Professional Documents

Culture Documents

PressurePulse, Static Condition 4

Uploaded by

garciahoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PressurePulse, Static Condition 4

Uploaded by

garciahoCopyright:

Available Formats

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

PressurePulse® Survey Procedure

Static Conditions

Originator:

Checker:

Approver:

C1 Approved for construction

B1 For Client review and comment

A1 Internal review

Prepared Checked Approved Agreed

Rev No. Date Description

HPPS Client

PPS SFAS 16 PR 001 A1

Document Number

PSL Country Year Doc. Type Seq. No Rev.

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 1 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

REVISION HISTORY

Revision Revised

Description of Change Date

No. By

Initial Issue 1.0 20 MAY 2016

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 2 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

TABLE OF CONTENTS

REVISION HISTORY.....................................................................................................................2

TABLE OF CONTENTS.................................................................................................................3

1. INTRODUCTION.....................................................................................................................4

1.1 SCOPE OF WORK..................................................................................................................... 4

1.2 ABBREVIATIONS AND DEFINITIONS............................................................................................ 4

1.3 REFERENCE DOCUMENTS........................................................................................................ 5

1.4 FIELD SCHEMATIC................................................................................................................... 6

1.5 PIPELINE DETAILS.................................................................................................................... 6

1.6 COMMUNICATIONS................................................................................................................... 6

1.7 ASSUMPTIONS......................................................................................................................... 6

2. HEALTH, SAFETY & ENVIRONMENT..................................................................................7

2.1 GENERAL INFORMATION........................................................................................................... 7

2.2 INCIDENT REPORTING.............................................................................................................. 8

3. PREPARATIONS..................................................................................................................11

3.1 RESOURCES REQUIRED HPPS SUPPLY..................................................................................11

3.2 PRE-MOBILISATION FUNCTION TESTING OF EQUIPMENT...........................................................11

4. OPERATIONAL PROCEDURE............................................................................................12

4.1 PRE-SURVEYS....................................................................................................................... 12

4.2 DETAILED PROCEDURE FOR THE SURVEYS..............................................................................13

4.3 POST SURVEY ANALYSIS....................................................................................................... 16

5. MATERIAL SAFETY DATA SHEETS..................................................................................17

6. RISK ASSESSMENT............................................................................................................18

7. ON-SITE PAPERWORK.......................................................................................................19

APPENDIX 1: MARKED-UP P&IDS............................................................................................20

APPENDIX 2: PRESSUREPULSE® CALCULATIONS AND SIMULATIONS............................21

APPENDIX 3: PRESSUREPULSE® SURVEY EQUIPMENT HPPS DATASHEET....................22

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 3 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

1. INTRODUCTION

1.1 Scope of work

Halliburton Pipeline and Process Services have been contracted by Customer to carry out a

PressurePulse® survey on the (ID SIZE)” pipeline from INLET to OUTLET. The scope of work is

to perform the surveys in “static mode” with XXX fluid in the line to locate the position of a

blockage or stuck tool in the pipeline.

The PressurePulse® surveys will be performed by a technology specialist from Halliburton

Pipeline and Process Services, with the assistance of field technicians from the Customer. The

PressurePulse® survey will be repeated at least 3 times from INLET/OUTLET LOCATION.

The timing of the surveys will be at the discretion of THE CUSTOMER. The data will be quality

checked on site for consistent impulse signature and repeatability of pressure traces. Then the

data will be submitted to the SureStream ® Flow Assurance Services team for analysis to locate

the position of the blockage and issue a final report. The result will be reported with upper and

lower uncertainty limits. Preliminary results of the surveys will be communicated within 2 days

after the operation and the final report will be issued within 5 working days after demobilisation.

This document contains the detailed procedure for the PressurePulse ® surveys, the equipment,

personnel required and the risk assessment analysis associated to this operation and an HSE

and Incident report section.

1.2 Abbreviations and Definitions

CCR Central Control Room

HMS Halliburton Management System

HP High Pressure

HPPS Halliburton Pipeline & Process Services

HSE Health & Safety Executive

ID / OD Inside / Outside Diameter

JSA Job Safety Analysis

MAOP Maximum Allowable Operating Pressure

MSDS Material Safety Data Sheet

NORM Natural Occurring Radioactive Material

P&ID Piping and Instrumentation Diagram

PPE Personal Protective Equipment

PRV Pressure Relief Valve

PSL Product Service Line

PTW Permit to Work

SCADA Supervisory Control And Data Acquisition

SMS Safety Management System

Wt Wall Thickness

ΔP Differential Pressure

To be completed

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 4 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

