Professional Documents

Culture Documents

Structural Analysis Report: Commercial Building, Gwarko

Uploaded by

Quality Design & ConstructionOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Analysis Report: Commercial Building, Gwarko

Uploaded by

Quality Design & ConstructionCopyright:

Available Formats

Commercial Building, Gwarko

AT

Gwarko, Lalitpur

Structural Analysis Report

Structural Design Consultant:

1 Project Detail

Name of the Project :

Location : Gwarko, Lalitpur

Type of Building : The Building covers a total plinth area of 111.89 sq. ft. The

building has been designed for two and half numbers of storeys.

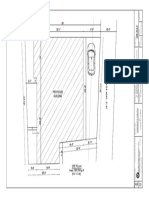

Ground Floor Plan

1 Building Design Parameters

The building consists of a RCC framed structure, which is essentially an assembly of cast-

in-situ-concrete beams and columns. Floors and roof consists of cast-in-place concrete

slabs. Lateral load resisting system consists of bare frame elements only and the system has

been designed to meet the ductility requirements of IS 800 - 2007.

For the design of the building, the Indian Standard criteria for earthquake resistant IS

1893:2002 have been referred to. All other factors related with the seismic design were also

adopted as for Kathmandu Valley of NBC 105:1994 and soil performance factor is based on

the geo technical investigation carried out at the site.

2 Load Calculation

Structural Analysis Report

Page 1

Following loads have been considered for the analysis and design of the building based on

the relevant Indian Standards.

2.1 Material

2.1.1 Concrete

Concrete is to conform to IS 456:2000 Structural use of concrete. Unless noted otherwise

concrete is to be normal-weight, with a typical dry density of 2400 kg/m3. Concrete is to

achieve the 28-day cube strength as 20 N/mm2 and 25 N/mm2.

2.1.2 Reinforcement

Reinforcement bars are to be in accordance with IS 456: specification for carbon steel bars

for the reinforcement of concrete is to be in accordance with IS 1786: specification for high

deformed steel bars for the reinforcement of concrete.

The following design strengths are to be used for the design of concrete and reinforcement.

Grade of Concrete : M20 for all columns and M20 for all other

Grade of steel : High Yield Fe 500 N/mm2

2.2 Load Calculations

2.2.1 Dead load calculation

1. Unit Weight of materials

Reinforced concrete = 25 KN/m3

Brick masonry = 18.85 KN/m3

Screed = 20.4 KN/m3

Cement plaster = 20.4 KN/m3

marble = 26.7 KN/m3

2. Floor Loads

Thickness of structural slab = 0.125 m

Thickness of screed = 0.025 m

Structural Analysis Report

Page 2

Thickness of celling plaster = 0.0125 m

Thickness of marble = 0.02 m

Dead Load of structural slab = 3.125 KN/m2

Dead Load of screed = 0.51 KN/m2

Dead Load of cement plaster = 0.255 KN/m2

Dead Load of marble = 0.534 KN/m2

Total dead load of floor finishes = 1.299 KN/m2

Dead load of partition

KN/m2

walls = 1

Total dead load = 5.424 KN/m2

3. Heights of Beams, Walls & parapet walls

Depth of Beam in Longitudinal

direction = 0.355 m

Depth of Beam in transverse

direction = 0.355 m

Height of each story of

building = 2.667 m

Height of parapet wall = 1 m

4. Dead Loads of Walls

Dead load of 230mm thick wall in longitudinal

KN/m

direction = 10.02

dead load of side plaster of exterior

KN/m

wall(12.5mm+25mm)thick = 1.77

Total dead load(Long. Dir.) = 11.79 KN/m

Dead load of 230mm thick wall in transverse

KN/m

direction = 10.02

Structural Analysis Report

Page 3

dead load of side plaster of exterior

KN/m

wall(12.5mm+25mm)thick = 1.77

Total dead load(Transverse. Dir.) = 11.79 KN/m

Dead load of 230mm thick wall with 30% in

KN/m

longitudinal direction = 8.25

Dead load of 230mm thick wall with 30%in

KN/m

transverse direction = 8.25

Dead load of 115mm thick wall in long. Direction = 5.01 KN/m

Dead load of 115mm thick wall in trans. Direction = 5.01 KN/m

Dead load of parapet wall 4"

KN/m

thick = 2.16775

2.2.2 Live Load Calculation

Live load in bedroom , living room = 2 KN/m2

Live load in corridor, staircase, balconies = 3 KN/m2

Roof live load access = 1.5 KN/m2

roof live load not access = 0.75 KN/m2

2.2.3 Seismic Loads:

Lateral Seismic Load is computed as per NBC 105:1994

The design base shear is computed as follows:

VB = C d * W

W=Seismic weight of the building

Cd=CZIK

Where,

Z = Zone factor = 1.0

Structural Analysis Report

Page 4

I = Importance factor = 1.0

R = Response reduction factor = 0.05

K = Structural performance factor = 1.0

C = Basic seismic coefficient = 0.08 if T≤ 0.5sec and

0.04/T ; T> 0.5sec

T = Natural time period

ETABS utilizes the following procedure to generate the lateral seismic loads.

User provides seismic zone co-efficient and desired seismic load command.

The structural period (T) and seismic coefficients were calculated manually.

W is obtained from the weight data provided by the user.

The total lateral seismic load (base shear) is then distributed by the program

among different levels of the structure

3 Structural Analysis

The analysis and design have been carried out using software called SAP2000 v16. It

provides the Structural Engineer with all the tools necessary to create, modify, analyze,

design, and optimize the structural elements in a building model.

Structural Analysis Report

Page 5

The building geometry based on architectural drawings been generated using above named

software. The dead load, live load and lateral loads were supplied to the digital models as

per standard code of practices. Several analysis run were performed to achieve the best

result to meet the design and service requirements.

