Professional Documents

Culture Documents

sHOTPATCH 10 v3 PDF

Uploaded by

Ankita Baban Gavade0 ratings0% found this document useful (0 votes)

195 views2 pagesOriginal Title

sHOTPATCH_10_v3.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

195 views2 pagessHOTPATCH 10 v3 PDF

Uploaded by

Ankita Baban GavadeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

™

SHOTPATCH 10

Micro-silica enhanced, dry process shotcrete for repair to large surface areas

Description micro-concrete shall have compressive strength

SHOTPATCH 10 is a ready to use cement based minimum of 15 MPa at 1 day and 40 MPa at 28 days.

single component shotcrete mortar modified with The repair mortar shall not require polymer bonding

microsilica. The formulation is designed to achieve a agent as primer.

durable, structural grade, dry process shotcrete Directions for use

applied mortar. It gives high early strength, reduced

rebound and allows for maximum application Surface preparation

thickness, coupled with resistivity values All surfaces to be treated should be sound and clean.

commensurate with accepted criteria for cathodic Saw cut the edges of the repair locations to a depth of

protection (CP) overlays. The ingredients are carefully at least 15mm to avoid featheredging and to provide a

selected to give minimum dust during the spraying. square edge. Break out the complete repair area by

mechanical means or by high pressure water jetting to

Uses a minimum depth of 15 mm up to the sawn edge.

Large areas of concrete repairs. Clean the surfaces by removing any dust, unsound or

Refurbishment of columns, bridges, tunnels, contaminated material, oil, paint, grease, or corrosion

retaining walls. deposits. Where breaking out is not required, roughen

Single high build application. the surface and remove any laitance by mechanical

Repair of fire damaged structures, marine means or high-pressure water jetting to provide a

structures, piers, quays, off shore platforms, etc minimum of 5mm profile.

Rock and embankment stabilisation. All surface-preparation procedures used should ensure

Sealing of mine roadways, tunnels, etc. that adequate mechanical key is achieved. Remove oil

Rock and embankment stabilisation, swimming and grease deposits by steam cleaning, detergent

pool construction. scrubbing, or degreasing. To ensure optimum repair

Cathodic protection overlays. results, assess the effectiveness of decontamination

Advantages with a pull-off test.

Single component - ready to use. Traces of rust and corrosion products should be

Non-reactive aggregates removed by wet or dry sand blasting of exposed

High build - up to 150mm can be applied at one reinforcing steel.

pass.

Low rebound - grading and formulation allow for Priming

excellent penetration and compaction with The prepared substrate should be thoroughly soaked

minimum loss of aggregate through rebound. with clean water and all standing water removed before

Low dust - formulation ensures dust is kept to a the application of SHOTPATCH 10.

minimum. The concrete substrate should be in a saturated-

Safe to handle - no added caustic accelerators. surface-dry (SSD) condition immediately before the

Excellent adhesion to concrete and steel. application of SHOTPATCH 10.

Rapid strength gain. In chloride laden environment apply CONCRESIVE ZRi

Low water absorption & chloride ion diffusion. on prepared steel reinforcement

High resistance to carbon dioxide penetration.

Excellent resistivity values ( for CP overlays) Application

Empty the bags of SHOTPATCH 10 directly into the

Typical properties hopper of the dry process shotcrete pump.

Appearance : Grey granular powder SHOTPATCH 10 may be introduced dry directly to the

Maximum aggregate size : 5mm gun or predampened first. Use a maximum of 1 Litre of

Density : Dry bulk : 1700kg/m³ water per bag of 25 Kg for predampening.

: Applied : 2400kg/m³

Once the surface is properly cleaned and placement

Water/powder ratio, by weight : 0.085

has started, the nozzle operator is responsible for

Compressive Strengths : 24 Hours 15N/mm²

adding the correct amount of water at the nozzle to

(ASTM C109) : 28 Days 40N/mm²

achieve proper hydration of the sprayed material. This

Alkali contents : < 3.0 kg/m3 (as Na2O)

water/powder ratio is critical and will affect the physical

Specification Clause properties and performance of sprayed material.

The one-component, dry-spray, micro-concrete shall Consider total water addition (predampening & added

be SHOTPATCH 10, high strength, cementitious at the nozzle) in the range of 2 ~ 2.25 Litre/ Bag of 25

formulation modified with microsilca. The repair kg as a guideline.

