Professional Documents

Culture Documents

Heating and Ventilation: Issue 02

Uploaded by

RuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heating and Ventilation: Issue 02

Uploaded by

RuanCopyright:

Available Formats

18:03-01

Issue 02 en

Heating and ventilation

Work description

111 626

© Scania CV AB 1999, Sweden

1 585 372

Contents

Heat exchanger Removal.............................................................3

Modification of heat exchanger and

damper housing .................................................5

Insulation of defroster member .........................8

Recirculation of cab air .....................................9

Fitting ................................................................13

Temperature control cable Renewal .............................................................15

Ventilation control cable Removal.............................................................16

Lubrication ........................................................16

Fitting ................................................................17

Water valve Removal.............................................................18

Fitting ................................................................19

Fan motor Removal.............................................................20

Fitting ................................................................21

Fan resistor unit Renewal .............................................................22

2 © Scania CV AB 1999, Sweden

Heat exchanger

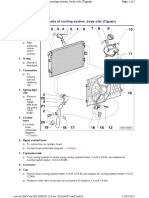

Heater unit and controls

Heat exchanger

Removal

1 Drain the coolant Refer to the Workshop

manual group 2, Cooling system.

2 Remove the upper front grille panel.

3 Remove the ventilation grille 4 or the coarse

filter 1.

Note: If fitted, coarse filter 1 should be replaced

with ventilation grille 4 on P and R cabs.

4 Remove the cab air filter 2.

115 218

2 3 4 1

Note: Note how the cab air filter is fitted. It must

be refitted in the same way.

5 Remove the outer air duct 3.

6 Loosen the wire to the windscreen wipers.

Loosen the washer hoses from the reservoir

at the T-junction and loosen them from the

clamps (2 clamps).

7 Remove the bracket for the windscreen

wipers and the front grille panel.

8 Disconnect and loosen the wiring to the fan

resistor unit and the fan motor.

1870w01b.mkr © Scania CV AB 1999, Sweden 3

Heat exchanger

9 For vehicles equipped with recirculation 1

damper. Remove the recirculation damper 10

14 and loosen the control motor 17. The

6

motor can remain in the recirculation duct.

10 Loosen the coolant pipes 7 at the bracket 6,

bracket 4 and at the water valve 5.

17

11 Remove the coolant pipes 7. 7

9

4

5

8

115 219

14

12 Detach the cable and the clamp from the

water valve 5.

Cable and clamp, older and newer design

13 Loosen the water valve from the bracket 4. 1

10

14 Remove the heat exchanger cover 8 and the

plate 9. 6

15 Remove the bolt that on the older designs

retains the heat exchanger in its housing, see

arrow at pos. 10.

17

7

16 Remove the heat exchanger 10. 9

4

Note: Be careful, there may still be coolant 5

inside the heat exchanger. 8

115 219

14

4 © Scania CV AB 1999, Sweden 1870w01b.mkr

Heat exchanger

Modification of heat exchanger

and damper housing

The temperature of the incoming warm air in the

cab may on earlier trucks be too low when the

ambient temperature is low. One cause is that

too much fresh air is mixed with the heated air

in the heater unit.

The following measures raise the temperature of

the incoming warm air. The measures are

introduced in production from September 1998

and the following chassis numbers:

Scania Södertälje 1 242 946

Scania Zwolle 4 398 440

Scania Angers 9 035 140

List of measures

1

1 Change to a more effective heat exchanger

with improved sealing against the damper

housing.

2 Fitting of an extra seal plate 1 to prevent

unheated air from leaking into the cab. This

permits use of the air distribution control

between the positions panel air vents and

floor air vents, without the addition of fresh

air. In this way, the temperature of the air

from the panel air vents is raised. The

damper housing must be adapted to the new

seal plate.

111 944

1870w01b.mkr © Scania CV AB 1999, Sweden 5

Heat exchanger

3 The air resistance is greater in the new heat

exchanger. Increase the fan speed in the fan

knob positions 1 and 2 in order to maintain

the same air flow as before, by changing the

fan resistor unit R2 from 1.5 ohms to

0.9 ohms.

4 The sealing of the recirculation damper is 140 +

− 10

70 +

−5

improved by the introduction of a new

bracket for the control motor. This reduces

the risk of cold air leaking into the cab.