For the analysis, following loading parameters were considered:

i. Self weight of the frames and slabs

ii. Floor finishing dead loads

iii. Fixed wall loads as per architectural drawings

iv. Staircase load

v. Partition wall loads as per architectural drawings only

vi. Live loads

Structural Analysis Report

Page 6

3.1 3D modeling of the building:

i. 3D model of the building

ii. Plan of the building

iii. Elevation of the building

3D Modeling of the building

Structural Analysis Report

Page 7

Plan of the building

Structural Analysis Report

Page 8

Elevation of the building

Structural Analysis Report

Page 9

3.2 Load Pattern Definitions

TABLE: Load Patterns

Self

Weight Auto

Name Type

Multiplie Load

r

Dead Dead 1

Live Live 0

officelive Live 0

stairs/passage Live 0

toilet/bath Live 0

roofacess Live 0

roof no acess Live 0

Superimposed

Parapet 0

Dead

Superimposed

9'' wall 0

Dead

9'' wall Superimposed

0

opening Dead

Superimposed

4'' wall 0

Dead

IS1893

EQx Seismic 0

2002

IS1893

EQy Seismic 0

2002

3.3 Methodology

Structural Analysis Report

Page 10

The design base shear is computed by ETABS 2016in accordance with the IS cod

Mass source

TABLE: Mass Source

Incl

Lu

Inclu ude Incl Incl Inclu

mp

Nam de Add ude ude de IsDef Load Multip

at

e Eleme ed Loa Late Verti ault Pattern lier

Stor

nts Mas ds ral cal

ies

s

MsS

rc1 No No Yes Yes No Yes Yes Dead 1

MsS

rc1 No No Yes Yes No Yes Yes Parapet 1

MsS

rc1 No No Yes Yes No Yes Yes 9'' wall 1

MsS 9'' wall

rc1 No No Yes Yes No Yes Yes opening 1

MsS

rc1 No No Yes Yes No Yes Yes 4'' wall 1

MsS

rc1 No No Yes Yes No Yes Yes Live 0.5

MsS officeliv

rc1 No No Yes Yes No Yes Yes e 0.5

MsS stairs/pas

rc1 No No Yes Yes No Yes Yes sage 0.5

MsS toilet/bat

rc1 No No Yes Yes No Yes Yes h 0.5

MsS

rc1 No No Yes Yes No Yes Yes roofacess 0.5

MsS roof no

rc1 No No Yes Yes No Yes Yes acess 0.5

The seismic weight and base shear generated by ETABS2016 is shown below:

Structural Analysis Report

Page 11

Load Dir. Damping Time Zone Soil Importance Seismic Base Shear

case Coeff. (%) Perid factor Type factor, (I) weight (kN)

(Z) (kN)

(Sec)

EQX X 5 0.3 1.00 II 1.0 6469.1533 221.1026

EQY Y 5 0.3 1.00 II 1.0 6469.1533 233.1449

3.3.1 Load Cases and Combinations used for analysis

Following Load combinations are to be used as per IS code:

1. 1.5DL + 1.5LL

2. 1.2DL+1.2LL1.2Ex

3. 1.2DL+1.2LL 1.2Ey

3. 1.5DL 1.5Ex

4. 1.5DL 1.5EEy

50% of LL as reduced live load RLL is to be considered when combined with EQ Load. Similarly,

earthquake load is to be considered in two horizontal directions X and Y and in each direction, the

load will be reversible, i.e. in +X and +Y directions.

3.3.2 Control of Deflection

In order to control deflection of structural elements, the criteria given in clause 23.2 of IS 456:2000

is proposed to be used.

To control overall deformation due to earthquake load, the criteria given in clause 7.11 of IS

1893:2002 is applied.

3.3.3 Control of Cracking

In order to avoid excessive cracking in the flexural members, maximum diameter and spacing of

the reinforcement is restricted as per the detailing rules indicated in clause 26.0 IS:456-2000.

3.3.4 Masonry Walls

Masonry walls have been treated as non-structural infill panels. Therefore, the structural safety of

these walls is ensured by treating them as one way / two way slab panels spanning between

adjoining beams and columns. These walls are designed as un-reinforced masonry as per` IS:1905-

1987 and IS:4326-1993.

Structural Analysis Report

Page 12

While external walls are provided with shear connector reinforcement on the underside of upper

beams and sides of columns the internal partition walls are connected to roof slabs using dry

packing mortar between top of walls and soffit of slab / beam.

3.3.5 Site conditions:

Soil Type : Gravel mixed soil

Allowable Bearing Capacity : 150 KN/sq m

3.3.6 Design procedure:

Adopt initial size of members on the basis of Architectural and serviceability requirement.

Analysis the structure in design load.

Conform the section on deflection criteria.

Design for stresses

Conform with construction criteria.

3.4 ANALYSIS PART

3.4.1 Design Software

A three dimensional analysis of the structure was carried out using a Seismic Coefficient method.

ETABS2016 software was used for analysis of the model as well as the design of beam, column,

slab element and foundation.

3.4.2 Output data results

Some of the important sample output data are presented below:

a) Base Shear

Base Reaction (UNIT KN METER)

