Professional Documents

Culture Documents

Break Down Maintenance Process Flow Diagram: Start Finish

Uploaded by

fahadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Break Down Maintenance Process Flow Diagram: Start Finish

Uploaded by

fahadCopyright:

Available Formats

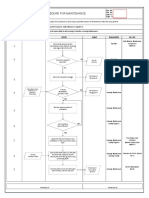

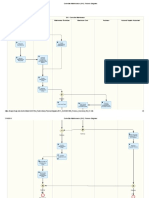

BREAK DOWN MAINTENANCE PROCESS FLOW DIAGRAM

START

Finish

Doc No: MH-Maint-31

FEED BACK TO PRODUCTION REQUEST

GENERATION

FEED BACK TO QUALITY

REQUEST RECIVED

BY ENGINEERING

REJECT /REPLACE MATRIAL

OR ADJUST MACHINE SETTING

ASSIGN

TECHNICIAN

INITIAL RM /PM QUALITY ISSUE

INSPECTION

BD report DOC #MH -Maint-31

01

If Minor fault

02

FAULT If Process failure Failure

FILL REQUIRE Repair

Finish DOCUMENTS TYPE ? TYPE ?

/Fix issue

BD record DOC # MH -Maint-14

03 If Major fault If Machine issue

FEED BACK TO

PRODUCTION

If parts delivery takes extra time

MACHINE SETTING ISSUE

IF NO

CRITICAL PARTS AVAILIBILITY IN CAN WE IF NO

LOCAL MARKET FIX? Require external support / OEM

support (Non- Spare parts)

RECTIFY MACHIEN SETTING

ORDER PARTS YES CHECK AND UPDATE

CL STANDARD

GET EXTERNAL SUPPORT MH-ENG-CL -01

SPARE PARTS ISSUE REQUEST

RECIVE PARTS

RECIVE PARTS FILL REQUIRE

DOCUMENTS

HANDOVER PARTS TO TEAM

FOR REPLCEMENT

DOC # MH -Maint-14

ASSIGN TEAM

DOC #MH -Maint-31

Finish

HANDOVER PARTS TO TEAM

FOR REPLCEMENT

PERFORME

MAINTENANCE

Follow SOP MH-SOP-ENG-01/ MH-SOP-ENG-03

CREATE REQUIRE

DOCUMENTS BD record DOC # MH -Maint-14

BD record DOC # MH -Maint-31

MACHINE TESTING

SANITIZATION /

CLEANING

AFTER MAINTENANCE Doc No: MH-Maint-19

CHECKLIST

NOT OK

QUALITY Quality sing after maintenance MH-Maint-19

INSPECTION

OK

HAND OVER TO LEGENDS:

PRODUCTIN

01 Minor Stop : require less than 15mints

machine adjustment to resolve

02 Process failure :Machine parameter setting or

FINISH machine stop due product quality.

03 Major Stop : require more than 15mints

machine adjustment /parts change to resolve

You might also like

- A320 Exterior Placards Catalogue (Approved)Document375 pagesA320 Exterior Placards Catalogue (Approved)Jan kopáček100% (1)

- Design Thinking for Business Growth: How to Design and Scale Business Models and Business EcosystemsFrom EverandDesign Thinking for Business Growth: How to Design and Scale Business Models and Business EcosystemsNo ratings yet

- Strategy Implementation, Evaluation and ControlDocument6 pagesStrategy Implementation, Evaluation and Controlbonny MishNo ratings yet

- MARY, Woman of Faith, Hope, Love (Lyrics & Chords)Document2 pagesMARY, Woman of Faith, Hope, Love (Lyrics & Chords)Jessa Marie Maquiling88% (8)

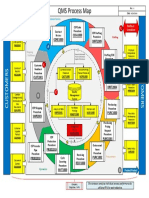

- QM Process Map PDFDocument1 pageQM Process Map PDFghafoorian_khoshgovar148850% (2)