On previously modified trucks, secure the

cold air damper with screws 1 as shown in

the figure.

112 260

Description

1 Remove the rubber moulding 1.

112 262

6 © Scania CV AB 1999, Sweden 1870w01b.mkr

Heat exchanger

2 Modify the damper housing. Make a recess

for the seal plate as shown in the figure.

112 263

3 Make a new recess for the pipe at 2. The 225

recess should have the same shape as the

existing recess at 1.

4 Check that the seal strip 3 between the

upper and lower damper housing is correctly

positioned.

1

2

3

112 264

5 Fit the new heat exchanger and seal plate.

Clamp the seal plate in position, between

the heat exchanger and the damper housing.

Snap the plate in place as shown in the

figure.

4 3

112 265

2 1

6 Renew fan resistor unit, refer to Fan resistor 1 Heat exchanger

unit, Renewal.

2 Seal plate

3 Damper housing

4 Heater housing

1870w01b.mkr © Scania CV AB 1999, Sweden 7

Defroster member

Insulation of member under

defroster duct

The temperature of the incoming warm air in the

cab may on earlier trucks be too low when the

ambient temperature is low. This is partly due to

the heated air in the heater assembly being

cooled by the ram air.

The member under the defroster duct is now

insulated in production from chassis numbers:

Scania Södertälje 1 242 946

Scania Zwolle 4 398 440

Scania Angers 9 035 140

For modification of earlier vehicles, a self-

adhesive insulation is available, which should be

fitted when the modification of the heat

exchanger unit is carried out.

Description

1 Remove the upper front grille panel and

brackets.

2 Remove the windscreen wiper wiring.

3 Loosen the washer hoses and remove the

windscreen wipers.

4 Remove dirt and grease from the defroster

member.

5 Remove the protective foil from the

insulation and fit the insulation.

6 Fit the windscreen wipers and the washer

hoses.

7 Refit the windscreen wiper wiring.

111 649

8 Fit the upper front grille panel and brackets.

8 © Scania CV AB 1999, Sweden 1870w01b.mkr

Heat exchanger

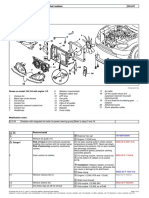

Recirculation of cab air

Trucks without AC can be complemented with a

separate function for recirculation of the cab air.

The recirculation can be used to exclude

contaminated air from the cab. The function can

also be used for quicker warming up.

Description

1 Fit the new mechanical parts.

2 Connect according to the wiring diagram

and the Workshop manual 18:03-40.

3 Fit the new switch for recirculation in a

vacant position in the heating control panel.

New electrical parts

Designation Comments New parts

Cable harness 1 378 472

Cable harness Left-hand drive 1 420 863

Cable harness Right-hand drive 1 420 864

Switch 1 421 036

1870w01b.mkr © Scania CV AB 1999, Sweden 9

Heat exchanger

New mechanical parts

Quantity Quantity

Designation Part No. Position Comments

P/R cab T cab

Seal strip 1 342 282 1 1 14

Damper 1 373 259 1 1 13

Bolt 815 871 2 2 9

Rod 1 372 940 1 1 7

Washer 144 181 1 1 -

Bolt 394 009 3 3 19

Control motor 1 372 941 1 1 6

Bolt 805 912 4 4 12

Bracket 1 423 959 1 1 8

Switch 338 617 2 2 10

Retainer 756 483 2 2 11

Air duct 1 368 749 1 15

Seal strip 1 368 829 1 (15) Pos. 15 and

16 only

Air duct 1 368 750 1 16

apply to R

Seal strip 1 368 830 1 (16) cab

Bushing 810 860 1 (16)

Seal strip 1 368 829 1 17

Air duct 1 379 524 1 15

Air duct 1 379 525 1 16

Ring 1 379 526 1 (16)

Bolt 815 871 1 19

Bracket 1 374 815 1 18

10 © Scania CV AB 1999, Sweden 1870w01b.mkr

Heat exchanger

19

6

2

7

4

5 12

8

10

11

1

9

15 17

16

14

18

13

110824

Parts for P and R cab

20

6

2

7

4

5 12

8

10

11

1

19

3

9

17 18

15

16

14

13

107195

Parts for T cab

1870w01b.mkr © Scania CV AB 1999, Sweden 11

Heat exchanger

Wiring diagram for modification to recirculation of cab air

B

111 518

A. New cable harness 1 420 863 for left-hand drive and 1 420 864 for right-hand drive trucks.

B. Not connected

12 © Scania CV AB 1999, Sweden 1870w01b.mkr

Heat exchanger

Fitting 1

10

1 Place the new heat exchanger in the heater

housing. 6

2 Fit the heat exchanger cover 8 and the plate

9.

