Professional Documents

Culture Documents

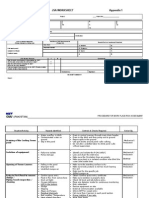

Normal Abnormal Condition Check Sheet

Normal Abnormal Condition Check Sheet

Uploaded by

ravindra kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Normal Abnormal Condition Check Sheet

Normal Abnormal Condition Check Sheet

Uploaded by

ravindra kumarCopyright:

Available Formats

casting condition daily inspcetion check sheet

※inspection as per Standard, morning , evening at the time of start up (

2times /shift) 。

×

※as for point 5 & 6 morning start up clean ( 1time/shift) 。 ○

※judgement record method : view ○ ( OK ), × ( NG ), after repair

ok 。

※ at the time of abnormility, quicly inform to patrol inspector and repair

the bad conditon parts 。 component name/ die number

※this inpsection check sheet, was executed on 15.12. 08 。

casting amchine

One with thin treatment device

Thing that enters space inspector

inspection judgement inspection

No inspection confirmation items method standard frequency abnormility treatmet method

water leakage from fie (including no water 2times / per

1 view shift(before start, hose, cuplur change

sleeve) leakage after start)

confirmation of water leakage of jet

2 cool hose view water leakage ↑ Hose damage part repair exchange

no water

3 water leakage from chip cupling part view leakage ↑ injection lot O ring change,

tightening bolt loose correction

special clearence entry

4 biscuit flash thickness tools

of thin method of ↑ Chip sleeve exchange

tool

80×50(mm)

5 biscuit flash scale below ↑ Chip sleeve exchange

6 dirt of PL surface clean execution once/day wipe of with wess

clean the chiller vent with wire

7 chill vent flash, aluminium case adhesio clean execution once/day brush

report to inspection and bad

condition treatement

before start up time ・・・ inspection item1 ~ 5

N o 1.2.6.7 処置前後品専用エフの添付

500 t~ 800 t No 1.2 inspection time 3 minutes

1250 t~ 3500 t No 1.2 inspection time 5 minute inspection after stoping

after start up time ・・・ inspection item1 ~ 7 the casting machine

500 t~ 800 t No 1.2 inspection time 3 minutes Sub leader confirmation sign

No 7.8 inspection time 5 minutes No 3.4.5

1250 t~ 3500 t No 1.2 inspection time 6 minutes inspection without stopping

No 7.8 inspection time 7minutes casting machine

※製品が多数鋳造していて点検出来ない場合は1直で1回点検とする

2008.12.3 作成 榊原

casting condition daily check procedure sheet, content explanation

water leakage check from die inspection time contents

it is confirmed that water leakage is not because of die( hose, cuplur, cylinder).

before start up after start up

A water leakage check(specialy inside cavity・

important check when entering in back of the die.

B water leakage check inside the cylinder

when NG

(if it is not detailed than also OK)

1 repair the

※for the past trouble of clloing water floating from the gate area water leakage

※When leakage buchbuch type voice was coming

A B C (It is not assumed that the sleeve gets cold. )

C water leakage check from the cavity

(if it is not detailed than also OK)

※ confirmation of water

leakage(fix. moving) ※look inside the cylinder and chec※ok even if not detailed check ※in cooling inspection check the cooling in manual

500t~800t

3 minute

confirmation of passage of jet cool 1250t~3500 contents

t 5

minute ・confirmt the passage of jet cooling

(seen, at the time of not seen)

A check whether water is flowing or not in returning

when NG

2 (confirm the chock of the jet cool) repair the

water leakage

(water quantity was not checked)

B confirm the passage one by one

A B (confirm the chock of the jet cool)

(water quantity was not checked)

※ check the return of the jet cool ( fix.

moving ) ※check the water flow in each jet cool

dirt of PL surface contents

・Dirt on PL side is wiped off by Wess.

※ certainly execute

1spray the trial lubrication oil in the PL surface of die

6 ① ② execution

2 wipe the PL side with the Wess

・Dirt on PL side is wiped off in Wess.

※

※ use trial lubrication oil clean the PL surface with the wiase(fix・moving)

aluminium case and flash of chil vent part contents

chill vent flash, alumi case adhesion

※ certainly execute

1 use trial use lubrication oil, and wire bursh carefully

7 execution

2 apply trial lucrication oil in the chill vent part

① and wipe of aluminium with the file and wise

②

※clean

※apply trial use lubrication oil and use file the chill vent part (GF) with file(fix・moving)

water leakage from the chip culping part inspection time contents

water leakage from chip cupling part

1.It is confirmed that there is no water leakage

from the chip cupling part

when NG

3 repair the

water leakage

①

※check the water leakage from the chip cupling

biscuit flash thickness contents

・biscuit flash thickness

1 check the flash stuck on the drawing no. 4.

