Professional Documents

Culture Documents

Lumino's Low Loss Conductor Solution For Renewable Sector

Uploaded by

vishnu ojhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lumino's Low Loss Conductor Solution For Renewable Sector

Uploaded by

vishnu ojhaCopyright:

Available Formats

Lumino’s Low Loss Conductor Solution for

renewable Sector

Nowadays world is moving towards Green/Renewable energy. Line Loss is crucial factor in renewable energy

transmission. Aside climate change and global warming pose serious threats to our planet and to the quality of

life of next generations. It is imperative to limit the emission in the atmosphere of greenhouse gases (e.g. CO2,

CH4, N2O) by reducing I2R Losses of transmission lines. Our Low Loss Type conductor (hereinafter called “3L

conductor”) can reduce transmission losses by 41% compared to equivalent ACSR Conductor. Renewable lines

adopting our 3L conductor can operate more efficiently, reducing the need of electricity from power stations.

These latter can then reduce their per unit cost, as well as CO2 emission

3L – Low Line Loss Conductor

Lumino’s 3L conductor is specially designed for renewable sector

for distribution and transmission lines. It is designed to operate

continuously at temperatures up to 85°C without loss of strength, it

designed with High conductivity Al and Special Alloy.

Advantage: -

41% less line loss than equivalent ACSR Conductor.

Easy to install similar to conventional Alloy conductors.

Can be installed with existing tower with slight

modification.

Higher volume of Aluminium in define diameter.

Construction

3L, a homogenous conductor, is a concentric-lay stranded conductor made from TW shape wire high conductivity

aluminium 1370-H19 wires and core having round wire of Special Al Alloy.

Applications

3L conductors are useful for:

Re-conductoring lines: Increase ampacity with low loss.

New lines: with slight modification in structures to match sag.

Specifications

Lumino's 3L conductor meets or exceeds the following International specifications:

ASTM B230 Specification for Aluminium Wire for Electrical Purposes.

AS/NZS-1531 Specification for Alloy Wire for Electrical Purposes.

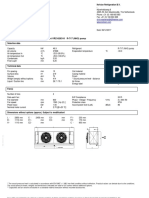

Typical size of 3L conductor and Specification

Cross Conductor Linear DC Tensile *Max Current Modulus Coefficient

Item sectional Diameter Weight Resistance at strength Carrying of Of linear

description area (mm) (kg/km) 20 Deg C (kN) capacity elasticity Expansion

sqmm (Ohm/km) 85 Deg C Gpa Per deg

3L Panther

353 22.00 974 0.0817 61.4 617 56.5 23 X 10-6

Conductor

3L Dog

177 15.65 484 0.1635` 30.9 395 56.5 23 X 10-6

Conductor

Losses comparison with ACSR Panther & 3L Conductors

S.no Discription ACSR Panther 3L Panther

1 Ampacity at 40 MW @ 0.8 PF 437 437

2 AC resistance at 40 MW 0.1747 0.0989

3 Conductor temp 82 71

4 Losses at 40 MW @ 0.3 LLF (KWH) 601 340

5 Difference in losses (KWH) N/A -261

Note: -

1. Voltage - 66 Kv, carrying 40 MW Power, Line length - 20 Ckm.

2. 3L Panther has 43.4% less loss than ACSR Panther.

Losses comparison with ACSR Dog & 3L Conductors

S.no Discription ACSR Dog 3L Dog

1 Ampacity at 28 MW @ 0.8 PF 302 302

2 AC resistance at 28 MW 0.3519 0.1981

3 Conductor temp 85 72

4 Losses at 28 MW @ 0.3 LLF (KWH) 577 325

5 Difference in losses (KWH) N/A -252

Note: -

1. Voltage - 66 Kv, carrying 28 MW Power, Line length - 20 Ckm.

2. 3L Dog has 43.67% less loss than ACSR Dog.

Cross sectional view of conductor

3L Panther 3L Dog

Assumption for Ampacity calculation: -

- Ampacity based on referenced conductor temperature, 45°C ambient temperature, 0.56 m/sec wind, in

sun, with an emissivity of 0.45 and a coefficient of solar absorption of 0.8, at sea level. (IEEE-738).

- Resistance and ampacity based on an aluminium conductivity of 61.2% IACS at 20°C and a Alloy

conductivity of 59% IACS at 20°C.