3 Fit the water valve to the bracket 4. 17

7

9

4 Set the temperature control in the cab to "0".

Close the water valve by turning the arm 4

fully anti-clockwise. Connect the cable and 5

8

the clamp to the water valve 5.

116 263

14

5 Renew the O rings on the coolant pipes 7,

lubricating them with vaseline. Two O rings

per pipe on the same side of the flanges.

6 Connect the coolant pipes to the valve and at

bracket 4. Fit the coolant pipes using

104 410

bracket 6, which secures the pipes.

Tightening torque 8 Nm.

1 Coolant pipe

2 Bracket

3 O rings

7 For trucks equipped with recirculation

damper. Fit the recirculation damper 14 and

the control motor 17.

8 Connect the wiring to the fan resistor unit

and the fan motor. Secure the wiring using

the hooks on the heat exchanger cover.

9 Fit the wiper system and front grille panel

bracket.

10 Connect the washer hoses to the windscreen

wipers and connect the electrical connector.

1870w01b.mkr © Scania CV AB 1999, Sweden 13

Heat exchanger

11 Fit the outer air duct 3.

12 Fit the ventilation grille 4 or the coarse filter

1. If fitted, coarse filter 1 should be replaced

with ventilation grille 4 on P and R cabs.

13 Fit the cab air filter 2.

Note: Make sure the cab air filter faces the

correct way.

115 218

2 3 4 1

14 Refit the front grille panel.

15 Fill with coolant. Refer to the Workshop

manual group 2, Cooling system.

16 Run the engine until it reaches operating

temperature.

17 Check that the temperature control

functions and that no hose or pipe

connections are leaking.

14 © Scania CV AB 1999, Sweden 1870w01b.mkr

Temperature control cable

Temperature control cable

Renewal

1 Remove the sections on and under the

instrument panel as marked for left-hand

and right-hand drive trucks. In addition, fold 1

up the central electric unit on left-hand drive

trucks.

101456

1 Panels to remove on left-hand drive trucks.

2 Panels to remove on right-hand drive trucks.

2 Disconnect the cable from the temperature

control at 1.

3 Loosen the cable from the water valve at 2.

4 Set the temperature control 3 in the cab to

"0". Close the water valve by turning the

arm fully anti-clockwise.

5 Renew the cable. Clamp the new cable using

a strap at 1. The cable should otherwise be

loose without being clamped.

1870w01b.mkr © Scania CV AB 1999, Sweden 15

Ventilation control cable

Ventilation control cable

3

Removal

2

1 Loosen the panel for temperature and 1 5

ventilation control on the instrument panel.

2 Loosen the other sections in the instrument

panel centre section.

3 Disconnect the cables 1 and 2 from the 1

cable wheel 3 on the damper housing.

4

4 Disconnect the cables 1 and 2 from the

cable wheel 4 on the control panel. 2

115 220

5 Remove the cables.

Lubrication

Lubricate the cam disc, the axle, groove and any

other plastic parts of the cam disc if required,

using grease 584 084.

Note: Use of any other grease can irreparably

damage the plastic components.

16 © Scania CV AB 1999, Sweden 1870w01b.mkr

Ventilation control cable

Fitting

1 Set the temperature control on the panel to

3

"0".

2

2 Close all dampers by rotating the cam disc 5

on the damper housing anti-clockwise until 1 5

it stops.

3 Fit the common attachment point for the

cables to the cable wheel 4 on the control

panel. Wind the cable 1 (red or blue) one 1

revolution clockwise and cable 2 (black) a

half revolution anti-clockwise. 4

4 Fit the cable wheel to the axle of the

2

115 220

ventilation control on the panel.

5 Press the cable casings into the retainer on

the control panel and screw in place.

