Professional Documents

Culture Documents

FR-TOIPL-HO-Hira Painting

Uploaded by

HARSHADOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FR-TOIPL-HO-Hira Painting

Uploaded by

HARSHADCopyright:

Available Formats

AMENDMENT CONTROL RECORD

CURRENT REVISION

SR.NO DATE NO. NATURE OF AMENDMENT

1 02.03.2020 00 INTRODUCTION

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

CORD

AMENDMENT Entered by

UCTION SJ / RF

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

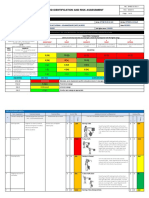

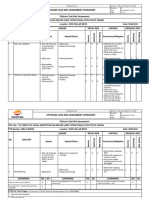

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

A. Document Number : HIRA/Projects/2020/09 Revision Number

0 : B.Date: Original-09.09.2020

C. Department / Area: Engg & Projects D.Team Members

E: Activities / Resource at workplace / work environment: RCC Drainage Work

F. Work done / Resource provided by : Contractor Gubbi Civil Engineers

Hazard Identification Risk Evaluation

Normal / Risk Rating

Abnormal /

S.No Hazard

Emergency Likelyhood (Probability) Consequence Ro - Risk Rating before

(N/A/E) (Severity) Control Implementation

1 2 3 4 5=3*4

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Plaster Breaking

1 Loose Material Collapse 3 2 6

N

2 Slip of man/Fall of materials 4 1 4

N

3 Eye injury 4 1 4

N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Demolishing of RCC Road

1 Minor cut injury 5 1 5

N

2 Eye injury 5 1 5

N

3 Electric shock 3 2 6

A

4 Fire hazards. 3 1 3

E

5 Vibrating Hazard 3 1 3

N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Manual Excavation & Trenching

1 Fall in excavated pit 3 1 3

N

2 Damaged to underground pipeline 4 1 4

A

3 Underground cables 3 2 6

A

4 Damaged to Underground Existing Structure 2 1 2

N

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

5 Obstruction To Road 4 1 4

N

6 Flying Objects 3 1 3

N

7 Layout As Per Drawing 3 1 3

N

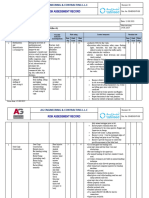

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Rubble Soling

1 Fall of Boulders During Handling 4 1 4

N

2 Dust/ Particulate matter 4 1 4

N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Conventional Formwork

1 Materials falling during the striking of formwork 3 1 3

N

2 Silica dust from scrabbling operations 4 1 4

N

3 Manual handling of shutters, reinforcing bars etc 3 1 3

N

4 Arm and back strain for steel fixers 4 1 4

N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Plain Cement Concrete.

1 Work without safety of hands causes skin problems. 3 1 3

N

2 Careless work causes falling of materials and workmen causing 3 1 3

major injuries. N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Loading & Unloading of Pipe Loading & Unloading of Pipe

1 Fall Pipe from slings. Breakage of lifting accessories like rope and 3 1 3

chain

E

2 Electric shock due to touch of boom to overhead electrical cables 5 1 5

E

Sub activity / Sub assembly of facilities & equipments / Situation / Event - RCC Hume Pipe Joints

1 Fall of objects 3 1 3

N

2 Cut, crush, abrasion injury 4 1 4

N

3 Health hazard due to cement dust 3 1 3

N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Backfilling & Leveling

1 Collapse of soil/pits 4 1 4

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

1 Collapse of soil/pits 4 1 4

N

2 Electric shock while touch to cable 5 1 5

E

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Operating of Earth compactor

1 Dust exposure 3 1 3

N

2 Emission of noise 4 1 4

N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Plain Cement Concrete.

