Professional Documents

Culture Documents

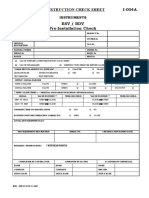

Pre-Commissioning Check Sheet: Mechanical

Uploaded by

Kailash PandeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pre-Commissioning Check Sheet: Mechanical

Uploaded by

Kailash PandeyCopyright:

Available Formats

W-0002B

PRE-COMMISSIONING CHECK SHEET

MECHANICAL

Heat Exchanger

PROJECT

DESCRIPTION

n-BUTYL LITHIUM DILUTION FACILITY PROJECT No. 40 – NC – 2900

SYSTEM

DESCRIPTION

HEAT EXCHANGER SYSTEM No. 11

SERVICE

TAG No. W-0002

DESCRIPTION

Item Description of check Results

01 Confirm that the Construction check list is completed and no subsequent damage occurred

02 Confirm that the Preservation is removed

03 Check operability of all valves associated with the vessel

04 Confirm earth bonding completed

05 Confirm that Inspection doors / Manway(s) closed out with correct gaskets and bolting

06 Check that the correct material has been used for drain/vent plugs

Check that threaded holes for pulling eyes in contact with the fluid are plugged off with

07

dummy bolts

08 Check that impingement protection, K provided, is properly installed

Check that the extended bolt ends for bolt tensioning (external as well as internal) are

09

properly protected

10 Check that the test flange/ring & any other special tools are available and properly stored.

New heat exchangers which have been tested at the Manufacturer's works in accordance

with the design test pressures need not be re-tested after installation, unless required by

11

local regulations. It is good practice, however, to test the tightness of the floating head and

channel flanges. Pneumatic testing at a pressure of 1 bar (g) is normally sufficient

12 Confirm all connections & isolations are as per PEFS and correct gaskets fitted

13 Confirm all safety relief devices fitted & certification available

14 Confirm spare gaskets available for plate type exchangers

REMARKS / OBSERVATIONS:

COMPLETED BY CONTRACTOR APPROVED BY JACOBS ACCEPTED BY CHEMETALL

NAME NAME NAME

COMPANY

SIGN & DATE SIGN & DATE SIGN & DATE

You might also like

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- Tank B-0005B: Pre-Commissioning Check SheetDocument1 pageTank B-0005B: Pre-Commissioning Check SheethrimklimNo ratings yet

- Tank B-0002B: Pre-Commissioning Check SheetDocument1 pageTank B-0002B: Pre-Commissioning Check SheethrimklimNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- Tank B-0004B: Pre-Commissioning Check SheetDocument1 pageTank B-0004B: Pre-Commissioning Check SheetKailash PandeyNo ratings yet

- Tank B-0004B: Pre-Commissioning Check SheetDocument1 pageTank B-0004B: Pre-Commissioning Check SheethrimklimNo ratings yet

- Tank B-0015B: Pre-Commissioning Check SheetDocument1 pageTank B-0015B: Pre-Commissioning Check SheethrimklimNo ratings yet

- Construction Check Sheet Heat Exchanger W-0002A: MechanicalDocument1 pageConstruction Check Sheet Heat Exchanger W-0002A: MechanicalKailash PandeyNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheethrimklimNo ratings yet

- Construction Check Sheet Vessel B-0001A: MechanicalDocument1 pageConstruction Check Sheet Vessel B-0001A: MechanicalhrimklimNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheethrimklimNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheethrimklimNo ratings yet

- Construction Check Sheet Relief Valve RV-0020A: MechanicalDocument1 pageConstruction Check Sheet Relief Valve RV-0020A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Tank B-0005A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0005A: MechanicalhrimklimNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheethrimklimNo ratings yet

- Filters: Pre-Commissioning Check SheetDocument1 pageFilters: Pre-Commissioning Check SheetKailash PandeyNo ratings yet

- Construction Check Sheet Tank B-0015A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0015A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Tank B-0004A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0004A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Vessel B-0003A: MechanicalDocument1 pageConstruction Check Sheet Vessel B-0003A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Tank B-0002A: MechanicalDocument1 pageConstruction Check Sheet Tank B-0002A: MechanicalhrimklimNo ratings yet

- Pre-Commissioning Check Sheet: PipingDocument1 pagePre-Commissioning Check Sheet: PipinghrimklimNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Fire Fighting Equipment Installation E-0017ADocument2 pagesConstruction Check Sheet Fire Fighting Equipment Installation E-0017AhrimklimNo ratings yet

- Construction Check Sheet Fire Fighting Equipment Installation E-0017ADocument2 pagesConstruction Check Sheet Fire Fighting Equipment Installation E-0017AKailash PandeyNo ratings yet

- Construction Check Sheet Piping Installation For Test PI-0021ADocument1 pageConstruction Check Sheet Piping Installation For Test PI-0021AhrimklimNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumphrimklimNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumpKailash PandeyNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- Construction Check Sheet P-0010A-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010A-A: Mechanical Installation of PumphrimklimNo ratings yet

