Professional Documents

Culture Documents

3176C Engine Inspection & Measurement SheetRev2

Uploaded by

bumatio latiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3176C Engine Inspection & Measurement SheetRev2

Uploaded by

bumatio latiCopyright:

Available Formats

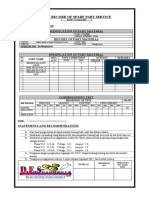

WO TR1 MODEL 3176C

1-Feb-12`

Affected Model : Form No: Date : Literature Refer to: Issued By: Authorization:

All 3176 Engines TTD.CRC.QS.082.001.R02 12 / 2010 GRPTs Marnie Alado. Kamaruddin Tajuddin

Service Manual

ACTUAL PART NUMBERS UPON DISASSEMBLY

No Components Actual Part Number (or casting) Checked by

ENGINE BLOCK CASTING

CONNECTING ROD

PISTON CROWN

PISTON SKIRT

UNIT INJECTOR

MAIN BEARING

CONNECTING ROD BEARING

COOLING JET

Update/Improvement Description 3176C Engine Remarks By

The boltholes of Block for Front Housing are counterbored to 5mm or 15mm?

SEPD0902

The boltholes of Block for Rear Housing are 12mm or 14mm diameter?

The boltholes of Block for Front Support (8 holes) are 12mm or 14mm diameter?

The Oil Filter Base PN is updated 166-1328? SEPD0509

PARTS FOR REPAIR/SALVAGE

Repair Foreman/

No Part Number Part Name Description

Completed? Supervisor

KKCRC Page 1 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

CYLINDER BLOCK INSPECTION

VISUAL INSPECTION

TOP DECK THREAD SIZE

Checked by. Checked by.

LOWER LINER SEAL AREA FLYWHEEL BOLTS

Checked by. Checked by.

FRONT SURFACE REAR SURFACE

Checked by. Checked by.

MOUNTING BOLTS REAR ENGINE MOUNT

Checked by. Checked by.

Important : For 3176C, flywheel bolts and front housing support bolts should be upgraded to M14. Refer to Special

Instruction for housing & block modification.

CYLINDER BLOCK MAIN BORE INSPECTION

(A + B )−

No C A B C REUSABILITY

2

1

2

3

4

5

6

7

SPECIFICATION NOTE :

116.000 ± 0.013 mm

Standard (4.5669 ± 0.0005 inch)

116.510 ± 0.013 mm

Oversized (4.5870 ± 0.0005 inch)

Decision : Mechanic, Checked by,

KKCRC Page 2 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

CRANKSHAFT INSPECTION

CL of

Measure diameter at two places 90o apart.

THRUST PLATES

Reusable? □- Yes □- No Remarks:

FILLET RADIUS FRONT & REAR

CONDITIONS BOLT HOLES

THRUST FACE MAIN & ROD

CONDITIONS JOURNALS

FRONT & REAR SEAL

CRANKSHAFT GEAR

SURFACES

Performed By: Checked By:

CRACK TESTING USING

MAGNAFLUX MACHINE

Note:

MEASUREMENT

MAIN JOURNAL ROD JOURNAL

STANDARD

FIRST UNDERSIZED

SECOND UNDERSIZED

No MAIN JOURNAL CONROD JOURNAL TOTAL INDICATOR RUNOUT

▼ A1 A2 D1 D2 Max: 0.13 mm (0.005”)

1

2

3

4

5

6

7

CRANKSHAFT JOURNAL DIAMETERS (check one box)

Standard 1st Undersized 2nd Undersized

Decision: Mechanic, Checked by,

KKCRC Page 3 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

CON ROD INSPECTION AND MEASUREMENT

VISUAL INSPECTION

BOLTS & NUTS THRUST FACE

FILLET RADIUS SHANK AREA

SEATS OF BOLT/NUT PIN BUSHING

.