2. take out the stuck flash by the special tool and When NG

4 change

do the inspection while check the flash thickness cylinder chip

① casting machine is operating.

②

※check the flash stuck in this area ※ check by tool

contents contents

・ biscuit flash

confiramation of ① check the flash stuck in the drawing

flash in 2 places (check the tip of the part)

check the flash height of the back

5 of the injection

①

※flash behind the ② ② take out the stuck casting by special tool

injection

check width and height

width 80 and height 50 mm less

You might also like

- ADAMS - HA 8180V - Operation and Maintenance (2020 - 08 - 20 02 - 50 - 44 UTC)Document51 pagesADAMS - HA 8180V - Operation and Maintenance (2020 - 08 - 20 02 - 50 - 44 UTC)Arnoldo Felix0% (1)

- Safety Shower ChecklistDocument1 pageSafety Shower Checklistshakti123456789No ratings yet

- App G - Filter Press 2016Document2 pagesApp G - Filter Press 2016Quoc An100% (1)

- Report of Bekasi Homebase On Job Training Program: Dimas Helmy Engineer TraineeDocument36 pagesReport of Bekasi Homebase On Job Training Program: Dimas Helmy Engineer TraineeDimas HelmyNo ratings yet

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDocument3 pages6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARNo ratings yet

- Daihatsu Sirion Model m300 Series Service Manual No9890 EngineDocument32 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 EngineJakub TarasinNo ratings yet

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementFrom EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementRating: 4.5 out of 5 stars4.5/5 (2)

- Project Consent FormDocument4 pagesProject Consent FormJackie ChenNo ratings yet

- Wavecom Q2403 Q2406B AT - Command PDFDocument284 pagesWavecom Q2403 Q2406B AT - Command PDFanviozzyNo ratings yet

- (001-026) Cylinder BlockDocument30 pages(001-026) Cylinder Blockteknisi ABNo ratings yet

- Smoke Detector ChecklistDocument7 pagesSmoke Detector ChecklistUD. Gunung JatiNo ratings yet

- Daily Preventive Mantainence SheetDocument4 pagesDaily Preventive Mantainence Sheetcer.qualityNo ratings yet

- Maintenance Check ListDocument1 pageMaintenance Check ListMarcelo MesoNo ratings yet

- Chiller MaintenanceDocument5 pagesChiller MaintenanceSergio HernandezNo ratings yet

- 900 Liter Wheeled Water Cum Foam MonitorDocument2 pages900 Liter Wheeled Water Cum Foam MonitorvivekvpsfeNo ratings yet

- Construction - Piling - Construction Cycle TimingsDocument4 pagesConstruction - Piling - Construction Cycle TimingsWee Kim GohNo ratings yet

- QCV Test CertificatesDocument1 pageQCV Test CertificatesShashank RajputNo ratings yet

- AQT MFV 1 - Manual PDFDocument8 pagesAQT MFV 1 - Manual PDFAlex MarNo ratings yet

- M (V) - 4 FW Rehardening FilterDocument10 pagesM (V) - 4 FW Rehardening Filtererkan aksoyNo ratings yet

- Coiled Tubing OperationDocument68 pagesCoiled Tubing OperationVladyslav100% (1)

- Rehardening FinalDocument11 pagesRehardening FinalGemmyl YsatamNo ratings yet

- Transferpettor: Testing Instructions (SOP)Document14 pagesTransferpettor: Testing Instructions (SOP)PaaahMullerNo ratings yet

- QCV Key Test CertifiactesDocument1 pageQCV Key Test CertifiactesShashank RajputNo ratings yet

- Flush Valve: Jeevan Bhar Ka Saath..Document2 pagesFlush Valve: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Job Safety Analysis Form HydrotestDocument3 pagesJob Safety Analysis Form Hydrotestyayongjcs100% (4)

- Preventive MaintenanceDocument14 pagesPreventive Maintenancetristan20100% (6)

- Operations Manuals RO PlantDocument21 pagesOperations Manuals RO Plantengrasadullah000No ratings yet

- Training Foundry BasicsDocument37 pagesTraining Foundry Basicssai saiNo ratings yet

- Mirani Water Recycling Facility (WRF) Daily Site Checklist: Name: Time: DateDocument20 pagesMirani Water Recycling Facility (WRF) Daily Site Checklist: Name: Time: Dateyinka omojesuNo ratings yet

- CIP Cleaning in Place: The Circulation of Non Foaming Cleaners Without Dismantling The EquipmentDocument23 pagesCIP Cleaning in Place: The Circulation of Non Foaming Cleaners Without Dismantling The EquipmenttomkingNo ratings yet