Page 1 of 2

The proper placement of SHOTPATCH 10 depends Degussa affiliate MEYCO. Your representative will

primarily on the ability of the nozzleman. The provide details and assistance with equipment selection

nozzleman must perform the spray application using on request.

recognized procedures for nozzle angle, material Equipment care

build-up, coverage of reinforcement, consideration of All tools shall be cleaned with water immediately after

rebound, and surface finishing. use. All spraying equipment should be blown clear of

Finishing SHOTPATCH 10 at stopping of work and for extended

Any necessary trowelling or profiling should be done breaks, trowels etc. should be washed with clean water

immediately after spraying has finished. If overcoating immediately after use.

is to follow, finish with a wooden float or damp Hardened SHOTPATCH 10 can only be removed by

sponge. Over finishing should be avoided to prevent mechanical means.

excessive laitance and surface hairline cracking.

Storage and Shelf life

Curing Store under cover, out of direct sunlight and protect

Good curing practice is essential. Particular care is from extremes of temperature. In tropical climates the

required in hot and windy condition.

[

product must be stored in an air-conditioned

Curing can be by the application of MASTERKURE environment.

181 curing compound which compatible with most Shelf life is 12 months when stored as above.

subsequent protective coatings, or by covering the

work with properly secured plastic sheeting. Failure to comply with the recommended storage

conditions may result in premature deterioration of the

Apply the curing compound when the surface can

product or packaging. For specific storage advice

not be marred by the application process.

please consult BASF's Technical Services Department.

For intra-layer curing, consider the use of MEYCO

TCC 735. A multi-role admixture that enhances Safety precautions

hydration of the cement, increases bond to steel, As with all chemical products, care should be taken

reduces shrinkage and eliminates the requirement for during use and storage to avoid contact with eyes,

curing between layers. In high ambient temperatures mouth, skin and foodstuffs (which can also be tainted

or hot drying winds, MEYCO TCC 735 treated with vapour until product fully cured or dried). Treat

SHOTPATCH 10 will still require shading and splashes to eyes and skin immediately. If accidentally

sheltering. ingested, seek immediate medical attention. Keep

Coverage away from children and animals. Reseal containers after

A 25kg bag of SHOTPATCH 10 after mixing with 2.0 use. Do not reuse containers for storage of consumable

to 2.25 Ltrs will yield approximately 11.3 litres and item. For further information refer to the material safety

shall cover 0.25 m2 at 40mm thickness depending data sheet. MSDS available on demand or on BASF

upon the water/powder ratio used. construction chemicals web site.

Site trials are advisable to obtain accurate wastage

Note

factors due to variations in surface preparation,

equipment and nozzlemen. All BASF Technical Data Sheets are updated on regular

basis; it is the user's responsibility, to obtain the most

Packaging recent issue.

SHOTPATCH 10 is supplied in 25kg bags Field services where provided, does not constitute

supervisory responsibility, for additional information

Watch points

contact your local BASF representative.

Protect newly applied SHOTPATCH 10 from

heavy rain or frost. Disclaimer

Over application should be avoided to prevent Whilst any information contained herein is true,

slumping away form prepared concrete surfaces accurate and represents our best knowledge and

or steel. experience, no warranty is given or implied with any

Movement joints should be continued through recommendations made by us, our representatives or

the applied SHOTPATCH 10 and sealed with a distributors, as the conditions of use and the

suitable sealant from the MASTERFLEX range. competence of any labour involved in the application

Equipment are beyond our control.

An extensive range of dry and wet process

shotcreting and ancillary equipment is available from

TDS Ref. no. :Stpxxx10/03/1106

BASF Construction Chemicals (India) Private Limited

C-68, MIDC, Thane Belapur Road, Turbhe, Navi Mumbai - 400 613 India

Tel: +91 22 27619992/3, Fax: +91 22 27619242

e-mail: basfcc@vsnl.net www.basf-cc.co.in Page 2 of 2

You might also like

- Air Regulations RK Bali PDFDocument1 pageAir Regulations RK Bali PDFsudhar sanan0% (1)

- 1RTR Intro First ClassDocument156 pages1RTR Intro First Classabhishek soni100% (1)

