Professional Documents

Culture Documents

Planning Lifting & Hoisting Operations Page 1 of 2

Uploaded by

Mohammed JassimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Planning Lifting & Hoisting Operations Page 1 of 2

Uploaded by

Mohammed JassimCopyright:

Available Formats

PLANNING LIFTING & HOISTING OPERATIONS Page 1 of 2

PERMIT TO WORK NUMBER:

LOCATION:

MAX WIND SPEED FORECAST:

BRIEF DESCRIPTION OF THE LIFTING & HOISTING OPERATION:

CATEGORISATION OF LIFTING AND HOISTING OPERATION (UNDERLINED: HSSE CF CATEGORIES; free format in “Other”):

Routine Non Routine Simple Non-Routine Complicated Non-Routine Complex

Drawing Number: Drawing Number:

BRIEF DESCRIPTION OF THE LIFTING & HOISTING EQUIPMENT TO BE USED (E.G. TYPE, WLL, SWL, ETC and including rigging weight total)

CURRENT

COLOUR CODE

BRIEF INFORMATION OF THE LOAD(S) (including base weight/s):

LOAD WEIGHT CALCULATION (including weight contingency + any other factors such as DAF) Note: Utilization > 75% = Non-Routine, Complex

MAXIMUM

UTILIZATION %

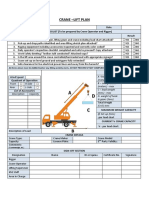

ALL L&H OPERATIONS REQUIRE THE FOLLOWING - AS A MINIMUM - TO BE CONSIDERED

THIS INFORMATION IS TO BE CAPTURED IN A SEPARATE DOCUMENT (E.G. JHA/TRiC)

1. Relevant Life Saving Rules 14. Conflicting tasks in area

2. 10 Questions for safe Lifting & Hoisting 15. Working under suspended loads

3. Toolbox or Pre-Job meeting 16. Overturning, load integrity, need for tag lines

4. Weight, size, shape and centre of gravity load 17. Environmental conditions incl. weather, sea state

5. Method of slinging, attaching, detaching the load 18. Experience, competence & training of personnel

6. Availability of approved hoisting points on the load 19. Number & names of personnel required for task

7. Maximum radius of hoisting the load 20. Communication requirements

8. Verified details of ground conditions/capacity 21. Lighting in the pick-up and lay down area

9. Area for setting up with outriggers fully extended 22. Initial and final load positions & how it gets there

10. Access and emergency escape routes 23. Proximity hazards, obstructions, path of load

11. Number and duration of lifts, hoists 24. Suitability and condition of equipment

12. Visibility of load (blind lifts = Non-Routine Complex) 25. Pre-use inspection of certified equipment only

13. Hoisting over live equipment 26. Max dynamic calculated load is within capacity

METHOD (S) OF COMMUNICATION TO BE USED:

Radio: Verbal: Hand Signals :

PRE-TASK PREPARATION (as a minimum – not exhaustive)

1. All personnel associated with the lifting operation to review the lifting plan and risk assessment and complete toolbox

talk

2. Crane operator to inspect the load/s and ensure the actual weight/s of the cargo measured by the crane matches the

lifting plan

3. Crane operator and PICWS to inspect work area and ensure load bearing surface is safe/adequate for maximum loads

imposed by this operation, crane must be level within tolerance.

4. Crane operator to carry out pre-check/inspection of the crane and test all safety devices

5. PICWS to ascertain that the environmental conditions are within crane parameters as stated in Lifting Plan

6. PICWS to ensure area barricaded, no conflicting activities ongoing in surrounded/landing areas and load path is clear of

obstructions

7. PICWS to ensure suitable access for Rigger/s to safely attach/adjust rigging at height, and load is free to lift

8. PICWS to inspect all rigging and equipment prior to use, and confirm colour code is valid

Doc. no.: VEN-00000-SIPD-00-HX-6180-00018 Rev. No. 009 1 of 2

The information contained on this page is subject to the disclosure on the front page of this document.

PLANNING & HOISTING OPERATIONS Page 2 of 2

TASK STEP BY STEP – ATTACH ADDITIONAL PAGES IF REQUIRED

LIFT PLAN DRAWINGS (incl. load path & rigging arrangement) – ATTACH ADDITIONAL PAGES IF REQUIRED

LEARNING FROM THIS L&H ACTIVITY

PLANNED BY (CONTRACTOR):

NAME: SIGNATURE: DATE:

APPROVED BY (CONTRACTOR) DIFFERENT INDIVIDUAL TO THE ABOVE)):

NAME: SIGNATURE: DATE:

APPROVED BY SIPD LIFTING AND HOISTING DEPT:

NAME: SIGNATURE: DATE:

Doc. no.: VEN-00000-SIPD-00-HX-6180-00018 Rev. No. 009 2 of 2

The information contained on this page is subject to the disclosure on the front page of this document.