MEASUREMENT

Conrod Pin

A(1) B(1) C (A + B )− C Bushing

Nominal: Nominal: Nominal: 2

Diameter

No New:

Remarks

▼ 50.830 ± 0.008 mm

86.800 ± 0.013 mm

86.800 ± 0.013 mm 86.800 ± 0.013 mm (2.0012 ± 0.0003”)

(3.4173 ± 0.0005”)

(3.4173 ± 0.0005”) (3.4173 ± 0.0005”) Service Limit:

RENR1217-09

50.856 mm (2.0022”)

SEBF8244-03

6

Maximum permissible clearance between conrod bushing and piston pin (worn) ... 0.25 mm (.010 in) SEBR0560 (for 3176C)

Notes: Mechanic, Checked by,

KKCRC Page 4 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

CONNECTING ROD MEASUREMENT using CONROD FIXTURE

NOTES: 1. The specs and formula below is for 5P-2050 Conrod Fixture Only (SEBF8149-12). 2. All reading are in mm.

Center to

Bend

Center

Twist

Reading Reading Conrod

ConRod (D1+D2)/2 D1 – D2

Dial 1 Dial 2 Bushing Remarks

▼

(D1) (D2) Specs: Max Specs: Max Specs: Max Retention

± 0.076 mm 0 to 0.08 0 - 0.30mm

(± 0.0030”) mm (0.003”) (0.012”)

SEBF8244-03 SEBF8244-03 SEBF8244-03

#1

#2

#3

#4

#5

#6

NOTE :

Decision : Mechanic, Checked by,

KKCRC Page 5 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

PISTON & PIN INSPECTION

PISTON P/N : …………………………………………….

SPECIFICATION

RING GAUGE 4C-8165 SEBF8059-18

CROWN BUSHING DIA 50.830 ± 0.008 mm (2.0012 ± .0003 inch) RENR1217-09

PIN DIAMETER 50.795 ± 0.005 mm (1.9998 ± 0.0002 inch)

PISTON

No TOP GROOVE GENERAL CONDITION

USING GAUGE CROWN SKIRT

1

2

3

4

5

6

No PIN DIAMETER REMARK

ALWAYS REPLACE THE PIN IF HIGH HOURS

1

2

3

4

5

6

NOTE :

Decision: Mechanic, Checked by,

NOTE: ALWAYS REPLACE THE PIN IF HIGH HOURS.

COOLER CORE INSPECTION

ENGINE FAILURE DESCRIPTION :

VISUAL PRESSURE

COOLER INSPECTION PART NUMBER REUSABILITY

INSPECTION TESTED BY

ENGINE OIL COOLER

TRANS. OIL COOLER

HYD. OIL COOLER

NOTE :

Decision : Mechanic, Checked by,

KKCRC Page 6 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

LINER INSPECTION

VISUAL INSPECTION

No Flange Surface Outside Surface Inside Surface Remark

1

2

3

4

5

6

LINER BORE MEASUREMENT

SPECIFICATION 125.037 ± 0.037 mm (4.9227 ± .0015 inch) RENR1217-09

Upper End Lower End

No REUSABILITY REMARK

Point A Point B Point A Point B

1

2

3

4

5

6

Point A and Point B are 90o apart.

NOTE :

Mechanic, Checked by,

Decision :

KKCRC Page 7 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

CAMSHAFT INSPECTION

VISUAL INSPECTION

CAMSHAFT P/ N

CAM LOBES (1)

CAM JOURNALS (3)

CAM DRIVE GEAR

Note : Mechanic, Checked by,

Decision :