- Syllabus For RTR ExamDocument3 pagesSyllabus For RTR Exampushpak kumar JhaNo ratings yet

- Instructions For Filling ELogBookDocument9 pagesInstructions For Filling ELogBookPallove KumarNo ratings yet

- 234 1 Result Notice Written TestDocument5 pages234 1 Result Notice Written TestcaptrohitNo ratings yet

- Frtol Pre Exam BriefDocument3 pagesFrtol Pre Exam BriefAnonymous PgUrgaG0No ratings yet

- ATPL(A) Theory internal test questionsDocument15 pagesATPL(A) Theory internal test questionsbaknedicemNo ratings yet

- GPS Instrument Approaches - Dhana CHIMES AVIATION ACADEMYDocument4 pagesGPS Instrument Approaches - Dhana CHIMES AVIATION ACADEMYSrinath S. BhaumikNo ratings yet

- Flight Performance and PlanningDocument18 pagesFlight Performance and PlanningAF CSL100% (1)

- AIP Myanmar Ad 2.Vyyy-Ils/Dme21 03 JAN 2019: Aerodrome Elev - FT Heights Related To THR Elev - FTDocument1 pageAIP Myanmar Ad 2.Vyyy-Ils/Dme21 03 JAN 2019: Aerodrome Elev - FT Heights Related To THR Elev - FTshan ma layNo ratings yet

- Dgca Book ListDocument3 pagesDgca Book ListGunjan KalwarNo ratings yet

- Ca 39Document4 pagesCa 39Altivia Aviation AcademyNo ratings yet

- ENR5.1 Prohibited Danger and Restricted AreaDocument34 pagesENR5.1 Prohibited Danger and Restricted Areaitsrijo0% (1)

- Cessna C172R Technical ExamDocument7 pagesCessna C172R Technical ExamMoshiurRahmanNo ratings yet

- RTR SyllabusDocument3 pagesRTR SyllabusNational HeraldNo ratings yet

- Questions: Qu Es Tio NsDocument54 pagesQuestions: Qu Es Tio NsRahul C PuttuNo ratings yet

- Bank: Private Pilot Airman Knowledge Test Question BankDocument114 pagesBank: Private Pilot Airman Knowledge Test Question BankkczeuchNo ratings yet

- EASA & FAA Exam Preparation & Question Bank For Pilots Aviationexam 3 PDFDocument1 pageEASA & FAA Exam Preparation & Question Bank For Pilots Aviationexam 3 PDFAghiles Doumane67% (3)

- Ats Sample ExamDocument14 pagesAts Sample ExamA320viatorNo ratings yet

- Air LawDocument11 pagesAir Lawmoataztarek3026No ratings yet

- 01 Air Regulations RK Bali 4 PDF FreeDocument1 page01 Air Regulations RK Bali 4 PDF FreeHunter fNo ratings yet

- PDF (1) SRM Compiler Design 15314j Question PaperDocument2 pagesPDF (1) SRM Compiler Design 15314j Question PaperaravinthNo ratings yet

- Reference BooksDocument1 pageReference Bookspayalagrawal36No ratings yet

- Performance Aide Memoire: R MC S1 2 Toss MC S1Document8 pagesPerformance Aide Memoire: R MC S1 2 Toss MC S1Eduardo AlmeidaNo ratings yet

- CAA CPL - IR-ME - Fee Structure For January 2020Document2 pagesCAA CPL - IR-ME - Fee Structure For January 2020Shravan MeshramNo ratings yet

- VabbDocument66 pagesVabbUshin VakilNo ratings yet

- Emergency Check List Technam p2008jcDocument4 pagesEmergency Check List Technam p2008jcGourav DasNo ratings yet

- Weight and BalanceDocument81 pagesWeight and BalanceHUGO MORA100% (1)

- 1.1. ATIS 1.2. Advanced Surface Movement Guidance and Control System (SMGCS) 11.. GgeenneerraallDocument94 pages1.1. ATIS 1.2. Advanced Surface Movement Guidance and Control System (SMGCS) 11.. Ggeenneerraallmehul da aviatorNo ratings yet

- Navigation QuestionsDocument5 pagesNavigation Questionsgregm100% (1)