- Worksheet GlobeDocument1 pageWorksheet GlobeJolens VelasquezNo ratings yet

- Brand Awareness Questionnaire SampleDocument2 pagesBrand Awareness Questionnaire SampleYogesh Sangani77% (13)

- CCR 980NG AbkDocument13 pagesCCR 980NG AbkSMKN 6 SAMARINDA PANGESTUNo ratings yet

- Part M - The Big PictureDocument1 pagePart M - The Big PictureSamuel ForemanNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- G2 Garage Breakdown Report July 2021Document54 pagesG2 Garage Breakdown Report July 2021sanjay ohriNo ratings yet

- NRC Flow ProcessDocument1 pageNRC Flow ProcessSutarto SutartoNo ratings yet

- 447 Final Inspn Edited PDFDocument3 pages447 Final Inspn Edited PDFATHIBAN VNo ratings yet

- Mirdc Work From Home Arrangements: Weekly Accomplishment ReportDocument22 pagesMirdc Work From Home Arrangements: Weekly Accomplishment ReportImags GamiNo ratings yet

- Atik Potential Failure Mode and Effect Analysis (Process Fmea)Document2 pagesAtik Potential Failure Mode and Effect Analysis (Process Fmea)prasad sapareNo ratings yet

- Contoh PROSES BISNIS (VER. 1.0)Document1 pageContoh PROSES BISNIS (VER. 1.0)lutvieka95.len.len11No ratings yet

- Service Repair Enabler With / Without MaterialDocument1 pageService Repair Enabler With / Without MaterialSatisNo ratings yet

- Fmea Main 1Document9 pagesFmea Main 1krishnan selvanNo ratings yet

- Epic FSBDocument12 pagesEpic FSBjoseNo ratings yet

- MDC - Maintenance Management System For SAP © 18 December 2018Document1 pageMDC - Maintenance Management System For SAP © 18 December 2018Riza BagusNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- 5051 - APU StarterDocument4 pages5051 - APU StarterMarty SmallwoodNo ratings yet

- Ford Supplement K TemplateDocument3 pagesFord Supplement K TemplateelevendotNo ratings yet

- Procedure For MaintenanceDocument2 pagesProcedure For MaintenanceAnmol ChetriNo ratings yet

- PSW Signature TemplateDocument1 pagePSW Signature TemplateKM MuiNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document1 pagePotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- Broken Needle Change Process FlowDocument1 pageBroken Needle Change Process FlowKamal NayanarangaNo ratings yet

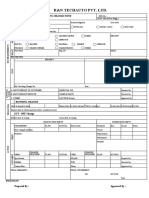

- R&N Techauto Pvt. LTD.: Engineering Change NoteDocument3 pagesR&N Techauto Pvt. LTD.: Engineering Change NoteUttrakhand Vibes- OriginalNo ratings yet

- Emergency Action Plan DibbaDocument6 pagesEmergency Action Plan Dibbaabisankar333No ratings yet

- Sims Report c18 PT Dendymarker Indah Lestari So 8600445523Document1 pageSims Report c18 PT Dendymarker Indah Lestari So 8600445523Teguh Prabowo CenaNo ratings yet

- Abnormal Handling RuleDocument1 pageAbnormal Handling RuleSuraj RawatNo ratings yet

- FAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Document7 pagesFAR 8600041294 - PTP - Engine Black Smoke 16DZ0186Fros DiamonNo ratings yet

- Service Report: General InformationDocument3 pagesService Report: General Informationjerald noblezaNo ratings yet

- Facility Requirement & Evaluation Sheet: For Production IncreaseDocument1 pageFacility Requirement & Evaluation Sheet: For Production IncreaseAlfi BachtiarNo ratings yet

- Sandhar Components, Bawal Matrix For Abnormal Situation For Paint ShopDocument1 pageSandhar Components, Bawal Matrix For Abnormal Situation For Paint Shoplalit rohillaNo ratings yet

- Appearance Approval ReportDocument2 pagesAppearance Approval ReportJosué PérezNo ratings yet