1.3 Reference Documents

To be completed

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 5 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

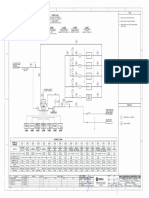

1.4 Field Schematic

To be completed

1.5 Pipeline Details

OD ID Wt Length Volume Design Pressure

Pipeline Material

(mm) (mm) (mm) (km) (m³) (bar G)

***To be completed

1.6 Communications

Communications throughout shall be maintained between the production team leader on both

platforms (if offshore) or from the inlet and outlet (if onshore), the Production Operator, and the

HPPS personnel at all times. Radios will be required on site. The Production Operator will

coordinate operations between platforms during the surveys.

Important information such as fluid composition, flow rate, and pressure through the pipeline will

be required. This information will be provided by the Customer to the HPPS engineer on site

and is required at later stages for effective analysis.

1.7 Assumptions

The following assumptions have been made in the writing of this procedure.

Client Supply Items:

One Production Operator during the operation to manipulate the valves, to connect the

pressure transmitter to the pipework etc.

SCADA available for pressure, temperature and flow recording

Transport to and from site

Transport of equipment to and from site

Electrical supply 240 V 50 Hz single phase in the accommodation to charge the Data

Logger

Worksite inductions

Worksite Permit to Work system

Site Medical Response

Medical evacuation

Site lighting if required

Messing, accommodation and ablutions

Scaffolding support if required

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 6 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

2. HEALTH, SAFETY & ENVIRONMENT

2.1 General Information

2.1.1 All personnel will attend site safety induction prior to commencing any operations. Toolbox talks

shall be performed with all relevant personnel and the appropriate form completed.

2.1.2 All relevant generic JSA’s for the job MUST be reviewed, amended if necessary and signed off

as reviewed by the HPPS Engineer/supervisor.

2.1.3 Workforce leaders will be identified and will be responsible for raising Work Permits and

Isolation Certificates to suit platform/vessel/site requirements.

2.1.4 HPPS Senior person on site (Project Engineer, Field Engineer or Supervisor) will ensure that all

requirements of the permit are met before commencing work.

2.1.5 Barriers and warning signs will be erected to cordon off the area of testing or other hazard and

no unauthorised personnel allowed within the area. Safety PA announcements will also be made

before commencement and after completion of testing operations.

2.1.6 All hoses, fittings and instruments will be of a suitable working pressure, and leak tested to a

pressure in excess of the highest system test pressure.

2.1.7 Confirm pressure setting of all Pressure Relief Devices and ensure they operate as required.

2.1.8 Ensure valve status check list filled in, signed off and filed as required. Ensure any additional

and any special safety equipment is identified and provided before actual operations commence

(e.g. special PPE for handling chemicals, eye wash stations, fire extinguishers, etc.)

2.1.9 Valves under pressure should be opened and closed carefully (in a controlled manner).

2.1.10 All personnel will wear personal protective clothing at all times on the work site. Additional

protective clothing will be worn in accordance with details of any hazardous substances being

handled.

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 7 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

2.2 Incident Reporting

General Information

The client reporting and investigating procedure will take precedence in the event of an

emergency.

However any incidents involving injury to Halliburton personnel, damage to equipment,

or high potential “Near Misses” will also be reported through Halliburton’s own reporting

system, the Global Crisis Management plan.

Synopsis of Global Crisis Management Plan

EMERGENCY RESPONSE FRAMEWORK

Emergencies are classified, under the Halliburton Company Crisis Management plan, in three

general levels. Escalation potential must always be included in assessing the appropriate

response levels.

Level 1

A worksite incident which can be handled by an on-scene HPPS Project

Minor

engineer/Field engineer, or Senior Supervisor.

Incident

Level 2 A worksite incident, where the on-scene HPPS Project engineer/Field

Serious engineer, or Senior Supervisor requires additional assistance from the offsite

Incident Incident Management Team for the Halliburton Production Enhancement PSL

Level 3 A worksite incident where the Halliburton Production Enhancement Incident

Major Management Team requires assistance from the Halliburton Business Unit

Incident Management Team.

Escalation to a higher level of incident

The decision on whether to escalate the level of the incident to a higher level, in the Halliburton

incident reporting system, is taken by the person in charge of the site (HPPS Project

engineer/Field engineer, or Senior Supervisor.).

As a general guide the next level of response must always be notified of an emergency situation

as near to it’s onset as practicable.

If in doubt, always escalate the response to the next level.