You might also like

- CPCS A62 Crane Lifting Operations Supervisor Theory Test AnswersDocument7 pagesCPCS A62 Crane Lifting Operations Supervisor Theory Test AnswersLulezim Skeja100% (1)

- Timeline of Rizal Travels in EuropeDocument3 pagesTimeline of Rizal Travels in EuropeJoebin Corporal Lopez100% (11)

- Lifting Plan Template - Portacamp Container 20'' (East Side 1)Document2 pagesLifting Plan Template - Portacamp Container 20'' (East Side 1)dadang16100% (3)

- Crane Lifting Plan Lifting Operation Method Statement/Lift Plan & Risk AssessmentDocument20 pagesCrane Lifting Plan Lifting Operation Method Statement/Lift Plan & Risk AssessmentIskandar AzriNo ratings yet

- Global Medical DevicesDocument50 pagesGlobal Medical DevicesLavanya SubramaniamNo ratings yet

- Action Plan School Governing Council: Sampaloc National High SchoolDocument3 pagesAction Plan School Governing Council: Sampaloc National High SchoolLem Rada100% (14)

- Appendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesDocument32 pagesAppendix - Nlng-lp-017 - Lift Plan For Lifting and Installation of Roof Trusses of Amenities Building (19418) - Comments From MosesAdebayo M JayeolaNo ratings yet

- Lifting Plan TemplateDocument16 pagesLifting Plan TemplatezwvvsoNo ratings yet

- Lifting Plan For UnloadingDocument5 pagesLifting Plan For Unloadingkhaled redaNo ratings yet

- Medical SurgicalDocument1 pageMedical SurgicalTruly0% (2)

- Maj Concslb 043 0Document3 pagesMaj Concslb 043 0Mohammed JassimNo ratings yet

- SGTF-LP-161 Gas Valve Skid 156-SK01 A BDocument3 pagesSGTF-LP-161 Gas Valve Skid 156-SK01 A BMohammed JassimNo ratings yet

- SSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckDocument4 pagesSSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckSagar SharmaNo ratings yet

- LIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Document16 pagesLIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Balram Kumar PandeyNo ratings yet

- Pri-Hse-Frm-011 Lifting PermitDocument3 pagesPri-Hse-Frm-011 Lifting PermitTopeNo ratings yet

- Lifting Operations 2.034Document10 pagesLifting Operations 2.034svdnolen0% (1)

- Lift Plan FormDocument6 pagesLift Plan FormBibin JohnNo ratings yet

- 009 Lifting PlanDocument2 pages009 Lifting Planromedic36No ratings yet

- Crane Lift RAMsDocument18 pagesCrane Lift RAMsKaren Olivier100% (1)

- Lift Plan NRS - Toilet Block - Meram ECWDocument40 pagesLift Plan NRS - Toilet Block - Meram ECWTagubilin DailyNo ratings yet

- G18-2-LP-003 DG - Lifting PlanDocument25 pagesG18-2-LP-003 DG - Lifting PlanMohammed JassimNo ratings yet

- Gas Turbine and Generator UnloadingDocument9 pagesGas Turbine and Generator Unloadingamritrj444No ratings yet

- Lifting Operation ChecklistDocument8 pagesLifting Operation ChecklistHein SiNo ratings yet

- 46.lifting PlanDocument2 pages46.lifting PlanIbrahim EsmatNo ratings yet

- Lifting Operation Plan: Document No: Revision. No: 0 Effective DateDocument1 pageLifting Operation Plan: Document No: Revision. No: 0 Effective Datemuhammad umarNo ratings yet

- Construction Lifting PlanDocument5 pagesConstruction Lifting PlanJuma KavesuNo ratings yet

- 01 - Lifting Personnel Basket - ADNOCDocument4 pages01 - Lifting Personnel Basket - ADNOCEmad ZakiNo ratings yet

- Lift Plan REV 2Document6 pagesLift Plan REV 2Jonathan BadgerNo ratings yet

- Specific Lifting Pland - OHS-PR-009 - FM-01-051. Rv2Document2 pagesSpecific Lifting Pland - OHS-PR-009 - FM-01-051. Rv2cmrig74No ratings yet

- Portsaid Tunnels Project: Critical Lift ChecklistDocument2 pagesPortsaid Tunnels Project: Critical Lift ChecklistMuhammad Ahmed Abd Elmonem100% (1)

- Lifting Plan For CranesDocument9 pagesLifting Plan For CranesBibin JohnNo ratings yet