Structural Analysis Report

Page 13

TABLE: Base Reactions

Load

Case/Combo FX FY FZ MX MY MZ

kN kN kN kN-m kN-m kN-m

Comb1 0.00 0.00 10550.75 40857.75 -89414.31 0.00

Comb2 -272.60 0.00 8440.60 32686.20 -74355.73 1021.14

Comb3 272.60 0.00 8440.60 32686.20 -68707.16 -1021.14

Comb4 0.00 -287.45 8440.60 35664.31 -71531.45 -2229.48

Comb5 0.00 287.45 8440.60 29708.09 -71531.45 2229.48

Comb6 -340.75 0.00 9485.96 36683.83 -83236.96 1276.42

Comb7 340.75 0.00 9485.96 36683.83 -76176.24 -1276.42

Comb8 0.00 -359.31 9485.96 40406.47 -79706.60 -2786.85

Comb9 0.00 359.31 9485.96 32961.20 -79706.60 2786.85

Comb10 Max 340.75 359.31 10550.75 40857.75 -68707.16 2786.85

Comb10 Min -340.75 -359.31 8440.60 29708.09 -89414.31 -2786.85

b) Modal Mass Participation Ratios

TABLE: Modal Participating Mass Ratios

Cas Mo Period( U Su Su Su R Su Su Su

UX UY RY RZ

e de sec) Z m m m X m m m

Structural Analysis Report

Page 14

U

UX UY RX RY RZ

Z

Mo 0.46 0.2 0.4 0.2 0. 0.11 0.04 0.0 0.1 0.0

1 1.433 0 0

dal 83 8 68 8 09 96 48 88 2 45

Mo 0.32 0.3 0.7 0.6 0. 0.08 0.14 0.2 0.2 0.1

2 1.359 0 0

dal 05 33 89 13 11 93 53 01 09 9

Mo 0.00 0.1 0.7 0.8 0. 0.00 0.57 0.2 0.2 0.7

3 1.307 0 0

dal 68 93 96 06 01 09 53 12 1 65

Mo 0.01 0.0 0.8 0.8 0. 0.07 0.03 0.4 0.2 0.8

4 0.491 0 0

dal 6 33 12 4 2 77 89 1 88 04

Mo 0.06 0.0 0.8 0.8 0. 0.32 0.00 0.4 0.6 0.8

5 0.465 0 0

dal 12 09 73 49 05 15 98 6 09 14

Mo 0.00 0.0 0.8 0.8 0. 0.00 0.02 0.6 0.6 0.8

6 0.397 0 0

dal 06 45 73 94 21 17 96 69 11 44

Mo 0.00 0.0 0.8 0.8 0. 0.02 0.02 0.6 0.6 0.8

7 0.316 0 0

dal 71 03 81 96 01 46 04 77 35 64

Mo 0.02 2E- 0.9 0.8 0.07 0.00 0.6 0.7 0.8

8 0.304 0 0 0

dal 99 04 11 96 86 21 77 14 66

Mo 7.3E 0.0 0.9 0.9 0. 1E- 0.01 0.7 0.7 0.8

9 0.271 0 0

dal -07 14 11 1 03 06 78 09 14 84

Mo 0.00 0.0 0.9 0.9 0. 0.00 0.00 0.7 0.7 0.8

10 0.253 0 0

dal 02 02 11 12 01 06 11 15 15 85

Mo 3.4E 1E- 0.9 0.9 3E- 0.00 0.7 0.7 0.8

11 0.207 0 0 0

dal -05 04 11 13 05 11 16 15 86

Mo 0.00 0.0 0.9 0.9 0. 0.00 0.00 0.7 0.7 0.8

12 0.187 0 0

dal 02 14 11 27 04 06 51 53 15 91

c) Story Drifts

TABLE: Story Drifts

Story Load Directi Drif Lab X Y Z

Case/Com on t el

Structural Analysis Report

Page 15

bo

m m m

-

Story 0.00 14.8

Comb1 X 64 4.99 1.1

4 2 8

9

Story 0.00 - 7.7 14.8

Comb2 X 31

4 2 0.95 5 8

Story 8E- - 7.7 14.8

Comb2 Y 31

4 04 0.95 5 8

-

Story 0.00 14.8

Comb3 X 64 4.99 1.1

4 4 8

9

-

Story 0.00 14.8

Comb4 X 64 4.99 1.1

4 2 8

9

Story 0.00 - 7.7 14.8

Comb4 Y 31

4 3 0.95 5 8

-

Story 0.00 14.8

Comb5 X 64 4.99 1.1

4 2 8

9

-

Story 0.00 14.8

Comb5 Y 64 4.99 1.1

4 3 8

9

Story 0.00 - 7.7 14.8

Comb6 X 31

4 3 0.95 5 8

Story 9E- - 7.7 14.8

Comb6 Y 31

4 04 0.95 5 8

-

Story 0.00 14.8

Comb7 X 64 4.99 1.1

4 5 8

9

-

Story 0.00 14.8

Comb8 X 64 4.99 1.1

4 3 8

9

Story 0.00 - 7.7 14.8

Comb8 Y 31

4 4 0.95 5 8

-

Story 0.00 14.8

Comb9 X 64 4.99 1.1

4 2 8

9

-

Story 0.00 14.8

Comb9 Y 64 4.99 1.1

4 4 8

9

Story Comb10 0.00 - 7.7 14.8

X 31

4 Max 3 0.95 5 8

Story Comb10 0.00 - 7.7 14.8

Y 31

4 Max 4 0.95 5 8

Story Comb10 0.00 - 14.8

X 64 4.99

4 Min 5 1.1 8

Structural Analysis Report

Page 16

9

-

Story Comb10 0.00 14.8

Y 64 4.99 1.1

4 Min 4 8

9

-

Story 0.00 20.0 11.1

Comb1 X 55 1.4

3 1 6 8

2

-

Story 0.00 20.0 11.1

Comb1 Y 55 1.4

3 1 6 8

2

Story 0.00 - 7.7 11.1

Comb2 X 31

3 3 0.95 5 8

-

Story 0.00 20.0 11.1

Comb3 X 55 1.4

3 4 6 8

2

-

Story 0.00 20.0 11.1

Comb3 Y 55 1.4

3 1 6 8

2

-

Story 0.00 20.0 11.1

Comb4 X 55 1.4

3 1 6 8

2

Story 0.00 - 11.1

Comb4 Y 41 -1

3 4 0.95 8

-

Story 8E- 20.0 11.1

Comb5 X 55 1.4

3 04 6 8

2

-

Story 0.00 20.0 11.1

Comb5 Y 55 1.4

3 3 6 8

2

Story 0.00 - 7.7 11.1

Comb6 X 31

3 4 0.95 5 8

-

Story 0.00 20.0 11.1

Comb7 X 55 1.4

3 5 6 8

2

-

Story 0.00 20.0 11.1

Comb7 Y 55 1.4

3 2 6 8

2

-

Story 0.00 20.0 11.1

Comb8 X 55 1.4

3 2 6 8

2

Story 0.00 - 11.1

Comb8 Y 41 -1

3 5 0.95 8

-

Story 0.00 20.0 11.1

Comb9 X 55 1.4

3 1 6 8

2

-

Story 0.00 20.0 11.1

Comb9 Y 55 1.4

3 4 6 8

2

Structural Analysis Report

Page 17

Story Comb10 0.00 - 7.7 11.1

X 31

3 Max 4 0.95 5 8

Story Comb10 0.00 - 11.1

Y 41 -1

3 Max 5 0.95 8

-

Story Comb10 0.00 20.0 11.1

X 55 1.4

3 Min 5 6 8

2

-

Story Comb10 0.00 20.0 11.1

Y 55 1.4

3 Min 4 6 8

2

Story 9E- -

Comb1 X 41 -1 8.01

2 04 0.95