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 8 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

Duties and Responsibilities

The duties and responsibilities of our onsite personnel, (Project engineer, Field engineer or

Supervisor) when involved in any incident or emergency, are outlined below

Assess the situation and decide the Response Level. (1, 2 or 3)

Determine the extent of injury/damage.

Report the full circumstances of the incident, as soon as possible, to the HPPS Service

co-ordinator or deputy (during working hours), or HPPS duty engineer (if outside working

hours).

If a Level 2 incident mobilise the Incident Management Team and request that the

Deputy Incident Manager be contacted. The person answering the phone will request

details of the incident

Do not talk to anyone else outside the company, except the client, about the incident

and in particular do not release any information of any nature whatsoever to the media.

Complete the Incident early notification form, as soon as possible and within 12 hours of

the incident; (see sample of ENF in following page). Subsequently other forms may need

to be raised.

Keep abreast of the situation as it develops, logging information, time, personnel

present, decisions made, etc.

Offer assistance wherever possible.

Be aware of the reactions that any of your actions may have on other personnel or

property nearby.

Remain calm.

In an emergency the time of day does not matter. An immediate response and contact

with management is required.

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 9 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

HS & E Incident Early Notification Form

Sample below (FO-UK-HES-HSE-002-1 Rev 5)

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 10 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

1. PREPARATIONS

1.1 Resources Required HPPS Supply

Equipment

2 PressurePulse® survey units, each of them contained in a case 54 cm(l), 36 cm (w), 22 cm (h),

weight 14 Kg and will be mobilised to Location.

Summary of units’ content

Personnel

Item Discipline Location Quantity

1 PressurePulse® Field Engineer xxx 1

1.2 Pre-Mobilisation Function Testing of equipment

Prior to mobilisation, all equipment certificates will be reviewed by the customer.

The following will be checked:

EC declarations of conformity

Calibration certificates

Instructions manual

Evidence of up to date maintenance

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 11 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

2. OPERATIONAL PROCEDURE

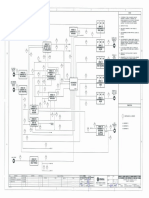

2.1 General considerations for a survey in “static” mode

A PressurePulse® in “static mode” is similar to a sonar technique and consists in recording the

time of flight from the pulse to travel from the Wellhead to the blockage. Initially the well needs

to be pressurised, then a pulse is generated by a quick depressurisation of the line. At the

position of the blockage a reflex should be visible.

The drawing below illustrates a typical configuration for a PressurePulse® survey in “static

mode” for a pipeline.

The graph below is an example of a pressure response in static conditions

Note: the fluid density and bulk modulus and the temperature and pressure profiles are critical

to estimate the acoustic velocity in the system and get accurate results.

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 12 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

2.2 Pre-surveys

Tie-ins and Valve Operations

During the preparation, the preferential tie in location for the pressure transmitter and the

preferred valve to generate the pulse have been identified by HPPS, highlighted in P&IDs and

validated by the Customer (refer to Appendix 1).

Pre survey checklist

Confirmed

Checklist Item

(HPPS Initials)

Pressure transmitter with pressure range containing the operating

pressure

Data Logger battery full

Correct date and time

Correct scale setting

Correct graph being displayed

Correct input being recorded with the suitable frequency

Correct calibration

Use the current transmitter simulator 4-20 mA to check

Record timestamp below to identify offset between recording devices:

GMT PressurePulse® Data Logger time SCADA time

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 13 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

2.3 Detailed procedure for the surveys

Action

Step Description Signature

by

Timing of the PressurePulse® surveys will be at the discretion of the

1. Customer

Customer

Locate the tie in point for the HPPS pressure transmitter HPPS /

2.

(highlighted in P&ID Appendix 1) Customer

Choose the pressure transmitter with the relevant range

For Example: if outlet pressure is around 50 barg, a pressure transmitter

3. HPPS

0-100 bar is acceptable.

Set this parameter in the Data Logger (value low “0” / high “FSD”)

Isolate the tie-in point for pressure transmitter and install the high

resolution, high fidelity HPPS instrument

4. Customer

Ensure that the correct fitting type and crossover are used.

5. Connect the HPPS pressure transmitter to the Data Logger, PRES#1 HPPS

6. Ground the Data Logger using the specified grounding cable HPPS

7. Open the isolation valve to the temporary pressure transmitter Customer

8. Switch on the Data Logger HPPS

Check that the pressure is reading via the Data Logger and that the value

is similar to a permanent instrument value on location.