You might also like

- Bartle Introduction To Real Analysis SolutionsDocument7 pagesBartle Introduction To Real Analysis SolutionsSam Sam65% (20)

- Material Datasheets for Fire Resistant CablesDocument74 pagesMaterial Datasheets for Fire Resistant Cablesabdowais0% (1)

- A 59 ConductorsDocument2 pagesA 59 ConductorsPRAGATHI REDDYNo ratings yet

- Short Circuit CalculationDocument3 pagesShort Circuit CalculationA Hem Navas Navas100% (1)

- 3L Condcutor - Latest FinalDocument2 pages3L Condcutor - Latest Finalvishnu ojhaNo ratings yet

- MethodDocument2 pagesMethoda.singhNo ratings yet

- Ampacity of 230kV Taungoo-Loikaw LineDocument6 pagesAmpacity of 230kV Taungoo-Loikaw Line정상진No ratings yet

- RFQ For The Supply of LT (1.1,6.6 and 11KV) Cable For Steels-2 Revamping Project - 15092022 - Rev-00Document49 pagesRFQ For The Supply of LT (1.1,6.6 and 11KV) Cable For Steels-2 Revamping Project - 15092022 - Rev-00jamilNo ratings yet

- Ehv Unit 1Document11 pagesEhv Unit 1Anonymous RJvdTNNo ratings yet

- Polycab HT XLPE Cable CatlougeDocument36 pagesPolycab HT XLPE Cable CatlougeManoj Kumar PanigrahiNo ratings yet

- PV Solar Plant 30MW Project Location SpecsDocument2 pagesPV Solar Plant 30MW Project Location SpecsManohar DasNo ratings yet

- 3ph Isc at LV InstallationDocument7 pages3ph Isc at LV InstallationbambangNo ratings yet

- Typical HT & LT Power Cable Sizing CalculationDocument13 pagesTypical HT & LT Power Cable Sizing CalculationSamant SauravNo ratings yet

- 345 - OTHER-Relay SettingsDocument2 pages345 - OTHER-Relay SettingsRuchir Bhoglekar100% (1)

- LT Cable Sizing-FormulaesDocument17 pagesLT Cable Sizing-FormulaesMamoon MohdNo ratings yet

- Line Materials & Stringing in 400KV LinesDocument20 pagesLine Materials & Stringing in 400KV LinesbijoyNo ratings yet

- 1100 kWp PV Solar Project Cable and BUS DUCT SizingDocument2 pages1100 kWp PV Solar Project Cable and BUS DUCT SizingManohar Das100% (1)

- Conductor SelectingDocument9 pagesConductor SelectingtanujaayerNo ratings yet

- CT VT Calculation Al AIN Rev.2Document43 pagesCT VT Calculation Al AIN Rev.2jm.mankavil623080% (5)

- To Study The Power Cable Into Its Distinguished Parts.Document4 pagesTo Study The Power Cable Into Its Distinguished Parts.Mr Hassan RazaNo ratings yet

- Vendor DetailsDocument8 pagesVendor DetailsNeeraj NegiNo ratings yet

- MV Power CablesDocument2 pagesMV Power CablesQC ĐNNo ratings yet

- Cable Diameter 4 Core Cable Diameter 1 Core (Cu/Mica/Lshf)Document9 pagesCable Diameter 4 Core Cable Diameter 1 Core (Cu/Mica/Lshf)ershadabsaifiNo ratings yet

- Pkg-2 CT Calculation - R3 15.05.19Document8 pagesPkg-2 CT Calculation - R3 15.05.19Navaneetha KrishnanNo ratings yet

- LSCC Catalogue FinalDocument4 pagesLSCC Catalogue Finaljuan mellaNo ratings yet

- Detuning ReactorsDocument1 pageDetuning ReactorsMostafa ElSayedNo ratings yet

- AL59 157 SQMM Transmission Line SpecificationDocument2 pagesAL59 157 SQMM Transmission Line SpecificationMohamed RafiNo ratings yet

- Low Voltage Alternator - 4 Pole: 1860 To 2750 kVA - 50 HZ / 2230 To 3400 kVA - 60 HZ Electrical and Mechanical DataDocument12 pagesLow Voltage Alternator - 4 Pole: 1860 To 2750 kVA - 50 HZ / 2230 To 3400 kVA - 60 HZ Electrical and Mechanical DataParinyaNo ratings yet

- Schedule of LoadsDocument46 pagesSchedule of LoadsDel James LambongogNo ratings yet