- Construction Check Sheet Insulation of Piping PIN-0023ADocument1 pageConstruction Check Sheet Insulation of Piping PIN-0023AhrimklimNo ratings yet

- Construction Check Sheet P-0008A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0008A: Mechanical Installation of PumphrimklimNo ratings yet

- Fire Fighting Equipment: Commissioning Check SheetDocument2 pagesFire Fighting Equipment: Commissioning Check SheethrimklimNo ratings yet

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanNo ratings yet

- Construction Check Sheet Piping Cleanliness PC-0024ADocument1 pageConstruction Check Sheet Piping Cleanliness PC-0024AhrimklimNo ratings yet

- Construction Check Sheet Piping Cleanliness PC-0024ADocument1 pageConstruction Check Sheet Piping Cleanliness PC-0024AKailash PandeyNo ratings yet

- MGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031Document9 pagesMGT (Manifold Group Trunkline) System For The Gcs 29, 30 and 31 in North Kuwait Company Contract No.: 15051614 Petrofac Job No.: JI-2031velmurug_balaNo ratings yet

- Construction Check Sheet Safety Shower / Eye Bath S-0019A: MechanicalDocument1 pageConstruction Check Sheet Safety Shower / Eye Bath S-0019A: MechanicalhrimklimNo ratings yet

- Construction Check Sheet: PipingDocument1 pageConstruction Check Sheet: PipingKailash PandeyNo ratings yet

- Construction Check Sheet: PipingDocument1 pageConstruction Check Sheet: PipinghrimklimNo ratings yet

- PRES-E-04 Electrical Equipment - Oil & TransformerDocument2 pagesPRES-E-04 Electrical Equipment - Oil & TransformersalamlinNo ratings yet

- Pre-Commissioning Check Sheet: MechanicalDocument1 pagePre-Commissioning Check Sheet: MechanicalhrimklimNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0006B-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0006B-AhrimklimNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0006A-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0006A-AhrimklimNo ratings yet

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- Capacitor Banks - Schedules FILLEDDocument11 pagesCapacitor Banks - Schedules FILLEDyahyaNo ratings yet

- Construction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederDocument2 pagesConstruction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederhrimklimNo ratings yet

- Mechanical WIP ChecklistsDocument20 pagesMechanical WIP ChecklistsJovani G. BallonNo ratings yet

- Apollo Proton Therapy & Cancer Care Hospital: Check Sheet For Installation of PlumbingDocument1 pageApollo Proton Therapy & Cancer Care Hospital: Check Sheet For Installation of PlumbingGokulan LoganathanNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0003B-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0003B-AhrimklimNo ratings yet

- Checklist For Above Ground Water Piping InstallationDocument1 pageChecklist For Above Ground Water Piping InstallationBelal Alrwadieh50% (2)

- Hot Insulation Method Statement Rev.Document25 pagesHot Insulation Method Statement Rev.Hassan Helmy100% (1)

- Piping Reinstatement: Inspection Test Report Form NoDocument2 pagesPiping Reinstatement: Inspection Test Report Form NoFrancisco75% (4)

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- Construction Check Sheet Filter: Mechanical F-0003A-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0003A-AKailash PandeyNo ratings yet

- Construction Check Sheet Filter: Mechanical F-0003A-ADocument1 pageConstruction Check Sheet Filter: Mechanical F-0003A-AhrimklimNo ratings yet

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- Std-Insp-0127 Procedure For Commissioning ProcedureDocument54 pagesStd-Insp-0127 Procedure For Commissioning ProcedureAkshay KalraNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- P5504mew SWK 10 SS V PPR 001 - ADocument14 pagesP5504mew SWK 10 SS V PPR 001 - Avignesh558855No ratings yet

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- Construction Check Sheet I-004A: InstrumentsDocument1 pageConstruction Check Sheet I-004A: InstrumentsKailash PandeyNo ratings yet

- Construction Check Sheet Instrument Field Cable Insulation and Continuity Test I-006ADocument1 pageConstruction Check Sheet Instrument Field Cable Insulation and Continuity Test I-006AKailash PandeyNo ratings yet

- HAZOP Worksheet Adani Wilmar 26.7.2021Document11 pagesHAZOP Worksheet Adani Wilmar 26.7.2021Kailash PandeyNo ratings yet

- Construction Check Sheet Switch Pre-Installation Calibration I-002ADocument1 pageConstruction Check Sheet Switch Pre-Installation Calibration I-002AKailash PandeyNo ratings yet

- Construction Check Sheet Instrument Multi-Core Cable Insulation and Continuity Test I-007ADocument1 pageConstruction Check Sheet Instrument Multi-Core Cable Insulation and Continuity Test I-007AKailash PandeyNo ratings yet

- Construction Check Sheet Instrument Nitrogen Signal Lines Pneumatic Leak Test I-010ADocument1 pageConstruction Check Sheet Instrument Nitrogen Signal Lines Pneumatic Leak Test I-010AKailash PandeyNo ratings yet

- Is Iec 61508 0 2005Document21 pagesIs Iec 61508 0 2005Kailash Pandey100% (1)