Check the date is correct and adjust the time to the time at location

9. HPPS

Check that:

- the pressure transmitter is calibrated using the current simulator

- only the required input is selected and will be recorded (“Recorded

Channel in Common Parameters)

- a suitable frequency is chosen (4000 Hz in Common Parameters)

Identify proper positioning of all valves in line of the survey with a

HPPS /

10. particular focus on the bleed valve where the pulse will be generated

Customer

(highlighted in P&ID Appendix 1)

Communicate with operator to pressurize the line to predetermined HPPS /

11.

pressure. Customer

Ensure pressure on all trends are stable and constant on both SCADA HPPS /

12.

and the Data Logger Customer

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 14 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

Action

Step Description Signature

by

HOLD: HPPS / Customer to perform a risk assessment and

HPPS /

13. mitigations.

Customer

Maintain permanent communication between inlet and outlet.

Customer to inform HPPS of the process condition, just prior to

opening/closing the bleed valve. This is required for effective analysis.

HPPS to take note of time on valve closure and use stopwatch or similar

to count the time for the pulse to travel to the other end of the pipeline and

come back. (INSERT ESTIMATED TIME VALUE IN SECONDS FOR

PULSE TO TRAVEL TO END OF PIPE AND BACK)

Pipe Inlet Pipe Outlet Pipe Inlet Pipe Outlet HPPS /

14. File name

P (barg) P (barg) T (degC) T (degC) Customer

Blockage1

Blockage2

Blockage3

Blockage4

Blockage5

Change the name of the file to BlockageX and then press “Record” on

the Data Logger.

File name Time of record ON

Blockage1

15. Blockage2 HPPS

Blockage3

Blockage4

Blockage5

Record data for at least 1 min prior to closing the valve to generate the

16. HPPS

pulse.

Operator to open/close the specified bleed valve as quickly as possible to HPPS /

17.

generate the pulse. Customer

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 15 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

Action

Step Description Signature

by

At the end of the survey, hold record pressure from logger display.

File name Pressure (barg)

Blockage1

18. Blockage2 HPPS

Blockage3

Blockage4

Blockage5

After a survey, operator is to record the duration of the survey

Duration of survey

File name

(seconds)

Blockage1

HPPS /

19.

Blockage2 Customer

Blockage3

Blockage4

Blockage5

Press “Stop Record”. The file is saved to Data Logger.

File name Time of record OFF

Blockage1

20. Blockage2 HPPS

Blockage3

Blockage4

Blockage5

HPPS field engineer to check the data quality of the survey, the pulse HOLD

21.

generated, and the reflex measured are acceptable HPPS

If the quality of the survey is acceptable, repeat the steps 11 to 20 at

least two more times (total of at least 3 surveys)

HPPS /

22.

Customer

If the quality is not acceptable contact HPPS support team onshore and

Customer Production team

After at least 3 successful surveys and Customer agreement, disconnect

23. HPPS

HPPS pressure transmitter

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 16 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

2.4 Post Survey Analysis

After the survey the data will be quality checked on site for consistent impulse signature and

repeatability of pressure traces.

Then the data will be submitted to the SureStream ® Flow Assurance Services team for analysis

to locate the position of the blockage and issue a final report. The result will be reported with

upper and lower uncertainty limits. Preliminary results of the surveys will be communicated in

the day following the measurements and the final report will be issued within 5 working days

after demobilisation.

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 17 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

3. MATERIAL SAFETY DATA SHEETS

Title Pages

Sonata® 4400 and SwingTM 4400 MSDS (Lithium ion battery) 6

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 18 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

4. RISK ASSESSMENT

Risk assessments:

The following Risk Assessments have been included in the job package:

Reference Title

RA-GL-HAL-PPS-407 Rig-up Equipment Risk Analysis

RA-GL-HAL-PPS-408 Rig-down Equipment and Backload Risk Analysis

RA-GL-HAL-PPS-444 PPS Manual Handing Risk Analysis

RA-GL-HAL-PPS-405 Communication Risk Analysis

RA-GL-HAL-PPS-468 PressurePulse® kit inspection / handling

RA-GL-HAL-PPS-467 Bleed valve to generate the pulse in “Static mode”

RA-GL-HAL-PPS-469 Valve Closure & Opening during the PressurePulse® Survey

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 19 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

5. ON-SITE PAPERWORK

The following paperwork will be completed by HPPS Field Engineer

Reference Title

FO-UK-HAL-PPS-201 Pipeline Job Pack

FO-UK-HAL-PPS-605 End Job Customer Satisfaction Report

FO-GL-HAL-PPS-407 Daily Report

FO-GL-HAL-PPS-406 Deviation to Procedure

FO-GL-HAL-PPS-403 Tool Box Talk

FO-GL-HAL-PPS-401 Operations Log

FO-GL-HAL-PPS-302 Pre Job Briefing

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 20 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

