConstruction Check of Neutral Earth ResistorhrimklimNo ratings yet

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- DTTN DT2 PC MET EL 0011 A Method Statement For Hydraulic CrimpingDocument8 pagesDTTN DT2 PC MET EL 0011 A Method Statement For Hydraulic CrimpingTariq Ali SialNo ratings yet

- Std-Insp-0127 Procedure For Commissioning ProcedureDocument54 pagesStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraNo ratings yet

- Corrosion Coupan Check ListDocument2 pagesCorrosion Coupan Check Listtrichysayee100% (1)

- Construction Check Sheet Vessel B-0001A: MechanicalDocument1 pageConstruction Check Sheet Vessel B-0001A: MechanicalhrimklimNo ratings yet

- Adobe Scan 09-Mar-2023Document3 pagesAdobe Scan 09-Mar-2023himanshu koleyNo ratings yet

- Vacuum Box Test Report of Tank T-8112 Bottom PlatesDocument8 pagesVacuum Box Test Report of Tank T-8112 Bottom PlatesShalom LivingstonNo ratings yet

- Construction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederDocument2 pagesConstruction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederhrimklimNo ratings yet

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocument4 pagesVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNo ratings yet

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureDocument34 pages000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- Fire Fighting Equipment: Commissioning Check SheetDocument2 pagesFire Fighting Equipment: Commissioning Check SheethrimklimNo ratings yet

- XG32-130-001 - Rev 1 - REV1 - SIGNED - AG PIPING ISOMETRIC DRAWING FOR WBS 130 PDFDocument606 pagesXG32-130-001 - Rev 1 - REV1 - SIGNED - AG PIPING ISOMETRIC DRAWING FOR WBS 130 PDFjosejohn1No ratings yet

- Construction Check Sheet Inverter E-019A: ElectricalDocument1 pageConstruction Check Sheet Inverter E-019A: ElectricalhrimklimNo ratings yet

- Tank B-0002B: Pre-Commissioning Check SheetDocument1 pageTank B-0002B: Pre-Commissioning Check SheethrimklimNo ratings yet

- Construction Check Sheet Control & Relay Panel E-025A: ElectricalDocument1 pageConstruction Check Sheet Control & Relay Panel E-025A: ElectricalhrimklimNo ratings yet

- Construction Check Sheet Relief Valve RV-0020A: MechanicalDocument1 pageConstruction Check Sheet Relief Valve RV-0020A: MechanicalhrimklimNo ratings yet

- Construction equipment earthing checklistDocument1 pageConstruction equipment earthing checklisthrimklimNo ratings yet

- NPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level GaugeDocument5 pagesNPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level Gaugekkumar_717405No ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- Pipes Backfilling Release Check List 2inch Air LineDocument1 pagePipes Backfilling Release Check List 2inch Air LineAnwar QaisNo ratings yet

- EI-014 Rev.1 - GroutDocument11 pagesEI-014 Rev.1 - GroutDavid Ricardo Lozano RondonNo ratings yet

- Construction Check Sheet Safety Shower / Eye Bath S-0019A: MechanicalDocument1 pageConstruction Check Sheet Safety Shower / Eye Bath S-0019A: MechanicalhrimklimNo ratings yet

- Piping Fabrication ProcedureDocument11 pagesPiping Fabrication ProcedureMohammed Elsaid Yousef Harhera100% (2)

- MS A. Method Statement of UPVC Pipe Installation & Testing For Soil Waste Vent & Rain 29.06.23Document19 pagesMS A. Method Statement of UPVC Pipe Installation & Testing For Soil Waste Vent & Rain 29.06.23Rashmiranjan SamalNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- Pre-Commissioning Check Sheet: PipingDocument1 pagePre-Commissioning Check Sheet: PipinghrimklimNo ratings yet

- Construction Check Sheet: PipingDocument1 pageConstruction Check Sheet: PipinghrimklimNo ratings yet

- TEC-0026A: Test Equipment CalibrationDocument1 pageTEC-0026A: Test Equipment CalibrationhrimklimNo ratings yet

- Construction Check Sheet Safety Shower / Eye Bath S-0019A: MechanicalDocument1 pageConstruction Check Sheet Safety Shower / Eye Bath S-0019A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet P-0010A-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010A-A: Mechanical Installation of PumphrimklimNo ratings yet

- Construction Check Sheet Relief Valve RV-0020A: MechanicalDocument1 pageConstruction Check Sheet Relief Valve RV-0020A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Piping Installation For Test PI-0021ADocument1 pageConstruction Check Sheet Piping Installation For Test PI-0021AhrimklimNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- PFT - 0025A: Construction Check Sheet Piping Flushing & TestingDocument1 pagePFT - 0025A: Construction Check Sheet Piping Flushing & TestinghrimklimNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheethrimklimNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0006B-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0006B-AhrimklimNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheethrimklimNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0003B-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0003B-AhrimklimNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0006A-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0006A-AhrimklimNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0003A-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0003A-AhrimklimNo ratings yet

