Professional Documents

Culture Documents

Cutting & Grinding & Welding

Cutting & Grinding & Welding

Uploaded by

ghazi kallelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cutting & Grinding & Welding

Cutting & Grinding & Welding

Uploaded by

ghazi kallelCopyright:

Available Formats

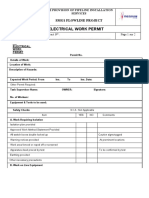

THE PROVISION OF PIPELINE INSTALLATION

SERVICES

SMG1 FLOWLINE PROJECT

JSA

CONTRACT N°……………………………………………………………….. Rev: 0

Page: 1 of 2

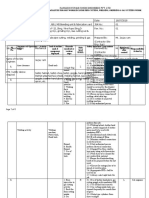

JOB SAFETY ANALYSIS (JSA)

Location: Person in charge: Date:

Work activity (Job): cutting ,Grinding ,welding

Work team:

Potential accidents or hazards Recommendations to eliminate or reduce potential hazards associated

Sequence of basic job steps

associated with each step with each step

Work start-up Unauthorized work Obtain a hot work permit before starting the job

Invalid permit Provide good lighting for all the area.

Lack of competency Provide clear access and egress.

Lack or poor communication Supervisor must ensure that all work activities are carried

Haste or shortcut out by competent personnel

Responsible person will conduct inspection, monitor the

work activities and have to ensure safety standards and

procedures are following.

Cutting & Grinding Rotating equipment sparks. Make sure guards are fitted to all moving parts

Damaged grinding disc Ensure the proper use of guards

Electrocution. Make sure that disc is compatible with the grinding

High Pressure air machine

Flying object/eye injuries Check the RPM of disc & machine

fire Proper PPE (Gloves + Mask).

Correct installation of Grinder Wheel.

Only experienced personnel to use the equipment.

Wear a face shield while grinding

Make sure fire extinguishers are available on site

Before starting welding make sure the area is clear of all

types of combustible materials

THE PROVISION OF PIPELINE INSTALLATION

SERVICES

SMG1 FLOWLINE PROJECT

JSA

CONTRACT N°……………………………………………………………….. Rev: 0

Page: 2 of 2

Welding Fire Hazard Before starting welding make sure the area is clear of all

Burns. types of combustible materials

Electrocution/ Spatter burns Provide a fire blanket on site

Damage cable Make sure fire extinguishers are available on site

Hot tabs end pieces of Wear proper PPE for welding i.e., leather jackets, Gloves,

welding rods. welding goggles/welding mask,

Sparking Certified Equipment and to be sited as near as possible to

Damage cable work site.

Proper earthling of equipment.

Certified Welder.

Make sure spark containment is used such as a welding

hood/fire blanket.

Ensure that rod holder is in good condition.

Use proper cable connector for extension.

The welder & the welder helpers must wear welding goggles

You might also like

- 1.JSA-Mechanical Work Hydrant InstallationDocument9 pages1.JSA-Mechanical Work Hydrant InstallationMuhammad Umar GondalNo ratings yet

- RA Mini Excavator MovementDocument3 pagesRA Mini Excavator MovementFrancis Enriquez Tan50% (2)

- Working at HeightsDocument2 pagesWorking at HeightsDoo PLTGU100% (1)

- JHA Fabrication WorkDocument4 pagesJHA Fabrication WorkRavi thokalNo ratings yet

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- Welding, Cutting and GrindingDocument6 pagesWelding, Cutting and GrindingMohammed MinhajNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- JSA Confined Sapce EntryDocument1 pageJSA Confined Sapce EntryprasongNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Electrical Work Permit: Smg1 Flowline ProjectDocument2 pagesElectrical Work Permit: Smg1 Flowline Projectghazi kallel33% (3)

- Confined Space Entry Permit: Smg1 Flowline ProjectDocument2 pagesConfined Space Entry Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- Master Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDocument6 pagesMaster Builders SA - Safe Work Method Statement - Timber Roof Truss Installation CraneDaniel JulianNo ratings yet