Story 0.00 18.9

Comb1 Y 20 0 8.01

2 1 5

Story 0.00 16.6 7.7

Comb2 X 24 8.01

2 4 9 5

Story 0.00 -

Comb3 X 41 -1 8.01

2 4 0.95

Story 0.00 - 7.7

Comb4 Y 31 8.01

2 5 0.95 5

Story 6E- -

Comb5 X 41 -1 8.01

2 04 0.95

Story 0.00 18.9

Comb5 Y 20 0 8.01

2 4 5

Story 0.00 16.6 7.7

Comb6 X 24 8.01

2 4 9 5

Story 0.00 -

Comb7 X 41 -1 8.01

2 5 0.95

Story 0.00 - 7.7

Comb8 Y 31 8.01

2 6 0.95 5

Story 8E- -

Comb9 X 41 -1 8.01

2 04 0.95

Story 0.00 18.9

Comb9 Y 20 0 8.01

2 5 5

Story Comb10 0.00 16.6 7.7

X 24 8.01

2 Max 4 9 5

Story Comb10 0.00 - 7.7

Y 31 8.01

2 Max 6 0.95 5

Story Comb10 0.00 -

X 41 -1 8.01

2 Min 5 0.95

Story Comb10 0.00 18.9

Y 20 0 8.01

2 Min 5 5

Story 3E-

Comb1 X 16 1.82 0 4.84

1 04

Story 6E- 18.9

Comb1 Y 20 0 4.84

1 04 5

Story 0.00 7.7

Comb2 X 21 4.99 4.84

1 3 5

Structural Analysis Report

Page 18

Story 0.00

Comb3 X 16 1.82 0 4.84

1 4

Story 0.00 - 7.7

Comb4 Y 31 4.84

1 4 0.95 5

Story 4E- - 7.7

Comb5 X 31 4.84

1 04 0.95 5

Story 0.00 - 7.7

Comb5 Y 31 4.84

1 4 0.95 5

Story 0.00 7.7

Comb6 X 21 4.99 4.84

1 4 5

Story 0.00

Comb7 X 16 1.82 0 4.84

1 4

Story 0.00 - 7.7

Comb8 Y 31 4.84

1 5 0.95 5

Story 6E- - 7.7

Comb9 X 31 4.84

1 04 0.95 5

Story 0.00 - 7.7

Comb9 Y 31 4.84

1 5 0.95 5

Story Comb10 0.00 7.7

X 21 4.99 4.84

1 Max 4 5

Story Comb10 0.00 - 7.7

Y 31 4.84

1 Max 5 0.95 5

Story Comb10 0.00

X 16 1.82 0 4.84

1 Min 4

Story Comb10 0.00 - 7.7

Y 31 4.84

1 Min 5 0.95 5

Pstor 1E- 7.7

Comb1 X 1 0 1.67

ey 04 5

Pstor 3E- 13.7

Comb1 Y 19 0 1.67

ey 04 7

Pstor 0.00 5.1

Comb2 X 2 0 1.67

ey 1 5

Pstor 0.00 7.7

Comb3 X 21 4.99 1.67

ey 1 5

Pstor 4E- 5.1

Comb4 X 2 0 1.67

ey 04 5

Pstor 0.00 5.1

Comb4 Y 2 0 1.67

ey 2 5

Pstor 0.00

Comb5 Y 17 4.99 0 1.67

ey 2

Pstor 0.00 5.1

Comb6 X 2 0 1.67

ey 2 5

Pstor 0.00 7.7

Comb7 X 21 4.99 1.67

ey 2 5

Pstor 4E- 5.1

Comb8 X 2 0 1.67

ey 04 5

Pstor 0.00 5.1

Comb8 Y 2 0 1.67

ey 2 5

Structural Analysis Report

Page 19

Pstor 0.00 7.7

Comb9 Y 21 4.99 1.67

ey 2 5

Pstor Comb10 0.00 5.1

X 2 0 1.67

ey Max 2 5

Pstor Comb10 0.00 5.1

Y 2 0 1.67

ey Max 2 5

Pstor Comb10 0.00 7.7

X 21 4.99 1.67

ey Min 2 5

Pstor Comb10 0.00 7.7

Y 21 4.99 1.67

ey Min 2 5

Footing Sample Design

a) Strap footing

Design of strap footing

Strap Beam along 1, F and H

Working Load

carry by

column A 395.42 Factored load 434.

(PA)= 67 KN (PAu)= 97 KN

Working Load

carry by

column Factored load 518.

B(PB)= 471.5 KN (PBu)= 65 KN

sizeof column

A x-dir A 300 mm

y-dir A 300 mm

size of column

B x-dir B 350 mm

y-dir B 350 mm

c/c distance

between

column A & B

(x')= 5.18 m

consdering;

unit weight of KN/

soil (We)= 20 m2

Angle of

repose (φ) = 30 degree

safe bearing of

capacity of KN/

soil(sqc)= 150 m2

Structural Analysis Report

Page 20

characteristic

strength of N/m

concrete(fck)= 25 m2

characteristic

strength of N/m

steel(fy)= 500 m2

1. Depth of

foundation:

h=

= 0.833441 1 m

The base of foundation is located at the depth

of 1m below which soil is not subjected to

seasonal volumn

changes caused by alternate wetting and

drying;

2. Footing

dimensions:

assuming selfweight of footing=10%

of (PA+PB)

(PA+PB)

Total service +10% of

load= (PA+PB)

= 953.6193 KN

Required area

of footing 6.3574

(Af)= 62 m2

…….

L1B1 +L2B2 = 6.357462 m2 (i)

length and width of footing

L1,B1 :- under exterior column A

length and width of footing

L2,B2 :- under interior column B

considering ;

B1=B2=B= 1.9 m

3.346 …….

L1+L2 = 033 m (ii)

c/c distance between column A & B

(x)= 5.18 m

Structural Analysis Report

Page 21

c.g. of column loads from the axis of column A (x')=

2.8172

x'= 74 m

the distance of c.g. of column loads from the

left edge column A (x")= 2.97 m

distance of the centroid of the whole area from

the left edge of column A;

L1B1*L1/2+L2B2*( x- …….

dirA/2+x)=(L1B1+L2B2)*x" (iii)

(L1^2)/2+L2*( (x-

dirA)/2+x)=(L1+L2)*x"

9.9285

(L1^2)/2+L2*( (x-dirA)/2+x)= 96

9.9285

(L1^2)/2+ 5.33 L2 = 96

substituting the value of 3.3460

L1 as L1= 33 -L2

L2^2

+ 3.967935 L2 + -8.7 = 0

1.5653

L2 = 12 m

L1 = 1.780721 m

L1= 1.8 m L2 = 1.6 m

Desig

n of

footin

3. g slab

Thickness of the footing based on

a. moment:

The effective thickness of footing may be determined by

considering singly reinforced balanced section;

