Professional Documents

Culture Documents

TBE GRP PIPE SUBOR OFFRE - ZONE EAU DE MER-Eau Produite - SUBOR

Uploaded by

Bilel MahjoubOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TBE GRP PIPE SUBOR OFFRE - ZONE EAU DE MER-Eau Produite - SUBOR

Uploaded by

Bilel MahjoubCopyright:

Available Formats

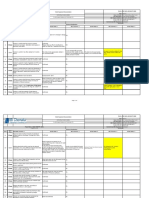

PROJET : « ETUDE, FOURNITURE ET INSTALLATION D’UNE STATION DE DESSALEMENT D’EAU DE MER A SOUSSE DE CAPACITE 50 000 m3/j –LOT N° 1- »

PROJECT NO. AR 15-17 ISSU'D CHK'D APP'D

DOCUMENT NO. Technical Bid Evaluation for GRP Pipes

AAB AMG MMH

REQ' NO. 01306-SPE-GEA-000-223-0001

REQUIREMENTS

H DEVIATIONS

Vendor to complete

I CLARIFICATIONS

I.1 All calculations by vendor shall be reviewed and approved by company Vendor to confirm Please check our Engineering Service Offer.

I.2 Installation, construction method of statement and construction supervision shall be part of vendor supply as per specification Vendor to confirm Please check our Engineering Service Offer.

I.3 Differential soil settlement calculation shall be perform by vendor Vendor to confirm Please check our Engineering Service Offer.

I.4 All construction drawing shall be part of scope and shall be generated by vendor Vendor to confirm Please check our Engineering Service Offer.

I.5 Installation spare part shall be supply from vendor Vendor to confirm Please check our Engineering Service Offer.

I.6 Construction supervision shall be part of vendor service for system guarantee. Vendor to confirm Please check our Engineering Service Offer.

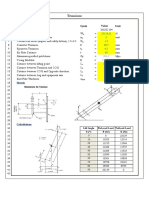

II STRESS REQUIREMENTS

The requested work for each station:

-Realize the calculation of stress / flexibility of lines in GRP, the work can be transmitted to the supplier in several independent batch depend of the case.

-Provide the descents of load which must be reasonable and acceptable to transfer them to the civil engineering department for the calculation of the

foundations,

-Propose the types of support according to the results of the calculations,

-Propose local GRP fitting reinforcements as needed.

II.1 - Provide the thicknesses of the pipes and fittings (if they must be out of standard) Vendor to confirm Please check our Engineering Service Offer.

- Provide the calculation report with a presentation of the results and recommendation (file word + model C II)

- desired execution time: Receipt of the first revision of the calculation report within (02) weeks from the date of the request.

The stress calculation must be done according to good practice and must take into consideration the following minimum requirements:

- Calculation according to the case of hydraulic load, service, design, earthquake and wind.

- Take into account the boundary conditions of the calculation object lines

- the charges on equipment connections (filter, tank, pump, etc.) must be verified according to the applicable standard for each equipment

- the supplier is responsible for giving, if necessary, any proposal for (inevitable) modification of the path to stay within the llowable limit of the constraints on

the pipe or for the equipment connected to it.

After transmission of the calculation report, a work session should be scheduled between the supplier and EPPM for the approval of the calculations.

The documents that will be communicated to supplier are:

- Model 3D piping system calculation object

- Caesar II file (conversion of the 3D model to CII)

- ISOs

II.2 - General layout or Piping drawing Vendor to confirm Please check our Engineering Service Offer.

- Process data of the calculation object lines

- Soil characteristics for buried lines

The offer must include:

- List of references for similar calculations for GRP pipe

- a specimen of stress calculation report

II.3 - the time of execution for each station Vendor to confirm Please check our Engineering Service Offer.

- List of resources (calculation engineers and number of software licenses Caesar II) to make available for the performance of this service.

