Professional Documents

Culture Documents

Itp-Mps-Hsaw Qa Awwa 001

Itp-Mps-Hsaw Qa Awwa 001

Uploaded by

Armando BiringkanaeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itp-Mps-Hsaw Qa Awwa 001

Itp-Mps-Hsaw Qa Awwa 001

Uploaded by

Armando BiringkanaeCopyright:

Available Formats

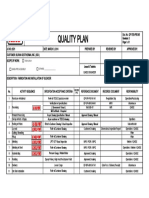

SUPPLIER : PT BAKRIE PIPE INDUSTRIES

COMPANY : PT PEMBANGUNAN PERUMAHAN (PERSERO),TBK

PROYEK SISTEM PENYEDIAAN AIR MINUM (SPAM)

LINTAS PEKANBARU-KAMPAR

0 26-04-2021 ISSUED FOR APPROVAL

Plant

QA QHSE

General Customer

Supervisor Manager

REV DATE DESCRIPTION Manager

Prepared by Reviewed by Approved by

INSPECTION AND TEST PLANT (ITP) FOR

DOC. NAME

HSAW BARE PIPE

DOC.

ITP-MPS-HSAW/QA/AWWA/001

NUMBER

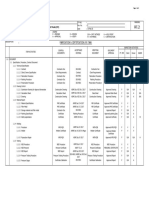

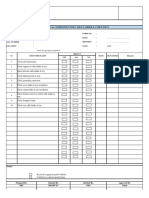

INSPECTION AND TEST PLAN DOC No. ITP-MPS-HSAW/QA/AWWA/001

PAGE No. 1 OF 2

REVISION 0

CUSTOMER : PT PEMBANGUNAN PERUMAHAN (PERSERO),TBK

RFQ / PO No. : DESCRIPTION OD 1016 mm (40.000 inch) x 10 mm (0.394 inch) WT x 12 mtr L (40 ft) DATE April 26th, 2021

AWWA C200 Latest Edition

INSPECTION

ITEM VERIFYING SURVEILLANCE

INSPECTION ACTIVITY BY CONTROL DOCUMENT ACCEPTANCE CRITERIA

No. DOCUMENT CODE

BPI CUSTOMER

1 Steel Making BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No II.3 Mill Certificate of HRC I R

2 Uncoiling and Leveling of the BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.4 I R

-

strip

3 Shearing and joining BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.5 - I R

4 Edge Preparation BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.6 - I R

5 Forming BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.7 - I R

6 BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.8 Welding Procedure I R

Inside & Outside Welding

Specification

7 Cutting off BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.9 - I R

8 Numbering BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.10 - I R

9 Visual and dimension inspection BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.11 First Inspection Report I R

10 BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.12 Welding Procedure I R

Repair by welding

Specification Repair

11 End cropping, sampling of test BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.13 I R

-

specimens

12 Product chemical analysis BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.14 Chemical Analysis Report I R

13 Tensile Test BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.14 Tensile Test Report I R

14 Guided Bend Test BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.14 Guided Bend Test Report I R

15 BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.14 Macro Examination I R

Etching Test

Report

16 Beveling BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.15 - I R

INSPECTION AND TEST PLAN DOC No. ITP-MPS-HSAW/QA/AWWA/001

PAGE No. 2 OF 2

REVISION 0

CUSTOMER : PT PEMBANGUNAN PERUMAHAN (PERSERO),TBK

RFQ / PO No. : DESCRIPTION OD 1016 mm (40.000 inch) x 10 mm (0.394 inch) WT x 12 mtr L (40 ft) DATE April 26th, 2021

AWWA C200 Latest Edition

INSPECTION

ITEM VERIFYING SURVEILLANCE

INSPECTION ACTIVITY BY CONTROL DOCUMENT ACCEPTANCE CRITERIA CODE

No. DOCUMENT

BPI CUSTOMER

17 Hydrostatic Test BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.16 Hydrostatic Test Report I R

18 Final inspection BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.17 Final Inspection Report I R

17 Marking BPI MPS-HSAW/QA/SNI/001 MPS-HSAW/QA/SNI/001, Procedure Section No III.2.18 - I R

KEY TO INSPECTION SURVEILLANCE CODE: H: HOLD POINT R: REVIEW POINT I: MANUFACTURER’S PROCESS & INSPECTION

M: MONITORING POINT, W: WITNESS POINT, IN CASE RESIDENT INSPECTOR ARE ASSIGNED BY CUSTOMER

You might also like

- Introduction To Financial Accounting 11th Edition Horngren Test BankDocument43 pagesIntroduction To Financial Accounting 11th Edition Horngren Test Bankmymaximiliandwo100% (34)