- Food DefenseDocument59 pagesFood DefensesatriawanNo ratings yet

- Metallurgical Coal SDSDocument5 pagesMetallurgical Coal SDSTirsa Iriani maya rinaNo ratings yet

- JSA For Welding of HVACDocument4 pagesJSA For Welding of HVACMohammed Minhaj100% (1)

- 3..hot Work ActivitiesDocument2 pages3..hot Work ActivitiesFrancis VinojNo ratings yet

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti Janardhanarao100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingWidodo D PrasetyoNo ratings yet

- Mig Welding Work JSA HSE ProfessionalsDocument2 pagesMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- JSA For Formwork (Shuttering)Document1 pageJSA For Formwork (Shuttering)HSE fahadNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- JSA For Hydrotesting PDFDocument6 pagesJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationD FiransyahNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA For HDPE SLEEVING DEL 89Document3 pagesJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- 19.hydro Pressure Testing.Document8 pages19.hydro Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- MTA2018-JHA-012 Air Compressor OperationDocument10 pagesMTA2018-JHA-012 Air Compressor OperationKelvin TanNo ratings yet

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorMohammed Minhaj100% (1)

- JSA For Work at HeightDocument3 pagesJSA For Work at Heightbagas prakoso100% (1)

- Jsa Bitumen Heating, Lying at DahejDocument6 pagesJsa Bitumen Heating, Lying at DahejJayavant LoharNo ratings yet

- JHA Formation Preparation or Leveling.Document2 pagesJHA Formation Preparation or Leveling.Mark Buendia100% (1)

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- 11.pneumatic Pressure Testing.Document7 pages11.pneumatic Pressure Testing.Mohammad Fazal KhanNo ratings yet

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahNo ratings yet

- 6-R A For Handling, Storage and Use of Gas CylindersDocument4 pages6-R A For Handling, Storage and Use of Gas CylindersMohamedSaidNo ratings yet

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- JHA Jack Hydraulic PalletDocument1 pageJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- Working at Height - JHA-1Document13 pagesWorking at Height - JHA-1Burhan KhanNo ratings yet

- HIRA-Metalic Pipe ErectionDocument13 pagesHIRA-Metalic Pipe ErectionShams Tabrez100% (2)

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- 008 JSA - Manual BoringDocument3 pages008 JSA - Manual BoringMohammed MinhajNo ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- JSA 04 Confined Sapce EntryDocument1 pageJSA 04 Confined Sapce Entrywahyu nugrohoNo ratings yet

- JSA For Installation of Precast SlabDocument4 pagesJSA For Installation of Precast SlabMohammed Minhaj100% (3)

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- HEAT Job Safety Analyisis (JSA)Document6 pagesHEAT Job Safety Analyisis (JSA)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Jsa Insulation WorkDocument20 pagesJsa Insulation WorkazerNo ratings yet

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pages2020 06 17 JSA For AC Servicing-Server RoomDarren OscarNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Jsa Ground Grid MocksvilleDocument2 pagesJsa Ground Grid MocksvilleChristopher NewbyNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Jsa-001 Manual Handling & Heavy LiftingDocument2 pagesJsa-001 Manual Handling & Heavy LiftingDamien Monize100% (1)

- JHA - Gas Cutting For ReferenceDocument2 pagesJHA - Gas Cutting For ReferenceNarayanKavitakeNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document2 pagesJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallel100% (1)

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document7 pagesJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document2 pagesJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Excavation Permit: Smg1 Flowline ProjectDocument2 pagesExcavation Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- Accident Incident Reporting and Investigation PolicyDocument9 pagesAccident Incident Reporting and Investigation Policyghazi kallelNo ratings yet

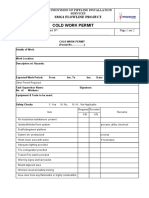

- Cold Work Permit: Smg1 Flowline ProjectDocument2 pagesCold Work Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- DRRR ReportDocument50 pagesDRRR ReportSTAR CHINEMA100% (1)