Pu = net upward ultimate soil pressure

KN/m

= 201.2988 2

The width of beam is considered as the max

width of pedestal = 300 mm

Structural Analysis Report

Page 22

Cantilever projection of the footing slab = 0.8 m

Maximum

bending

moment per KN

meter width = 129 m

Equating

Mu,lim to Mu;

k fck

b d^2 0.13 ( for N/m

= 128.8312 k= 3 Fe= 500 m2 )

d= 196.8406 mm

b.Thickness of footing based on one

way shear

The effective thickness of footing may be determined by

considering that the shear is resisted without

shear reinforcement as

follows;

or; d=

maximum ultimate shear per unit width at a section at

Vu,max= distance d from the face of beam

Pu(0.5B-

= 0.5b-d)

201.29 KN/

here; Pu= 88 m2

B= 1.9 m

b= 300 mm

Takin

g; bo= 1 m

shear strength of concrete in

foundation

k which may be taken as 1.0 for 300mm *shear

assumed total depth strength of concrete

which may be taken as its minimum value of

0.36 N/mm2 on consideration that the

flexural reinforcement shall be small due to

large depth of foundation slab on shear

consideration

N/mm

= 0.36 2

Therefore;

Structural Analysis Report

Page 23

0.2869

or, d= 04 m

the thickness of footing is governed

Therefore; by one way shear.

Hence; d= 286.9043 mm

clear cover of 50mm +

and , D= 286.9043 mm + (assumed diameter)/2

at a

clearco

Providing 10 mm φ ver = 40 mm

D= 331.9043 mm

consider; D= 350 mm

effective depth

(d) = 305 mm

upto

a

dista

A uniform nce

thickness of 350 mm of 305 mm

(from the face

and then it is reduced linearly to of footing

200mm at the edge; beam)

Provided

overall depth

(D) = 350 mm d= 305 mm

Mu/b

d2 = 1.38491

Percentage of steel

required

pt,li 0.94 ( for N/m

pt % 0.34191 % m = 75 % Fe= 415 m2 )

Ast = 1042.824 mm2

75.312 mm

Spacing of 10 mm φ bar 3 c/c

Provided mm φ

spacing of 10 bar @ 75 mm c/c

Actual area of steel 1047.1

provided = 67 mm2

rebar

percentage of steel provided (Pt% percent

provided) = 0.34 % OK

Structural Analysis Report

Page 24

For the development length , the following

conditon should be satisfied,

Length of bar beyond

the face of beam Ld

0.5(B-b)-clearcover of

25mm Ld =

( for N/m

= 775 = 566 mm Fck= 20 m2 )

it is N/m

Hence, safe τbd= 1.2 m2

Distribution steel = 0.12% of bd

= 366 mm2

require mm

spacing of 10 mm dia d 215 c/c

mm mm

provided spacing of 10 dia 200 c/c

Design of strap beam

The maximum bending moment for the strap

beam will occur where the shear force is zero.

Let , zero shear force occur at a distance x'''

from left edge of column A;

(from

1.550 left x''' (form right

x''' = 824 m edge) = 1.36 m edge)

Maxiu

Maxiumum mum KN

B.M = -138.513 KNm B.M = -261 m

Then, Maximum Bending Moment KN

(Mu,max) = -261 m

Consider

The width of beam is considered as the max

width of pedestal = 300 mm

Equating Mu,lim to Mu,

Mu k fck b ……. 0.13 ( for N/m

= d^2 (iv) k= 3 Fe= 500 m2 )

d = 511.4206

mm

at a

clearco

ver of

let , 16 mm = 25 mm

overall depth 544.4206 mm

Structural Analysis Report

Page 25

=

Provide an overall

depth of = 450 mm

Thus, effective depth = 417 mm

5.00122

pt % pt,li 0.94 ( for N/m

= 1.793886 % m = 75 % Fe= 500 m2 )

Therefore, Ast = 2244.151 mm2

Provide 3 25 mm + 4 16 mm

provide

Provded d pt%

Ast = 2277 mm2 = 1.82 %

Check for

shear

S.F. at distance 'd' from the face of the column

A= -319 KN

S.F. at distance 'd' from the face of the column

B= 414 KN

Nominal shear stress at 2.5492 N/m

column A = 46 m2

Nominal shear stress at 3.3085 N/m

column B = 32 m2

percentage of steel 1.8199

provided (pt%) = 86 %

N/m

permissible shear stress = 0.54 m2

shear reinforcement is

require at column A

shear reinforcement is

require at column B

Spacing shear

reinforcement ;

- legged

stirrups of

2 dia 8 mm

Sv = 60.21626 mm 313 mm &

Structural Analysis Report

Page 26

min

of

0.75d 450

c/c = mm

min. shear

reinforcement

criteria

mm

302.4732 c/c

Provide shear 2- legged stirrups of

stirrups of 8mm dia @ 200mmc/c

b) Isolated

Isolated Footing

Column no. C3

load case 37

Concrete grade, M 25

Steel grade, Fe 500

Axial load, kN 684.74 kN

My, kNm 18.33 kNm

Mz, kNm 0.003 kNm

Column size, b 300 mm

Column size, d 300 mm

SBC of soil, kN/m2 150 kN/m2

Design factor 1.5

Pressure: Axial load 684.74 kN

App. Self weight 68.474 kN

753.21

Total weight 4 kN

5.0214

Area of footing 3 m2

size of footing, Bf 2.3 mt

size of footing, Df 2.3 mt

Projection, b1 1 mt

Projection, d1 1 mt

Footing Pressure,

Pmax = P/A + My/Zy +

Mz/Zz

Structural Analysis Report

Page 27

138.48

Pmax 1 kN/m2

Pmin = P/A - My/Zy -

Mz/Zz

Pmin 120.4 kN/m2

Eccentricity:

1.2303

Y 2 mt

1.0696

X 8 mt

L 2.3 mt

1.5333

2/3 L 3 mt

b 2.3 mt

194.16

qu 1 kN/m2

194.16

Eff. qu 1 kN/m2

Shear Chk.

One way Shear : At

distance d from face of

column.

pt assumed 0.25 %

N/mm

Designed shear stress 0.36 2

vu 290.27

350.36

d= 9 mm

d provided 350 mm

Two way Shear : At

distance d/2 from face of

column.