- Check List Installation - ADocument1 pageCheck List Installation - AhrimklimNo ratings yet

- Construction Check Sheet Tank B-0015A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0015A: MechanicalhrimklimNo ratings yet

- Discription of Check ListDocument2 pagesDiscription of Check ListhrimklimNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheethrimklimNo ratings yet

- Check List Precommi-BDocument1 pageCheck List Precommi-BhrimklimNo ratings yet

- Construction Check Sheet Fire Fighting Equipment Installation E-0017ADocument2 pagesConstruction Check Sheet Fire Fighting Equipment Installation E-0017AhrimklimNo ratings yet

- Module 5 Review 1 (Day 2)Document7 pagesModule 5 Review 1 (Day 2)Ibrahim FareedNo ratings yet

- Aluminum Conductor Steel Reinforced Trapezoidal Wire (ACSR/TW)Document5 pagesAluminum Conductor Steel Reinforced Trapezoidal Wire (ACSR/TW)manohargud100% (1)

- Chapteradf 5Document27 pagesChapteradf 5yikamnn100% (5)

- Canon EOS R5 and R6 Overheating Media AlertDocument2 pagesCanon EOS R5 and R6 Overheating Media AlertMichael ZhangNo ratings yet

- Erection Enquiry Power TechDocument1 pageErection Enquiry Power TechKundan PrasadNo ratings yet

- Moeller ManualDocument12 pagesMoeller ManualAlexandre DiasNo ratings yet

- Pac24 ImDocument40 pagesPac24 ImCarlyson SilvaNo ratings yet

- EMKO ecoPID PID Temperature Controller Instruction ManualDocument2 pagesEMKO ecoPID PID Temperature Controller Instruction ManualWaldo herbas montaño100% (1)

- Custom KnifemakingDocument1 pageCustom Knifemakingpseudo3No ratings yet

- Honeywell VisionPro 8000 Install InstructionsDocument12 pagesHoneywell VisionPro 8000 Install InstructionskoolermanNo ratings yet

- Service Manual: ConfidentialDocument105 pagesService Manual: ConfidentialRu80% (5)

- Vertical and Horizontal Screw ConveyorsDocument4 pagesVertical and Horizontal Screw ConveyorsLLNo ratings yet

- Ipad Document Camera StandDocument5 pagesIpad Document Camera StandAlberto DazaNo ratings yet

- 27c Confined Space PermitDocument1 page27c Confined Space PermitMohammed MinhajNo ratings yet

- Waukesha Gas Engines: GE Power Distributed PowerDocument4 pagesWaukesha Gas Engines: GE Power Distributed PowerdfmolinaNo ratings yet

- Load Summary for Demand Under 100kVADocument2 pagesLoad Summary for Demand Under 100kVAPacu BerjemaahNo ratings yet

- ELECTRONIC COMPONENTS HandoutDocument22 pagesELECTRONIC COMPONENTS HandoutVineeth WilsonNo ratings yet

- Bubble-Free Basic BrochureDocument2 pagesBubble-Free Basic BrochureKft Akkor-DekorNo ratings yet

- FEM1 - 007 EnglishDocument20 pagesFEM1 - 007 Englishmssm_sNo ratings yet

- D223 - D224 - D225 - Exp Ricoh - SPDocument489 pagesD223 - D224 - D225 - Exp Ricoh - SPEduardo SánchezNo ratings yet

- Furuno RadarDocument195 pagesFuruno RadarПавел СубботинNo ratings yet

- Elna 6004 Service ManualDocument32 pagesElna 6004 Service ManualGinny RossNo ratings yet

- SPPB AssemblingDocument83 pagesSPPB AssemblingMuhammad Reza GadranNo ratings yet

- Proteus Data Sheet - 2022Document8 pagesProteus Data Sheet - 2022Rubel AguilarNo ratings yet

- Industrial Gas Generator Drive Components CatalogDocument18 pagesIndustrial Gas Generator Drive Components CatalogjuanaNo ratings yet

- HobartDocument36 pagesHobartcirodelgado78No ratings yet

- Diagrama Ligação Controlador de Carga C/ Função LOAD em InversorDocument3 pagesDiagrama Ligação Controlador de Carga C/ Função LOAD em InversorNikolas AugustoNo ratings yet

- Model P282 With PD Sensor For 40 To 80 NBDocument1 pageModel P282 With PD Sensor For 40 To 80 NBGanesh MulyaNo ratings yet

- RMCC E2 Reflects ManualDocument207 pagesRMCC E2 Reflects ManualMark DeMateo100% (1)

- Pump troubleshooting guideDocument1 pagePump troubleshooting guidePreett Rajin MenabungNo ratings yet