Professional Documents

Culture Documents

Risk Analysis & Contigency Plan For Devlivery of Product

Uploaded by

tavhare kisanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Analysis & Contigency Plan For Devlivery of Product

Uploaded by

tavhare kisanCopyright:

Available Formats

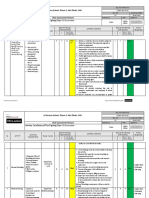

Risk Analysis & Contingency Plan for Delivery of product

MICRON CONTROL GAUGES & INSTRUMENTS

Sr. Present controls

No DETECTION RPN

POTENTIAL EFFECT OF POTENTIAL CAUSES OF CONTIGENCY

1. RISK PARAMETER FAILURE SEVERITY OCCURENCE FAILURE Prevention Detection PLAN

2 Power Failure Delivery commitments likely to fail. 3 1 2 6 non availability of Gen set Gen set available N/A

1.Preventive maintenance is

Preventive

Delivery commitments likely to fail 1.Preventive maint.not done. done as per QMSP

3 UTM machine breakdown effect on business 2 2 3 12 2.Immediate breakdown procedure.2. Alternate maintenance

machines are available machines

1. Callibration is done as per

4 non availability of Measuring Delivery commitments likely to fail. 1 2 1 2 Instruments/ Gauge value out of plan. 2. Spare instruments/ verification

instruments, gauges & fixtures acceptance criteria Gauge are available callibration certificate

tool room machine breakdown Preventive

5 Delivery commitments likely to fail 2 2 3 12 1.Preventive maint.not done. 1.Preventive maintenance is maintenance

effect on business 2.Immediate breakdown done as per QMSP procedure. machines

1. Supplier approval is done as

packing material, , 1. non availability of material with

per purchasing procedure. 2. Monitoring supplier

6 not supply by supplier Delivery commitments likely to fail. 2 2 3 12 supplier. 2.Supplier loaded with

Alternate suppliers developed performance

other customer order

non availability of Lens Fitter, Head Multi skill Personel are

7 Ban fitter Delivery commitments likely to fail. 2 2 2 8 Absent of Personnnel leave approval

Available

1.Preventive maintenance is

1.Machine problem. 2. non done as per QMSP

Delivery commitments likely to fail availability of competent procedure.2.selection

8 Rejection during process 2 2 2 8 100% Inspection

effect on business personnel.3.use of non callibrated personnel as per competency

Instruments requirements.3.Callibration is

done as per plan

Preventive

9 DG breakdown Delivery commitments likely to fail 2 2 3 12 1.Preventive maint.not done. 1.Preventive maintenance is maintenance

effect on business 2.Immediate breakdown done as per QMSP procedure. machines

Prepared By Approved By

You might also like

- Vacuum Test Risk AssessmentDocument6 pagesVacuum Test Risk AssessmentJohn Mark Macoy100% (1)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk and Opportunity RegisterDocument7 pagesRisk and Opportunity RegisterSandeep B100% (1)

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Risk Assessment For Laying of Pipes TextDocument3 pagesRisk Assessment For Laying of Pipes TextBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDocument15 pagesNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasNo ratings yet

- Dresding Medical Pom Case StudyDocument8 pagesDresding Medical Pom Case StudyPraveen Trivedi100% (4)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Example JSA Job Safety AnalysisDocument13 pagesExample JSA Job Safety AnalysisSiti MaisarahNo ratings yet

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (5)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- PMP Flash Cards: 244 Madison Ave, New YorkDocument19 pagesPMP Flash Cards: 244 Madison Ave, New YorkMMNo ratings yet

- Quality AssuranceDocument1 pageQuality AssuranceMarisa Signar100% (1)

- Commercial Interested Parties Needs Expectations As Per IMSDocument6 pagesCommercial Interested Parties Needs Expectations As Per IMSAnkurNo ratings yet

- Shyam Enterprises - Unit - Ii Contingency Plan For Abnormal ConditionsDocument4 pagesShyam Enterprises - Unit - Ii Contingency Plan For Abnormal Conditionsঅর্ঘ্য রায়No ratings yet

- General Concept of Preventive MaintenanceDocument11 pagesGeneral Concept of Preventive MaintenanceSayed NagyNo ratings yet