Perimeter 2600 mm

945.07

S.F. at this section 7 kN

Ks 1

N/mm

tc 1.25 2

1.0385 N/mm

tv 5 2

Resistance 1137.5 N/mm Saf

Structural Analysis Report

Page 28

2 e

Flexure design:

For section efbg

138.47

pressure@f 8 kN/m2

138.48

pressure@b 1 kN/m2

97.080

Moment@eg. Meg 3 kNm

145.62

Mu 1 kNm

d provided 350 mm

1.1887 N/mm

Mu/bd2 4 2

pt 0.2902 %

pt provided 0.2902

mm2/

m

Ast 1015.7 width

provide 10 50

mm2/

m

Ast Provided 1413 width

Check in other

direction :

For section abcd

138.48

pressure@b 1 kN/m2

120.40

pressure@c 3 kN/m2

97.080

Moment@ad, Mad 3 kNm

145.62

Mu 1 kNm

209.25

d req 4 mm

1.1887

M/bd2 4

pt 0.2902%

mm2/

m

Ast 1016 width

Structural Analysis Report

Page 29

provide 10 50

Ast provided 1413 mm2

Slab Design

Slab design

C-

D

INPU fro

T m

Location 1-2

g

Design 9.2 fc N/m c 1.

moment, M 5 kNm/m u 25 m² = 5

g

50 N/m s 1.

ßb 1 fy 0 m² = 1

42

span 54 mm

12

Height, h 5 mm

Bar Ø 8 mm

mm to this

reinforcem

cover 20 ent

OUTP A-C from 2-3

Structural Analysis Report

Page 30

UT

d = 115 - 20 -

8/2 = 91.0

mm .

(3.4.4. K' = 0.156 >

4) K = 0.045 ok .

z = 91.0 [0.5

+ (0.25 -

0.045 /0.9)^½

= 86.2 >

(3.4.4. 0.95d = 86.5

4) mm

As = 9.25E6 /

500 /86.2 x

1.05 = 225 >

(3.4.4. min As = 150

1) mm²/m

PROVIDE Y8 As increased by

@ 100 = 503 90.5% for

mm²/m deflection

fs = 2/3 x 500

x 225 /503

/1.00 = 149.4

(Eqn 8) N/mm²

Tens mod

factor = 0.55

+ (477 -

149.4) /120

/(0.9 + 1.117)

(Eqn 7) = 1.904 CHECKS

Permissible

L/d = 26.0 x

(3.4.6. 1.904 =

3) 49.493 Deflection is ok

Actual L/d =

4254 /91.0 = Maximum

. 46.747 ok spacing is ok

Minimum spacing

. is ok

Staircase Design

Staircase Design

Data

Effective Span (l) 2640 mm

Structural Analysis Report

Page 31

Riser (R) 177.8 mm

Thread (T) 254 mm

Waist Slab thickness

125 mm

(t)

Clear Cover 15 mm

Effective Depth of

110 mm

Waist Slab (d)

Grade of Concrete

20 mpa

(fck)

Grade of Steel (fy) 500 mpa

Loading

Loads on

Loads on going

waist slab

Self

Self weight of waist KN/ weight of KN/

3.81454863 3.125

slab m landing m

slab

KN/ Live KN/

Self weight of steps 2.2225 2

m Load m

Floor

KN/ KN/

Live Load 3 Finish 1

m m

Load

KN/ Total KN/

Floor Finish Load 1 6.125

m Load m

10.0370486 KN/ Factored 9.187 KN/

Total Load

3 m Load 5 m

15.0555729 KN/

Factored Load

4 m

Bending Moment

13.11641515

Reaction

19.87335629

Area of Main Steel

Structural Analysis Report

Page 32

Ast 293.880957

Spacing

Diameter of bar 12ø 16ø

384.840639

Spacing across x 684.2

9

10ø @ 150

Provded Main Steel:

c/c

Area of Distribution

Steel

Ast 150

Spacing

Diameter of bar 8ø 10ø

335.103216

Spacing across y 523.6

4

Provided Distridution 10ø @ 150

Steel: c/c

Structural Analysis Report

Page 33

You might also like

- Seismic Design of Elevated TanksDocument64 pagesSeismic Design of Elevated TanksMahadev Sastry100% (3)

- Loading For Structural Analysis - ManilaDocument30 pagesLoading For Structural Analysis - ManilajayNo ratings yet

- Structural Analysis and Design ReportDocument31 pagesStructural Analysis and Design Reportlaxmi sunder libiNo ratings yet

- ABC Office Civil Design ChecklistsDocument15 pagesABC Office Civil Design ChecklistsGia Vinh Bui TranNo ratings yet

- SubstationDocument73 pagesSubstationShubham MittalNo ratings yet

- Protection PileDocument10 pagesProtection PilePrakash GuragainNo ratings yet

- ANALYSIS AND DESIGN OF COMPOSITE SLAB (STEEL DECK SLABDocument1 pageANALYSIS AND DESIGN OF COMPOSITE SLAB (STEEL DECK SLABAndro Rebuyas0% (1)

- Structural Analysis & Design: Code and SpecificationsDocument2 pagesStructural Analysis & Design: Code and SpecificationsArnold Verceles100% (1)

- 25M x 40M Sugar Godown DesignDocument23 pages25M x 40M Sugar Godown DesignabbasamuNo ratings yet

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)Document25 pagesAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)AVBP100% (3)

- Raft DesignDocument28 pagesRaft DesignMkh Engcivil75% (4)

- Reinforced Concrete DesignDocument43 pagesReinforced Concrete DesignWilbert Carlo RachoNo ratings yet

- Design Structural EngineeringDocument12 pagesDesign Structural EngineeringHarshana PrabhathNo ratings yet

- Basement Wall Load Determination for Two Storey BlockDocument1 pageBasement Wall Load Determination for Two Storey BlockkayshephNo ratings yet

- Design of Drain Box FoundationDocument16 pagesDesign of Drain Box FoundationGOMASH RCPNo ratings yet

- Detailing of ReinforcementDocument37 pagesDetailing of Reinforcementsoroware100% (9)

- Manual Deisgn Shear WallDocument4 pagesManual Deisgn Shear WallQuality Design & ConstructionNo ratings yet

- RC Example-Problems Canete PDFDocument45 pagesRC Example-Problems Canete PDFRhonoelle Reevenujlah100% (1)

- DCP Reviewed - 091117 One Hyde Park DFI PaperDocument10 pagesDCP Reviewed - 091117 One Hyde Park DFI PaperAnonymous v1blzDsEWA100% (1)

- Concrete DesignDocument78 pagesConcrete Designongora geoffreyNo ratings yet

- Fire Pipe Trench-Doc TemplateDocument63 pagesFire Pipe Trench-Doc TemplateSivaAgathamudiNo ratings yet

- A Report On Structure Analysis and Design of Residential BuildingDocument12 pagesA Report On Structure Analysis and Design of Residential BuildingBinod Raj GiriNo ratings yet