APPENDIX 1: MARKED-UP P&IDS

***Attach marked-up P&ID on both ends of the pipeline

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 21 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

APPENDIX 2: PRESSUREPULSE® CALCULATIONS

AND SIMULATIONS

***Attach PressurePulse® spreadsheet calculations and any simulations performed prior to the survey

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 22 of 23

Halliburton Pipeline and Process Services

PressurePulse® Survey Procedure

SFAS-16-XXX-PR-001 Rev XX DATE

APPENDIX 3: PRESSUREPULSE® SURVEY EQUIPMENT

HPPS DATASHEET

HMS Document Number FO-GL-HAL-PPS-138

Rev. No: 1.0

Rev. Date ; 20 MAY 2016 PIPELINE & PROCESS SERVICES

Page 23 of 23

You might also like

- PressuePulse, Dynamic Flow 5Document24 pagesPressuePulse, Dynamic Flow 5garciahoNo ratings yet

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- Section 3 - Scope of WorkDocument14 pagesSection 3 - Scope of Worktrung nguyen tranNo ratings yet

- Liquid Penetrant Inspection ProcedureDocument21 pagesLiquid Penetrant Inspection ProcedureJeffrey HartNo ratings yet

- Hydrostatic & Pneumatic Test For PipingDocument12 pagesHydrostatic & Pneumatic Test For PipingFaqih Alaina FilhasmiNo ratings yet

- MMS Evaluation of HIPPS Systems for Deepwater Oil and Gas DevelopmentDocument137 pagesMMS Evaluation of HIPPS Systems for Deepwater Oil and Gas DevelopmentEyoma EtimNo ratings yet

- CFU Factory Acceptance Test Procedure PDFDocument19 pagesCFU Factory Acceptance Test Procedure PDFAgung PrasetyooNo ratings yet

- VPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Trunnion Mounted Ball ValvesDocument32 pagesVPC Erection, Installation, Commissioning, Operation and Maintenance Procedures For Trunnion Mounted Ball ValvesXmanyeyNo ratings yet

- Manual Compressor Cloro Siemmens BAYERDocument53 pagesManual Compressor Cloro Siemmens BAYERJoao Carlos PereiraNo ratings yet

- Pipeline Transient Study PS 00000 1163 0105 E - NativeDocument249 pagesPipeline Transient Study PS 00000 1163 0105 E - NativeNAMITA MODAKNo ratings yet

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDocument8 pagesHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- Rapid P0030 CPP Qac PRC 0001 0024 - A CCDocument14 pagesRapid P0030 CPP Qac PRC 0001 0024 - A CCAtuk SafizNo ratings yet

- Attach-3 ITP For Process PipingDocument11 pagesAttach-3 ITP For Process PipingSukalyan BasuNo ratings yet

- Attach-9 Work Procedure For Piping Pressure TestDocument11 pagesAttach-9 Work Procedure For Piping Pressure TestSukalyan BasuNo ratings yet

- 000 Az 001 e - SignedDocument19 pages000 Az 001 e - Signedgustavo aguilarNo ratings yet

- ISES CP Report 5Document17 pagesISES CP Report 5Tamer Hesham AhmedNo ratings yet

- Pipeline Transient StudyDocument98 pagesPipeline Transient StudyNAMITA MODAK100% (1)

- Hydraulic Report Lifting Station R0Document12 pagesHydraulic Report Lifting Station R0Unni CyriacNo ratings yet

- Hydraulic Analysis - Segment C and D Gathering SystemDocument41 pagesHydraulic Analysis - Segment C and D Gathering SystemEmad El GebesyNo ratings yet

- NCS2-TPGM-CW-1-00-02-PR-136 - POS-TOS - AlphaNDT Procedure For RT, MT, MUT (LFS-LFP, Tie-In, PLEM, Structural) - AC - Approved PDFDocument115 pagesNCS2-TPGM-CW-1-00-02-PR-136 - POS-TOS - AlphaNDT Procedure For RT, MT, MUT (LFS-LFP, Tie-In, PLEM, Structural) - AC - Approved PDFnkvonNo ratings yet

- Sop Pressure TestDocument5 pagesSop Pressure TestRichard Adolf100% (1)

- Piping Pre-Commissioning ProcedureDocument11 pagesPiping Pre-Commissioning ProcedureMarvan Audy BurikoNo ratings yet