- NDT RaDocument8 pagesNDT RaHassanNo ratings yet

- Risk Assessment FormDocument1 pageRisk Assessment FormALICIA JOYCE MALAPADNo ratings yet

- INTRO To MaintenanceDocument76 pagesINTRO To MaintenancehwhhadiNo ratings yet

- Fundamental Process Control: Butterworths Series in Chemical EngineeringFrom EverandFundamental Process Control: Butterworths Series in Chemical EngineeringNo ratings yet

- INTRO To MaintenanceDocument76 pagesINTRO To MaintenancehwhhadiNo ratings yet

- LLC Tatneft-Samara Sales and Purchase Agreement (Spa) Issued To Future Engineering & Gold Mining Co., LTD (En590-10ppm)Document16 pagesLLC Tatneft-Samara Sales and Purchase Agreement (Spa) Issued To Future Engineering & Gold Mining Co., LTD (En590-10ppm)TCL T100% (1)

- Risk Analysis & Contigency Plan For Devlivery of ProductDocument1 pageRisk Analysis & Contigency Plan For Devlivery of Producttavhare kisanNo ratings yet

- Idle FinanceDocument26 pagesIdle Financeali razaNo ratings yet

- Risk Analysis Corrosion Protection Engineers IndiaDocument3 pagesRisk Analysis Corrosion Protection Engineers IndiaRajeshNo ratings yet

- Risk Assessment MatrixDocument2 pagesRisk Assessment MatrixRubie Anne SaducosNo ratings yet

- IMS-FR-FS-28 Process Food Defense (Mandalay) Ver 001 Eff 02.11.18Document4 pagesIMS-FR-FS-28 Process Food Defense (Mandalay) Ver 001 Eff 02.11.18Ko HeinNo ratings yet

- F-QMS-07 Minutes of MRM - 02-21-22Document3 pagesF-QMS-07 Minutes of MRM - 02-21-22pradeep.jagdhaniNo ratings yet

- Doc5.hirard PilingDocument3 pagesDoc5.hirard PilingJames JoviNo ratings yet

- Dell 3400 LCD FmeaDocument13 pagesDell 3400 LCD Fmeaarif.fahmiNo ratings yet

- MPT RaDocument9 pagesMPT RaHassanNo ratings yet

- Audit Program - Inventory Management - RRRDocument9 pagesAudit Program - Inventory Management - RRRashishhpandey99No ratings yet

- ISO9001 Risk RegisterDocument2 pagesISO9001 Risk RegisterAlan PainterNo ratings yet

- Chapter 7 Larson Project ManagementDocument10 pagesChapter 7 Larson Project ManagementHaddistNo ratings yet

- GOVBUS g3 5Document6 pagesGOVBUS g3 5Ivan Jay EsminoNo ratings yet

- Project Risk Register Drone Delivery 1.0: Risk Identification Qualitative Rating Risk ResponseDocument1 pageProject Risk Register Drone Delivery 1.0: Risk Identification Qualitative Rating Risk Responsefreddy ramdinNo ratings yet

- Fmea Guide q1Document161 pagesFmea Guide q1Mahesh VaneNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- Supply Chain ObjectivesDocument1 pageSupply Chain ObjectivesAnis Hanani Abd Mu'minNo ratings yet

- Final Vaccine Regulatory Oversight in Indonesia - Workshop OIC-KemenkesDocument24 pagesFinal Vaccine Regulatory Oversight in Indonesia - Workshop OIC-KemenkesSherwin ArmandaNo ratings yet

- Assessment Review: 2 Risk Analysis and Action Plan: Running HeadDocument9 pagesAssessment Review: 2 Risk Analysis and Action Plan: Running HeadsorwclghtthgpvhwjxNo ratings yet

- Risk & Opportunity Assessment Worksheet: For Fiscal Year 2023 - 2024Document4 pagesRisk & Opportunity Assessment Worksheet: For Fiscal Year 2023 - 2024qa.dpo.complianceNo ratings yet

- 08-2-Resource Allocation-0002 Corona Contingency ProcedureDocument2 pages08-2-Resource Allocation-0002 Corona Contingency ProcedureAllocation ResourceNo ratings yet