FLYWHEEL HOUSING

VISUAL INSPECTION

ALL BOLT THREAD

T / C BOLT HOLE

T / C SEAL SURFACE

BOLT HOLE MOUNTING ENGINE

FLYWHEEL AND RING GEAR

Decision : Mechanic, Checked by,

COOLING JET INSPECTION

CYL CYL

CONDITION / DIRECTION OF SPRAY CONDITION / DIRECTION OF SPRAY

NO. # NO. #

1 4

2 5

3 6

Decision : Mechanic, Checked by,

KKCRC Page 8 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

VALVE MECHANISM

Qty Need

Item Description Qty in Eng Remarks

to replace

1 LIFTER – Valve 12

2 LIFTER – Injector 6

3 BRACKET 148-2065 2

4 BRACKET 148-2064 2

5 SHAFT – of lifters 2

6 PUSHROD - Valve 12

7 PUSHROD - Injector 6

8 ROCKER ARM – Exh 6

9 ROCKER ARM – Inj 6

10 ROCKER ARM – Intake 6

11 SCREW 12

12 NUT 12

13 SCREW 6

14 NUT 6

15 BUTTON 6

16 SHAFT – rocker arms 6

17 PIN - SPRING 6

18 SUPPORT AS 6

19 DOWEL 6

20 BRIDGE 12

Decision : Mechanic, Checked by,

KKCRC Page 9 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

GEAR TRAIN INSPECTION

NO PART NUMBER DESCRIPTION /SPEC ACTUAL MEASUREMENT/REMARK REUSABILITY

1 GEAR AS (61 TEETH)

55.163 ± 0.041 mm (2.1718 ± 0.0016 inch)

2 SHAFT

55.047 ± 0.020 mm (2.1672 ± 0.0008 inch)

3 GEAR AS-IDLER

69.205 ± 0.013 mm (2.7246 ± 0.0005 inch)

4 SHAFT

69.141 ± 0.008 mm (2.7221 ± 0.0003 inch)

5 GEAR-PUMP DRIVE (34 TEETH)

NOTE : Mechanic, Checked by,

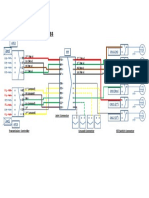

ECM INSPECTION

ECM Part Number: Flashfile:

Diagnostic Clock: Condition:

Decision : Mechanic, Checked By

DAMPER

DAMPER "Do not use Damper again" if any of the following conditions are present:

1. The engine has had a failure because of a broken crankshaft

P/N 2. There is any sign of heat damage or discoloration of the damper

3. shows there is fluid leakage or a dented housing for Viscous Damper

REUSE YES NO

Decision : Mechanic, Checked by,

KKCRC Page 10 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

EXHAUST MANIFOLD

DESCRIPTION CONDITION REMARK

1 MANIFOLD

2 MANIFOLD

3 MANIFOLD

4 SPACERS

Decision : Mechanic: Check By:

FUEL SYSTEM INSPECTION

ASSEMBLE

REF DESCRIPTION REUSABILITY

Reuse / New

1 INJECTOR

2 SPACER

3 INJECTOR CLAMP

4 CHECK VALVE

NOTE :

INSPECTION ASSEMBLY

Mechanic, Checked by, Mechanic, Checked by,

Note : Do not reuse the hold down bolts for the fuel injector.( SEPD0828)

KKCRC Page 11 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

CYLINDER HEAD INSPECTION

VISUAL INSPECTION ASSEMBLE

CRACK TEST INJECTOR SLEEVE

Checked by. Checked by.

EXHAUST FACE VALVE

Checked by. Checked by.

SURFACE GRIND VALVE GUIDE

Checked by. Checked by.

VACUUM TEST VALVE SEAT

Checked by. Checked by.

CYLINDER HEAD THICKNESS (A)

Actual

Specification Remark

Front Rear

Decision : Mechanic, Checked by,

VALVE GUIDE INSPECTION

VALVE GUIDE HEIGHT (B)