- Structure Analysis&Design Report FinalDocument38 pagesStructure Analysis&Design Report FinalAbdulFatah El-falah100% (1)

- Oneway SlabDocument4 pagesOneway Slabvishnumani3011No ratings yet

- 5x2 U TroughDocument5 pages5x2 U Troughsantosh yevvariNo ratings yet

- Building seismic analysis data sheetDocument20 pagesBuilding seismic analysis data sheetBilal A BarbhuiyaNo ratings yet

- Plot 02Document157 pagesPlot 02George GeorgianNo ratings yet

- Design of Pier FinalDocument5 pagesDesign of Pier FinalAnonymous mcHqIfbnV1100% (1)

- A Report On Structural Analysis and Design OF Industrial BuildingDocument20 pagesA Report On Structural Analysis and Design OF Industrial BuildingRoshan KejariwalNo ratings yet

- Deck Slab - Box CulvertDocument4 pagesDeck Slab - Box CulvertSrinivas Regulavalasa100% (2)

- 5x2 U Trough SignedDocument5 pages5x2 U Trough Signedsantosh yevvariNo ratings yet

- Loading Structrual Design TemplateDocument1 pageLoading Structrual Design TemplateJelal EdrisNo ratings yet

- Lea Associates South Asia Pvt. LTDDocument41 pagesLea Associates South Asia Pvt. LTDajayNo ratings yet

- Types of RebarDocument3 pagesTypes of RebarSanderNo ratings yet

- A Report On Structural Design of Residential Building of Ms. Kalpana ThapaDocument16 pagesA Report On Structural Design of Residential Building of Ms. Kalpana ThapaKrishnaNo ratings yet

- Stair Calculation SheetDocument28 pagesStair Calculation SheetShuvam PyakurelNo ratings yet

- Materials, reinforcement and structural dimensionsDocument1 pageMaterials, reinforcement and structural dimensionsajay thakulNo ratings yet

- Dead Load Calculation First Floor: 230mm Thick Block Wall LoadDocument18 pagesDead Load Calculation First Floor: 230mm Thick Block Wall Loadsagu27No ratings yet

- Ug Sump DesignDocument12 pagesUg Sump DesignMiko AbiNo ratings yet

- Rest AreaDocument37 pagesRest Areachiranjeevi OMSNo ratings yet

- Residential Building Analysis ReportDocument25 pagesResidential Building Analysis ReportSANDIP BUDHATHOKINo ratings yet

- 16 ShearwallDocument1 page16 ShearwallNiranjan ShresthaNo ratings yet

- 2015-27-Ed4-Brick Masnory Wall Load Calc.Document8 pages2015-27-Ed4-Brick Masnory Wall Load Calc.burhan.kanjeta1988No ratings yet

- Preliminary Design Beam Load CalculationDocument3 pagesPreliminary Design Beam Load CalculationshaimenneNo ratings yet

- Boundry Wall DesignDocument4 pagesBoundry Wall DesignHikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- SS0-5000-J-005-R1 & S-005-R1 Containerized Substation FoudationDocument15 pagesSS0-5000-J-005-R1 & S-005-R1 Containerized Substation FoudationAllan MwesigwaNo ratings yet

- LOAD CALCULATION DEAD LIVEDocument2 pagesLOAD CALCULATION DEAD LIVEEr Saroj PaudelNo ratings yet

- Structural Analysis of Residential BuildingDocument32 pagesStructural Analysis of Residential Buildingramesh sitaulaNo ratings yet

- Boundry Wall Design (A)Document2 pagesBoundry Wall Design (A)Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- LOADING AND SLAB DESIGN DETAILS FOR KALESWARAM PUMP HOUSEDocument29 pagesLOADING AND SLAB DESIGN DETAILS FOR KALESWARAM PUMP HOUSEp_ignatiusNo ratings yet

- Oil SumpDocument4 pagesOil SumpSuchitra PandaNo ratings yet

- Staticaculationr ModDocument8 pagesStaticaculationr ModEngineeri TadiyosNo ratings yet

- Boundry Wall Design (B)Document2 pagesBoundry Wall Design (B)Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Structural data for wet well designDocument328 pagesStructural data for wet well designHarsh BhavsarNo ratings yet

- Design of Box Culvert Type Section (E-E)Document4 pagesDesign of Box Culvert Type Section (E-E)ask.kulkarni KulkarniNo ratings yet

- Retaining Wall Design and AnalysisDocument13 pagesRetaining Wall Design and Analysisnejat belayNo ratings yet

- Structural Analysis & Design of 3 Storey Residential BuildingDocument28 pagesStructural Analysis & Design of 3 Storey Residential BuildingBikal BastakotiNo ratings yet

- 1 NirdeshDocument28 pages1 NirdeshBikal BastakotiNo ratings yet

- Load calculation for ERA HOMES G+8 buildingDocument2 pagesLoad calculation for ERA HOMES G+8 buildingJoseph SebastianNo ratings yet

- Report Wash RoomDocument14 pagesReport Wash Roomjuliyet strucNo ratings yet

- Masonry Wall Footing DesignDocument18 pagesMasonry Wall Footing DesignAnonymous 0JQGC2No ratings yet

- STAAD - Pro & STAAD Advanced Concrete Designer: Reinforced-Concrete Building Project UsingDocument1 pageSTAAD - Pro & STAAD Advanced Concrete Designer: Reinforced-Concrete Building Project UsingHolly WestNo ratings yet

- Load Calculation Input DetailsDocument2 pagesLoad Calculation Input DetailsJoseph SebastianNo ratings yet

- 2015 08 ED4 Masonary Cantilever WallDocument12 pages2015 08 ED4 Masonary Cantilever Wallburhan.kanjeta1988No ratings yet

- Two Way Slab DesignDocument6 pagesTwo Way Slab DesignsarathNo ratings yet

- 1.structure Report - HOmeDocument23 pages1.structure Report - HOmeBibek WagleNo ratings yet

- Equations UsedDocument6 pagesEquations Usedneeta rautelaNo ratings yet

- Contractor Title: ProjectDocument10 pagesContractor Title: ProjectChinu PurohitNo ratings yet

- Asrafeege Calc Sheet PDFDocument8 pagesAsrafeege Calc Sheet PDFSaaidhNo ratings yet

- Training Package - ParticipantsDocument10 pagesTraining Package - ParticipantsQuality Design & ConstructionNo ratings yet