- Contingency PlanDocument1 pageContingency PlanManoharar RNo ratings yet

- Verse Security AuditDocument6 pagesVerse Security AuditLeciaNo ratings yet

- Cross Docking Distribution - Project ManagementDocument48 pagesCross Docking Distribution - Project ManagementOshini WimalasenaNo ratings yet

- AIAG Guidelines FOR FmeaDocument1 pageAIAG Guidelines FOR Fmeakumarkk1969No ratings yet

- Work Instructions Work Instructions: Display Standard-Assembly & FirewallDocument7 pagesWork Instructions Work Instructions: Display Standard-Assembly & Firewallshobha shelarNo ratings yet

- 1.initial Risk Identification Evalu-CS 18116246 - (DAYUNG-3)Document2 pages1.initial Risk Identification Evalu-CS 18116246 - (DAYUNG-3)synyster92xNo ratings yet

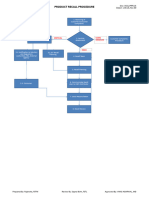

- Product RecallDocument4 pagesProduct Recalldileepkumar.gNo ratings yet

- ELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentDocument46 pagesELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentRavinder SharmaNo ratings yet

- Risk Assessment Plan: Focus On Health & Safety Risks in Three Main Activities of Flyover ConstructionDocument8 pagesRisk Assessment Plan: Focus On Health & Safety Risks in Three Main Activities of Flyover Constructionamnaakram996No ratings yet

- Risk Assessment For Stakeout ReportDocument3 pagesRisk Assessment For Stakeout ReportRussell EsperasNo ratings yet

- PNR 000190 Highlights EN - Rev00Document11 pagesPNR 000190 Highlights EN - Rev00CID MARTIOLINo ratings yet

- 07 - Risk ReductionxDocument20 pages07 - Risk ReductionxAdriana HubleaNo ratings yet

- SaddleFinance - Quantstamp AuditDocument12 pagesSaddleFinance - Quantstamp AuditF CNo ratings yet

- Security Thread and Vulnerability Assessment FormDocument5 pagesSecurity Thread and Vulnerability Assessment FormAmril Al RizaNo ratings yet

- SMM7 23Document1 pageSMM7 23Elmo CharlesNo ratings yet

- Risks Assessment-29april2020Document7 pagesRisks Assessment-29april2020NISARNo ratings yet

- Summer Placement Report MBA BA & MBA DT 2022-30 AprilDocument11 pagesSummer Placement Report MBA BA & MBA DT 2022-30 Apriltavhare kisanNo ratings yet

- Cresta Paints India Pvt. LTD Quality System Manual: CP/QPO/01Document1 pageCresta Paints India Pvt. LTD Quality System Manual: CP/QPO/01tavhare kisanNo ratings yet

- Kvqa Certification Services PVT - Ltd. Dubai (Dac Accridation)Document1 pageKvqa Certification Services PVT - Ltd. Dubai (Dac Accridation)tavhare kisanNo ratings yet

- Internal Audit 1Document1 pageInternal Audit 1tavhare kisanNo ratings yet

- Cresta Paints India Pvt. LTD Quality System Manual: CP/QPO/01Document1 pageCresta Paints India Pvt. LTD Quality System Manual: CP/QPO/01tavhare kisanNo ratings yet

- Micron Control Gauges & Instruments Process Sequence & InteractionsDocument2 pagesMicron Control Gauges & Instruments Process Sequence & Interactionstavhare kisanNo ratings yet

- Kisan Sopan Tavhare Experience Letter PDFDocument1 pageKisan Sopan Tavhare Experience Letter PDFtavhare kisanNo ratings yet

- Quality Structure 3Document1 pageQuality Structure 3tavhare kisanNo ratings yet

- Shiva Tech Engineering: STE/WI/01Document5 pagesShiva Tech Engineering: STE/WI/01tavhare kisanNo ratings yet

- Department of Electronics & Communication Engineering: Government Polytechnic, BeedDocument1 pageDepartment of Electronics & Communication Engineering: Government Polytechnic, Beedtavhare kisanNo ratings yet

- Road Map For Krishna and Varad AlloyDocument5 pagesRoad Map For Krishna and Varad Alloytavhare kisanNo ratings yet

- Scrutiny Letter 04 Jun 2019Document2 pagesScrutiny Letter 04 Jun 2019tavhare kisanNo ratings yet