- Flow Diagrams TemplateDocument18 pagesFlow Diagrams TemplateNaveen Reddy KasarlaNo ratings yet

- PMD Process OverviewDocument1 pagePMD Process Overviewrezamae89No ratings yet

- 18 Management ReviewDocument1 page18 Management Reviewkumarnitesh173No ratings yet

- Matrix For 4 M Change ManagementDocument3 pagesMatrix For 4 M Change ManagementSuraj RawatNo ratings yet

- H0294281 CP UpdatedDocument2 pagesH0294281 CP UpdatedSandeep SinghNo ratings yet

- SFT 0090 Control PlanDocument24 pagesSFT 0090 Control PlanspdhimanNo ratings yet

- Sandhar Components, Bawal Matrix For Abnormal Situation For Machine ShopDocument1 pageSandhar Components, Bawal Matrix For Abnormal Situation For Machine Shoplalit rohillaNo ratings yet

- TerrainDocument1 pageTerrainMarty SmallwoodNo ratings yet

- Field Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Document2 pagesField Service Report: Trip Dispatch Arrival at Jobsite Travel Hour Mileage Date Time Date Time 1 2 3Henny Komala Sari SibaraniNo ratings yet

- SKH Metals LTD.: Process Control StanderdDocument2 pagesSKH Metals LTD.: Process Control StanderdshinuNo ratings yet

- PSACC Performance Evaluation Form - Rev - 27Jan2023-CRADDocument3 pagesPSACC Performance Evaluation Form - Rev - 27Jan2023-CRADcarlosraylandNo ratings yet

- Straero Part 21Document1 pageStraero Part 21Bogdan RusuNo ratings yet

- QAP (Honeycomb Fabric)Document4 pagesQAP (Honeycomb Fabric)Ahamed UmarNo ratings yet

- Rev2 - MRA-TEC-P02 HATS (GENERAL)Document10 pagesRev2 - MRA-TEC-P02 HATS (GENERAL)Mohd Harraz AbbasyNo ratings yet

- Sims Report Hydrostatic Main Control ValveDocument1 pageSims Report Hydrostatic Main Control ValveEdo FedricoNo ratings yet

- Material Safety Data Sheet FOR Co2 Recovery UnitDocument6 pagesMaterial Safety Data Sheet FOR Co2 Recovery Unitgudapati9No ratings yet

- S.O.P. Breakdown Maintenance of Equipment, Machinery and FacilityDocument1 pageS.O.P. Breakdown Maintenance of Equipment, Machinery and Facilitylive.shoaibNo ratings yet

- How To Do Focuses ImprovementDocument39 pagesHow To Do Focuses Improvementashutoshpal21No ratings yet

- Proforma For New Requirement/repairing of Computational ITEMDocument1 pageProforma For New Requirement/repairing of Computational ITEMvarun3dec1No ratings yet

- KWPG2-EN-FRM-009 REV C FMEA-Bracket KUDocument8 pagesKWPG2-EN-FRM-009 REV C FMEA-Bracket KUMyst ToganNo ratings yet

- TH460 Service Report 023832Document1 pageTH460 Service Report 023832eskully92No ratings yet

- MTC - Materi Dojo SPVDocument13 pagesMTC - Materi Dojo SPVFXRianWicaksonoNo ratings yet

- Corrective Maintenance (BH1) - Process DiagramsDocument2 pagesCorrective Maintenance (BH1) - Process DiagramsAsfar100% (1)

- Zodiac Aerospace Services: Letter of TransmittalDocument146 pagesZodiac Aerospace Services: Letter of Transmittalfernando he100% (1)

- Xerox: OrdinaryDocument1 pageXerox: Ordinaryvijay kumarNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document37 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- PM PillarDocument56 pagesPM PillarjesusmemNo ratings yet

- Employee Performance Appraisal Section A - Identifying Information Employee Name: Ernesto Ii P. Saldivar Job Title & DeptDocument4 pagesEmployee Performance Appraisal Section A - Identifying Information Employee Name: Ernesto Ii P. Saldivar Job Title & DeptAnn SaldivarNo ratings yet