- 1.0 Membership Application With KYM FormDocument3 pages1.0 Membership Application With KYM FormQuality Design & ConstructionNo ratings yet

- Story displacement under EQ loadDocument2 pagesStory displacement under EQ loadQuality Design & ConstructionNo ratings yet

- Traditional building design training for heritage sitesDocument2 pagesTraditional building design training for heritage sitesQuality Design & ConstructionNo ratings yet

- Request Letter - LumantiDocument1 pageRequest Letter - LumantiQuality Design & ConstructionNo ratings yet

- Max story displacements under EQ loadDocument2 pagesMax story displacements under EQ loadQuality Design & ConstructionNo ratings yet

- ICAN building painting supervision agreementDocument1 pageICAN building painting supervision agreementQuality Design & ConstructionNo ratings yet

- DR ULSyDocument2 pagesDR ULSyQuality Design & ConstructionNo ratings yet

- Site PlanDocument1 pageSite PlanQuality Design & ConstructionNo ratings yet

- DR SLSyDocument2 pagesDR SLSyQuality Design & ConstructionNo ratings yet

- First & Second Floor PlanDocument1 pageFirst & Second Floor PlanQuality Design & ConstructionNo ratings yet

- Dis ULSyDocument2 pagesDis ULSyQuality Design & ConstructionNo ratings yet

- Dis SLSyDocument2 pagesDis SLSyQuality Design & ConstructionNo ratings yet

- DR SLSXDocument2 pagesDR SLSXQuality Design & ConstructionNo ratings yet

- Running Bill IDocument3 pagesRunning Bill IQuality Design & ConstructionNo ratings yet

- Dis SLSXDocument2 pagesDis SLSXQuality Design & ConstructionNo ratings yet

- DR ULSxDocument2 pagesDR ULSxQuality Design & ConstructionNo ratings yet

- Ground FloorDocument1 pageGround FloorQuality Design & ConstructionNo ratings yet

- GF Extra BillsDocument1 pageGF Extra BillsQuality Design & ConstructionNo ratings yet

- Home renovation floor planDocument1 pageHome renovation floor planQuality Design & ConstructionNo ratings yet

- Renovation and Construction Project Cost EstimateDocument2 pagesRenovation and Construction Project Cost EstimateQuality Design & ConstructionNo ratings yet

- Running IDocument3 pagesRunning IQuality Design & ConstructionNo ratings yet

- Env ScreeningDocument54 pagesEnv ScreeningQuality Design & ConstructionNo ratings yet

- Hidcl 353@226Document1 pageHidcl 353@226Quality Design & ConstructionNo ratings yet

- InventoryDocument63 pagesInventoryQuality Design & ConstructionNo ratings yet

- Running NewDocument10 pagesRunning NewQuality Design & ConstructionNo ratings yet

- NGPL 152@523Document1 pageNGPL 152@523Quality Design & ConstructionNo ratings yet

- Cit 15@2108 Upper 101@476Document1 pageCit 15@2108 Upper 101@476Quality Design & ConstructionNo ratings yet

- Analysis of Singly Reinforced Concrete Beam PDFDocument3 pagesAnalysis of Singly Reinforced Concrete Beam PDFAnton_Young_1962No ratings yet

- Welded Deformed Steel Bar Mats For Concrete ReinforcementDocument3 pagesWelded Deformed Steel Bar Mats For Concrete Reinforcementnorerny shuhadaNo ratings yet

- Staircase & Ramps Duration (DAYS) Appendix StaircaseDocument7 pagesStaircase & Ramps Duration (DAYS) Appendix StaircaseLai ChungyiNo ratings yet

- Composite Steel Deck Slab Design ReportDocument6 pagesComposite Steel Deck Slab Design ReportPandaman227No ratings yet

- Fusion Bond Epoxt Coating BrochureDocument12 pagesFusion Bond Epoxt Coating Brochure4uengineerNo ratings yet

- 1.8 Anchor Systems Indd 2009Document80 pages1.8 Anchor Systems Indd 2009ihpeter100% (1)

- What Factors Causes Failure of Concrete StructuresDocument4 pagesWhat Factors Causes Failure of Concrete StructuresNick Genese100% (1)

- WF, H, UNP, C, L profiles and piping material listDocument9 pagesWF, H, UNP, C, L profiles and piping material listJhon AndriNo ratings yet

- PC Beam Slab Pham2017Document17 pagesPC Beam Slab Pham2017Corona DrawingNo ratings yet

- This Means 1 Meter of 12mm Diameter Steel Weighs 0.888 KGDocument1 pageThis Means 1 Meter of 12mm Diameter Steel Weighs 0.888 KGNella RamsarranNo ratings yet

- Potential Use of Eucalyptus Leaves As Green Corrosion Inhibitor of Steel ReinforcementDocument8 pagesPotential Use of Eucalyptus Leaves As Green Corrosion Inhibitor of Steel Reinforcementaboodalshouha1998No ratings yet

- Eccentric Footing Design in ACI 318-05Document8 pagesEccentric Footing Design in ACI 318-05Wintun73No ratings yet

- Sebeta Prieced Boq Final Edited OneDocument57 pagesSebeta Prieced Boq Final Edited OneHailuGelanHubenaNo ratings yet

- Residential Apartment Building Estimation & Rate AnalysisDocument32 pagesResidential Apartment Building Estimation & Rate AnalysisEng-Ahmed BaasaayNo ratings yet

- General NotesDocument1 pageGeneral NotesMuhammad Idrees KhanNo ratings yet

- ARSTRUCTS - Chapter 4Document20 pagesARSTRUCTS - Chapter 4Pau CruzNo ratings yet

- Provisional Specification For Composite Sleeper (2014) - Rev. 01-2017Document17 pagesProvisional Specification For Composite Sleeper (2014) - Rev. 01-2017CTE WCRNo ratings yet

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 pagesProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauNo ratings yet

- DRILLING HOLES AND GROUTING DOWELSDocument2 pagesDRILLING HOLES AND GROUTING DOWELSNoor MohdNo ratings yet

- Reporte Analisis Etabs Local YancanchaDocument78 pagesReporte Analisis Etabs Local YancanchaFremin Andrade JavierNo ratings yet

- CE 552 Lecture 9 Reinforced Concrete Column DesignDocument29 pagesCE 552 Lecture 9 Reinforced Concrete Column DesignKeyvin dela CruzNo ratings yet

- UTHM MoM Lab Report AnalysisDocument36 pagesUTHM MoM Lab Report AnalysisArif AfifiNo ratings yet