6 Hook the wires onto the cable wheel 3 on

the damper housing.

7 Press the cable casings into the retainers on

the damper housing and screw into place.

The black cable should be on the right.

Note: Ensure that the cables are not twisted

behind the ventilation control panel.

1870w01b.mkr © Scania CV AB 1999, Sweden 17

Water valve

Water valve

Removal

1 Drain the coolant, at least down to the T

junction of the pipe. Refer to Workshop

manual group 2, Cooling system.

100819

2 Loosen the coolant pipes 1 at bracket 2.

3 Remove the bolt that secures the pipes at the

water valve 3 and the bracket 4.

2

4 Remove the coolant pipes.

4

3

101440

5 Remove the two water valve retaining bolts

and detach the cable and clamp from the

water valve 3.

Cable and clamp, older and newer design

18 © Scania CV AB 1999, Sweden 1870w01b.mkr

Water valve

Fitting

1 Screw the water valve 3 onto the retainer 4.

2 Set the temperature control in the cab to "0". 2

Close the water valve by turning the arm

fully anti-clockwise. Connect the cable and

the clamp to the water valve 3.

3 Connect the coolant pipes 1 to the valve 3.

4

3

101440

4 Renew the O rings on the coolant pipes 1,

lubricating them with Vaseline. Two O rings

per pipe on the same side of the flanges.

104 410

1 Coolant pipe

2 Bracket

3 O rings

5 Fit the coolant pipes 1 using the bracket 2.

Tightening torque 8 Nm.

6 Screw the coolant pipes 1 into the retainer 4.

7 Fill with coolant. Refer to the Workshop

manual group 2, Cooling system.

8 Run the engine until it reaches operating

temperature.

9 Check that the temperature control

functions and that no hose or pipe

connections is leaking.

1870w01b.mkr © Scania CV AB 1999, Sweden 19

Fan motor

Fan motor

Removal

1 Remove the ventilation grille 4 or the coarse

filter 1.

Note: If fitted, coarse filter 1 should be replaced

with ventilation grille 4 on P and R cabs.

2 Remove the cab air filter 2.

Note: Note how the cab air filter is fitted. It must

115 218

2 3 4 1

be refitted in the same way.

3 Remove the outer air duct 3.

4 Remove the fan cowlings 1 by opening the

snap latches.

5 Disconnect the electrical connector and the 2

fan resistor electrical connector. Remove the

motor bracket 2.

6 Remove the complete motor unit 3.

115 228

1 3

20 © Scania CV AB 1999, Sweden 1870w01b.mkr

Fan motor

Fitting

1 Fit the motor unit 3.

2

2 Fit the bracket 2 and electrical connectors

for the motor.

3 Fit the fan cowlings 1 using the snap

latches.

4 Check that the fan rotates freely, without

115 228

striking the cowlings.

1 3

5 Fit the outer air duct 3.

6 Fit the ventilation grille 4 or the coarse filter

1. If fitted, coarse filter 1 should be replaced

with ventilation grille 4 on P and R cabs.

7 Fit the cab air filter 2.

Note: Ensure the cab air filter faces the correct

way.

115 218

2 3 4 1

1870w01b.mkr © Scania CV AB 1999, Sweden 21

Fan resistor unit

Fan resistor unit

Renewal

1 Remove the ventilation grille 4 or the coarse

filter 1.

Note: If fitted, coarse filter 1 should be replaced

with ventilation grille 4 on P and R cabs.

2 Remove the cab air filter 2.

Note: Note how the cab air filter is fitted. It must

115 218

2 3 4 1

be refitted in the same way.

3 Remove the outer air duct 3.

4 Loosen the electrical connector and the

bolts on the fan resistor unit 5 between the

air ducts 4.

5 Fit the fan resistor unit 5.

6 Fit the outer air duct 3.

7 Fit the ventilation grille 4 or the coarse filter

1. If fitted, coarse filter 1 should be replaced

with ventilation grille 4 on P and R cabs.

115 227

8 Fit the cab air filter 2.

Note: Ensure the cab air filter faces the correct

way.