PROJET : « ETUDE, FOURNITURE ET INSTALLATION D’UNE STATION DE DESSALEMENT D’EAU DE MER A SOUSSE DE CAPACITE 50 000 m3/j –LOT N° 1- »

PROJECT NO. AR 15-17

DOCUMENT NO. Technical Bid Evaluation for GRP Pipes -ZONE EAU DE MER

SPC' NO. 01306-SPE-GEA-000-223-0001

REQUIREMENTS REV 1

Compliant Not Compliant Supplier offer Observation Supplier Repply

A GENERAL

A.1 PROJECT EXECUTION

What is project schedule? Time

limitation after delivery should be

Warranty must be 24 months after commissioning & Start-up, Please

A.2 WARRANTY 24 Months after Commissioning & Start-up (*) not indicated considered. ( or 36 Months after

Confirm

competion of delivery wich come

first)

Confirmed. Both specification and

Please confirm as per indicated in specification Doc 01306-SPE-GEA-

A.3 INSPECTION As per specification Doc 01306-SPE-GEA-000-223-0001 (*) not indicated isometrics are considered for our

000-223-0001

offer.

B SCOPE OF SUPPLY

B.1 ITEMS TO BE PURCHASED

SUBOR is offered only material

Lamination Kit , the Design of Protective sleeve at road crossing, valve

which are listed in BoQ list. Defined

DESIGN AND EQUIPMENT SUPPLY AND - Supply of GRP pipes , fittings ,elbow and flanges ,Lamination Kit -Supply of GRP pipes , fittings ,elbow and flanges pit crossing are under supplier scope of supply, Please Confirm

B.1.1 (*) works should be contractor's scope.

INSTALLATION (EPC) - Design of Protective sleeve at road crossing and valve pit crossing -Please note that, lamination kit is included in our offer as an option

We did not consider site installations

Installation is under supplier Scope, Please Confirm

operations.

Plastic pipes must be protected against UV radiation. SUBOR is considered UV protective

GRP piping exposed to the direct effects of UV radiation must be inhibitors for our offer. It is not

B.1.2 PAINTING As per specification Doc 01306-SPE-GEA-000-223-0001 (*) not indicated painted with a clear acrylic or latex paint that is chemically compatible colored and added into the resin. We

with plastic products. do not recommend to paint pipe before

Please confirm as per specification Doc 01306-SPE-GEA-000-223-0001 site acceptance test.

B.2 SPARE PART

- SPARE PARTS FOR START-UP AND

B.2.1 As per vendor recommandation (*) not indicated Not offered.

COMMISSIONING

- ANY SPECIAL TOOLS FOR INSTALLATION AND

B.2.2 As per vendor recommandation (*) not indicated Not offered.

MAINTENANCE

B.2.3 SPARE PARTS FOR INSTALLATION Required (*) not indicated Not offered.

C TECHYICAL REQUIREMEYTS

D.1.2 DESIGN DATA

Please revise your offer , pressure class mentioned for GRP lines are

Our biaxial pipe has minimum PN10

D.1.2.1 Design Pressure PN 10 / PN16 X PN06 / PN 10 / PN16 PN 10/16

pressue class.

pressure rating shall be as per Isometric drawings

D.1.2.2 Design T° -5°C / 60°C (*) not indicated Please Confirm Confirmed.

C.1 PIPE

C.1

C.1.1.1 Design code : AWWA C950 X Pipe GRP AWWA C950 BW resins

butt & wrap Our offer is not containing coupler.

to confirm:

SP / SP (Spigot ends) for use with couplers We offered hand lamination joint. It

C.1.1.2 End SP/SP The type of connection between pipes (underground / aboveground) is

SK/SP (Socket-Spigot ends) can be used for UG / AG GRP pipe

the responsibility of the supplier

connections.