- Inspection and Test Plan - Pressure Vessel Fabrication (ITP)Document9 pagesInspection and Test Plan - Pressure Vessel Fabrication (ITP)Senthil Kumaran100% (2)

- Schaum's Outline of Principles of Accounting I, Fifth EditionFrom EverandSchaum's Outline of Principles of Accounting I, Fifth EditionRating: 5 out of 5 stars5/5 (3)

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- DT. 19.03.2021strategic Lead-Time ManagementDocument18 pagesDT. 19.03.2021strategic Lead-Time ManagementMohaimin Azmain NuhelNo ratings yet

- 1029 Itp Asme R.ADocument23 pages1029 Itp Asme R.AAnonymous dj2xK2XONo ratings yet

- ITP FOR Air Compressor PackageDocument1 pageITP FOR Air Compressor PackageAgus SuriptoNo ratings yet

- INSPECTION AND TEST PLAN PipingDocument4 pagesINSPECTION AND TEST PLAN PipingTaofik HidayatullohNo ratings yet

- Complete PackageDocument105 pagesComplete PackagesarangpuneNo ratings yet

- SATIP-W-013-01 Welding of Offshore Structures.Document5 pagesSATIP-W-013-01 Welding of Offshore Structures.mathew.genesis.inspNo ratings yet

- HSE Plan SubconDocument27 pagesHSE Plan SubconTaufan Arif Zulkarnain100% (1)

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Floating Ball ValvesDocument21 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Floating Ball ValvesXmanyeyNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Itp Pi 001 Piping Work RevDocument8 pagesItp Pi 001 Piping Work Revcrusher28No ratings yet

- Ongc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Document7 pagesOngc B-22 Field Development Project CONTRACT NO. MR/OW/MM/B-22/19/2008 NPCC Project No. 8118Ankit Kumar100% (1)

- P1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkDocument4 pagesP1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkEILA545 QAQCNo ratings yet

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- HSE Plan SubcontDocument22 pagesHSE Plan SubcontTaufan Arif ZulkarnainNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Steel TankDocument4 pagesSteel TankRanu JanuarNo ratings yet

- Nit 2800 3 PDFDocument7 pagesNit 2800 3 PDFAnonymous uXdS9Y7No ratings yet

- Protocol - 21-01-2022Document14 pagesProtocol - 21-01-2022systacare remediesNo ratings yet

- P1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkDocument9 pagesP1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkEILA545 QAQCNo ratings yet

- PP13 00 y QPT Gam 016 R0Document10 pagesPP13 00 y QPT Gam 016 R0Rıdvan UyarNo ratings yet

- ISO UT ProsedureDocument43 pagesISO UT ProsedureTotok Tj IndriantoNo ratings yet

- 26071-100-VSC-BD4-00028 - 00A - Work Method Statement For Bituminous Coating Rev.00A (R)Document13 pages26071-100-VSC-BD4-00028 - 00A - Work Method Statement For Bituminous Coating Rev.00A (R)rony_lesbtNo ratings yet

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- Satip N 110 01Document11 pagesSatip N 110 01jerinNo ratings yet

- Satip A 000 01Document10 pagesSatip A 000 01Akansha SharmaNo ratings yet

- Quality Assurance Plan - hd-99Document6 pagesQuality Assurance Plan - hd-99quality japtechNo ratings yet

- For Field Joint CoatingDocument8 pagesFor Field Joint Coatingrebbouche bilelNo ratings yet

- Majnoon CPF 2 Project: Fired Heater CP2-F-50701 A/B Coil Prefabrication Hydrostatic Test ProcedureDocument14 pagesMajnoon CPF 2 Project: Fired Heater CP2-F-50701 A/B Coil Prefabrication Hydrostatic Test ProcedureMassimo FumarolaNo ratings yet

- Receiving Material Procedure (Done) (Sudah Direvisi)Document8 pagesReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangNo ratings yet

- Itp Ash HandlingDocument4 pagesItp Ash HandlingPratama Trendy LeoNo ratings yet

- 2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02Document7 pages2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02teethai2524No ratings yet

- ITP For Main Line WeldingDocument8 pagesITP For Main Line Weldingrebbouche bilelNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Inspection & Test Plan Advance Valves Butterfly ValvesDocument2 pagesInspection & Test Plan Advance Valves Butterfly Valvessyed jafarNo ratings yet