- RP 30-10 Tube & FittingsDocument33 pagesRP 30-10 Tube & Fittingstural.abdullayevNo ratings yet

- Pipe Stress Analysis Design BasisDocument25 pagesPipe Stress Analysis Design Basischandru683100% (3)

- Pipeline Transient StudyDocument107 pagesPipeline Transient StudyNAMITA MODAKNo ratings yet

- Petrofac Limited Hsseia StandardDocument14 pagesPetrofac Limited Hsseia Standardrodman823No ratings yet

- Hydrotest Pressure Procedure - 2023Document15 pagesHydrotest Pressure Procedure - 2023Amit HasanNo ratings yet

- Project- Pipeline stress analysis reportDocument881 pagesProject- Pipeline stress analysis reportAnkithNo ratings yet

- Port Arthur Liquefaction Project: Port Arthur, TX Document Title: Radiographic Examination ProcedureDocument19 pagesPort Arthur Liquefaction Project: Port Arthur, TX Document Title: Radiographic Examination Procedurebaris121919No ratings yet

- Compliance ReportDocument1 pageCompliance Reportvirendra katkeNo ratings yet

- SC-RPS-SWP-0800-001 Z1 Pneumatic Testing for Piping SystemsDocument15 pagesSC-RPS-SWP-0800-001 Z1 Pneumatic Testing for Piping SystemsGabriel IriminNo ratings yet

- Tpp-Abe-Mp-0701-0006 - Specification For Mechanical Materials (Pig Trap) - A1 - 24-May-2016Document22 pagesTpp-Abe-Mp-0701-0006 - Specification For Mechanical Materials (Pig Trap) - A1 - 24-May-2016OlusayoNo ratings yet

- Petronas Technical Standards: Pressure Vessel - Manufacturing ReportDocument12 pagesPetronas Technical Standards: Pressure Vessel - Manufacturing ReportBenjamin LeeNo ratings yet

- 1019 PS IPS 131G - PT (E 103) - Rev.0Document3 pages1019 PS IPS 131G - PT (E 103) - Rev.0DHAVAL PANCHALNo ratings yet

- Data Sheet Ultra ReaderDocument22 pagesData Sheet Ultra ReaderPrayogo WibisonoNo ratings yet

- 311-QD60-F-4002 Test Package of Station Pipe Section of Utility Water Supply System at HTS Station-Rev.0Document32 pages311-QD60-F-4002 Test Package of Station Pipe Section of Utility Water Supply System at HTS Station-Rev.0Mohammad gani100% (1)

- KU-TWK-00-QA-PRO-0001 - 0 - Hydrostatic Pressure Testing ProcedureDocument29 pagesKU-TWK-00-QA-PRO-0001 - 0 - Hydrostatic Pressure Testing Procedurebmanojkumar16No ratings yet

- CPOC-GS-PI-0004 Rev 0 PDFDocument19 pagesCPOC-GS-PI-0004 Rev 0 PDFPCHAN@TOMNo ratings yet

- PP10CC 00 6LBB Yr Abc 001 PDFDocument26 pagesPP10CC 00 6LBB Yr Abc 001 PDFanbesivam87No ratings yet

- Tinrhert Field Development Project - Epc 1 Inlet Separation and Boosting Facility in OhanetDocument19 pagesTinrhert Field Development Project - Epc 1 Inlet Separation and Boosting Facility in OhanetbelhaskaNo ratings yet

- Piping Support SpecificationDocument18 pagesPiping Support SpecificationWahono Kris MantonoNo ratings yet

- Reporte Para Realizar Planta HDS de Una Sola Etapa en BarrickDocument51 pagesReporte Para Realizar Planta HDS de Una Sola Etapa en BarrickJuan Orlando Loaiza MurilloNo ratings yet

- L2CM 000 10 DS 001 - RaDocument15 pagesL2CM 000 10 DS 001 - RaidilfitriNo ratings yet

- Offshore Vietnam Piping ProcedureDocument15 pagesOffshore Vietnam Piping ProcedureMohammed Sibghatulla100% (1)

- Prj-10052-23-04-Lis-Pr-001 Oz - PT TDS R.00Document6 pagesPrj-10052-23-04-Lis-Pr-001 Oz - PT TDS R.00Halouani IsmailNo ratings yet

- Metallic Pipe Pressure Testing MethodDocument18 pagesMetallic Pipe Pressure Testing MethodEmirhan Pay100% (1)

- G S661 1367 001 PDFDocument250 pagesG S661 1367 001 PDFSiva baalanNo ratings yet