Offer is prepared with different type of resin: We follow sopecification. We confirm

- Except DN150 and DN200 pipes, In the liner and structure sections of the isophtalic resin is suitable for seawater

Please Clarify your proposition for material selection, please Confirm

C.1.1.4 Material GLASS REINFORCED POLYESTER Résines: vinylester / isophtalique (*) pipes, superior quality unsaturated isophtalic resin shall be used applications. We complete many

the resistance of isophthalic for seawater applications

- For diameterDN150 and DN200 mm pipes, liner shall be produced with subaqueous project with iso / ortho

vinylester resin and structure shall be produced with isophtalic resin resin.

Please revise your offer , pressure class mentioned for GRP lines are PN We follow isometric drawings. Our

C.1.1.5 Schedule / Specification PN 10 / PN16 X PN 06/ PN 10 / PN 16 10/16 biaxail pipe has minimum PN10

pressure rating shall be as per Isometric drawings pressure class.

-2500/10000 (Mentioned in Attachment-8_SUBOR GRP Pipe and Fitting Offer )

We never recommend and use

C.1.1.6 SN SN 2500/5000 X The required Stiffness are 2500 /5000 as mentioned in the attached ISO, SN2500 stiffness class pipe for such

-Pipe is selected SN 5000 N/m2 Stiffness Class accordingly your requirement for

Please Clarify industrial applications.

your project. (mentioned in the SUBOR Letter of Offer)

C.1.1.7 Size DN 20 - DN1400 X DN 20 - DN1400

C.2 Fittings

C.1

C.1.6.1 Design code ASTM D5685, ISO 10639 (*) not indicated Please Confirm Confimred.

Offer is prepared with different type of resin: We follow sopecification. We confirm

- Except DN150 and DN200 pipes, In the liner and structure sections of the isophtalic resin is suitable for seawater

Please Clarify your proposition for material selection, please Confirm

C.1.6.2 Material GLASS REINFORCED POLYESTER Résines: vinylester / isophtalique (*) pipes, superior quality unsaturated isophtalic resin shall be used applications. We complete many

the resistance of isophthalic for seawater applications

- For diameterDN150 and DN200 mm pipes, liner shall be produced with subaqueous project with iso / ortho

vinylester resin and structure shall be produced with isophtalic resin resin.

We follow sopecification. We confirm

butt & wrap

isophtalic resin is suitable for seawater

SP / SP (Spigot ends) for use with couplers Please Clarify your proposition for material selection, please Confirm

C.1.6.3 End SP/SP applications. We complete many

SK/SP (Socket-Spigot ends) the resistance of isophthalic for seawater applications

subaqueous project with iso / ortho

resin. drawings. Our

We follow isometric

C.1.6.5 Schedule PN 10 / PN16 X PN 10 / PN16 pressure rating shall be as per Isometric drawings biaxail pipe has minimum PN10

pressure class.

C.1.6.6 Size DN 250- DN1400 (*) DN 100 - DN1400 Please refer to attched ISO

C.3 FLANGES

C.1

FF Bride fixe. Norme de perçage DIN EN1092/ ASME B16.5

C.1.6.1 End connection X flange DIN 2501 / SP/FF flange drilling shall be as per ISO drawings Noted

RF ASME B16.5

Offer is prepared with different type of resin: We follow sopecification. We confirm

- Except DN150 and DN200 pipes, In the liner and structure sections of the isophtalic resin is suitable for seawater

Please Clarify your proposition for material selection, please Confirm

C.1.6.2 Material GLASS REINFORCED POLYESTER Résines: vinylester / isophtalique (*) pipes, superior quality unsaturated isophtalic resin shall be used applications. We complete many

the resistance of isophthalic for seawater applications

- For diameterDN150 and DN200 mm pipes, liner shall be produced with subaqueous project with iso / ortho

vinylester resin and structure shall be produced with isophtalic resin resin.

We follow isometric drawings. Our

Please revise your offer , pressure class mentioned for GRP lines are PN

C.1.6.3 Class PN 10 / PN16 X PN06 / PN 10 / PN16 biaxail pipe has minimum PN10

10/16

pressure class.