- Unit 2Document42 pagesUnit 2Kalaiselvan PunniyamoorthyNo ratings yet

- Program Orientation HandoutsDocument125 pagesProgram Orientation Handoutsapi-391214898No ratings yet

- Pps Overview BrochureDocument15 pagesPps Overview BrochureizzybjNo ratings yet

- 24 - Mubangizi-WHOPQP GMP Inspections UpdatesDocument17 pages24 - Mubangizi-WHOPQP GMP Inspections UpdatessamxuNo ratings yet

- Lesson 2 - Língua Inglesa 7Document21 pagesLesson 2 - Língua Inglesa 7Shara Maria Venâncio SilvaNo ratings yet

- Facilities 2013 SG - Full Time, 2nd YearDocument49 pagesFacilities 2013 SG - Full Time, 2nd Yearsaifasad100% (2)

- Activity Sheets Q1 - SVADocument5 pagesActivity Sheets Q1 - SVAAlma ReynaldoNo ratings yet

- Economics Key WordsDocument30 pagesEconomics Key WordsJanetNo ratings yet

- Chapter 3 QuantiDocument5 pagesChapter 3 QuantiChristine NavidadNo ratings yet

- Geometry Sparkcharts Geometry Sparkcharts: Book Review Book ReviewDocument3 pagesGeometry Sparkcharts Geometry Sparkcharts: Book Review Book ReviewAyman BantuasNo ratings yet

- Projects & Operations: IN: NE Power Systm ImprvmDocument5 pagesProjects & Operations: IN: NE Power Systm ImprvmGaurang PatelNo ratings yet

- Structure Fires Caused by Hot Work: Marty AhrensDocument14 pagesStructure Fires Caused by Hot Work: Marty AhrensBurgosg ValeryNo ratings yet

- General Office Administration Level 1 (CVQ) PDFDocument129 pagesGeneral Office Administration Level 1 (CVQ) PDFddmarshall2838No ratings yet

- Exercises - PronounsDocument3 pagesExercises - PronounsTerritório PBNo ratings yet

- STEPOSOLMET10 UHousehold Cleaning Sales ToolDocument2 pagesSTEPOSOLMET10 UHousehold Cleaning Sales Toolpkh29No ratings yet

- Statistics II Week 6 HomeworkDocument3 pagesStatistics II Week 6 Homeworkteacher.theacestudNo ratings yet

- A321 DIFFERENCE GUIDE From A320Document72 pagesA321 DIFFERENCE GUIDE From A320NigelNo ratings yet

- HECKMAN, J. James - Schools, Skills and SynapsesDocument36 pagesHECKMAN, J. James - Schools, Skills and SynapsesAndré Gonçalves OliveiraNo ratings yet

- Agitated Thin Film Dryer ClaculationDocument12 pagesAgitated Thin Film Dryer ClaculationakaashNo ratings yet

- Snigdha Chaturvedi PDFDocument5 pagesSnigdha Chaturvedi PDFHitesh KohliNo ratings yet

- Digital ThermometerDocument28 pagesDigital ThermometerRajith SebastianNo ratings yet

- BDU-BIT-Electromechanical Engineering Curriculum (Regular Program)Document187 pagesBDU-BIT-Electromechanical Engineering Curriculum (Regular Program)beselamu75% (4)

- 300 Top Fluid Mechanics Multiple Choice Questions With Answers PDFDocument20 pages300 Top Fluid Mechanics Multiple Choice Questions With Answers PDFpiluNo ratings yet

- Technical Specifications Technical Specifications: Optional Equipment MeasurementsDocument1 pageTechnical Specifications Technical Specifications: Optional Equipment MeasurementsBjorn IsakssonNo ratings yet

- The Top Level Diagram Is A Use Case Diagram That Shows The Actors andDocument5 pagesThe Top Level Diagram Is A Use Case Diagram That Shows The Actors andsin2pNo ratings yet