1 Work without safety of hands causes skin problems. 4 1 4

N

Careless work causes falling of materials and workmen causing

2 3 1 3

major injuries. N

Sub activity / Sub assembly of facilities & equipments / Situation / Event - Plastering

1 Improper use of tools and equipment may cause accidents. 5 1 5

N

2 Proximity to loose debris and falling objects. 3 1 3

N

3 Exposure to hazardous chemicals and airborne particles. 5 1 5

N

4 Airborne irritants may get inhaled or enter the eyes. 5 1 5

N

Prepared by

Department Representative

Note:- Refer "Amendment Control Record (ACR) to note history of changes / periodic review

OHSP 01

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

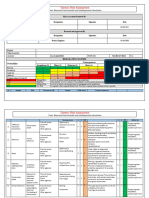

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA) SHEET

Current -dd/mm/yy & Revision Number xx

RF/SJ

Risk Evaluation

Risk Rating Ri - Risk rating

after valuation

Adequacy of of control

Existing controls Preventive Additional controls

control (Ro x C)

6 7=5*6 H T

The Work Area cover by safety barrigation Tape at site And Protection Screen 1 6 Only experience & skills labours allow to

applying work.

All Material Tie 1 4 Work to be Supervised By Experienced &

responsible Person

Use Safety safety goggles. 1 4 Working Platform Check before Working

1 5

Use Safety Helmet, Handgloves, safety shoes, safety goggles. Use Tested hand tools such as breaker

1 5 Trained and approved work should be

Use Safety safety goggles. deployed for cutting steel.

ELCB board must present on the site. 2 12 Work to be Supervised By Experienced &

responsible Person

Keep EXTINGUISHER Near Working Place. 2 6 Only experience & skills labours allow to

work.

Use of Ear plug 1 3 Use of PPE’s Like Safety Shoes, Hardhat,

safety goggles & Handgloves.

1 3 Keep heavy equipment away from trench

Barricading of the area by barrigation tape all around site. edges.

2 8 Work to be Supervised By Experienced &

Allow only authorized person inside the barricading responsible Person

Excavation only done through permit to work 1 6 Continuous Dewatering is Required in high

Seepages area.

Follow the permit to work system 1 2 Temporary gives support to existing

underground structure

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

Cordoning The Work area by Cordoning Tape

Diversion sign board placed Properly 1 4 and appropriate Signboard.

Use of good quality nose mask 2 6

Check All PPE is used or not by labours

Excavation shall be done with proper sloping and it should be properly Use Consultant Approve Structural Drawing

1 3

shored and Drawing during Work

1 4

Use Safety Helmet, Handgloves, safety shoes, safety goggles. Use of Wheelbarrow vehicle

1 4

Use of good quality nose mask Check All PPE is used or not by labours

1 3 Keep Construction Material Safely While

Guard rails must be put in place as work progresses Handling.

1 4

Use of good quality nose mask Check All PPE is used or not by labours

Access ladders must be properly erected tied and project at least 1 meter Work to be Supervised By Experienced &

above the landing platform. 1 3

responsible Person

Equipment must be in good order

Workers must be provided with safe access to the work. 1 4 before use. Original manufacturer’s pins

must be used in adjustable props.

1 3

Use Safety Helmet, Handgloves, safety shoes, safety goggles. Use cotton handglooves for breaking.

2 6

Only experience & skills labours allow to work. Use Tested hand tools.

pe Loading & Unloading of Pipe

1 3 Crane/lifting equipments to be operated by

Ensure proper use of slings and rope after balancing before lifting pipes. authorize person.

All Rigger/Lifting Equipment must be

2 10 inspected prior to use and determined to be

Allow only authorized person inside the barricading in safe working order

1 3 Use of PPE’s Like Safety Shoes, Hardhat &

Use of PPE’s Like Safety Shoes, Hardhat & Handgloves Handgloves

1 4 Work to be Supervised By Experienced &

Use of PPE’s Like Safety Shoes & Handgloves responsible Person

Use of good quality nose mask 1 3

Check All PPE is used or not by labours

1 4

Safe access shall be provided for unloading the sand/soil. Use stopper at the time of unloading

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

1 4

Safe access shall be provided for unloading the sand/soil. Use stopper at the time of unloading

2 10

Checking of live lighting cable Checking of live lighting cable.

1 3

Use of good quality nose mask Check All PPE is used or not by labours

1 4 Only authorized experience person shall be

Use of ear plug deployed in the job with safety

1 4 Use cotton handglooves & safety goggles

Use Safety Helmet, Handgloves, safety shoes, safety goggles. While Mixing Concrete

1 3

Observer hazards at work place and surrounding area. Use Tested hand tools.

1 5

Use Safety Helmet, Handgloves, safety shoes, safety goggles. Inspect All PPE Before Use

1 3 Work to be Supervised By Experienced &

Workers must be provided with safe access to the work. responsible Person

Use of good quality nose mask & Handgloves 1 5

Check All PPE is used or not by labours

Use safety goggles 1 5 Only experience & skills labours allow to

work.