C.1.6.4 Size DN 20- DN1400 X DN 20 - DN1400

C.4 GASKET

C.5.1

O-ring gasket for flange connection

C.5.1.1 Design code DIN EN1092/ ASME B16.5 (*) not indicated Gaskets are Under Supplier Scope, Please Confirm and provide details shall be provided by SUBOR. There is

no need for pipe connection

C.5.1.2 Material EPDM (4mm). (*) not indicated

We follow isometric drawings. Our

biaxail pipe has minimum PN10

C.5.1.3 Class PN 10 / PN16 (*) not indicated pressure rating shall be as per Isometric drawings

pressure class. We are able to produce

PN16

C.5.1.6 Size DN 20 - DN1400 (*) not indicated

C.5 BOLTS / NUTS

C.5.1

It is not in our scope. If it is required

from us, please provide required

C.2.1.1 Design code ISO/ pour brides DIN EN 1092/ASME B16.5 (*) not indicated Bolts are Under Supplier Scope, Please Confirm and provide details

specification for bolts and we can

revie our offer.

C.2.1.2 Material A320 - AISI 316 (*) not indicated

C.2.1.5 Size DN 20 - DN1400 (*) not indicated

C.6 Lamination Kit

C.5.1

Lamintaion Kit is under supplier scope of supply , Please Confirm and PN10 an PN16 pressure class

Specify the design code lamination kit shall be provided upon

Please note that, lamination kit is included in our offer as an option

C.3.1.1 Design code Vendor to advise (*) -to confirm: request from client. Our price inclding

The type of connection between pipes (underground / aboveground) is glassfiber and rsin. Workmanship is

the responsibility of the supplier not included in our offer.

-X62to provide more details and please clarify the lamination procedure

C.3.1.2 Material GLASS REINFORCED POLYESTER Résines: vinylester / isophtalique (*) Resin, Glassfiber and other chemicals for pipe joint lamination

C.1.1.6 SN SN 2500/5000 (*) not indicated

C.3.1.3 Size DN 20 - DN1400 X DN 200-DN 1400 Size shall be as per Isometric drawings

D DOCUMENTATION

Confirmed. Both specification and

D.1 General Documentation As per specification Doc 01306-SPE-GEA-000-223-0001 (*) note indicated to confirm isometrics are considered for our

offer.

Confirmed. Both specification and

D.1 Piping design drawings and materials As per specification Doc 01306-SPE-GEA-000-223-0001 (*) not indicated to confirm isometrics are considered for our

offer.

Confirmed. Both specification and

D.2 Quality documents and mangement system As per specification Doc 01306-SPE-GEA-000-223-0001 (*) not indicated to confirm isometrics are considered for our

offer.

Confirmed. Both specification and

D.3 Quality control plan/procedure As per specification Doc 01306-SPE-GEA-000-223-0001 Acc Attachment-6 - SUBOR Quality Plan and Manual isometrics are considered for our

offer.

Confirmed. Both specification and

D.4 Certificate of compliance As per specification Doc 01306-SPE-GEA-000-223-0001 (*) not indicated to confirm isometrics are considered for our

offer.

Confirmed. Both specification and

D.5 Material certificate 3.1 As per specification Doc 01306-SPE-GEA-000-223-0001 (*) not indicated to confirm isometrics are considered for our

offer.

D.6 Deviation list Requis (*) not indicated to provide if their is deviation to project documents/supply…

E Supply Limits

Please confirm:

-EPPM will provide ISOs drawings and supplier will provide material

list and prefabricated spools and will be responsable of the assembly at Confirmed but excluding site

E.1 List of material ( According to ISO attched ) provided

site operation responsibilities.

-Complete MTO provision with its quantities is on supplier

responsability

it will be checked with supplier and

E.1 PVC Pipe, fittings and Flange are excluded X Non-GRP Material - Not offered to provide as option

submitted in followngrevision.