22 © Scania CV AB 1999, Sweden 1870w01b.mkr

You might also like

- Renewal of Valve Tappet On The 14 Litre Engine: BackgroundDocument5 pagesRenewal of Valve Tappet On The 14 Litre Engine: BackgroundjoaojitoNo ratings yet

- Radiator Fan, V6: WarningDocument7 pagesRadiator Fan, V6: Warningraquettelaker2No ratings yet

- Group62-3 Aire AcondicionadoDocument9 pagesGroup62-3 Aire AcondicionadoKonax Lihysd MandeNo ratings yet

- 190404en PDFDocument36 pages190404en PDFModestasNo ratings yet

- GEA Cooler Operating InstructionsDocument26 pagesGEA Cooler Operating InstructionsAdetunji TaiwoNo ratings yet

- 5N Assembly Overview - Parts of Cooling System, Body Side (Document2 pages5N Assembly Overview - Parts of Cooling System, Body Side (AlexNo ratings yet

- SodaPDF Splitted LG856H.bookDocument30 pagesSodaPDF Splitted LG856H.bookleogerguzNo ratings yet

- Scania RDocument5 pagesScania Rnurul hidayatNo ratings yet

- 00-20-09 R&I Expansion TankDocument6 pages00-20-09 R&I Expansion Tankkang turuuNo ratings yet

- Water Pump (6HK1)Document10 pagesWater Pump (6HK1)tin tunlinNo ratings yet

- 9 Cooling SystemDocument11 pages9 Cooling SystemMehar Tariq GoheerNo ratings yet

- Yamaha T135 Service Manual CoolingDocument10 pagesYamaha T135 Service Manual CoolingRaditya Erlangga100% (2)

- Cooling System - Industrial EnginesDocument23 pagesCooling System - Industrial EnginesSyarifuddin RahmanNo ratings yet

- 31-9118 Part2Document31 pages31-9118 Part2dreamyson1983No ratings yet

- 14-CoolingDocument20 pages14-CoolingconsultasNo ratings yet

- Important: Turbocharger, V6 To RemoveDocument13 pagesImportant: Turbocharger, V6 To Removeraquettelaker2No ratings yet

- Bomba Agua Gti 1Document3 pagesBomba Agua Gti 1Carlos TopeteNo ratings yet

- EN - ACS800-04 - 04M - U4 Hardware ManualDocument3 pagesEN - ACS800-04 - 04M - U4 Hardware ManualMichael CamargoNo ratings yet

- Cooler ManualDocument15 pagesCooler Manualpiston brokeNo ratings yet

- Shown On Model 163.154 With Engine 112: AS20.00-Z-0001-01ADocument3 pagesShown On Model 163.154 With Engine 112: AS20.00-Z-0001-01AHermes VacaNo ratings yet

- Omvl Reparaturanleitung R90e Verdampfer EngDocument15 pagesOmvl Reparaturanleitung R90e Verdampfer EngbojanNo ratings yet

- Work Description: Issue 1Document9 pagesWork Description: Issue 1ruanNo ratings yet

- 6.4l Egr Delete InstructionsDocument17 pages6.4l Egr Delete Instructionssuperdick14No ratings yet

- Maintain Your Vehicle's Cooling SystemDocument28 pagesMaintain Your Vehicle's Cooling SystemLuis Daniel CortesNo ratings yet

- 1977 Jeep-1977 TSBDocument126 pages1977 Jeep-1977 TSBperzaklieNo ratings yet

- Part 412 Climate ControlDocument78 pagesPart 412 Climate ControlottenNo ratings yet

- SCANIA Work Description Engine - 12 Industrial and Marine EngineDocument76 pagesSCANIA Work Description Engine - 12 Industrial and Marine Enginemliugong82% (22)

- Repair ProcedureDocument45 pagesRepair ProcedureJefford Klein GogoNo ratings yet

- 1KD-FTV Motor Timing Belt RemovalDocument3 pages1KD-FTV Motor Timing Belt RemovalclodNo ratings yet

- OMVL R90 Use and Maintenance Manual - CompressedDocument15 pagesOMVL R90 Use and Maintenance Manual - CompressedAJNo ratings yet

- EGR Cooler Removal and InstallationDocument46 pagesEGR Cooler Removal and InstallationKevin VargasNo ratings yet