- (Day 3) (Final) The Aircraft Act, 1934Document7 pages(Day 3) (Final) The Aircraft Act, 1934Deb DasNo ratings yet

- Ae 2035-QBDocument127 pagesAe 2035-QBdennyfrancis19100% (1)

- Chap 1 General Navigation The Solar SystemDocument4 pagesChap 1 General Navigation The Solar SystemUmarul FarooqueNo ratings yet

- Revision Question Chapter 11Document7 pagesRevision Question Chapter 11Sealtiel1020No ratings yet

- Aircraft General and Principles of FlightDocument8 pagesAircraft General and Principles of FlightMartin Van Der SchyfNo ratings yet

- Conversion of Units and CP/PNR CalculationsDocument25 pagesConversion of Units and CP/PNR CalculationsAnmoldeep SinghNo ratings yet

- Simulators Approved by DGCA Updated Till 31 January 2020Document2 pagesSimulators Approved by DGCA Updated Till 31 January 2020MUQDOOM AliNo ratings yet

- AtcDocument48 pagesAtcfrancis GodoyNo ratings yet

- Aviation Study - Regulation Miscellaneous Que. Paper - 3Document4 pagesAviation Study - Regulation Miscellaneous Que. Paper - 3parul sharmaNo ratings yet

- Aircraft Electrical Systems and Performance QuestionsDocument7 pagesAircraft Electrical Systems and Performance QuestionsASHISH TOMAR100% (1)

- International Flight Plan: Form Approved OMB No. 2120-0026Document13 pagesInternational Flight Plan: Form Approved OMB No. 2120-0026Zarrar KhanNo ratings yet

- Navigation exam questions and answersDocument7 pagesNavigation exam questions and answersGerry RumahorboNo ratings yet

- Instrument and Avionics QuestionsDocument8 pagesInstrument and Avionics QuestionsBookMaggotNo ratings yet

- Inndigo Interview QuestionsDocument1 pageInndigo Interview QuestionsToughmastermind100% (1)

- THE DA 40 IN A 'CAPSULEDocument32 pagesTHE DA 40 IN A 'CAPSULEAnonymous QQEYUgwNo ratings yet

- AIP Lucknow Airport, IndiaDocument34 pagesAIP Lucknow Airport, Indiass khadri100% (1)

- Pilot Scholarships in IndiaDocument4 pagesPilot Scholarships in IndiaVedant KumarNo ratings yet

- AIR REGULATIONS EXAM REVIEWDocument6 pagesAIR REGULATIONS EXAM REVIEWAnuj GahlawatNo ratings yet

- General Aircraft KnowledgeDocument177 pagesGeneral Aircraft KnowledgeTomasz KurdzielNo ratings yet

- RTR Notes DhanawatDocument67 pagesRTR Notes DhanawatSufiyan KhanNo ratings yet

- IFR En Route Charts Guide PilotsDocument28 pagesIFR En Route Charts Guide PilotsNick Tsang100% (1)

- DGCA functions and responsibilitiesDocument60 pagesDGCA functions and responsibilitiesJeetendra SinghNo ratings yet

- Instrument Approach: ILS MLS PAR Military GPS Waas Egnos Laas Jpals GCADocument8 pagesInstrument Approach: ILS MLS PAR Military GPS Waas Egnos Laas Jpals GCASheikh Mahmud HabibNo ratings yet

- RTR SyllabusDocument4 pagesRTR SyllabusshombisNo ratings yet

- Rheomix 131: Page 1 of 2Document2 pagesRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- Sikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetDocument4 pagesSikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetjodemodeNo ratings yet

- Masterprotect 1814 TdsDocument3 pagesMasterprotect 1814 TdsfirozembrayilNo ratings yet

- tHORO STRUCTURITE PRIMER - v3Document2 pagestHORO STRUCTURITE PRIMER - v3Ankita Baban GavadeNo ratings yet

- 7 Renderoc SP30Document4 pages7 Renderoc SP30samueltee212No ratings yet

- Polycrete FC: Crack-Resistant Concrete Fairing CoatDocument2 pagesPolycrete FC: Crack-Resistant Concrete Fairing Coatmohamed ragabNo ratings yet

- ADDMIX 109 PCCI-v1Document2 pagesADDMIX 109 PCCI-v1Ankita Baban GavadeNo ratings yet