- Npe SD Sqe Pip Ax4303 0009 Pad Leak TestDocument7 pagesNpe SD Sqe Pip Ax4303 0009 Pad Leak TestYulian Adhriansyah100% (1)

- ENV-SPV-DR-B-002 Inspection and Test Plan-Rev - ADocument4 pagesENV-SPV-DR-B-002 Inspection and Test Plan-Rev - AyoeyNo ratings yet

- Fabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Document3 pagesFabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Rifki HasyaNo ratings yet

- 04 - Product Traceability Procedure - Asf-Qc-Ptp-001Document5 pages04 - Product Traceability Procedure - Asf-Qc-Ptp-001Sherif Yehia0% (1)

- BK91-1310-CPF-000-QAC-ITP-0035 - A - ITP of Pipe Support Work-C1Document11 pagesBK91-1310-CPF-000-QAC-ITP-0035 - A - ITP of Pipe Support Work-C1Panneer SelvamNo ratings yet

- SVDN CPP I 0031 Q04 0001 Rev.00 Inspection and Test PlanDocument4 pagesSVDN CPP I 0031 Q04 0001 Rev.00 Inspection and Test PlanjfdlksaNo ratings yet

- (32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Document18 pages(32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Gordon LongforganNo ratings yet

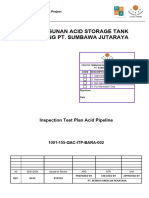

- 1001-155-QAC-ITP-BARA-002-Inspection and Test Plan (ITP)Document6 pages1001-155-QAC-ITP-BARA-002-Inspection and Test Plan (ITP)amirulardhian1996No ratings yet

- Quality Plan Fabrication and Installation of Silencer For BN6 & BN7Document1 pageQuality Plan Fabrication and Installation of Silencer For BN6 & BN7Aldrin HernandezNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Welding of Pipelines SATIP-W-012-01 31-Dec-14 Mechanicalpravin0% (1)

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument13 pagesSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289No ratings yet

- Final Protocol - Diasulin R Inj 100IUDocument49 pagesFinal Protocol - Diasulin R Inj 100IUrobin hasanNo ratings yet

- Approved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ADocument131 pagesApproved ITP - RTN - VS215B-101-A-PLN-7001 - 05 - Code ALionell Logesh0% (1)

- Saudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalpravinNo ratings yet

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Top Entry Ball ValvesDocument34 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Top Entry Ball ValvesXmanyeyNo ratings yet

- Quality Plan Fabrication and Installation of Silencer For BN4 & BN5Document1 pageQuality Plan Fabrication and Installation of Silencer For BN4 & BN5Aldrin HernandezNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalDocument4 pagesSaudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalpravinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilDocument11 pagesSaudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilKhurram ShehzadNo ratings yet

- Inspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok ADocument7 pagesInspection Test Plan: Provision To Supply and Delivery of V-Cone Flowmeter For Tiong A and Bekok AMUHAMMAD ABHAR AMZAR BIN ZAMZURINo ratings yet

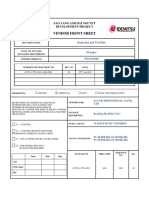

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocument7 pagesVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNo ratings yet

- 13 PT ProcedureDocument14 pages13 PT ProcedureThân KhaNo ratings yet

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Barracuda and Caratinga Crude Oil Fields ProductionDocument20 pagesBarracuda and Caratinga Crude Oil Fields Productionricky0201No ratings yet

- Codification of Statements on Auditing Standards: Numbers 122 to 133, January 2018From EverandCodification of Statements on Auditing Standards: Numbers 122 to 133, January 2018No ratings yet

- Book 1Document2 pagesBook 1Armando BiringkanaeNo ratings yet

- Electrical Completion Check List-Rev DDocument4 pagesElectrical Completion Check List-Rev DArmando BiringkanaeNo ratings yet

- Submittal For Document Weldeng Procedure Specification ApprovalDocument1 pageSubmittal For Document Weldeng Procedure Specification ApprovalArmando BiringkanaeNo ratings yet

- Chemical Building 01 MergedDocument27 pagesChemical Building 01 MergedArmando BiringkanaeNo ratings yet

- Katalog Suku Cadang Honda Tiger 2000Document58 pagesKatalog Suku Cadang Honda Tiger 2000Armando BiringkanaeNo ratings yet

- Item List FAT PP - SPAM Kampar PekanbaruDocument1 pageItem List FAT PP - SPAM Kampar PekanbaruArmando BiringkanaeNo ratings yet