- Installation, Start-Up and Service Instructions: Hermetic, Water-CooledDocument20 pagesInstallation, Start-Up and Service Instructions: Hermetic, Water-CooledSyed Ali KhanNo ratings yet

- Installation Procedure for Evans Waterless Coolant and ResistorPac in 2011 Navistar MaxxForce 13LDocument9 pagesInstallation Procedure for Evans Waterless Coolant and ResistorPac in 2011 Navistar MaxxForce 13LVeterano del CaminoNo ratings yet

- 1KD Timing Belt RemovalDocument3 pages1KD Timing Belt RemovalMohammed Peer100% (1)

- Oil CoolerDocument3 pagesOil CoolerCahyo Utomo100% (1)

- Multiple Aligned Cooling System: PART NO. 1568204 700 SRM 1159Document16 pagesMultiple Aligned Cooling System: PART NO. 1568204 700 SRM 1159Juanjo Garcia JimenezNo ratings yet

- Remove_install exhaust gas recirculation valveDocument2 pagesRemove_install exhaust gas recirculation valveparasol2115No ratings yet

- 2010 PONTIAC VIBE Service Repair Manual PDFDocument51 pages2010 PONTIAC VIBE Service Repair Manual PDFjksmmmddNo ratings yet

- Saab 9-5 AC Expansion ValveDocument3 pagesSaab 9-5 AC Expansion Valvemike3328037No ratings yet

- Chapter C Air Conditioning SystemsDocument54 pagesChapter C Air Conditioning Systemsara.mon872No ratings yet

- Change Engine Coolant SafelyDocument7 pagesChange Engine Coolant SafelysyyNo ratings yet

- Culata Motor 3406Document3 pagesCulata Motor 3406Julio GuillenNo ratings yet

- AR20.10-B-2460H.fm Removing and Installing The Thermostat 09.09.02Document4 pagesAR20.10-B-2460H.fm Removing and Installing The Thermostat 09.09.02Łukasz HadrzynskiNo ratings yet

- Como Desarmar en El Evaporador Nevera 4 PuertasDocument5 pagesComo Desarmar en El Evaporador Nevera 4 PuertasRamon OjedaNo ratings yet

- Sporlan TXV Inst Service 12 Pgs New VersionDocument12 pagesSporlan TXV Inst Service 12 Pgs New Versionsilentsoldier781344No ratings yet

- IMPCO Upgrade Kit Installation Instructions for HYSTERDocument14 pagesIMPCO Upgrade Kit Installation Instructions for HYSTERAlvaro MartinezNo ratings yet

- Remove and Install Fan and PulleyDocument2 pagesRemove and Install Fan and PulleyAnonymous cS9UMvhBqNo ratings yet

- 1-FL and FLS Gate Valve - Operation and ManintenceDocument53 pages1-FL and FLS Gate Valve - Operation and ManintenceEdwin Vargad100% (6)

- Saab 9-5 Heat Exchanger - WIS PDFDocument8 pagesSaab 9-5 Heat Exchanger - WIS PDFIgor LackoNo ratings yet

- Service Information: 871-2322 May 2002 AllDocument9 pagesService Information: 871-2322 May 2002 AllVASEKNo ratings yet

- Scotsman Flake and Nugget Technical Service ManualDocument22 pagesScotsman Flake and Nugget Technical Service Manual911servicetechNo ratings yet

- OWNER'S GUIDE FOR PRECISION PWS 5-3 WATER DISTILLERDocument13 pagesOWNER'S GUIDE FOR PRECISION PWS 5-3 WATER DISTILLERHencheal AtangaNo ratings yet

- Fitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7Document4 pagesFitting Instructions: Anti-Condensation Heaters, HC 4, 5, 6 & P7HanNo ratings yet

- Engine CoolingDocument5 pagesEngine CoolingEl OhmimetroNo ratings yet

- VOLVO EW160B-2 Engine With Mounting and EquipmentDocument139 pagesVOLVO EW160B-2 Engine With Mounting and EquipmentPIKO MOBNo ratings yet

- Maintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterFrom EverandMaintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterNo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Products Affected: Technical Information Ti 04-05 01 13 enDocument2 pagesProducts Affected: Technical Information Ti 04-05 01 13 enRuanNo ratings yet

- Self-Pumping and Tools For The Fuel SystemDocument4 pagesSelf-Pumping and Tools For The Fuel SystemRuanNo ratings yet