Reviewed by

Head of Function

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

Related Legal

l controls

requirements

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

wed by

Function

# TOTAL Classification: Restricted Distribution TOTAL - All rights reserved

You might also like

- 31.0.12 ALR - Traffic Control by FlagmanDocument3 pages31.0.12 ALR - Traffic Control by FlagmanGerrit100% (1)

- 01-Risk Assessment For Survey WorkDocument7 pages01-Risk Assessment For Survey Work287100% (3)

- Risk Assessment For Split AC UnitsDocument2 pagesRisk Assessment For Split AC UnitsAhmed mahlawyNo ratings yet

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- Excavation & Backfilling Risk AssessmentDocument6 pagesExcavation & Backfilling Risk AssessmentAbdul Rasheed Mangrio100% (1)

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- 02-RA For Panel InstallationDocument5 pages02-RA For Panel Installation287100% (1)

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerritNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayNo ratings yet

- Phase 3 Hardscape RA R0Document14 pagesPhase 3 Hardscape RA R0SIBIN100% (1)

- Soft Landscaping ROW Area Risk AssessmentDocument11 pagesSoft Landscaping ROW Area Risk AssessmentSIBIN100% (2)

- Painting WorksDocument3 pagesPainting WorksSaleem Basha100% (1)

- Scaffolding Erection and Dismantling CwhohsDocument3 pagesScaffolding Erection and Dismantling CwhohsmurasolimaranNo ratings yet

- Method Statement Concrete PouringDocument4 pagesMethod Statement Concrete PouringSmart ShivaNo ratings yet

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- JSA - RA 000-Water ProofingDocument5 pagesJSA - RA 000-Water ProofingNAGARJUNA100% (1)

- Master Hazard Identification & Risk Assesment (Hira) : Document No: Rev. 0 DateDocument2 pagesMaster Hazard Identification & Risk Assesment (Hira) : Document No: Rev. 0 DateHARSHADNo ratings yet

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287No ratings yet

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Document1 pageRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueNo ratings yet

- PreviewpdfDocument37 pagesPreviewpdfiandegs20100% (3)

- AFA HIRA - Electrical Control PanelDocument30 pagesAFA HIRA - Electrical Control PaneljavedNo ratings yet

- Risk / Impact Assessment Control Sheet: 000 Y N Y NDocument19 pagesRisk / Impact Assessment Control Sheet: 000 Y N Y NeDtutors. inNo ratings yet

- Risk Assement For Piling PDFDocument81 pagesRisk Assement For Piling PDFnagesh1234No ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Job Hazard Analysis & Risk Assessment Hot WorkDocument10 pagesJob Hazard Analysis & Risk Assessment Hot WorknavaniNo ratings yet

- Lifting Operations RA LdwcnsDocument3 pagesLifting Operations RA LdwcnsUmair Khan100% (1)

- Hazard Identification & Risk Assessment Theatre 01-06-17 02 (01.12.17) 08Document6 pagesHazard Identification & Risk Assessment Theatre 01-06-17 02 (01.12.17) 08sachin vaish100% (1)

- Risk Assessment Relocation Overhead LineDocument5 pagesRisk Assessment Relocation Overhead Lineghada gattouchNo ratings yet

- 05 - RISK ASSESSMENT-Winch MechineDocument3 pages05 - RISK ASSESSMENT-Winch Mechine287100% (1)

- Rmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)Document1 pageRmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)myn maliQueNo ratings yet

- Rmdjv-pj74-Hiradc-subc 10 (Turfing & Landscaping)Document2 pagesRmdjv-pj74-Hiradc-subc 10 (Turfing & Landscaping)myn maliQue100% (1)

- RMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)Document2 pagesRMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)myn maliQueNo ratings yet

- 04 - RISK ASSESSMENT CradleDocument5 pages04 - RISK ASSESSMENT Cradle287100% (4)

- RMDJV Pj74 Hiradc Subc 02 (Survey Work)Document1 pageRMDJV Pj74 Hiradc Subc 02 (Survey Work)myn maliQue100% (1)

- Sop - Bar BendingDocument1 pageSop - Bar BendingHARSHAD50% (2)