No need for biaxial pipe excep a case

Coupler in MTO list are not included in our offer and they are not priced. There

to provide more details for coupler (type, material,…) and to clarify which it is needed to compensate

E.2 Couplers (*) is no information about coupler in specification and isometric drawings and we

when coupler is required thermal expansion due to long

need to get more detail in order to give you correct price

aboveground pipeline.

Supplier shall provide:

- The list of material.

- Drawing and engineering

- The supply of gaskets and bolts.

- The collars in SVR It is included in our engineering

E.2 Supply limits and Exclusion (*) not indicated

- The sealing flange. service offer.

- Supports

-Spare parts for start-up and installation

Please confirm

It can be delivered to port. Inner

E.2 Transport and Installation (*) not indicated Transportaion and installation is under supplier scope transportation should be orginzed by

client.

F Notes

F.1 Please confirm / comment sheet number one ( DEVIATION & CLARIFICATION

You might also like

- Construction Transmittal Form TemplateDocument2 pagesConstruction Transmittal Form TemplatearthurNo ratings yet

- Inspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management ServicesDocument11 pagesInspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management Servicespunk cmNo ratings yet

- 171 BOQ PlumbingDocument26 pages171 BOQ PlumbingzeamalNo ratings yet

- Guidelines For Fabrication of Steel Girders For Field EngineersDocument55 pagesGuidelines For Fabrication of Steel Girders For Field EngineersradhakrishnangNo ratings yet

- 8188-MD-FEA-RFQ-001 Rev-0Document24 pages8188-MD-FEA-RFQ-001 Rev-0sridharNo ratings yet

- FRP Catalogue 04.2021Document84 pagesFRP Catalogue 04.2021Bilel MahjoubNo ratings yet

- This Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionDocument10 pagesThis Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionVidyut UjalaNo ratings yet

- Cs3000 Install - GuideDocument242 pagesCs3000 Install - Guidemurappanad100% (1)

- Consumables NormsDocument24 pagesConsumables NormsHema Nandh100% (1)

- Engineer ProcedureDocument7 pagesEngineer ProcedureRadziel EngineeringNo ratings yet

- DG Spec Final ApprovalDocument41 pagesDG Spec Final Approvalapi-3854942100% (7)

- Shurjoint Installation Handbook-2009 - 1Document131 pagesShurjoint Installation Handbook-2009 - 1DANE80No ratings yet

- 710DDocument798 pages710DSegundo Francisco Jauregui Valencia75% (4)

- Core Java BookDocument464 pagesCore Java Bookmallikarjun199No ratings yet

- 01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFDocument75 pages01 Rpspl-Civil-Doc-Ct-01-31-01-20 PDFkapilNo ratings yet

- CPSM 2014 Certification HandbookDocument11 pagesCPSM 2014 Certification HandbookabdulfatahbrohiNo ratings yet

- 921 - Design Build Comprehensive - Quality Plan PDFDocument19 pages921 - Design Build Comprehensive - Quality Plan PDFvelmurug_balaNo ratings yet

- Inspection Test Plan For Stat XDocument4 pagesInspection Test Plan For Stat XGinish KumarNo ratings yet

- Material Submittal For LouverDocument42 pagesMaterial Submittal For LouverYusuf Ziya DilbazNo ratings yet

- Inspection and Test Plan For Fire Proofing Sealer ApplicationDocument6 pagesInspection and Test Plan For Fire Proofing Sealer Applicationmoytabura96100% (6)

- Contractor HSE MNG PresentationDocument6 pagesContractor HSE MNG Presentationayman mohamedNo ratings yet

- Troubleshooting Kubernetes DeploymentDocument1 pageTroubleshooting Kubernetes DeploymentAlbert SuwandhiNo ratings yet

- Cat Ladder Details3Document36 pagesCat Ladder Details3Shoaib KhanNo ratings yet

- Automotive Storage and PackagingDocument68 pagesAutomotive Storage and PackagingViswanath AdithamNo ratings yet

- Mechanical WIP ChecklistsDocument20 pagesMechanical WIP ChecklistsJovani G. BallonNo ratings yet