- Changes: Ti 04-05 06 14 en-GB Technical InformationDocument3 pagesChanges: Ti 04-05 06 14 en-GB Technical InformationRuanNo ratings yet

- Ti 01-06 01 11 en Technical Information: BackgroundDocument4 pagesTi 01-06 01 11 en Technical Information: BackgroundRuanNo ratings yet

- Background: Ti 04-12 09 24 en-GB Technical InformationDocument2 pagesBackground: Ti 04-12 09 24 en-GB Technical InformationRuanNo ratings yet

- Changes Service Solution: Ti 01-07 04 13 en-GB Technical InformationDocument4 pagesChanges Service Solution: Ti 01-07 04 13 en-GB Technical InformationRuanNo ratings yet

- Tid 0002014 01Document1 pageTid 0002014 01RuanNo ratings yet

- Leakage From The Clutch Servo: BackgroundDocument3 pagesLeakage From The Clutch Servo: BackgroundRuanNo ratings yet

- Tid 0001678 01Document3 pagesTid 0001678 01RuanNo ratings yet

- Background Service Solution: Ti 04-11 11 21 en-GB Technical InformationDocument13 pagesBackground Service Solution: Ti 04-11 11 21 en-GB Technical InformationRuanNo ratings yet

- Background: Ti 01-08 09 26 en-GB Technical InformationDocument2 pagesBackground: Ti 01-08 09 26 en-GB Technical InformationRuanNo ratings yet

- Background: Ti 01-15 08 27 en-GB Technical InformationDocument4 pagesBackground: Ti 01-15 08 27 en-GB Technical InformationRuanNo ratings yet

- Tid 0002504 01Document2 pagesTid 0002504 01RuanNo ratings yet

- Changes: Ti 01-07 02 17 en-GB Technical InformationDocument3 pagesChanges: Ti 01-07 02 17 en-GB Technical InformationRuanNo ratings yet

- Background Production Solution: Ti 01-07 03 19 en Technical InformationDocument2 pagesBackground Production Solution: Ti 01-07 03 19 en Technical InformationRuanNo ratings yet

- Heat Shield Introduced For EGR Cooler Hose: BackgroundDocument2 pagesHeat Shield Introduced For EGR Cooler Hose: BackgroundRuanNo ratings yet

- The Engine Oil Plug Gets Stuck in The Oil Sump: BackgroundDocument1 pageThe Engine Oil Plug Gets Stuck in The Oil Sump: BackgroundRuanNo ratings yet

- Tid 0002599 01Document2 pagesTid 0002599 01RuanNo ratings yet

- Modification To Tool 99 109: BackgroundDocument1 pageModification To Tool 99 109: BackgroundRuanNo ratings yet

- New Repair Kits For Pistons and Piston Rings: Products AffectedDocument2 pagesNew Repair Kits For Pistons and Piston Rings: Products AffectedRuanNo ratings yet

- Gas Engines OSC9 G01 and OSC11 G03: en-GBDocument36 pagesGas Engines OSC9 G01 and OSC11 G03: en-GBRuanNo ratings yet

- Belt Transmission Bus: Issue 1Document20 pagesBelt Transmission Bus: Issue 1RuanNo ratings yet

- Tid 0002645 01Document1 pageTid 0002645 01RuanNo ratings yet

- Leakage at The Oil Dipstick Flange Pipe On The Cylinder BlockDocument3 pagesLeakage at The Oil Dipstick Flange Pipe On The Cylinder BlockRuanNo ratings yet

- 9 Litre Engine: Issue 2Document33 pages9 Litre Engine: Issue 2RuanNo ratings yet

- Automatic Engine Oil Filler: Issue 1Document4 pagesAutomatic Engine Oil Filler: Issue 1RuanNo ratings yet

- Pedal Assembly: Issue 1Document8 pagesPedal Assembly: Issue 1RuanNo ratings yet

- Atc Fault Code List PDFDocument10 pagesAtc Fault Code List PDFPutra PuguhNo ratings yet

- WSM 0000323 01Document34 pagesWSM 0000323 01RuanNo ratings yet

- X200 Hardware Maintenance ManualDocument260 pagesX200 Hardware Maintenance ManualAndre PennNo ratings yet