- A Practical Approach to Hazard Identification for Operations and Maintenance WorkersFrom EverandA Practical Approach to Hazard Identification for Operations and Maintenance WorkersNo ratings yet

- Constuction of RCC Telecom Chamber For Telecom WorksDocument14 pagesConstuction of RCC Telecom Chamber For Telecom WorkssajinNo ratings yet

- Rmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)Document2 pagesRmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)myn maliQueNo ratings yet

- Technical Requirement For Pre-Engineered Building Works: M/S Design SanyojakaDocument4 pagesTechnical Requirement For Pre-Engineered Building Works: M/S Design SanyojakaHARSHADNo ratings yet

- Risk Assessment Water Tank Cleaning 2023Document3 pagesRisk Assessment Water Tank Cleaning 2023Karan SuleNo ratings yet

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Maintenance Plan Sample 20131230Document10 pagesMaintenance Plan Sample 20131230Hallshe LallaveNo ratings yet

- Fire Protection CDPDocument29 pagesFire Protection CDPPopa IulianNo ratings yet

- Aspect Impact PressingDocument2 pagesAspect Impact Pressinglalit GuptaNo ratings yet

- RMDJV Pj74 Hiradc Subc 01 (Soil Investigation)Document2 pagesRMDJV Pj74 Hiradc Subc 01 (Soil Investigation)myn maliQueNo ratings yet

- Cargo Operations - Bulk CarrierDocument28 pagesCargo Operations - Bulk Carrierle100% (1)

- HIRA RCC Work (3) Approed by ClientDocument11 pagesHIRA RCC Work (3) Approed by ClientHARSHADNo ratings yet

- BIAL Project: Contractor's OH&S Hazard Identification & Risk Assessment Register Larsen & Toubro Limited 1 2 Valid ForDocument2 pagesBIAL Project: Contractor's OH&S Hazard Identification & Risk Assessment Register Larsen & Toubro Limited 1 2 Valid Forelahi MohammedNo ratings yet

- Site SurveyDocument1 pageSite Surveynaveen chandNo ratings yet

- CriticalDocument13 pagesCriticalleNo ratings yet

- SKC S Aerosol Safety Data Sheet EnglishDocument5 pagesSKC S Aerosol Safety Data Sheet EnglishkhairurNo ratings yet

- TGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2Document3 pagesTGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2Shubham ShuklaNo ratings yet

- Confined Space EntryDocument4 pagesConfined Space Entrykwame fosterNo ratings yet

- Block WorksDocument4 pagesBlock Workskwame fosterNo ratings yet

- 01.HEMP - Storm Water DrainageDocument2 pages01.HEMP - Storm Water DrainageSuhaimi ZamzarinaNo ratings yet

- Concreting With Concrete BucketDocument3 pagesConcreting With Concrete Bucketkwame fosterNo ratings yet

- Risk Assessment TemplateDocument2 pagesRisk Assessment TemplateMalefane Cortez TlatlaneNo ratings yet

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- 02.HEMP - Wing Wall Base SlabDocument2 pages02.HEMP - Wing Wall Base SlabSuhaimi ZamzarinaNo ratings yet

- 04 Piling Works 1Document2 pages04 Piling Works 1Rues AgNo ratings yet

- Generic Risk Assessment Rescues From Tunnels and Underground StructuresDocument5 pagesGeneric Risk Assessment Rescues From Tunnels and Underground Structurestumelo makgabutlaneNo ratings yet

- Pile Integrity Testing RADocument12 pagesPile Integrity Testing RAmdfahad0047No ratings yet

- Triple Height Area. Triple Height Area: Inadequate Communication of Task Planning and PreparationDocument5 pagesTriple Height Area. Triple Height Area: Inadequate Communication of Task Planning and PreparationMobin Thomas AbrahamNo ratings yet

- 03.HEMP - Hacking WorkDocument2 pages03.HEMP - Hacking WorkSuhaimi ZamzarinaNo ratings yet

- Advt 11 2015Document1 pageAdvt 11 2015Varun MalhotraNo ratings yet

- Report On Structural Audit of Terrace Johnson & Johnson PVT LTD, Mulund West, MumbaiDocument11 pagesReport On Structural Audit of Terrace Johnson & Johnson PVT LTD, Mulund West, MumbaiHARSHADNo ratings yet