- Lightning Protection System Submittal ISM Sialkot-EricoDocument51 pagesLightning Protection System Submittal ISM Sialkot-EricoImran Saeed100% (1)

- QCP - Concrete WorksDocument3 pagesQCP - Concrete WorksMitendra Kumar Chauhan100% (1)

- Ansi/isea 107 - 2010Document8 pagesAnsi/isea 107 - 2010thongtn2007No ratings yet

- Fire & Safety Lab and HPL Generator Building Modon-3 Dammam, KsaDocument5 pagesFire & Safety Lab and HPL Generator Building Modon-3 Dammam, KsaMiqdadNo ratings yet

- Document Submittal From Contractor: Method of Statements For RTR PipingDocument11 pagesDocument Submittal From Contractor: Method of Statements For RTR PipingAbdul raheem syed100% (1)

- Calculation of Trunnions Rev3Document3 pagesCalculation of Trunnions Rev3Bilel MahjoubNo ratings yet

- Introduction To TelematicsDocument3 pagesIntroduction To TelematicsRivegel BaclayNo ratings yet

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Document57 pagesBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduNo ratings yet

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Reconcilation of Welding Consumable and Associated Consumable For Piping and Structure PDFDocument44 pagesReconcilation of Welding Consumable and Associated Consumable For Piping and Structure PDFManu JojoNo ratings yet

- Wayfinding Symbol UsageDocument9 pagesWayfinding Symbol UsageSourav SarkarNo ratings yet

- TS - 1 - 2018 FinalDocument7 pagesTS - 1 - 2018 FinallatifNo ratings yet

- D - PkA - Submittals - MI AA A1 B08.07 M0 WS 005 07 00 03 08 2021 ACK BDocument7 pagesD - PkA - Submittals - MI AA A1 B08.07 M0 WS 005 07 00 03 08 2021 ACK BareNo ratings yet

- Fabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XDocument6 pagesFabricationandsupplyofteejointforairoutletheader-01 20221218112214.349 XAbdulrahman EladawyNo ratings yet

- Upvc Pipe Class DDocument4 pagesUpvc Pipe Class DnaagshreeNo ratings yet

- GEC (SD#094) Shop Drawings For Elevations Details For RW-11 NH08 RW-11Document5 pagesGEC (SD#094) Shop Drawings For Elevations Details For RW-11 NH08 RW-11Mohamed MandouhNo ratings yet

- 01 6261 ELV Technical Specs For Elevators R1dfvrgdvfeDocument8 pages01 6261 ELV Technical Specs For Elevators R1dfvrgdvfe9245126694No ratings yet

- Construction Check Sheet P-0008A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0008A: Mechanical Installation of PumphrimklimNo ratings yet

- MAT-AAC-NT-ARCH-070 R00 - Data Sheet For Clustera (Aluminum Works)Document6 pagesMAT-AAC-NT-ARCH-070 R00 - Data Sheet For Clustera (Aluminum Works)eromax1No ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumpKailash PandeyNo ratings yet

- Construction Check Sheet P-0010B-A: Mechanical Installation of PumpDocument1 pageConstruction Check Sheet P-0010B-A: Mechanical Installation of PumphrimklimNo ratings yet

- Shic A 0007Document3 pagesShic A 000701095902062ahmedNo ratings yet

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- RCDC-IRMW-5195-001 Inspection Request - Masonry WorksDocument3 pagesRCDC-IRMW-5195-001 Inspection Request - Masonry WorksAristeo GarzonNo ratings yet

- Shop Fabrication Welding & Painting Procedure 22-07 Rev-2Document48 pagesShop Fabrication Welding & Painting Procedure 22-07 Rev-262239a658fb23fNo ratings yet

- C08-016-000J-TS030 - 0 Pressure TranmitterDocument10 pagesC08-016-000J-TS030 - 0 Pressure TranmitterCristian RománNo ratings yet