- Ptw-Lifting Operation (Daily) : General Information OMC Permit NoDocument2 pagesPtw-Lifting Operation (Daily) : General Information OMC Permit NoKarthik KarunanithiNo ratings yet

- 200 T Crane Routine Lift PaperDocument10 pages200 T Crane Routine Lift Papershreeambikastore15No ratings yet

- FM-OHS-1300-02 Lift Plan - Mobile Crane R01Document4 pagesFM-OHS-1300-02 Lift Plan - Mobile Crane R01CosminZbirnaNo ratings yet

- Binzafrah Prefab LIFTING PROCESS W.O 26 PDFDocument31 pagesBinzafrah Prefab LIFTING PROCESS W.O 26 PDFMahmudul Alam kanakNo ratings yet

- Lift Details: Identify Hazards That Are PresentDocument1 pageLift Details: Identify Hazards That Are PresentJayson TorresNo ratings yet

- 009 Lifting PlanDocument2 pages009 Lifting Planepriyono100% (2)

- Method Statement & Lift PlanDocument6 pagesMethod Statement & Lift PlanGodfred Quarm100% (1)

- Appendix AB - Lifting Plan and ScheduleDocument5 pagesAppendix AB - Lifting Plan and ScheduleHYMTLNo ratings yet

- Mid Group Black White Building 74 Rivington ST Shoreditch London Raptor 184 Erect RAMS Rev 3Document40 pagesMid Group Black White Building 74 Rivington ST Shoreditch London Raptor 184 Erect RAMS Rev 3RADHE SHYAMNo ratings yet

- 80T Crane Routine Lifting Paper-1Document10 pages80T Crane Routine Lifting Paper-1shreeambikastore15No ratings yet

- EM0426 Lifting Plan For Bonnet at UtilityDocument10 pagesEM0426 Lifting Plan For Bonnet at Utilitygad404No ratings yet

- Lifting Plan Rev.01: Load Less Than 10 TonDocument19 pagesLifting Plan Rev.01: Load Less Than 10 Tonsajin100% (1)

- Lifting PlanDocument9 pagesLifting Plansatyabrath dhalNo ratings yet

- EM0419 Lifting Plan For Basket Above Main SubstationDocument10 pagesEM0419 Lifting Plan For Basket Above Main Substationgad404No ratings yet

- Crane Lift PlanDocument1 pageCrane Lift PlanHamid Ali100% (5)

- EM0407 Lifting Plan For Spicial Tool and Baskets and TableDocument9 pagesEM0407 Lifting Plan For Spicial Tool and Baskets and Tablegad404No ratings yet

- Lifting Plan TemplateDocument2 pagesLifting Plan Templatemohamed atefNo ratings yet

- ITB HSE Evaluasi Tender SGARDocument4 pagesITB HSE Evaluasi Tender SGARMy pouNo ratings yet

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDocument4 pagesLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNo ratings yet

- 3-Pre-Lift Checklist Rev A 06302015Document2 pages3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- General Instruction Manual: ContentDocument9 pagesGeneral Instruction Manual: ContentJithuRajNo ratings yet

- Form 5068A Crane Use Planning Process REV 2015Document4 pagesForm 5068A Crane Use Planning Process REV 2015Samuel LumbanrajaNo ratings yet

- Rig Move Procedures DevelopmentDocument23 pagesRig Move Procedures DevelopmentAli Ahmed Pathan100% (2)

- 06 - Tata Power Mobile Crane Safety ProcedureDocument27 pages06 - Tata Power Mobile Crane Safety Procedurehse bsj100% (1)

- 20t Franna ManualDocument28 pages20t Franna ManualEdisonNo ratings yet

- 20t Franna Load ChartDocument28 pages20t Franna Load ChartJames DickinsonNo ratings yet

- Lifting PlanDocument17 pagesLifting PlanzaimNo ratings yet

- TGH-HSE-F0018 Lifting Plan Template LOCKEDDocument5 pagesTGH-HSE-F0018 Lifting Plan Template LOCKEDthana rajNo ratings yet

- Alkami Air Inlet Elbow Lifting PlanDocument16 pagesAlkami Air Inlet Elbow Lifting PlanVuthpalachaitanya KrishnaNo ratings yet

- Pre-Lift Check List: A Toshiba America Energy Systems CompanyDocument2 pagesPre-Lift Check List: A Toshiba America Energy Systems Companyr afriantoNo ratings yet

- Crane ChecklistsDocument8 pagesCrane ChecklistscuraajNo ratings yet

- Mobile Crane Lifting Plan - Routine Operation1Document2 pagesMobile Crane Lifting Plan - Routine Operation1Becha MouradNo ratings yet

- Safety Precautions Durring Dismentling of StructresDocument36 pagesSafety Precautions Durring Dismentling of StructresLokeshwar YadagiriNo ratings yet