- J&J Garden ReportDocument80 pagesJ&J Garden ReportHARSHADNo ratings yet

- Eksar Road Chogle Chawl Babhai Naka Borivali West Gstin/Uin: 27AAHPR3098Q1ZQ State Name: Maharashtra, Code: 27Document1 pageEksar Road Chogle Chawl Babhai Naka Borivali West Gstin/Uin: 27AAHPR3098Q1ZQ State Name: Maharashtra, Code: 27HARSHADNo ratings yet

- AppraisalDocument2 pagesAppraisalHARSHADNo ratings yet

- Tax Invoice: Gstno: 27Aaacj0866E1ZrDocument49 pagesTax Invoice: Gstno: 27Aaacj0866E1ZrHARSHADNo ratings yet

- Bill 1Document1 pageBill 1HARSHADNo ratings yet

- Bill 1Document1 pageBill 1HARSHADNo ratings yet

- Ra Bill VoltasDocument11 pagesRa Bill VoltasHARSHADNo ratings yet

- Bill 1Document1 pageBill 1HARSHADNo ratings yet

- Unit No: 3: External Painting WorkDocument20 pagesUnit No: 3: External Painting WorkHARSHADNo ratings yet

- Material Description Material DescriptionDocument5 pagesMaterial Description Material DescriptionHARSHADNo ratings yet

- Work Procedure & Check ListDocument14 pagesWork Procedure & Check ListHARSHADNo ratings yet

- New Doc 2020-09-08 13.59.28 PDFDocument13 pagesNew Doc 2020-09-08 13.59.28 PDFHARSHADNo ratings yet

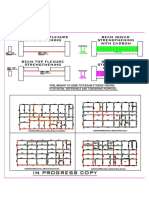

- Beam Bottom Flexure Strengthening Beam Shear Strengthening With CarbonDocument1 pageBeam Bottom Flexure Strengthening Beam Shear Strengthening With CarbonHARSHADNo ratings yet

- Gubbi - BLOWER MACHINE PRE USE CHECK LIST 7 SEP 2020Document1 pageGubbi - BLOWER MACHINE PRE USE CHECK LIST 7 SEP 2020HARSHADNo ratings yet

- Gubbi - BLOWER MACHINE PRE USE CHECK LIST 7 SEP 2020Document1 pageGubbi - BLOWER MACHINE PRE USE CHECK LIST 7 SEP 2020HARSHADNo ratings yet

- Job Safety AnalysisiDocument7 pagesJob Safety AnalysisiHARSHADNo ratings yet

- Jsa - Bar BendingDocument1 pageJsa - Bar BendingHARSHAD100% (1)

- M/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisDocument3 pagesM/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisHARSHADNo ratings yet

- Gubbi - GRINDER MACHINE PRE USE CHECK LIST1Document1 pageGubbi - GRINDER MACHINE PRE USE CHECK LIST1HARSHADNo ratings yet

- Gubbi - ELECTRIC VIBRATOR PRE USE CHECK LIST 7 SEP 2020Document1 pageGubbi - ELECTRIC VIBRATOR PRE USE CHECK LIST 7 SEP 2020HARSHADNo ratings yet

- Gubbi - GRINDER MACHINE PRE USE CHECK LIST1Document1 pageGubbi - GRINDER MACHINE PRE USE CHECK LIST1HARSHADNo ratings yet

- Gubbi - DRILL MACHINE PRE USE CHECK LISTDocument1 pageGubbi - DRILL MACHINE PRE USE CHECK LISTHARSHADNo ratings yet

- Gubbi - BLOWER MACHINE PRE USE CHECK LIST 7 SEP 2020Document1 pageGubbi - BLOWER MACHINE PRE USE CHECK LIST 7 SEP 2020HARSHADNo ratings yet

- Project Management - Assignment 1Document3 pagesProject Management - Assignment 1NURUL AQILAH AHMAD NASIRNo ratings yet

- GT Tilefix CG QAF OmegaDocument4 pagesGT Tilefix CG QAF OmegathomsonNo ratings yet

- Document Review Comments Sheet: Engineering and Procurement Services Contract 16/03/2022Document3 pagesDocument Review Comments Sheet: Engineering and Procurement Services Contract 16/03/2022حسن صالح حسن المياحيNo ratings yet