- Con Inject 1kDocument2 pagesCon Inject 1kAnkita Baban GavadeNo ratings yet

- ADDMIX 152-v4 PDFDocument1 pageADDMIX 152-v4 PDFAnkita Baban GavadeNo ratings yet

- Con Inject 1kDocument2 pagesCon Inject 1kAnkita Baban GavadeNo ratings yet

- ADDMIX 105-v4Document2 pagesADDMIX 105-v4Ankita Baban GavadeNo ratings yet

- Nanofines 822Document1 pageNanofines 822Ankita Baban GavadeNo ratings yet

- ADDMIX 55-v3Document2 pagesADDMIX 55-v3Ankita Baban GavadeNo ratings yet

- ADDMIX 210-v5Document2 pagesADDMIX 210-v5Ankita Baban GavadeNo ratings yet

- ADDMIX 200-v4Document2 pagesADDMIX 200-v4Ankita Baban GavadeNo ratings yet

- Lejell210 MSDS(英文版)Document16 pagesLejell210 MSDS(英文版)Ankita Baban GavadeNo ratings yet

- MR. DRY 701-v3Document3 pagesMR. DRY 701-v3Ankita Baban GavadeNo ratings yet

- Ripstar 109: SpecificationDocument3 pagesRipstar 109: SpecificationAnkita Baban GavadeNo ratings yet

- MR DRY195-v3Document3 pagesMR DRY195-v3Ankita Baban GavadeNo ratings yet

- Poly Urea Coating: Smart & Reliable Chemical SolutionsDocument12 pagesPoly Urea Coating: Smart & Reliable Chemical SolutionsAnkita Baban GavadeNo ratings yet

- RIPSTAR Saturant-V3Document3 pagesRIPSTAR Saturant-V3Ankita Baban GavadeNo ratings yet

- Report On Crystaline WaterproofingDocument11 pagesReport On Crystaline WaterproofingAnkita Baban GavadeNo ratings yet

- 450 Case StudyDocument11 pages450 Case StudyAnkita Baban GavadeNo ratings yet

- MR - DRY 830EL-v4Document4 pagesMR - DRY 830EL-v4Ankita Baban GavadeNo ratings yet

- Polymers 13 00189Document13 pagesPolymers 13 00189Ankita Baban GavadeNo ratings yet

- RIPSTAR 49v5Document4 pagesRIPSTAR 49v5Ankita Baban GavadeNo ratings yet

- SPLANDEK 2100v3Document4 pagesSPLANDEK 2100v3Ankita Baban GavadeNo ratings yet

- Lejell210 MSDS(英文版)Document16 pagesLejell210 MSDS(英文版)Ankita Baban GavadeNo ratings yet

- Strenghthning ResultsDocument1 pageStrenghthning ResultsAnkita Baban GavadeNo ratings yet

- RIPSTAR 49v5Document4 pagesRIPSTAR 49v5Ankita Baban GavadeNo ratings yet

- JONTSIL PU (PG) - v2Document4 pagesJONTSIL PU (PG) - v2Ankita Baban GavadeNo ratings yet

- FRP Strengthening Systems for Concrete StructuresDocument15 pagesFRP Strengthening Systems for Concrete StructuresAnkita Baban GavadeNo ratings yet

- Polymers 13 00189Document13 pagesPolymers 13 00189Ankita Baban GavadeNo ratings yet

- Quotation (JB Construction)Document2 pagesQuotation (JB Construction)Ankita Baban GavadeNo ratings yet

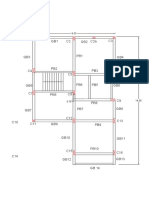

- Column PositionsDocument1 pageColumn PositionsAnkita Baban GavadeNo ratings yet

- Question BankDocument1 pageQuestion BankAnkita Baban GavadeNo ratings yet

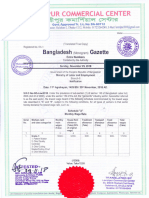

- Gazette On Minimum Wages RMG (Bangladesh) - 2018 - (English)Document11 pagesGazette On Minimum Wages RMG (Bangladesh) - 2018 - (English)Mazharul IslamNo ratings yet