- Invitation Letter-MDP Dec. 2017Document1 pageInvitation Letter-MDP Dec. 2017Susmit JainNo ratings yet

- Agam Agencies: Considering Sale Rate Effective Purchase RateDocument2 pagesAgam Agencies: Considering Sale Rate Effective Purchase RateaasifbidaniNo ratings yet

- De Thi Tuyen Sinh Lop 10 THPT 20162017Document5 pagesDe Thi Tuyen Sinh Lop 10 THPT 20162017Huy HaNo ratings yet

- RRT-PCR Covid-19 Testing Laboratory Performing Manual Rna ExtractionDocument1 pageRRT-PCR Covid-19 Testing Laboratory Performing Manual Rna ExtractionRanile CordovaNo ratings yet

- List of Network Hospitals - 1Document258 pagesList of Network Hospitals - 1SRINIVASARAO JONNALANo ratings yet

- Nama Nama KelompokDocument2 pagesNama Nama KelompokHarlyna Aulya FauzianaNo ratings yet

- White Grapefruit: Citrus X Paradisi 5 MLDocument1 pageWhite Grapefruit: Citrus X Paradisi 5 MLCristina CrăciunNo ratings yet

- Nepal National Building Code: Construction SafetyDocument15 pagesNepal National Building Code: Construction SafetyN TNo ratings yet

- Automatic Hand Sanitizer MachineDocument10 pagesAutomatic Hand Sanitizer MachineSaleem khanNo ratings yet

- IRTDocument2 pagesIRTIgnacioNo ratings yet

- Wichita Falls City Council Agenda 1/19/21Document60 pagesWichita Falls City Council Agenda 1/19/21Courtney-Ann Clarkin DelaneyNo ratings yet

- Bowie & Dick Tests - What Is It and Why Is It Important - Euronda Pro SystemDocument4 pagesBowie & Dick Tests - What Is It and Why Is It Important - Euronda Pro SystemMd Golam Nabi SarnamatNo ratings yet

- NPTE Tips Guide PlanDocument3 pagesNPTE Tips Guide Planzenab100% (1)

- VOH July-August 2013 NewsDocument2 pagesVOH July-August 2013 NewsvisionsofhopeNo ratings yet

- Section D. Oral Health Care and Services: For The Month OfDocument2 pagesSection D. Oral Health Care and Services: For The Month OfSeriel TismoNo ratings yet

- Kepatuhan Bidan Dalam Penerapan SOP Pemotongan Tali Pusat Pada Bayi Baru LahirDocument8 pagesKepatuhan Bidan Dalam Penerapan SOP Pemotongan Tali Pusat Pada Bayi Baru LahirMery Merdiana IsmailNo ratings yet

- Howrah - Orientation of MOs of Block, ULB RRT and Convergence Meeting With Supdt and Nodal Officers of DH, SDH and SGHs For The Ensuing MRVC-1Document1 pageHowrah - Orientation of MOs of Block, ULB RRT and Convergence Meeting With Supdt and Nodal Officers of DH, SDH and SGHs For The Ensuing MRVC-1Tapan MajumdarNo ratings yet

- Community Center: Design Studio - VDocument14 pagesCommunity Center: Design Studio - VKushal GhimireNo ratings yet

- Table of Contents: Method Statement FOR Lightning Protection System InstallationDocument10 pagesTable of Contents: Method Statement FOR Lightning Protection System Installationw fathyNo ratings yet

- T COLORaktiv 2000 SR (LP) - 200004010-GBDocument2 pagesT COLORaktiv 2000 SR (LP) - 200004010-GBCrist BoboNo ratings yet

- Carehome Nursing HomesDocument18 pagesCarehome Nursing HomesBLÁCK WOLFNo ratings yet

- B2 - WCET - INWOCNA 2017 by IrmaDocument37 pagesB2 - WCET - INWOCNA 2017 by Irmafajar adironiNo ratings yet

- Fik REtias DEwi Jayanti Template 3Document8 pagesFik REtias DEwi Jayanti Template 3MamangNo ratings yet

- Uptd Puskesmas Biau: Pemerintah Kabupaten Buol Dinas Kesehatan, Pengendalian Penduduk Dan KB Surat Bukti Barang KeluarDocument4 pagesUptd Puskesmas Biau: Pemerintah Kabupaten Buol Dinas Kesehatan, Pengendalian Penduduk Dan KB Surat Bukti Barang KeluarReza MuhammadNo ratings yet

- EXHALYZER: Device Used To Sense Alcohol Content: Background of The StudyDocument5 pagesEXHALYZER: Device Used To Sense Alcohol Content: Background of The StudyKimberleigh MetrioNo ratings yet