- Ausenco: Grid Mesh / Chequer Plate or Flooring Removal 9999HSESD7046Document6 pagesAusenco: Grid Mesh / Chequer Plate or Flooring Removal 9999HSESD7046leizel dacuNo ratings yet

- Field Guide AVBDocument76 pagesField Guide AVBRami TarrafNo ratings yet

- Steel Concrete Composite Systems For Modular Construction of High-Rise BuildingsDocument16 pagesSteel Concrete Composite Systems For Modular Construction of High-Rise BuildingsMichael ChewNo ratings yet

- CONCRETE (Material Science & Metallurgy)Document26 pagesCONCRETE (Material Science & Metallurgy)Shuvas KhanalNo ratings yet

- Certificate of Conformance: Crosby Europe N.V. Leuvensebaan 51 2580 Putte (Mechelen) BelgiumDocument1 pageCertificate of Conformance: Crosby Europe N.V. Leuvensebaan 51 2580 Putte (Mechelen) Belgiumorizas_1No ratings yet

- Fidic Questions and AnwersDocument35 pagesFidic Questions and AnwersRajendra TharmakulasinghamNo ratings yet

- Project I.D. No. Revisions Project Title Sheet Contents Owner / Approved Architect Allied EngineersDocument1 pageProject I.D. No. Revisions Project Title Sheet Contents Owner / Approved Architect Allied EngineersSabling DritzcNo ratings yet

- 0.1 - RFQ - Utility Boiler PacakgeDocument8 pages0.1 - RFQ - Utility Boiler Pacakgeabdelkader benabdallahNo ratings yet

- Firetrol Protection Systems - Technical Proposal 5-19-17Document40 pagesFiretrol Protection Systems - Technical Proposal 5-19-17Aidan YepsonNo ratings yet

- Bell (2002) - A History of The Queensland HouseDocument72 pagesBell (2002) - A History of The Queensland Houseexddidrl2768No ratings yet

- HT Meter Room LayoutDocument1 pageHT Meter Room LayoutprashantkothariNo ratings yet

- Gauge GuidelinesDocument1 pageGauge Guidelinespankaj kumarNo ratings yet

- DNV Type Approval Certificate Shipbuilding Offshore Quality EXD 22 11 2028 enDocument5 pagesDNV Type Approval Certificate Shipbuilding Offshore Quality EXD 22 11 2028 enfwfchmielewskiNo ratings yet

- April 18, 2022 Board MinutesDocument20 pagesApril 18, 2022 Board MinutesAnthony WarrenNo ratings yet

- S-PCM Minutes of Meeting: DCBM Sitemgr Eng Mohammad DCBM Hsemgr DCBMDocument3 pagesS-PCM Minutes of Meeting: DCBM Sitemgr Eng Mohammad DCBM Hsemgr DCBMsudeesh kumarNo ratings yet

- Civil Engineering and Society and Other Professions: By: Francisco, Alyssa Marie S. Bsce 1-ADocument21 pagesCivil Engineering and Society and Other Professions: By: Francisco, Alyssa Marie S. Bsce 1-AAlyssa Marie SP. FranciscoNo ratings yet

- Corrigendum No 2Document43 pagesCorrigendum No 2Jay UseitNo ratings yet

- M-14 Conduct On Site Supervision of BEIDocument172 pagesM-14 Conduct On Site Supervision of BEIkassamammukaNo ratings yet

- Haridwar Project - BOqDocument18 pagesHaridwar Project - BOqAniket AgarwalNo ratings yet

- High Risk Activities: GD22 Dangerous Substances Safety QuestionnaireDocument3 pagesHigh Risk Activities: GD22 Dangerous Substances Safety QuestionnaireAlbert PerezNo ratings yet

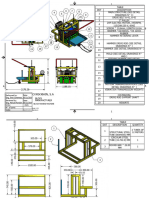

- Block Making Machine PlansDocument12 pagesBlock Making Machine PlansScribdTranslationsNo ratings yet

- Method Statement For Cutting & Recasting of Strap Beam) (C)Document5 pagesMethod Statement For Cutting & Recasting of Strap Beam) (C)Akash YadavNo ratings yet

- Special Inspection Manual: Building & SafetyDocument35 pagesSpecial Inspection Manual: Building & SafetyAntonio CastilloNo ratings yet