- EHS-E076-ICS-RFQ-CNL-0000-90008-00 G01 RevDocument30 pagesEHS-E076-ICS-RFQ-CNL-0000-90008-00 G01 RevOkoro KennethNo ratings yet

- Ayc Ic & Itp SealerDocument6 pagesAyc Ic & Itp Sealermoytabura96No ratings yet

- Gi ConduitDocument6 pagesGi ConduitnaagshreeNo ratings yet

- Rks 10255-Work DetailsDocument25 pagesRks 10255-Work DetailsviviNo ratings yet

- RCDC-IRCWE-7195-001 Inspection Request - Ceiling, Wall EnclosureDocument2 pagesRCDC-IRCWE-7195-001 Inspection Request - Ceiling, Wall EnclosureAristeo GarzonNo ratings yet

- Inspection Request For Police CameraDocument9 pagesInspection Request For Police Cameramohib.dlinkcssNo ratings yet

- NNEG3-30-LAA-SP-M0131 - A Technical Specification For Feed Water Storage and DeaerationDocument18 pagesNNEG3-30-LAA-SP-M0131 - A Technical Specification For Feed Water Storage and Deaerationsatvata.foodsNo ratings yet

- Pile Welding Quality Control Plan: SpecificationsDocument8 pagesPile Welding Quality Control Plan: Specificationsvelmurug_balaNo ratings yet

- 03 Rpspl-Civil-Doc-La-01-30-01-20 PDFDocument75 pages03 Rpspl-Civil-Doc-La-01-30-01-20 PDFkapilNo ratings yet

- Ehs E0766 Ics Req CNL 000 90006 00Document32 pagesEhs E0766 Ics Req CNL 000 90006 00Okoro KennethNo ratings yet

- TB#14 PDFDocument8 pagesTB#14 PDFAnonymous 2wNNl0ULENo ratings yet

- Volume I e (Technical Specifications) 1417692589Document28 pagesVolume I e (Technical Specifications) 1417692589gopal sudhirNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- Technical Query Sheet Format - ColumnDocument8 pagesTechnical Query Sheet Format - ColumnChetan PatelNo ratings yet

- Aoi-01-Eng-2024Document77 pagesAoi-01-Eng-2024Kuldeep ShekhawatNo ratings yet

- Hill Recommendations For Vertical Transportation SystemDocument2 pagesHill Recommendations For Vertical Transportation SystemPERVEZ AHMAD KHANNo ratings yet

- TDS Water Curtain Pump - R1Document22 pagesTDS Water Curtain Pump - R1SachinDivateNo ratings yet

- ITP SampleDocument2 pagesITP SampleahmedNo ratings yet

- Annex 3.6-LOT3 Technical QuestionnaireDocument3 pagesAnnex 3.6-LOT3 Technical QuestionnaireAiman AliNo ratings yet

- HYEN-RFQ-ME-004 - RFQ For FET - Rev.C - 210218Document22 pagesHYEN-RFQ-ME-004 - RFQ For FET - Rev.C - 210218MouiciNo ratings yet

- 7.6.1. Important NotesDocument2 pages7.6.1. Important Notesomardhaher1995No ratings yet

- C08-016-000J-TS040 - B Temperature TransmittersDocument8 pagesC08-016-000J-TS040 - B Temperature TransmittersCristian RománNo ratings yet

- Conair Equipment CatalogDocument516 pagesConair Equipment CatalogBilel MahjoubNo ratings yet

- Note de Calcul Ancrage Rev3Document3 pagesNote de Calcul Ancrage Rev3Bilel MahjoubNo ratings yet

- Process Equipment Catalog: Pumping Solutions For Process IndustriesDocument76 pagesProcess Equipment Catalog: Pumping Solutions For Process IndustriesBilel MahjoubNo ratings yet

- Test ReportDocument18 pagesTest ReportBilel MahjoubNo ratings yet

- Tank Handling and Installation Instructions: Equipment InspectionDocument7 pagesTank Handling and Installation Instructions: Equipment InspectionBilel Mahjoub100% (1)