- Construction Check Sheet Control Valve Pre-Installation Calibration I-003ADocument1 pageConstruction Check Sheet Control Valve Pre-Installation Calibration I-003AKailash PandeyNo ratings yet

- Identification of Leak Sources of Hydrocarbon LeakagesDocument19 pagesIdentification of Leak Sources of Hydrocarbon LeakagesKailash PandeyNo ratings yet

- Welcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToDocument26 pagesWelcome To The FMEA Worksheet: This Spreadsheet Can Be Used ToKailash PandeyNo ratings yet

- Construction Check Sheet Heat Exchanger W-0002A: MechanicalDocument1 pageConstruction Check Sheet Heat Exchanger W-0002A: MechanicalKailash PandeyNo ratings yet

- Construction Check Sheet Piping Cleanliness PC-0024ADocument1 pageConstruction Check Sheet Piping Cleanliness PC-0024AKailash PandeyNo ratings yet

- Process Safety AuditDocument21 pagesProcess Safety AuditKailash Pandey100% (2)

- Construction Check Sheet: PipingDocument1 pageConstruction Check Sheet: PipingKailash PandeyNo ratings yet

- TEC-0026A: Test Equipment CalibrationDocument1 pageTEC-0026A: Test Equipment CalibrationKailash PandeyNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumpKailash PandeyNo ratings yet

- Commercial Office Space - Cyber CityDocument8 pagesCommercial Office Space - Cyber CityankurNo ratings yet

- EZstrip O&M Manual PDFDocument60 pagesEZstrip O&M Manual PDFJesus S. QuijadaNo ratings yet

- IGS-NT Application Guide 05-2013 PDFDocument104 pagesIGS-NT Application Guide 05-2013 PDFNikitaNo ratings yet

- CM P1CM EP1 Operation ManualDocument24 pagesCM P1CM EP1 Operation Manualnguyen vuNo ratings yet

- Fischer Technical Services Safety ManualDocument15 pagesFischer Technical Services Safety ManualHenry FlorendoNo ratings yet

- Exp-3 (Speed Control by V-F MethodDocument4 pagesExp-3 (Speed Control by V-F MethoduttamNo ratings yet

- Department: First Year Name of Subject: Engg. Mechanics Unit Number: 04 (Analysis of Structure)Document2 pagesDepartment: First Year Name of Subject: Engg. Mechanics Unit Number: 04 (Analysis of Structure)JayNo ratings yet

- QuoteDocument3 pagesQuotemjnasar khan jamalNo ratings yet

- Caterpillar 990H BrochureDocument20 pagesCaterpillar 990H BrochureEugene MalinowskiNo ratings yet

- Data Sheet For Toys TestDocument2 pagesData Sheet For Toys TestAnonymous TYGiADNo ratings yet

- MECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Document4 pagesMECH 370 - Modeling, Simulation and Control Systems, Final Examination, 09:00 - 12:00, April 15, 2010 - 1/4Camila MayorgaNo ratings yet

- Gear Selector CableDocument3 pagesGear Selector CableojopodoabeNo ratings yet

- AASHTO GeoTechnical Design of PileDocument5 pagesAASHTO GeoTechnical Design of PiletrannguyenvietNo ratings yet

- SS-7 May Refer To:: RFC 2719 RFC 2719Document15 pagesSS-7 May Refer To:: RFC 2719 RFC 2719William GentryNo ratings yet

- Infinique Structured Cabling Installation ChecklistDocument2 pagesInfinique Structured Cabling Installation Checklistroot75% (4)

- Critical Care Systems Test Equipment For Repairs and PMS in The USA and CanadaDocument6 pagesCritical Care Systems Test Equipment For Repairs and PMS in The USA and CanadaMedsystem atNo ratings yet

- Eightspeed Guide 2022 CompressedDocument14 pagesEightspeed Guide 2022 CompressedCarlos0% (1)

- Ford Everes PDFDocument584 pagesFord Everes PDFTiến Hồ100% (6)

- Resistance WeldingDocument22 pagesResistance WeldingLOKENDRA91100% (2)

- Extra - Exercises Unistall InformixDocument14 pagesExtra - Exercises Unistall InformixМихаи БонцалоNo ratings yet

- Mathcad - 01 - Sump TankDocument10 pagesMathcad - 01 - Sump Tankisrar khan0% (1)

- LRVP PowerDocument28 pagesLRVP Powermnbvcx213323No ratings yet

- Transportation ChecklistDocument1 pageTransportation ChecklistHolly Smith100% (1)

- B200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10Document4 pagesB200S-LF Low Freq Sounder Base Install 56-4151-003R-06-10George P ReynoldsNo ratings yet

- 05 MathematicalReference PDFDocument484 pages05 MathematicalReference PDFHassanKMNo ratings yet

- Silhouette Training NotesDocument33 pagesSilhouette Training NotesMichael Lester67% (3)

- Chapter 11Document50 pagesChapter 11harish9No ratings yet

- Hitide 2i (BP)Document4 pagesHitide 2i (BP)Biju_PottayilNo ratings yet

- One JanDocument69 pagesOne JanDeep PatelNo ratings yet