Specification

Qty in Engine Qty need to be replaced Remark

KKCRC Page 12 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

VALVE INSPECTION

QTY IN ENGINE QTY NEED REPLACED REASON

VALVE INTAKE

VALVE EXHAUST

VALVE SEAT

INTAKE

EXHAUST

Decision : Mechanic, Checked by,

TURBOCHARGER INSPECTION

DESCRIPTION CONDITION REMARK

1 CLAMP AS

1a NUT

2 HOUSING - TURBINE

3 CLAMP AS

3a NUT

4 HOUSING - COMPRESSOR

5 CARTRIDGE

6 TURBINE BLADE CONDITION

Decision : Mechanic, Checked by,

KKCRC Page 13 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

OIL PUMP INSPECTION

ASSEMBLE

REF DESCRIPTION REUSABILITY

Reuse / New

1 Idler Shaft Assembly

2 Drive Shaft Assembly

3 Pump Cover Assembly

4 Pump Body Assembly

5 Gear

6 Sleeve Bearing

Spool (Pressure Relief

7

Valve)

Spring (Pressure Relief

8

Valve)

9 Hollow Dowel

Cover (Pressure Relief

10

Valve)

Pump Body Cover

11

Assembly

INSPECTION ASSEMBLY

Mechanic, Checked by, Mechanic, Checked by,

WATER PUMP INSPECTION

ASSEMBLE

REF DESCRIPTION REUSABILITY

Reuse / New

SHAFT AS–PUMP

1

DRIVE

WASHER-

2

THRUST

HOUSING AS-

3

PUMP

4 IMPELLER-PUMP

INSPECTION ASSEMBLY

Mechanic, Checked by, Mechanic, Checked by,

KKCRC Page 14 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

WO TR1 MODEL 3176C

1-Feb-12`

FAN DRIVE INSPECTION

ASSEMBLE

REF DESCRIPTION REUSABILITY

Reuse / New

1 BRACKET ASSY

2 PULLEY

SHAFT / FAN

3

DRIVE ASSY

BELT

4

TIGHTENER

INSPECTION ASSEMBLY

Mechanic, Checked by, Mechanic, Checked by,

KKCRC Page 15 of 15 3176C Engine Inspection & Measurement SheetRev2.doc

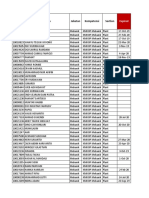

You might also like

- Elantra 2005 2.0LDocument276 pagesElantra 2005 2.0LSergio RocaNo ratings yet

- C9 Diesel Engine Labor Requirement GuideDocument97 pagesC9 Diesel Engine Labor Requirement GuideDjebali MouradNo ratings yet

- 385C Cat Vs 385B CatDocument69 pages385C Cat Vs 385B CatKolo BenduNo ratings yet

- L100N5 Getm3 PDFDocument17 pagesL100N5 Getm3 PDFkarol1177No ratings yet

- Diesel Generator Set QSX15 Series Engine: Power GenerationDocument4 pagesDiesel Generator Set QSX15 Series Engine: Power GenerationsdasdNo ratings yet

- Nissan CD17Document3 pagesNissan CD17jose luis calixto requisNo ratings yet

- Open Ended Lab: ObjectivesDocument4 pagesOpen Ended Lab: Objectivesaff123051No ratings yet

- Accent 2003 1.6LDocument215 pagesAccent 2003 1.6LMiguel GarciaNo ratings yet

- Kenr6232 00 PDFDocument100 pagesKenr6232 00 PDFPedroSantosNo ratings yet

- Mitsu Pajero Engine 4D5Document54 pagesMitsu Pajero Engine 4D5schumiizz2bestNo ratings yet

- 135 IDocument0 pages135 IAnonymous uEt1sNhU7l100% (1)

- M2000Document7 pagesM2000kylegazeNo ratings yet

- Cramkshaft Main Bearimg InstallDocument5 pagesCramkshaft Main Bearimg InstallNimNo ratings yet

- CAT C27 - C32 Ajuste La Luz de ValvulasDocument5 pagesCAT C27 - C32 Ajuste La Luz de ValvulasGdar KbzaNo ratings yet

- GD705A-5 Adjusting ValveDocument3 pagesGD705A-5 Adjusting ValveSurya FaniNo ratings yet

- Gear Group (Front) - Remove and InstallDocument16 pagesGear Group (Front) - Remove and InstallMbahdiro KolenxNo ratings yet