- Catering MenuDocument11 pagesCatering Menutavhare kisanNo ratings yet

- Authorization FormatDocument1 pageAuthorization Formattavhare kisanNo ratings yet

- Process Engineering Manager 1584877653Document2 pagesProcess Engineering Manager 1584877653azerty KuwaitNo ratings yet

- Akuntansi BiayaDocument4 pagesAkuntansi BiayaIntan Bella YuspramanaNo ratings yet

- B Com - Iv - Atkt - 2022Document1 pageB Com - Iv - Atkt - 2022Krish BuchaNo ratings yet

- Documentos Do 2105442Document19 pagesDocumentos Do 2105442juanNo ratings yet

- Shishir Hari Rajbhandari Nepal Case Analysis of Sears Changes Again and Again SynopsisDocument3 pagesShishir Hari Rajbhandari Nepal Case Analysis of Sears Changes Again and Again SynopsisrajbhandarishishirNo ratings yet

- 22 27351 002 Matter 1 1 Device Library SpecificationDocument95 pages22 27351 002 Matter 1 1 Device Library Specificationcagona5339No ratings yet

- Child Safeguarding Audit Report - TemplateDocument7 pagesChild Safeguarding Audit Report - TemplateLopes CassamáNo ratings yet

- Shaquille Clarke OSH 210 AssignmentDocument12 pagesShaquille Clarke OSH 210 Assignmentshaquillle clarkeNo ratings yet

- Corporate Governance Mallin Chapter 1: Prof. Dr. Laxmi RemerDocument13 pagesCorporate Governance Mallin Chapter 1: Prof. Dr. Laxmi RemeransarNo ratings yet

- InstallmentDocument10 pagesInstallmentNiki DimaanoNo ratings yet

- 25 Lean ToolsDocument26 pages25 Lean ToolsArif SantosoNo ratings yet

- Artikel Ilmiah IntanDocument6 pagesArtikel Ilmiah IntanFikri YasriNo ratings yet

- Dwnload Full Horngrens Cost Accounting A Managerial Emphasis 16th Edition Datar Solutions Manual PDFDocument36 pagesDwnload Full Horngrens Cost Accounting A Managerial Emphasis 16th Edition Datar Solutions Manual PDFaffluencevillanzn0qkr100% (10)

- General ExpenseDocument13 pagesGeneral ExpenseVina NafidzaNo ratings yet

- ReporteDocument63 pagesReporteRicardo RamosNo ratings yet

- SERVICE MANAGEMENT Unit 3Document10 pagesSERVICE MANAGEMENT Unit 3Parth KumarNo ratings yet

- Needs Prioritisation MethodsDocument20 pagesNeeds Prioritisation MethodsWALTER simsokweNo ratings yet

- Test Bank For Financial Accounting 4th Edition Paul D KimmelDocument46 pagesTest Bank For Financial Accounting 4th Edition Paul D KimmelMai SươngNo ratings yet

- Project Management A Managerial Approach 10th Edition Meredith Test BankDocument36 pagesProject Management A Managerial Approach 10th Edition Meredith Test Bankincubousbrocard.u8eo02100% (12)

- Bid Evaluation Report and Recommendation For Award of ContractDocument11 pagesBid Evaluation Report and Recommendation For Award of ContractAddisu TsegayeNo ratings yet

- B - Communication Management PlanDocument1 pageB - Communication Management PlanBig FleaNo ratings yet

- CBM 001 Activity#3 MidtermDocument4 pagesCBM 001 Activity#3 MidtermTrisha SacmanNo ratings yet

- 236 File725457078Document260 pages236 File725457078GANESH KUNJAPPA POOJARINo ratings yet

- How To Get and Write A Testimonial Letter That Will Increase Your Business!Document10 pagesHow To Get and Write A Testimonial Letter That Will Increase Your Business!Mobile MentorNo ratings yet

- Jurnal Skripsi Siska Nur IndahsariDocument9 pagesJurnal Skripsi Siska Nur IndahsariAnisa QasanahNo ratings yet

- BBC International LTD 1t 24may2020 UbsDocument19 pagesBBC International LTD 1t 24may2020 Ubspezhmanbayat924No ratings yet

- Professional SalesmanshipDocument12 pagesProfessional SalesmanshipMarianne Bag-aoNo ratings yet