- Diaphragm Pumps SOWDocument30 pagesDiaphragm Pumps SOWalliancemarine2011No ratings yet

- Flow Calibration Procedure PDFDocument32 pagesFlow Calibration Procedure PDFkfathi55100% (1)

- Piping Hydrostatic Test Procedure Rev0Document8 pagesPiping Hydrostatic Test Procedure Rev0smsunil12345No ratings yet

- Petrofac Limited Hsseia StandardDocument15 pagesPetrofac Limited Hsseia Standardrodman823No ratings yet

- M0237 01 RBP PD RP 3013Document159 pagesM0237 01 RBP PD RP 3013harishNo ratings yet

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Document34 pages9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- Hydrotest Blind PDFDocument9 pagesHydrotest Blind PDFManu Jojo100% (1)

- George Mathew George Mathew 14-Aug-2022 3Document6 pagesGeorge Mathew George Mathew 14-Aug-2022 3Muhammad NoumanNo ratings yet

- Grs-pr-q-0xx_rev.a_clearing & Grading Procedure (Review)Document11 pagesGrs-pr-q-0xx_rev.a_clearing & Grading Procedure (Review)gst ajahNo ratings yet

- SP-2156 Non Metallic PipesDocument24 pagesSP-2156 Non Metallic Pipesqaiser100% (1)

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- 0008 104 IP204000 Rev1Document3 pages0008 104 IP204000 Rev1garciahoNo ratings yet

- 0008 101 IP204000 Rev1Document1 page0008 101 IP204000 Rev1garciahoNo ratings yet

- 0008 000 IP203000 Rev0Document1 page0008 000 IP203000 Rev0garciahoNo ratings yet

- 0008 105 IP204000 Rev1Document1 page0008 105 IP204000 Rev1garciahoNo ratings yet

- 0008 000 IP203001 Rev0Document2 pages0008 000 IP203001 Rev0garciahoNo ratings yet

- Lesson Plan 13Document2 pagesLesson Plan 13garciahoNo ratings yet

- Lesson Plan 9Document5 pagesLesson Plan 9garciahoNo ratings yet

- Lesson 1aDocument4 pagesLesson 1aCarlos SilvaNo ratings yet

- Lesson Plan 12Document3 pagesLesson Plan 12garciahoNo ratings yet

- How Many Things? Quiz: Yellow FruitDocument3 pagesHow Many Things? Quiz: Yellow FruitLisbeth Roos RoosNo ratings yet

- Lesson Plan 14Document3 pagesLesson Plan 14garciahoNo ratings yet

- Lesson Plan 11Document4 pagesLesson Plan 11garciahoNo ratings yet

- Animal Noises QuizDocument4 pagesAnimal Noises QuizLisbeth Roos RoosNo ratings yet

- Lesson Plan 7Document4 pagesLesson Plan 7garciahoNo ratings yet

- Lesson Plan 6Document3 pagesLesson Plan 6garciahoNo ratings yet

- Lesson Plan 10Document4 pagesLesson Plan 10garciahoNo ratings yet

- Lesson Plan 8Document4 pagesLesson Plan 8garciahoNo ratings yet

- Lesson Plan 5Document3 pagesLesson Plan 5Lisbeth Roos RoosNo ratings yet

- Etymology Quiz: Word OriginDocument3 pagesEtymology Quiz: Word OriginLisbeth Roos RoosNo ratings yet

- Lesson Plan 2Document2 pagesLesson Plan 2Lisbeth Roos RoosNo ratings yet

- Curvas S Tipicas de ProgresoDocument3 pagesCurvas S Tipicas de ProgresogarciahoNo ratings yet

- Lesson Plan 4Document3 pagesLesson Plan 4Lisbeth Roos RoosNo ratings yet

- 1 - Contract TC - Chemical Cleaning Services Rev-20May19Document9 pages1 - Contract TC - Chemical Cleaning Services Rev-20May19garciahoNo ratings yet

- Maracaibo Oct 2010Document50 pagesMaracaibo Oct 2010garciahoNo ratings yet

- Presentation Distilate DesalDocument6 pagesPresentation Distilate DesalgarciahoNo ratings yet

- 2 - Appendix 1 - General Terms and Conditions For The PRC of Goods, Services and WorksDocument9 pages2 - Appendix 1 - General Terms and Conditions For The PRC of Goods, Services and WorksgarciahoNo ratings yet

- Engineering Standard MilestoneDocument23 pagesEngineering Standard MilestonegarciahoNo ratings yet

- Curso de Planificacion. Bibliografia RecomendadaDocument1 pageCurso de Planificacion. Bibliografia RecomendadagarciahoNo ratings yet