- Technical Data Sheet Simona PP-H AlphaplusDocument1 pageTechnical Data Sheet Simona PP-H AlphaplusBilel MahjoubNo ratings yet

- Appendix: Agitator Nozzle Analysis Wrc107 MethodDocument12 pagesAppendix: Agitator Nozzle Analysis Wrc107 MethodBilel MahjoubNo ratings yet

- 4729sbm01do05326b - Afg - Hot Water SystemDocument7 pages4729sbm01do05326b - Afg - Hot Water SystemBilel MahjoubNo ratings yet

- Attachment-3 - Subor Introduction PresentationDocument39 pagesAttachment-3 - Subor Introduction PresentationBilel MahjoubNo ratings yet

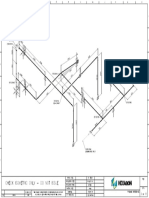

- LIGNEAIR3BBB2ADocument1 pageLIGNEAIR3BBB2ABilel MahjoubNo ratings yet

- LIGNEAIR3BBB2BDocument1 pageLIGNEAIR3BBB2BBilel MahjoubNo ratings yet

- LIGNEAIR3BBB2IDocument1 pageLIGNEAIR3BBB2IBilel MahjoubNo ratings yet

- AR15-17 Liste Des Isométrique Lot PRVDocument12 pagesAR15-17 Liste Des Isométrique Lot PRVBilel MahjoubNo ratings yet

- 1 1 3 Ak ScientificengineeringnotationDocument2 pages1 1 3 Ak Scientificengineeringnotationapi-290804719No ratings yet

- Tatra t815-7 Cas30Document4 pagesTatra t815-7 Cas30Forum PompieriiNo ratings yet

- ISO-6508-3-2005Document11 pagesISO-6508-3-2005Tiago SantanaNo ratings yet

- A Twine Cheat SheetDocument7 pagesA Twine Cheat SheetNIKOT2No ratings yet

- 2015 Substation Controls - HicksDocument54 pages2015 Substation Controls - HicksDave ChaudhuryNo ratings yet

- Conventional Coring - AAPG WikiDocument9 pagesConventional Coring - AAPG WikiAbhinav SharmaNo ratings yet

- Manual Multimix16 USB 2.0 AlesisDocument60 pagesManual Multimix16 USB 2.0 AlesisCarlos Robles AviñaNo ratings yet

- Multicarrier ModulationDocument4 pagesMulticarrier ModulationepriyantonoNo ratings yet

- Tutorial Angular Materialize HFRDocument4 pagesTutorial Angular Materialize HFRHernan flores ramirezNo ratings yet

- QFile - FTCPDocument27 pagesQFile - FTCPmass giridihNo ratings yet

- Tems InvestigationDocument12 pagesTems InvestigationMinto IssacNo ratings yet

- Product - Support-Trotter-600t Treadmill Service ManualDocument55 pagesProduct - Support-Trotter-600t Treadmill Service ManualdianNo ratings yet

- AC MachinesDocument41 pagesAC Machineskr_abhijeet72356587No ratings yet

- ISO 14971 ChangedDocument1 pageISO 14971 ChangedSen MingNo ratings yet

- Filled Notes For Chapter 5: Strategic Capacity Planning For Products and ServicesDocument4 pagesFilled Notes For Chapter 5: Strategic Capacity Planning For Products and ServicesfrtisNo ratings yet

- Dell Networking N2000 SCG 6.0.1.3 PDFDocument17 pagesDell Networking N2000 SCG 6.0.1.3 PDFronyemersonNo ratings yet

- BR457Document100 pagesBR457rharaksiNo ratings yet

- HUAWEI G510-0251V100R001C76B198 Upgrade Guideline PDFDocument7 pagesHUAWEI G510-0251V100R001C76B198 Upgrade Guideline PDFCristian Daniel Cordoba ANo ratings yet