- 5199o_enDocument12 pages5199o_enyuanmengli0801No ratings yet

- Electric ConductorsDocument6 pagesElectric ConductorsVăn Đình NhậtNo ratings yet

- Limitei) : BRB Cable IndustriesDocument10 pagesLimitei) : BRB Cable IndustriesShahriar AhmedNo ratings yet

- MV Cable Sizing CalculationDocument1 pageMV Cable Sizing Calculationsureshbabum85No ratings yet

- Al 59 ConductorsDocument3 pagesAl 59 ConductorstmmsekarNo ratings yet

- BS7870 Triplex 11kV 33kV CableDocument2 pagesBS7870 Triplex 11kV 33kV CablefoaadahmadNo ratings yet

- Surge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage ProtectionDocument4 pagesSurge Arrester For GIS ELK-3, 550 KV: Innovative and Compact Overvoltage Protectiondave chaudhuryNo ratings yet

- AC Transmission Voltage OptionsDocument4 pagesAC Transmission Voltage OptionsEng.abduallah SalemNo ratings yet

- New RegulationDocument12 pagesNew RegulationZuhaibNo ratings yet

- Current Limiting Reactors ApplicationsDocument24 pagesCurrent Limiting Reactors Applicationsmayalasan1No ratings yet

- IndianDocument15 pagesIndiansajjad_pirzadaNo ratings yet

- Collector Failures On 350 MHZ, 1.2 MW CW Klystrons at The Low Energy Demonstration Accelerator (Leda)Document3 pagesCollector Failures On 350 MHZ, 1.2 MW CW Klystrons at The Low Energy Demonstration Accelerator (Leda)SigmundNo ratings yet

- Calculating Short Circuit CurrentsDocument9 pagesCalculating Short Circuit CurrentsStiver MartinezNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- Cables in Deep WaterDocument14 pagesCables in Deep WaterCarlos GarridoNo ratings yet

- HV Cable SizingDocument11 pagesHV Cable Sizingvikasmit2k2100% (3)

- A Study On Analysis of Transmission Line Tower and Design of FoundationDocument11 pagesA Study On Analysis of Transmission Line Tower and Design of Foundationpawan paudelNo ratings yet

- 132 KV Tower Analysis PDFDocument11 pages132 KV Tower Analysis PDFViswanathan VNo ratings yet

- Module 4: Substation Equipment's Details and Operations: July 2021Document14 pagesModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiNo ratings yet

- Understanding Transmission LinesDocument133 pagesUnderstanding Transmission LinesLhorie Ladica Valerio100% (2)

- Typical HT and LT Power Cable Sizing PDFDocument26 pagesTypical HT and LT Power Cable Sizing PDF1382ace100% (2)

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- Installation Calculation Report SummaryDocument14 pagesInstallation Calculation Report SummaryToto SukisnoNo ratings yet

- CIRCUIT BREAKERS For NptiDocument56 pagesCIRCUIT BREAKERS For NptiJayPrakash YadavNo ratings yet

- System Design and Cost Estimation of Additional 100MVA Power Transformer at Balingueo SubstationDocument39 pagesSystem Design and Cost Estimation of Additional 100MVA Power Transformer at Balingueo SubstationMichael FontanillaNo ratings yet

- DEP-SFS-01 Substation Material SupplyDocument36 pagesDEP-SFS-01 Substation Material SupplyVamsi ManojNo ratings yet

- AC Transmission Line LossesDocument8 pagesAC Transmission Line LossesThakur YogendraNo ratings yet

- Cable sizing for 33kV feeder to 2MVA substationDocument3 pagesCable sizing for 33kV feeder to 2MVA substationmohanadsamaraNo ratings yet

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionFrom EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionRating: 5 out of 5 stars5/5 (1)

- ACSR - InformationDocument15 pagesACSR - Informationvishnu ojhaNo ratings yet

- Low Loss Conductor CatalogueDocument4 pagesLow Loss Conductor Cataloguevishnu ojhaNo ratings yet

- MVCC-Tech SpecDocument3 pagesMVCC-Tech Specvishnu ojhaNo ratings yet

- MVCC-Tech SpecDocument3 pagesMVCC-Tech Specvishnu ojhaNo ratings yet

- Lumino's Low Loss Conductor Solution For Renewable SectorDocument2 pagesLumino's Low Loss Conductor Solution For Renewable Sectorvishnu ojhaNo ratings yet