- Safety Induction Format: Job Procedure No: Project HDD & Associated Works For Chandragiri River For KKBMPL, Phase-IIDocument2 pagesSafety Induction Format: Job Procedure No: Project HDD & Associated Works For Chandragiri River For KKBMPL, Phase-IIIsrael Raja AbhilashNo ratings yet

- HACCPDocument11 pagesHACCPAyaaaa OmeyyNo ratings yet

- Rsa Sans Roadmap To Creating A World Class SocDocument1 pageRsa Sans Roadmap To Creating A World Class SocRoot100% (1)

- Vigon SDS US EnglishDocument14 pagesVigon SDS US EnglishFahad MaqsoodNo ratings yet

- Staff Training Slideshow 7-HACCPDocument20 pagesStaff Training Slideshow 7-HACCPHemen Sharadkumar UpadhyayaNo ratings yet

- 1326368294-HS6-19 Groundwork Excavation Risk AssessmentDocument1 page1326368294-HS6-19 Groundwork Excavation Risk AssessmentMianNo ratings yet

- Protocol For Storage and Handling of Hazardous Chemicals (Qh-ptl-275!3!1)Document23 pagesProtocol For Storage and Handling of Hazardous Chemicals (Qh-ptl-275!3!1)kanakarao1100% (1)

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Job Safety Analysis (Jsa) & Safe WorkmethodDocument29 pagesJob Safety Analysis (Jsa) & Safe WorkmethodHong Hai PhamNo ratings yet

- Nebosh Igc-1 Important Questions and AnswersDocument9 pagesNebosh Igc-1 Important Questions and AnswersWafula RobertNo ratings yet

- The Principles of Infection Prevention and ControlDocument25 pagesThe Principles of Infection Prevention and ControlRamona Lazurca100% (1)

- Occupational Health & Safety System ISO-18000Document12 pagesOccupational Health & Safety System ISO-18000A KNo ratings yet

- Lesson 4: Practice Occupational Safety and HealthDocument26 pagesLesson 4: Practice Occupational Safety and HealthNorman PolilinNo ratings yet

- Grinding: Thermax Engineering Construction Co. LTD Operational Control ProcedureDocument2 pagesGrinding: Thermax Engineering Construction Co. LTD Operational Control ProcedureNagendra Kumar SinghNo ratings yet

- Creating A Safety ProgramDocument127 pagesCreating A Safety ProgramSayed Darwish100% (1)

- Ci̇dezyme MSDS PDFDocument5 pagesCi̇dezyme MSDS PDFmochkurniawanNo ratings yet

- GDN 227Document31 pagesGDN 227Vasant Kumar Varma100% (2)

- Axial Group H&S Profile 052019Document11 pagesAxial Group H&S Profile 052019Heramb TrifaleyNo ratings yet

- Hazard Identification & Risk Assessment RegisterDocument1 pageHazard Identification & Risk Assessment RegisterHafiz Arshad100% (1)

- An Introduction To Health and Safety (Hindi)Document72 pagesAn Introduction To Health and Safety (Hindi)HealthSafety92% (13)

- QRG - Arc Flash PPE (Arcppe)Document1 pageQRG - Arc Flash PPE (Arcppe)Mohamed rasheed50% (2)

- MSDS Mechanix OrangeDocument7 pagesMSDS Mechanix OrangeDania Yesenia Rodriguez MoranNo ratings yet

- Form (Azard Dentification, Isk Ssessment, Isk, Ontrol) : Hirarc H I R A R CDocument2 pagesForm (Azard Dentification, Isk Ssessment, Isk, Ontrol) : Hirarc H I R A R CChezy629100% (1)

- IsiXosa 10 To 12 Adverts & Cartoon Isibhengezo Ntengiso NekhathuniDocument8 pagesIsiXosa 10 To 12 Adverts & Cartoon Isibhengezo Ntengiso NekhathuniSiphoNo ratings yet