- Maintanence9.preventive Maintenance SOP For DF50Document13 pagesMaintanence9.preventive Maintenance SOP For DF50freedNo ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- QY360 Blasting Wheel Operation ManualDocument15 pagesQY360 Blasting Wheel Operation ManualDecho KrachevNo ratings yet

- Kick DetectionDocument10 pagesKick DetectionEmil JaniyevNo ratings yet

- RM1110 & 1105 Service ReportDocument1 pageRM1110 & 1105 Service ReportshaktiNo ratings yet

- New Bottom PlateDocument9 pagesNew Bottom PlateEmmanuel kusimo100% (1)

- Model ST-2469 Series Water Closet Installation Instructions: New Installations Retrofit InstallationsDocument2 pagesModel ST-2469 Series Water Closet Installation Instructions: New Installations Retrofit InstallationsisaacgamezNo ratings yet

- Manual For Level Gauges UK Edition 1 5 - 2Document2 pagesManual For Level Gauges UK Edition 1 5 - 2slatimovNo ratings yet

- Well Integrity Management System: 3 Days Workshop, 14 - 16 Jan 2021 Summarized By: Hudan HidayatullohDocument34 pagesWell Integrity Management System: 3 Days Workshop, 14 - 16 Jan 2021 Summarized By: Hudan HidayatullohIslamNo ratings yet

- Cyclonic Desander: Sand and Solids Handling For All ApplicationsDocument2 pagesCyclonic Desander: Sand and Solids Handling For All Applicationsgacm98No ratings yet

- Wash Machine ManualDocument72 pagesWash Machine ManualvasilismNo ratings yet

- Horizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsDocument12 pagesHorizontal Wells Production Logging: Monitoring of Multi-Phase Flow in Horizontal WellsNoureddine AbidNo ratings yet

- WT 16 WSBDocument55 pagesWT 16 WSBJuan ChávezNo ratings yet

- Investigating From Instrument To Column 1684601941Document56 pagesInvestigating From Instrument To Column 1684601941AlexandreLuizdeSouzaNo ratings yet

- Final Inspectio Report 2259 Wt109Document1 pageFinal Inspectio Report 2259 Wt109Prem KumarNo ratings yet

- Belt Conveyor RT45-BDocument2 pagesBelt Conveyor RT45-BMahmoud HanafyNo ratings yet

- Conozca Soluciones Energéticas: Conceptos de Barreras de PozosDocument10 pagesConozca Soluciones Energéticas: Conceptos de Barreras de PozosAtreya Pacheco Acosta Miguel AngelNo ratings yet

- LG - f1261rd - WD 1259 0 9rdDocument40 pagesLG - f1261rd - WD 1259 0 9rdJosé Benavides100% (1)

- GB CZ SK Hu Ro BG PDFDocument72 pagesGB CZ SK Hu Ro BG PDFStelian Nicolae RoscaNo ratings yet

- MK Tron Auto Part: Procedure of Leak TestingDocument1 pageMK Tron Auto Part: Procedure of Leak Testingsachin kadamNo ratings yet

- Cooling Tower ChecklistDocument2 pagesCooling Tower ChecklistLaiq100% (5)

- Manual Lavadora SecadoraDocument84 pagesManual Lavadora Secadorakhalid mohamedNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- Experiment: WE - 1 Title: Infiltration Rate and Double-Ring Infiltrometer Test Duration: 2 Hours: 1 0F 7Document6 pagesExperiment: WE - 1 Title: Infiltration Rate and Double-Ring Infiltrometer Test Duration: 2 Hours: 1 0F 7asadNo ratings yet

- Chapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsDocument16 pagesChapter 5 Inspection and Maintenance: 5.1 List of Consumables and Regular Replacement PartsГоран ГорановNo ratings yet

- Jsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningDocument4 pagesJsa Worksheet Appendix 1: A-2401 Cooling Tower Pond CleaningAmmadRehmanNo ratings yet

- 2 Quarterly Presentation: Presented by MentorDocument23 pages2 Quarterly Presentation: Presented by MentorRishiNo ratings yet

- India Mark Ii Hand Pump: UnicefDocument47 pagesIndia Mark Ii Hand Pump: UnicefEr Manish PatelNo ratings yet

- Spin Valves - Dual Plate Wafer Check ValveDocument4 pagesSpin Valves - Dual Plate Wafer Check ValvePablo HurtubiaNo ratings yet

- 5b. STP Weekly Log BookDocument1 page5b. STP Weekly Log BookNISHANTH GANESHNo ratings yet