- SIE Brochure Telecontrol enDocument16 pagesSIE Brochure Telecontrol ensolbahiaNo ratings yet

- Corrintec Subsea CP Survey BrochureDocument8 pagesCorrintec Subsea CP Survey Brochurejorge alcivarNo ratings yet

- Ghanas Jubilee Gas Export Pipeline ProjectDocument26 pagesGhanas Jubilee Gas Export Pipeline ProjectEbenezer Amoah-Kyei100% (3)

- NT G 0001 A PDFDocument5 pagesNT G 0001 A PDFCarlos Ruiz DiazNo ratings yet

- Unit 3 Basics of TransportationDocument44 pagesUnit 3 Basics of TransportationRahul GoudaNo ratings yet

- Corrosion Sensors For Structural Health MonitoringDocument32 pagesCorrosion Sensors For Structural Health MonitoringFelipe TobiasNo ratings yet

- NetCol5000-A042 In-Row Air Cooled Smart Cooling Product Quick GuideDocument32 pagesNetCol5000-A042 In-Row Air Cooled Smart Cooling Product Quick GuideWilson DominguezNo ratings yet

- 2019 - Pubs Catalog - Final PDFDocument236 pages2019 - Pubs Catalog - Final PDFB rgNo ratings yet

- Improving Scale-Up Procedures for Pneumatic Conveying DesignDocument14 pagesImproving Scale-Up Procedures for Pneumatic Conveying DesignSupitchar MeesukchaosumranNo ratings yet

- Pipeline Nadhir - Saudi AramcoDocument23 pagesPipeline Nadhir - Saudi Aramcowaseemiqbal133No ratings yet

- Gas Reception Terminal InformationDocument7 pagesGas Reception Terminal InformationkhadijaNo ratings yet

- The Optimal Engineering Design For Natural Gas Dehydration Process by TEGDocument5 pagesThe Optimal Engineering Design For Natural Gas Dehydration Process by TEGijsretNo ratings yet

- Attachment 9 - Pipeline Stream Crossing Construction Mode DeterminationDocument48 pagesAttachment 9 - Pipeline Stream Crossing Construction Mode DeterminationAly AnisNo ratings yet

- Energy Security Risks for the Baltic RegionDocument25 pagesEnergy Security Risks for the Baltic RegionThe vegetal saiyanNo ratings yet

- OAG O&G Corporate ProfileDocument26 pagesOAG O&G Corporate Profiletrkira6964No ratings yet

- GE Age of Gas Whitepaper 20131014v2Document93 pagesGE Age of Gas Whitepaper 20131014v2kessbrokerNo ratings yet

- Terminal Operator Job Description: Essential Duties and ResponsibilitiesDocument3 pagesTerminal Operator Job Description: Essential Duties and ResponsibilitiesseguntaiwoNo ratings yet

- KNT 02 RP W 0021 - B1Document110 pagesKNT 02 RP W 0021 - B1Trong VuNo ratings yet

- Saudi Aramco 2616 document analysisDocument290 pagesSaudi Aramco 2616 document analysisbillNo ratings yet

- ISES CP Report 5Document17 pagesISES CP Report 5Tamer Hesham AhmedNo ratings yet

- SC Processengineering Assessment TemplateDocument36 pagesSC Processengineering Assessment TemplateasdasdNo ratings yet

- Summer Internship Report: Indian Oil Corporation LimitedDocument34 pagesSummer Internship Report: Indian Oil Corporation Limitedshakti shanker0% (1)

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Calculate pressure drop in 10-in. Schedule 40 pipeDocument15 pagesCalculate pressure drop in 10-in. Schedule 40 piperkm_rkmNo ratings yet

- Kitchen Equipment SpecificationDocument10 pagesKitchen Equipment SpecificationPalak BatraNo ratings yet

- Huawei Security Proposal For Pipeline SecurityDocument7 pagesHuawei Security Proposal For Pipeline SecurityNnaa Kalu NtoNo ratings yet

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IIzafarbadalNo ratings yet

- Navy's Defueling Plan On Red HillDocument20 pagesNavy's Defueling Plan On Red HillHonolulu Star-AdvertiserNo ratings yet

- Logindo Samuderamakmur Tambah 2 Kapal Offshore ...Document3 pagesLogindo Samuderamakmur Tambah 2 Kapal Offshore ...Widianto Eka PramanaNo ratings yet

- Corrib Field Environmental PlanDocument76 pagesCorrib Field Environmental PlanAndreea Burcea100% (1)