- CAT Measurment of The CamshaftDocument12 pagesCAT Measurment of The Camshaftmk100% (1)

- Electronic Unit Injector AdjustDocument2 pagesElectronic Unit Injector AdjustHesham HusseinNo ratings yet

- Man I Have A Question On A 928g Loader I Have Been Doing Some Test On The Transmission I Need A Little Bit of Direction.Document17 pagesMan I Have A Question On A 928g Loader I Have Been Doing Some Test On The Transmission I Need A Little Bit of Direction.ikperha jomafuvweNo ratings yet

- Scania dc12 Cylinder HeadDocument1 pageScania dc12 Cylinder HeadaliNo ratings yet

- Operation and Maintenance Manual: C7.1 Industrial EngineDocument144 pagesOperation and Maintenance Manual: C7.1 Industrial EngineAlonso FernandoNo ratings yet

- Improving Piston Ring Wear Resistance Through Coated SurfacesDocument47 pagesImproving Piston Ring Wear Resistance Through Coated SurfaceseshuNo ratings yet

- C4.4 NRP Maintenance SchedDocument3 pagesC4.4 NRP Maintenance SchedDerrick AramNo ratings yet

- 15 18 106 0C - Notice - 12M26.2 - GEB - ENDocument132 pages15 18 106 0C - Notice - 12M26.2 - GEB - ENsxturboNo ratings yet

- Visual Inspection Main & Connecting RodDocument56 pagesVisual Inspection Main & Connecting RodmkNo ratings yet

- Cummins Position Profiles - Mechanical EngineerDocument28 pagesCummins Position Profiles - Mechanical EngineerLakkakula SubbuNo ratings yet

- Cat c15 Cylinder Head RemovalDocument6 pagesCat c15 Cylinder Head RemovalMUHSIN MTNo ratings yet

- Pressure Test D16F Cylinder HeadDocument4 pagesPressure Test D16F Cylinder HeadbabyNo ratings yet

- Valve Clearance Check and AdjustmentDocument3 pagesValve Clearance Check and AdjustmentRodrigo MuñozNo ratings yet

- 988F Valve Lash Adjustment (5304)Document7 pages988F Valve Lash Adjustment (5304)John GrayNo ratings yet

- Engine C15 And 18 Valve Setting Task SheetDocument3 pagesEngine C15 And 18 Valve Setting Task SheetDian DeltraxNo ratings yet

- Workshop Manual. Agricultural Bearings. BPW-WH-Agrar eDocument17 pagesWorkshop Manual. Agricultural Bearings. BPW-WH-Agrar ebercketowzhenyaNo ratings yet

- Crankcase Pressure SM019901095211 - en PDFDocument5 pagesCrankcase Pressure SM019901095211 - en PDFDavy GonzalezNo ratings yet

- Marine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPDocument234 pagesMarine Diesel Engine Service Manual 6LY2-STE 6LY2A-STP 6LYA-STPJuniorJavier Olivo Farrera100% (1)

- Tad730ge 111797s01Document8 pagesTad730ge 111797s01roozbehxoxNo ratings yet

- Wechai WP12 Engine Maintenance ManualDocument198 pagesWechai WP12 Engine Maintenance ManualТүвшинтөгс Сэр-ОдNo ratings yet

- Perkins 400 Series: Workshop ManualDocument6 pagesPerkins 400 Series: Workshop ManualDella AstariNo ratings yet

- Engine Valve Lash - Inspect - Adjust... 3408E and 3412E Engines For Caterpillar Built Machines #I01625568 CaterpillarDocument4 pagesEngine Valve Lash - Inspect - Adjust... 3408E and 3412E Engines For Caterpillar Built Machines #I01625568 CaterpillarinduramNo ratings yet

- Series: Operator'S ManualDocument142 pagesSeries: Operator'S ManualDavid arango.No ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Excessive Oil ConsumptionDocument8 pagesExcessive Oil Consumptionabduallah muhammadNo ratings yet

- ProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsDocument29 pagesProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsJosephNo ratings yet

- C15 and C18 - Finding Top Center Position For No. 1 Piston - Caterpillar Engines TroubleshootingDocument3 pagesC15 and C18 - Finding Top Center Position For No. 1 Piston - Caterpillar Engines Troubleshootingmohd arif fahmi mohamad saleh100% (1)

- 2011-04-11 193232 Om353 Valve Clearance PDFDocument6 pages2011-04-11 193232 Om353 Valve Clearance PDFazyoudNo ratings yet

- Piston and Rings: Shutdown SIS Previous ScreenDocument9 pagesPiston and Rings: Shutdown SIS Previous ScreenalonsoNo ratings yet

- Deutz 1011 SpecsDocument514 pagesDeutz 1011 Specsrusyn100% (1)

- Rodamientos de Alternadores CAT GILBERTO PANTOJADocument16 pagesRodamientos de Alternadores CAT GILBERTO PANTOJAGilberto PantojaNo ratings yet

- Operation and Maintenance Manual for 2806D-E18TA Industrial EngineDocument3 pagesOperation and Maintenance Manual for 2806D-E18TA Industrial EngineMostafa ShannaNo ratings yet

- Berco RTM 270Document16 pagesBerco RTM 270Gurber Michael Choque MoralesNo ratings yet

- D399 Operation SystemDocument64 pagesD399 Operation SystemNOUR ZAINNo ratings yet

- Static Injector TimingDocument12 pagesStatic Injector TimingMohamed Mohamed100% (1)

- EPA Tier 4 Certified Diesel Engines for 2-3t Forklift TrucksDocument6 pagesEPA Tier 4 Certified Diesel Engines for 2-3t Forklift TrucksTien NguyenNo ratings yet

- ANU MPhil PhD Admission ApplicationDocument1 pageANU MPhil PhD Admission ApplicationDeva RajNo ratings yet

- Cat 3400Document8 pagesCat 3400cesaraugustom100% (1)

- Piston and Rings PDFDocument3 pagesPiston and Rings PDFJose PichinteNo ratings yet

- Especificações Técnicas - Motores JimbeiDocument4 pagesEspecificações Técnicas - Motores JimbeiWiterMarcosNo ratings yet

- Engine Valve LashDocument3 pagesEngine Valve LashYeremiaNo ratings yet

- Spare Part Service RecordDocument4 pagesSpare Part Service RecordKhalidperkasaNo ratings yet

- Collar Cam Chain Guide RollerDocument1 pageCollar Cam Chain Guide RollerPreetam KumarNo ratings yet

- Propeller Shaft Diagnosis and Repair GuideDocument18 pagesPropeller Shaft Diagnosis and Repair GuideSergio EspinozaNo ratings yet

- F-038 - MST List of Backlog Repair PlanDocument1 pageF-038 - MST List of Backlog Repair PlanTaufikNo ratings yet

- 107E 1 ShopManual PDFDocument371 pages107E 1 ShopManual PDFGanda PrajaNo ratings yet

- Sertifikat KMKOP Alat Angkut Hauler 2021Document1 pageSertifikat KMKOP Alat Angkut Hauler 2021bumatio latiNo ratings yet

- PRINSIP OPERASIONAL HYDRAULIC EXCAVATORDocument257 pagesPRINSIP OPERASIONAL HYDRAULIC EXCAVATORbumatio lati100% (2)

- F-038 - MST List of Backlog Repair PlanDocument1 pageF-038 - MST List of Backlog Repair PlanTaufikNo ratings yet

- D10T 2 Operation Manual Compressed - Compressed PDFDocument218 pagesD10T 2 Operation Manual Compressed - Compressed PDFrafael sa100% (1)

- Circuit - Diagram - 1Document1 pageCircuit - Diagram - 1bumatio latiNo ratings yet