- Caterpillar-3516C HD Marine EngineDocument4 pagesCaterpillar-3516C HD Marine EngineViswanathan Damodaran100% (4)

- FUJITSU Laptop Motherboard Schematics DiagramDocument69 pagesFUJITSU Laptop Motherboard Schematics Diagramuim100% (3)

- Survey FormDocument2 pagesSurvey FormJocelyn ReamicoNo ratings yet

- Universal Angle Grinder: GWS 26-230 - 3 601 G56 4D0Document6 pagesUniversal Angle Grinder: GWS 26-230 - 3 601 G56 4D0David MurilloNo ratings yet

- Perform Mensuration and CalculationDocument37 pagesPerform Mensuration and CalculationJasmine75% (4)

- CCM FMCSA Chassis Inspection FormDocument1 pageCCM FMCSA Chassis Inspection Formido4self100% (1)

- MM 5 C Installation InstructionsDocument9 pagesMM 5 C Installation InstructionsRAJANo ratings yet

- EditedDocument25 pagesEditedVISWA RAVINo ratings yet

- Bluetooth Optical Probe: Smart Wireless Auto Protocols Detection ProbeDocument6 pagesBluetooth Optical Probe: Smart Wireless Auto Protocols Detection ProbeRed JonhNo ratings yet

- API 6A Gate ValveDocument26 pagesAPI 6A Gate ValveindraNo ratings yet

- Q470EA IM A DatasheetDocument4 pagesQ470EA IM A Datasheetsgx.premiumNo ratings yet

- SGDH Sigma IIyashkawa PDFDocument498 pagesSGDH Sigma IIyashkawa PDFAdalmi Santos SilvaNo ratings yet

- 6FC5303-0AP02-0AA0 Datasheet enDocument1 page6FC5303-0AP02-0AA0 Datasheet enSyed RomailNo ratings yet

- Details For CTH DESCDocument3 pagesDetails For CTH DESCVivek BuddyNo ratings yet

- ISO/IEC 11801 Cat. 6A & Green IT in DC: Optimizing Cabling for Energy EfficiencyDocument44 pagesISO/IEC 11801 Cat. 6A & Green IT in DC: Optimizing Cabling for Energy EfficiencyalejandroNo ratings yet

- Sauter Face Mounted VDI 50 - DIN 5480 - Left - WTO - enDocument25 pagesSauter Face Mounted VDI 50 - DIN 5480 - Left - WTO - enkorray1No ratings yet

- PIKASHOESDocument18 pagesPIKASHOESMeenakshi S. RajpurohitNo ratings yet

- History of Inverter Technology EvolutionDocument24 pagesHistory of Inverter Technology EvolutionIqbal UsmanNo ratings yet

- Wittmann M7 ManualDocument107 pagesWittmann M7 ManualBobby SchmaltzNo ratings yet

- Downloaded From Manuals Search EngineDocument11 pagesDownloaded From Manuals Search EngineAnonymous Rn2wBQNo ratings yet

- ARGUS 180 P6214xx - GBDocument4 pagesARGUS 180 P6214xx - GBchris_ohaboNo ratings yet

- A Control System Using Parallel Interface.: Microprocessor ControllerDocument4 pagesA Control System Using Parallel Interface.: Microprocessor Controllernovo orderNo ratings yet

- E12 Series: Full Electric - Zero EmissionDocument2 pagesE12 Series: Full Electric - Zero Emissionmartin grandaNo ratings yet

- Compound ManualDocument28 pagesCompound ManualoveladoNo ratings yet

- Caterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K00001-00788)Document24 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K00001-00788)rpoy9396615No ratings yet

- Duet Logic g1 Medtronic User ManualDocument16 pagesDuet Logic g1 Medtronic User ManualDavid RichmondNo ratings yet

- Testing Electronic ComponentsDocument98 pagesTesting Electronic Componentshajasoftware100% (3)

- Introduction to HVAC Systems Design and Load CalculationsDocument8 pagesIntroduction to HVAC Systems Design and Load CalculationsbalajivangaruNo ratings yet

- Crystal Radio Project (For ISC)Document5 pagesCrystal Radio Project (For ISC)Nabhoneel Majumdar100% (1)