- Low Loss Conductor CatalogueDocument4 pagesLow Loss Conductor Cataloguevishnu ojhaNo ratings yet

- HTLS - QRDocument3 pagesHTLS - QRvishnu ojhaNo ratings yet

- Conductor FactsDocument2 pagesConductor Factsmeshari j100% (2)

- HTLS 132 KVDocument3 pagesHTLS 132 KVvishnu ojhaNo ratings yet

- Lumino - HTLSDocument11 pagesLumino - HTLSvishnu ojhaNo ratings yet

- Of Course 1 - Dossier de Revisions ConfinementDocument5 pagesOf Course 1 - Dossier de Revisions ConfinementCamNo ratings yet

- Estimation of Fabric Opacity by ScannerDocument7 pagesEstimation of Fabric Opacity by ScannerJatiKrismanadiNo ratings yet

- Enzyme ActivityDocument3 pagesEnzyme ActivityNabindra Ruwali100% (2)

- Seal Pores & ImperfectionsDocument1 pageSeal Pores & ImperfectionsP176414 Mohammad MazanNo ratings yet

- C32 MOTOR CAT Electronic Unit Injector - TestDocument2 pagesC32 MOTOR CAT Electronic Unit Injector - TestFreddy Villegas100% (1)

- English HL Grade 8 Language Exam Nov 2017 MEMODocument12 pagesEnglish HL Grade 8 Language Exam Nov 2017 MEMOThegn's PicklesNo ratings yet

- Quarter 1-Module 2 Modern ArtDocument20 pagesQuarter 1-Module 2 Modern ArtKimberly Trocio Kim100% (1)

- Guess The Animal!: ModelDocument2 pagesGuess The Animal!: ModelGiovanni Vilcapoma LauraNo ratings yet

- Rate Constant Determination 2Document8 pagesRate Constant Determination 2Divya UpadhyayNo ratings yet

- Digital control engineering lecture on z-transform and samplingDocument13 pagesDigital control engineering lecture on z-transform and samplingjin kazamaNo ratings yet

- GSL DIP Phase - 1 Cooler 45kWDocument1 pageGSL DIP Phase - 1 Cooler 45kWMuhasin PallikkalNo ratings yet

- November 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFDocument12 pagesNovember 2010 (v1) QP - Paper 3 CIE Biology A-Level PDFWiji NingNo ratings yet

- CHAPTER-9, Respiration in Organisms.Document3 pagesCHAPTER-9, Respiration in Organisms.HarshitAhelani2379ScribdNo ratings yet

- Part 1Document52 pagesPart 1Jeffry Daud BarrungNo ratings yet

- 07 - Structural Organisation in AnimalsDocument31 pages07 - Structural Organisation in AnimalsKamala Kannan XANo ratings yet

- Ex 2013 1 (Recurrent)Document30 pagesEx 2013 1 (Recurrent)alh basharNo ratings yet

- Chapter 16 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Document33 pagesChapter 16 - Gripping IFRS ICAP 2008 (Solution of Graded Questions)Falah Ud Din SheryarNo ratings yet

- Revision 2 Pages Grammar Drills 106078Document3 pagesRevision 2 Pages Grammar Drills 106078Ligia Dragomir100% (1)

- Fiber Crops - FlaxDocument33 pagesFiber Crops - Flaxmalath bashNo ratings yet

- Financing of New EnterpriseDocument8 pagesFinancing of New EnterpriseSunil BhamuNo ratings yet

- Concept of StateDocument10 pagesConcept of StateAryansh ShuklaNo ratings yet

- HymssheetDocument4 pagesHymssheettoby_wardmanNo ratings yet

- Factors to Consider in Reactor Design for Industrial ProcessesDocument3 pagesFactors to Consider in Reactor Design for Industrial Processesuma villashini100% (2)

- Aam April 2023Document198 pagesAam April 2023Adhitya DewantaraNo ratings yet

- Chapter 1 and 2Document67 pagesChapter 1 and 2Tle SupawidNo ratings yet

- RedactedDocument24 pagesRedactedJohn HarrisNo ratings yet

- #10 VHB SGT-APT Design SummaryDocument2 pages#10 VHB SGT-APT Design SummarySenthil KumarNo ratings yet

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Dip HenyDocument60 pagesDip HenyJinn Tanakrit HansuranantNo ratings yet