- HM400-3 ECMV fill switch error improvement activityDocument6 pagesHM400-3 ECMV fill switch error improvement activitybumatio latiNo ratings yet

- LS Circuit IntroductionDocument18 pagesLS Circuit IntroductionSatria Fajri80% (5)

- Sertifikat KMKOP Driver Light Vehicle LV 2021Document1 pageSertifikat KMKOP Driver Light Vehicle LV 2021bumatio latiNo ratings yet

- Recommended Oils 8. Recommended Oils: Use Only Oils Listed Below or EquivalentDocument1 pageRecommended Oils 8. Recommended Oils: Use Only Oils Listed Below or Equivalentbumatio latiNo ratings yet

- KMKOP MEKANIK Yang Belum Tes Dan PembekalanDocument15 pagesKMKOP MEKANIK Yang Belum Tes Dan Pembekalanbumatio latiNo ratings yet

- BCA ' Sheet R&I Hauling Hino-Ready For UseDocument163 pagesBCA ' Sheet R&I Hauling Hino-Ready For Usebumatio latiNo ratings yet

- Komtrax ReviewDocument5 pagesKomtrax Reviewbumatio latiNo ratings yet

- Hitungan Gear Ratio Torqflow TransmisiDocument2 pagesHitungan Gear Ratio Torqflow Transmisibumatio latiNo ratings yet

- BCA Sheet WA 180 - 1 RepairDocument173 pagesBCA Sheet WA 180 - 1 Repairbumatio latiNo ratings yet

- 2 OilDocument38 pages2 Oilbumatio latiNo ratings yet

- Maintenance Goals: Kemampuan Asset Awal (Apa Yang Bisa Dilakukan Oleh Asset)Document9 pagesMaintenance Goals: Kemampuan Asset Awal (Apa Yang Bisa Dilakukan Oleh Asset)bumatio latiNo ratings yet

- BCA Sheet KSBDocument65 pagesBCA Sheet KSBbumatio latiNo ratings yet

- BCA Sheet Multiflo RepairDocument65 pagesBCA Sheet Multiflo Repairbumatio latiNo ratings yet

- Bca Sheet MultiflowDocument55 pagesBca Sheet Multiflowbumatio latiNo ratings yet

- Saa6d140e-5 Sen00074-02d PDFDocument470 pagesSaa6d140e-5 Sen00074-02d PDFnur muhadi100% (1)

- PT. Bukitmakmur Mandiri Utama Forklift Repair AssessmentDocument65 pagesPT. Bukitmakmur Mandiri Utama Forklift Repair Assessmentbumatio latiNo ratings yet

- BCA Sheet Cran On Truck RepairDocument12 pagesBCA Sheet Cran On Truck Repairbumatio latiNo ratings yet

- PDP Buma Fundamental Lube 2017Document44 pagesPDP Buma Fundamental Lube 2017bumatio latiNo ratings yet

- Air IntakeDocument24 pagesAir Intakebumatio latiNo ratings yet

- BCA Sheet Manitou RepairDocument71 pagesBCA Sheet Manitou Repairbumatio lati100% (1)

- PDP Buma Fundamental Lube 2017Document44 pagesPDP Buma Fundamental Lube 2017bumatio latiNo ratings yet

- 2 OilDocument38 pages2 Oilbumatio latiNo ratings yet

- The Wall Street Journal - 31.01.23Document26 pagesThe Wall Street Journal - 31.01.23MarioNo ratings yet

- High Side Vendor Address ListDocument6 pagesHigh Side Vendor Address ListDivanshu GargNo ratings yet

- Introduction To MEMS Lecture 4Document12 pagesIntroduction To MEMS Lecture 4Vaibhav ChaudharyNo ratings yet

- Drilling horizontal wells with electric downhole motorsDocument10 pagesDrilling horizontal wells with electric downhole motorsGregory DemerjiNo ratings yet

- Chapter 8 Internal Forced ConvectionDocument26 pagesChapter 8 Internal Forced ConvectionDazuky UkyNo ratings yet