- Georadar ManualDocument39 pagesGeoradar ManualArmando BiringkanaeNo ratings yet

- Ground Penetrating Radar For Locating Buried Utilities: Operation ManualDocument75 pagesGround Penetrating Radar For Locating Buried Utilities: Operation ManualArmando BiringkanaeNo ratings yet

- Materi - Analisa Produksi Tenaga KeejaDocument8 pagesMateri - Analisa Produksi Tenaga KeejaArmando BiringkanaeNo ratings yet

- 2.shwe Set 162'x30' Two Storeyed (Summary Furniture)Document4 pages2.shwe Set 162'x30' Two Storeyed (Summary Furniture)SandarNo ratings yet

- Research On The Application of Digital Marketing IDocument6 pagesResearch On The Application of Digital Marketing IBil AlNo ratings yet

- Massilly Closures RangeDocument4 pagesMassilly Closures RangePaolo MarinNo ratings yet

- Tompkins Supply Chain Leadership Forum Presentation 2016 Integrating Supply Chain and Merchandise PlanningDocument37 pagesTompkins Supply Chain Leadership Forum Presentation 2016 Integrating Supply Chain and Merchandise PlanningPaula Marie De GraciaNo ratings yet

- Joint Product by Product QuestionsDocument7 pagesJoint Product by Product QuestionsShibin XavierNo ratings yet

- Dell SCMDocument25 pagesDell SCMArun KumarNo ratings yet

- Iso 22301 Implementation Guide 2016 PDFDocument12 pagesIso 22301 Implementation Guide 2016 PDFTarnaveanValeriuDan100% (1)

- 8.0 Siebel OverviewDocument29 pages8.0 Siebel OverviewsubbaraocrmNo ratings yet

- Notice: Casualty and Nonperformance Certificates: Carie Freight, Inc. CorrectionDocument1 pageNotice: Casualty and Nonperformance Certificates: Carie Freight, Inc. CorrectionJustia.comNo ratings yet

- Module 5Document5 pagesModule 5minshairene9No ratings yet

- Vivek Bala 405) 501-8646: SummaryDocument3 pagesVivek Bala 405) 501-8646: SummaryVijay LS SolutionsNo ratings yet

- Business Process and Functional ModelingDocument26 pagesBusiness Process and Functional ModelingLim Soong XIanNo ratings yet

- Indian Toy Industry: TH STDocument17 pagesIndian Toy Industry: TH STkunal87No ratings yet

- ADF BPM IntegrationDocument39 pagesADF BPM IntegrationAkhil RangarajuNo ratings yet

- S105465GC10 Mod07 PDFDocument70 pagesS105465GC10 Mod07 PDFHsie HsuanNo ratings yet

- CH 08 PresentationDocument29 pagesCH 08 PresentationKhandelwal CyclesNo ratings yet

- Personal Computers - LOGISTICSDocument10 pagesPersonal Computers - LOGISTICSKAPIL MEHRA100% (1)

- Refinery Revenue Optimization: Mr. Dharmendra MehtaDocument17 pagesRefinery Revenue Optimization: Mr. Dharmendra MehtaSunil PillaiNo ratings yet

- New Melke TwoDocument62 pagesNew Melke TwotalilaNo ratings yet

- Creating Long Term Loyalty Relationships MarketingDocument39 pagesCreating Long Term Loyalty Relationships MarketingPRETZEL RAGONJANNo ratings yet

- Research Paper Is at DominosDocument6 pagesResearch Paper Is at Dominosssharma83No ratings yet

- Product Product Description: Description of The Steel Products Covered by The Worldsteel LCI StudyDocument2 pagesProduct Product Description: Description of The Steel Products Covered by The Worldsteel LCI Studychan channsreyrathNo ratings yet

- Introducing The Next Gen Operating Model PDFDocument127 pagesIntroducing The Next Gen Operating Model PDFAnirban Dasgupta100% (4)

- Nykaa BRM Report PDFDocument23 pagesNykaa BRM Report PDFKANIKA SACHANNo ratings yet

- Chapter 5&6Document9 pagesChapter 5&6Bhebz Erin MaeNo ratings yet

- Literature Review CRMDocument9 pagesLiterature Review CRMArshdeep SiinghNo ratings yet

- Chief Digital Officer Job Description Template - LinkedIn Talent SolutionsDocument4 pagesChief Digital Officer Job Description Template - LinkedIn Talent Solutionsasvn30No ratings yet

- Bicc White PaperDocument7 pagesBicc White PaperAhmedMuradNo ratings yet