- Repair of DuctDocument1 pageRepair of Ductravindra kumarNo ratings yet

- Red Hot Area at The Shell of Furnace in Between Burner No. 1 & 2Document1 pageRed Hot Area at The Shell of Furnace in Between Burner No. 1 & 2ravindra kumarNo ratings yet

- Preheating of Crucible - InstallationDocument1 pagePreheating of Crucible - Installationravindra kumarNo ratings yet

- Holding DCM Cleaning With ToolDocument1 pageHolding DCM Cleaning With Toolravindra kumarNo ratings yet

- 20 Basic Quality RulesDocument23 pages20 Basic Quality Rulesravindra kumarNo ratings yet

- Die Trial BlankDocument2 pagesDie Trial Blankravindra kumar100% (1)

- TROUBLE SHOOTING (Ravindra)Document4 pagesTROUBLE SHOOTING (Ravindra)ravindra kumarNo ratings yet

- Series ResonanceDocument2 pagesSeries ResonancesreekanthaNo ratings yet

- Ricoh Aficio MP4000 MP5000 Troubleshooting Manual PDFDocument148 pagesRicoh Aficio MP4000 MP5000 Troubleshooting Manual PDFMagedNo ratings yet

- ZMP 3289887 Damp Proof Led Pro 1200 35 W 6500 K Gen2Document3 pagesZMP 3289887 Damp Proof Led Pro 1200 35 W 6500 K Gen2Abubakar Ashraf AnjumNo ratings yet

- British Standard Bs 8110Document10 pagesBritish Standard Bs 8110م.عمرو عبداللهNo ratings yet

- CV Resume - ZainubDocument2 pagesCV Resume - Zainubapi-309814633No ratings yet

- Fire Hydrant SystemDocument12 pagesFire Hydrant Systemabdullah sahib100% (1)

- Celcom Swap 3G Health Check - Rev2.0Document9 pagesCelcom Swap 3G Health Check - Rev2.0dhanamiwsNo ratings yet

- Air Trap PipelineDocument10 pagesAir Trap PipelineJulio César Rodríguez RodríguezNo ratings yet

- Types of GraphsDocument13 pagesTypes of GraphsDaniel John Abad DelaCruzNo ratings yet

- TTLDocument5 pagesTTLChaitanya Varma D100% (1)

- Edds PDFDocument30 pagesEdds PDFErlendur PetersenNo ratings yet

- f5 101 Study Notes PDFDocument7 pagesf5 101 Study Notes PDFSamir JhaNo ratings yet

- Axilock Dimensional DataDocument2 pagesAxilock Dimensional Datalunatic2000No ratings yet

- Bedini FanDocument44 pagesBedini FanTomislav Jovanovic100% (2)

- A Black Box Theatre IsDocument2 pagesA Black Box Theatre Isapi-258559565No ratings yet

- DOC023 54 03232 (Turbidimetro) PDFDocument30 pagesDOC023 54 03232 (Turbidimetro) PDFSrta IncognitaNo ratings yet

- Online Device ControllerDocument45 pagesOnline Device Controllercsarun143No ratings yet

- DR Anupam Saraph Open Letter To The CBDTDocument2 pagesDR Anupam Saraph Open Letter To The CBDTMoneylife FoundationNo ratings yet

- Design of Corrugated Buries PipesDocument119 pagesDesign of Corrugated Buries PipesKhemindra NarainNo ratings yet

- Leeltans Ank 4 PDFDocument66 pagesLeeltans Ank 4 PDFLeeltans RajasthaniNo ratings yet

- Security Operations Center v1Document4 pagesSecurity Operations Center v1Sanjeev Panwar100% (1)

- Lm-k3960 Manual de ServicioDocument65 pagesLm-k3960 Manual de Servicioluisrey1967No ratings yet

- Multilingual User Manual PDFDocument76 pagesMultilingual User Manual PDFCloud Drive JR SulutNo ratings yet

- Philippine Psychometricians Licensure Exam RevieweDocument1 pagePhilippine Psychometricians Licensure Exam RevieweKristelle Mae C. Azucenas0% (1)

- Mark L. Tanarte: 2194 Tramo Street Barangay 118 Pasay City Metro Manila Philippines 1300Document3 pagesMark L. Tanarte: 2194 Tramo Street Barangay 118 Pasay City Metro Manila Philippines 1300Mark TanarteNo ratings yet

- Title: How To Use This TemplateDocument8 pagesTitle: How To Use This TemplateAlex TomaNo ratings yet

- ELECTRICITY QuestionsDocument2 pagesELECTRICITY QuestionsshreenithishNo ratings yet

- Instrumentation in UreaDocument6 pagesInstrumentation in UreaGaurav MishraNo ratings yet