- Flange Insulating Gasket Kits: Advance Products & SystemsDocument8 pagesFlange Insulating Gasket Kits: Advance Products & SystemsJF ZLNo ratings yet

- Pending List of Secondary Drawing Upto 26-10 - 2023Document5 pagesPending List of Secondary Drawing Upto 26-10 - 2023Zahidul zahidNo ratings yet

- 1LE1002-1DA33-4AA4-Z Q02 Datasheet en PDFDocument2 pages1LE1002-1DA33-4AA4-Z Q02 Datasheet en PDFhmfNo ratings yet

- CISP Harar M & E Framework For RRLH Through IFSA Fedis & GGDocument79 pagesCISP Harar M & E Framework For RRLH Through IFSA Fedis & GGaberra100% (1)

- Electronic Manufacturing IndustryDocument4 pagesElectronic Manufacturing IndustryGilbert G. Asuncion Jr.No ratings yet

- Kia Sportage 2001 G 2.0 DOHC ECM Terminal Voltage ChartDocument6 pagesKia Sportage 2001 G 2.0 DOHC ECM Terminal Voltage ChartJorge Luis Espino Cruz50% (2)

- ATASDocument1 pageATASfranlenys mendozaNo ratings yet

- Induced Polarization Survey TechniquesDocument7 pagesInduced Polarization Survey TechniquesJavedkhanaNo ratings yet

- Hybrid Inverter User ManualDocument53 pagesHybrid Inverter User ManualIrfan RisaldiNo ratings yet

- Gasoline electronic Direct Injection SystemDocument34 pagesGasoline electronic Direct Injection Systemloganathanpalani100% (1)

- 919 - User Manual - English - Revk PDFDocument348 pages919 - User Manual - English - Revk PDFVENITHA KNo ratings yet

- PXF5 PXF9 ManualDocument24 pagesPXF5 PXF9 ManualGabriel LukodaNo ratings yet

- Rates For Major Works Materials/Equipments: Rates As Proposed For 2006-07 Amount in Rs LakhsDocument23 pagesRates For Major Works Materials/Equipments: Rates As Proposed For 2006-07 Amount in Rs Lakhsapi-25885200No ratings yet

- Danish Solar PV Technical Requirements For PV ConnectionDocument99 pagesDanish Solar PV Technical Requirements For PV ConnectionSudarmono SasmonoNo ratings yet

- Model Divison Musa PakDocument6 pagesModel Divison Musa PakSania AliNo ratings yet

- Ecs 1ZR PDFDocument17 pagesEcs 1ZR PDFReinaldo Arrivillaga100% (3)

- SW-F2.1 500 Service ManualDocument15 pagesSW-F2.1 500 Service ManualEzequiel CopettiNo ratings yet

- TC 10 19 PDFDocument159 pagesTC 10 19 PDFamare addisNo ratings yet

- EDL FEED Tanki Makasar Description Satuan TotalDocument12 pagesEDL FEED Tanki Makasar Description Satuan Totalm khaeronNo ratings yet

- QQ MeterDocument10 pagesQQ MeterHasiburNo ratings yet

- Oil Test Set quick reference guideDocument12 pagesOil Test Set quick reference guideประกาศิต ศรีทะแก้วNo ratings yet

- Perbandingan Sistem Irigasi Tenaga Listrik Dan Solar Sel Sebagai Energi Pengerak Pompa Air Metode SriDocument5 pagesPerbandingan Sistem Irigasi Tenaga Listrik Dan Solar Sel Sebagai Energi Pengerak Pompa Air Metode SriSri DearniNo ratings yet

- Energy Systems Explained for PE & HealthDocument14 pagesEnergy Systems Explained for PE & HealthLuzielEstradaEscalonaNo ratings yet

- Frako Power Factor Control RelaysDocument4 pagesFrako Power Factor Control RelaysTiek Wah TeongNo ratings yet

- UHoo ProductDocument35 pagesUHoo ProductmaheshNo ratings yet