- Work Order HDPE PipeDocument33 pagesWork Order HDPE PipeANKURNo ratings yet

- Gantt ChartDocument26 pagesGantt ChartianNo ratings yet

- Dielectric Properties Analysis of Gas Turbine Synchronous Generator by Polarization and Depolarization Current MeasuremenDocument4 pagesDielectric Properties Analysis of Gas Turbine Synchronous Generator by Polarization and Depolarization Current MeasuremenAriNo ratings yet

- MANOVA SPSS TablesDocument5 pagesMANOVA SPSS Tabless_m_u_yousafNo ratings yet

- WIDI Jack Owner S Manual v07 Mobile View enDocument17 pagesWIDI Jack Owner S Manual v07 Mobile View enMike BuchananNo ratings yet

- PartnerDocument14 pagesPartnerLeo van GorkumNo ratings yet

- Student Assessment GuideDocument72 pagesStudent Assessment GuideDavi MoraesNo ratings yet

- Survey On The Importance of Digital Education in SchoolsDocument7 pagesSurvey On The Importance of Digital Education in Schoolsbriello98No ratings yet

- Mini Project 2 Report Mba 2nd Semester 2Document51 pagesMini Project 2 Report Mba 2nd Semester 2Saurav KumarNo ratings yet

- Productivity: IncreaseDocument2 pagesProductivity: IncreaseJose Corcega britoNo ratings yet

- Etrade 1.5M 21082020Document3 pagesEtrade 1.5M 21082020zayar ooNo ratings yet

- AWM 5000 Series Microbridge Mass Airflow Sensor: Installation Instructions For TheDocument2 pagesAWM 5000 Series Microbridge Mass Airflow Sensor: Installation Instructions For ThewidsonmeloNo ratings yet

- Triaxial Accelerometer With Integral Magnet (A0643TX)Document2 pagesTriaxial Accelerometer With Integral Magnet (A0643TX)ORAMAYNo ratings yet

- Qualis VHDL-QuickReferenceCard V2.1 PDFDocument2 pagesQualis VHDL-QuickReferenceCard V2.1 PDFlakithaNo ratings yet

- Assignment & LabDocument5 pagesAssignment & LabXyus PoudelNo ratings yet

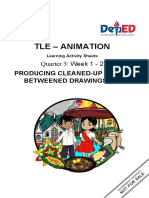

- Producing Cleaned-Up and In-Betweened DrawingsDocument10 pagesProducing Cleaned-Up and In-Betweened DrawingsErika C. Delos SantosNo ratings yet

- Lec4-5 QDocument4 pagesLec4-5 QBashir Emad kadimNo ratings yet

- Analysis The Effect of Environmental Conditions On Abs Grade A Steel and Bki Grade A Steel Coating On The Resistance Test of Impact CoatingDocument15 pagesAnalysis The Effect of Environmental Conditions On Abs Grade A Steel and Bki Grade A Steel Coating On The Resistance Test of Impact Coatingary rizkiNo ratings yet

- Class B Complementary Symmetry Power AmplifierDocument15 pagesClass B Complementary Symmetry Power AmplifierMuthukrishnan Vijayan VijayanNo ratings yet

- BS en 12405-3-2015Document82 pagesBS en 12405-3-2015Doiciel100% (1)

- POTS telephone service and local subscriber loopDocument2 pagesPOTS telephone service and local subscriber loopjeevanNo ratings yet

- ISO 30302 2015 SpanishDocument50 pagesISO 30302 2015 SpanishThant AungNo ratings yet

- Arduino ReportDocument3 pagesArduino ReportarunNo ratings yet

- Dgi ps-3206 SMDocument229 pagesDgi ps-3206 SMHoffman Elizalde100% (1)

- Power BI Vs Excel 1694801413Document1 pagePower BI Vs Excel 1694801413LifeNo ratings yet

- Assigned Questions ListDocument4 pagesAssigned Questions ListDeepam AsnaniNo ratings yet

- Bike TN02 BK 4721 RC Book Honda UnicornDocument1 pageBike TN02 BK 4721 RC Book Honda UnicornvinothNo ratings yet

- Produktkatalog BraDocument2 pagesProduktkatalog BraRodrigo ElhailNo ratings yet

- 15 KVA DG Invoice BillDocument1 page15 KVA DG Invoice Billgouthamj0No ratings yet